Servo control variable piston pump and control method thereof

A servo control, variable plunger technology, applied in the direction of variable displacement pump components, pumps, multi-cylinder pumps, etc., can solve the problems of difficult control, inability to meet, poor static characteristics, etc., to achieve good system response characteristics and reduce operation. Difficulty and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

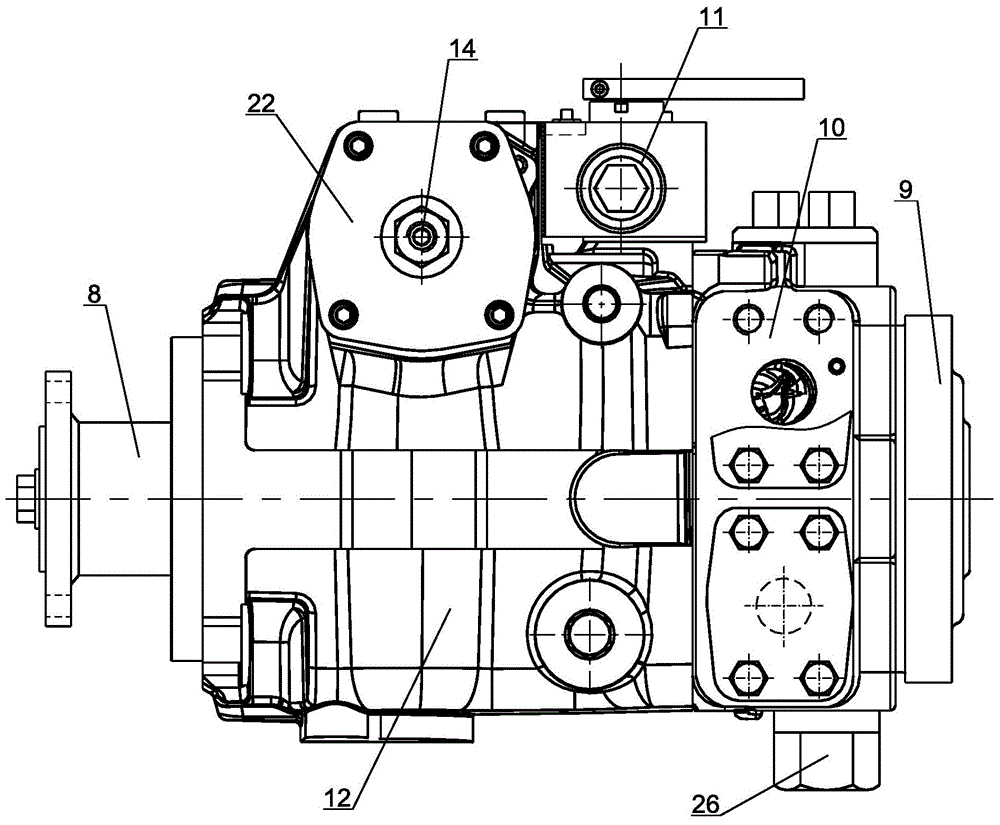

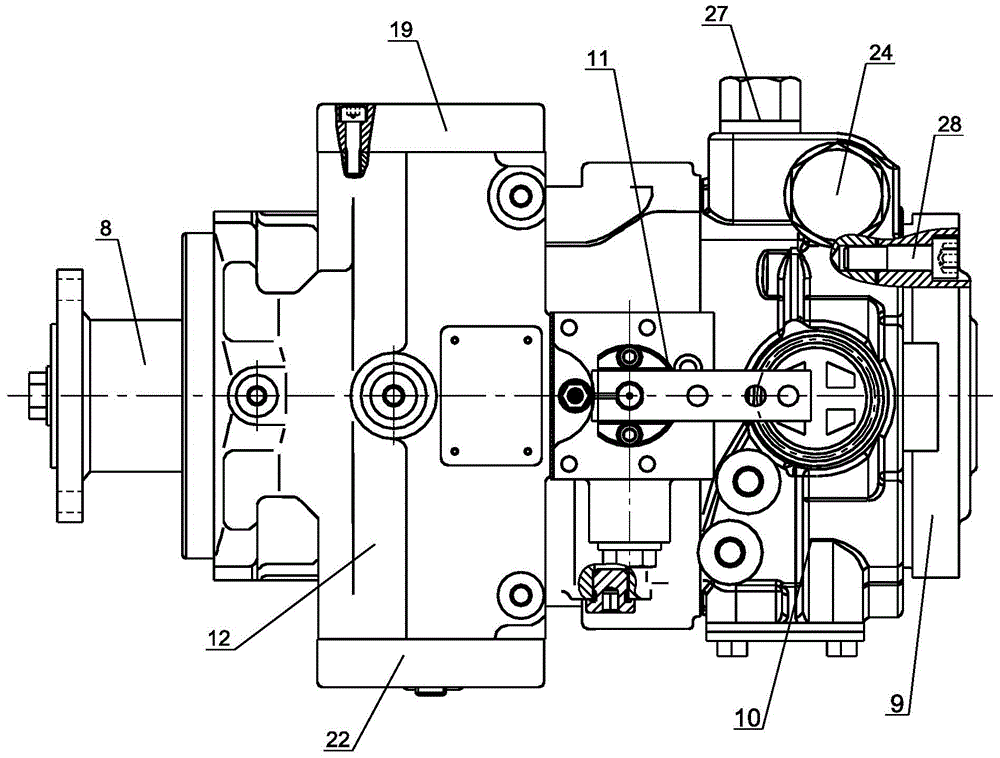

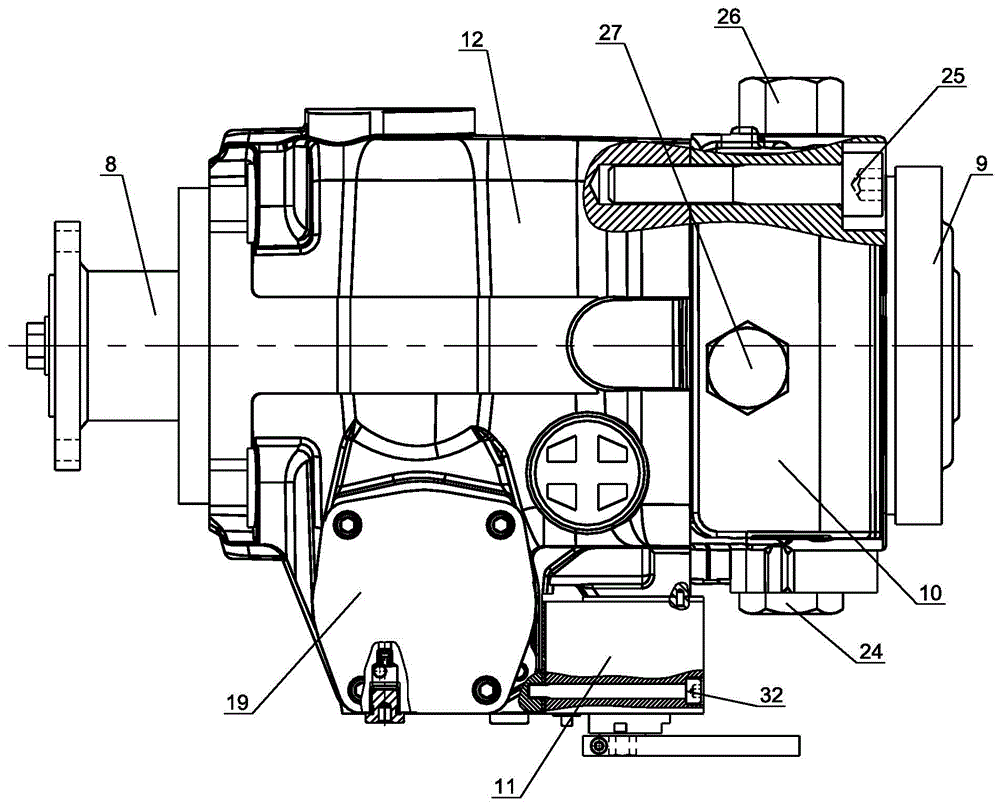

[0030] see Figure 1 to Figure 6 Servo-controlled variable plunger pump, including skeleton oil seal 1, bottom crescent bearing 2, swash plate 3, pressure plate 4, plunger assembly 5, cylinder block 6, oil distribution plate 7, transmission flange 8, charge pump 9, valve Body 10, servo control valve 11, housing 12, variable cylinder 13, central shaft 14, slider 15, top crescent bearing 16, ball bearing 17, driving shaft 18, left end cover 19, main return spring 20, auxiliary return spring 21. Right end cover 22, spring seat 23, bottom high pressure relief valve 24, valve body fastening bolts 25, top high pressure relief valve 26, low pressure relief valve 27, charge pump fastening bolts 28, spring cover 29, servo feedback Rod 30 , servo valve v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com