Water surface garbage collector

A technology of surface garbage and collector, applied in the field of surface garbage cleaning and surface garbage collector, can solve the problems of floating, occupation of labor, affecting the appearance of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

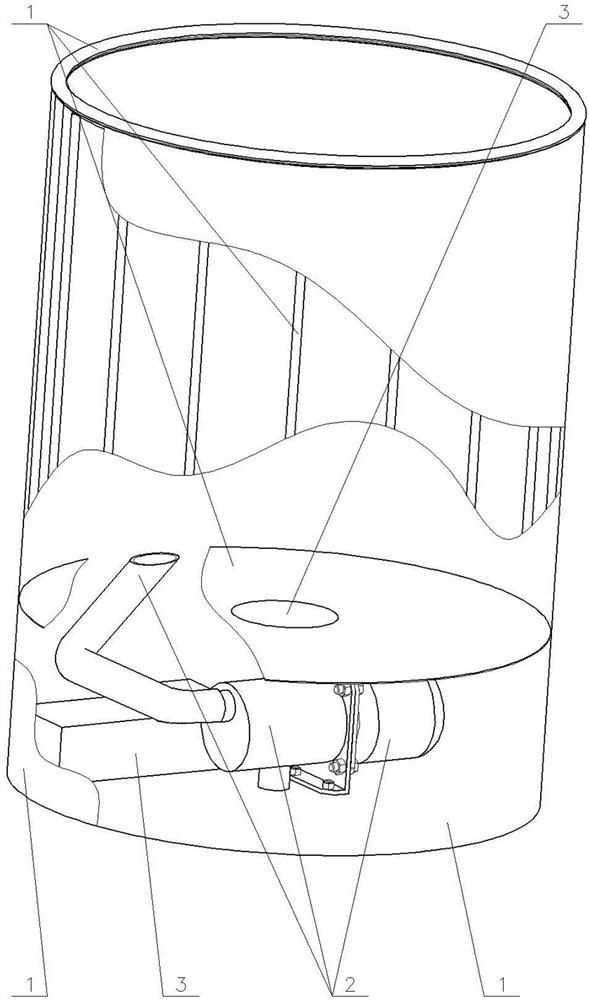

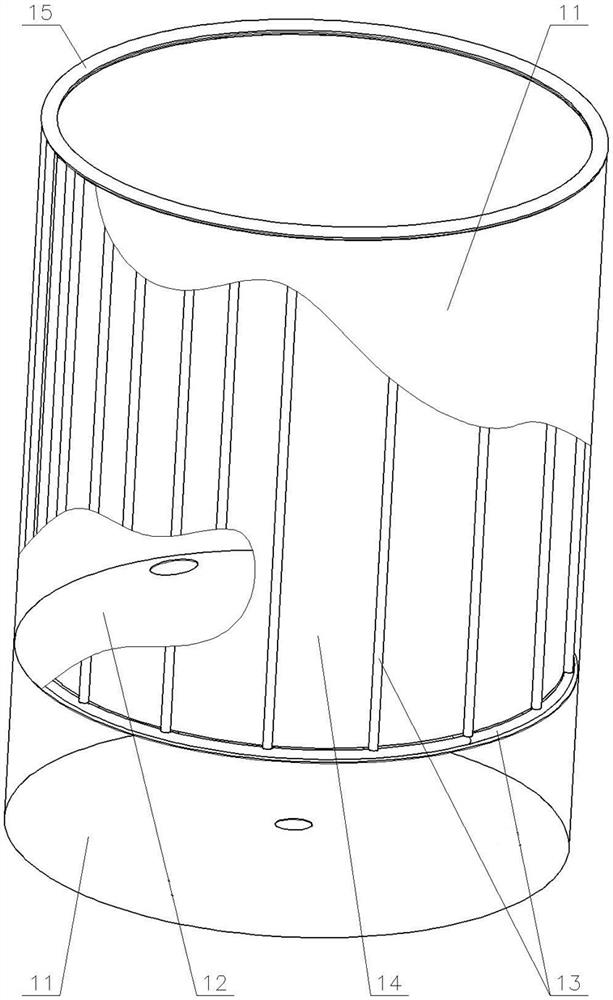

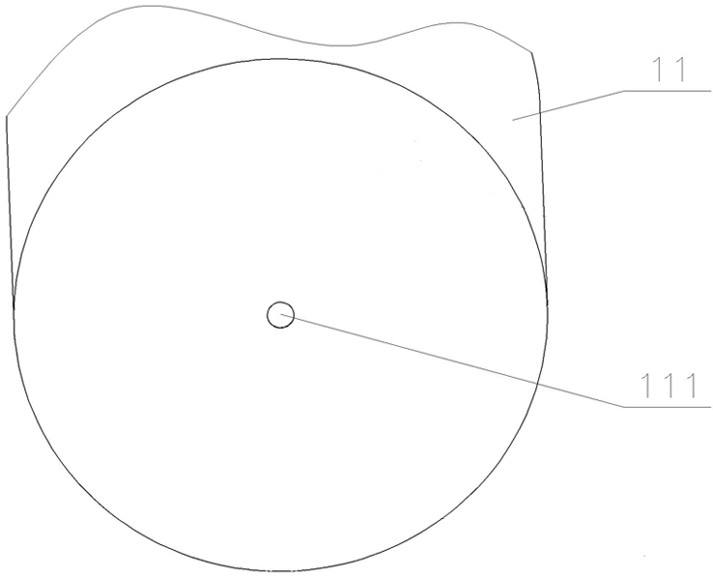

[0020] 1. Collection barrel 11, barrel body 111, drain port 12, partition 121, water suction port 13, filter screen frame 131, straight rod 132, ring rod 133, radial rod 14, filter screen 15, diversion cover 2, drainage Device 21, water pump 22, speed regulating motor 23, water suction pipe 3, control system 31, controller 32, accumulator 33, sensor.

[0021] exist Figure 1-Figure 7In the shown embodiment: the barrel body 11 of the collection barrel 1 is in the shape of a cylinder, the barrel body 11 is a structure with one end open and the bottom of the barrel at the other end closed, the bottom surface of the barrel is perpendicular to the axis of the cylindrical part of the barrel body 11, and The center of the bottom of the barrel is provided with a drain port 111; the end of the barrel 11 near the bottom of the barrel is provided with a partition 12 whose plate surface is perpendicular to the axis of the cylinder part of the barrel 11 and is circular. The outer diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com