Manual-adjusted variable gear pump

A manual adjustment and gear pump technology, applied in the direction of rotary piston/oscillating piston pump components, pumps, pump control, etc., can solve the problems of complex structure, hindering the development of variable gear pumps, and limiting the wide application of gear pumps, etc., to achieve The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

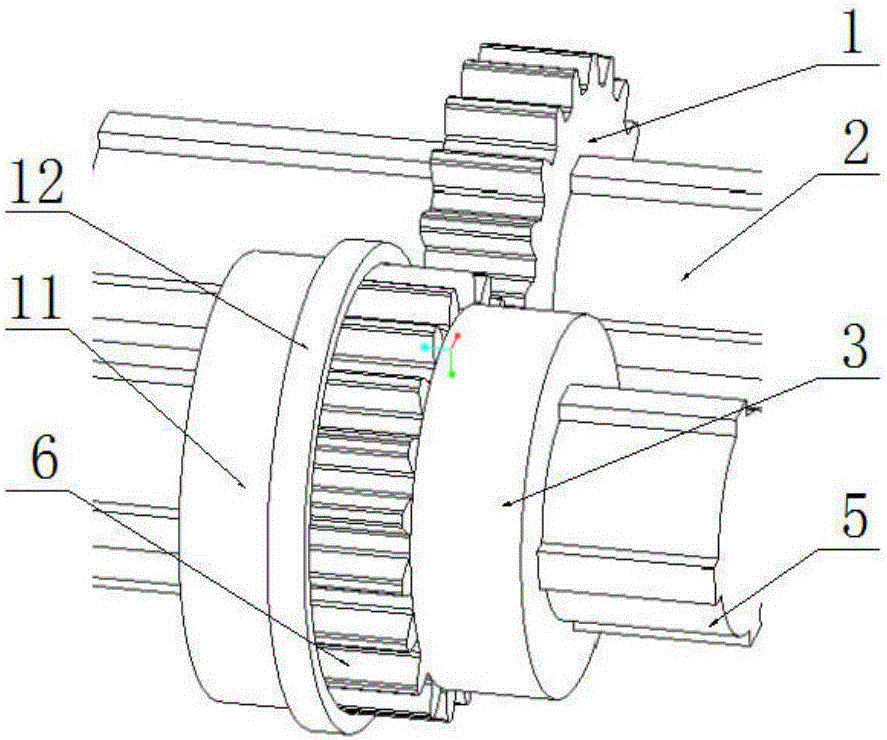

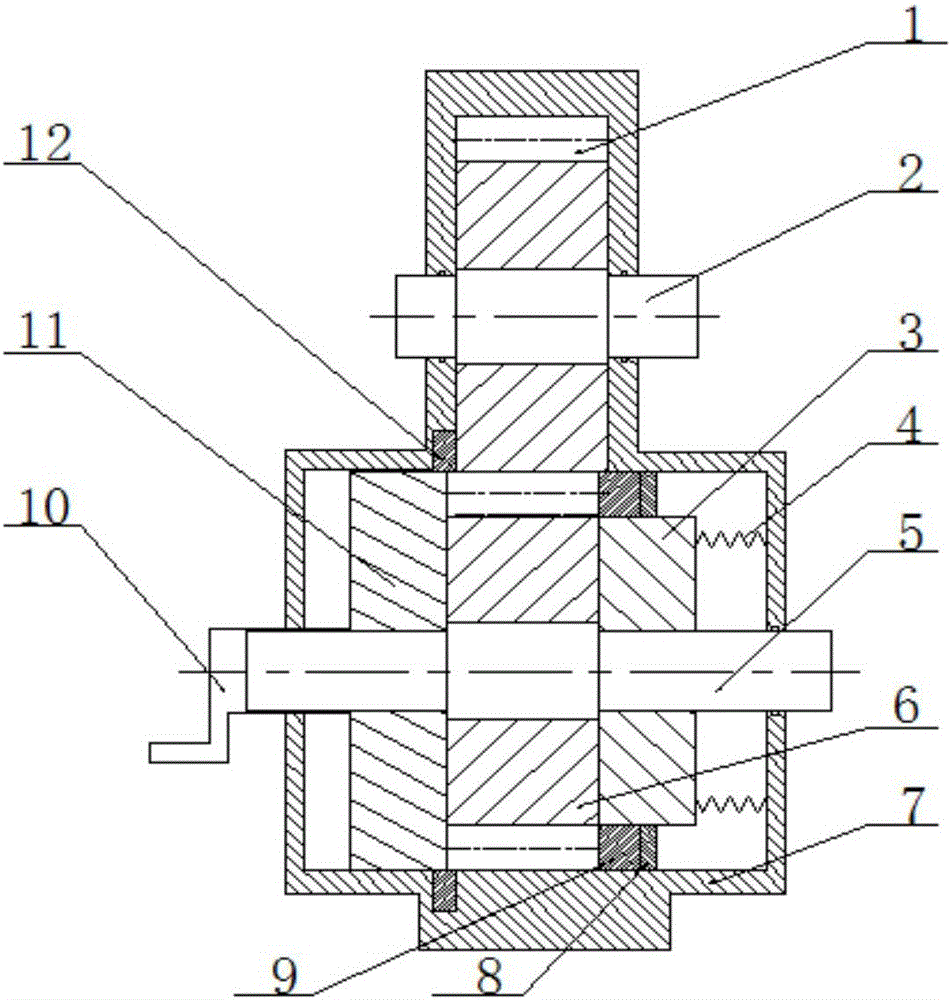

[0015] figure 1 with figure 2 One embodiment of the invention is shown. The manually adjustable variable gear pump of the present invention consists of a pump body 7, two externally meshed driving gears 1 and a driven gear 6, a reset block 3, an adjustment block 11, a toothed slider 9, a return spring 4, The adjustment handle 10, the ring gear 12 and the like are composed. Both the driving gear 1 and the driven gear 6 are spur gears, wherein the driving gear 1 is installed on the driving shaft 2, the position of the driving shaft 2 is fixed and cannot move axially, and both sides of the driving gear 1 are sealed by the pump body 7. The driven gear 6 is installed on the driven shaft 5, which is provided with a keyway, and the driven gear 6 can move axially along the keyway.

[0016] The adjustment block 11 and the reset block 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com