Direct evaporation type water-cooling fresh air unit

A fresh air unit, evaporative technology, applied in the field of direct evaporative water-cooled fresh air unit, can solve the problems that cannot meet the fresh air treatment requirements, achieve the effect of large energy adjustment range, improve comfort, and reduce cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

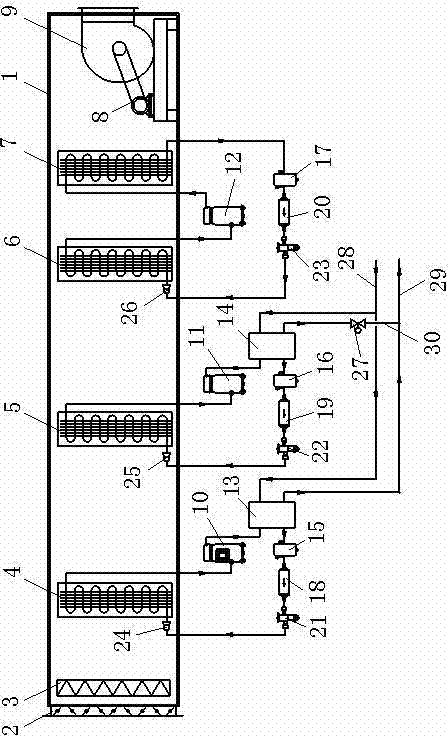

[0015] refer to figure 1 , a direct evaporative water-cooled fresh air unit provided by the present invention, one end of the fresh air treatment box 1 has an air inlet regulating valve 2, an air filter 3 is arranged on the inner side of the air inlet regulating valve 2, and a fan 9 is arranged at the other end, and the fan is composed of Driven by a motor 8; three refrigerating circuits that can operate independently or simultaneously are provided, and the first refrigerating circuit is composed of a frequency conversion compressor 10 connected through a refrigerant pipeline, a first plate heat exchanger 13, a first liquid storage tank 15, a first The drying filter 18, the first thermal expansion valve 21 and the first evaporator 4 are composed of a first liquid separator 24 installed at the refrigerant inlet of the first evaporator 4; The first fixed-speed compressor 11, the second plate heat exchanger 14, the second liquid storage tank 16, the second dry filter 19, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com