Axial piston machine with variable displacement volume, and hydraulic drivetrain having an axial piston machine

An axial piston machine and piston technology, which is used in machines/engines, liquid variable capacity machines, mechanical equipment, etc., can solve the problem of increasing the guide length, and achieve the effects of good efficiency, small structural volume, and expansion of the speed range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

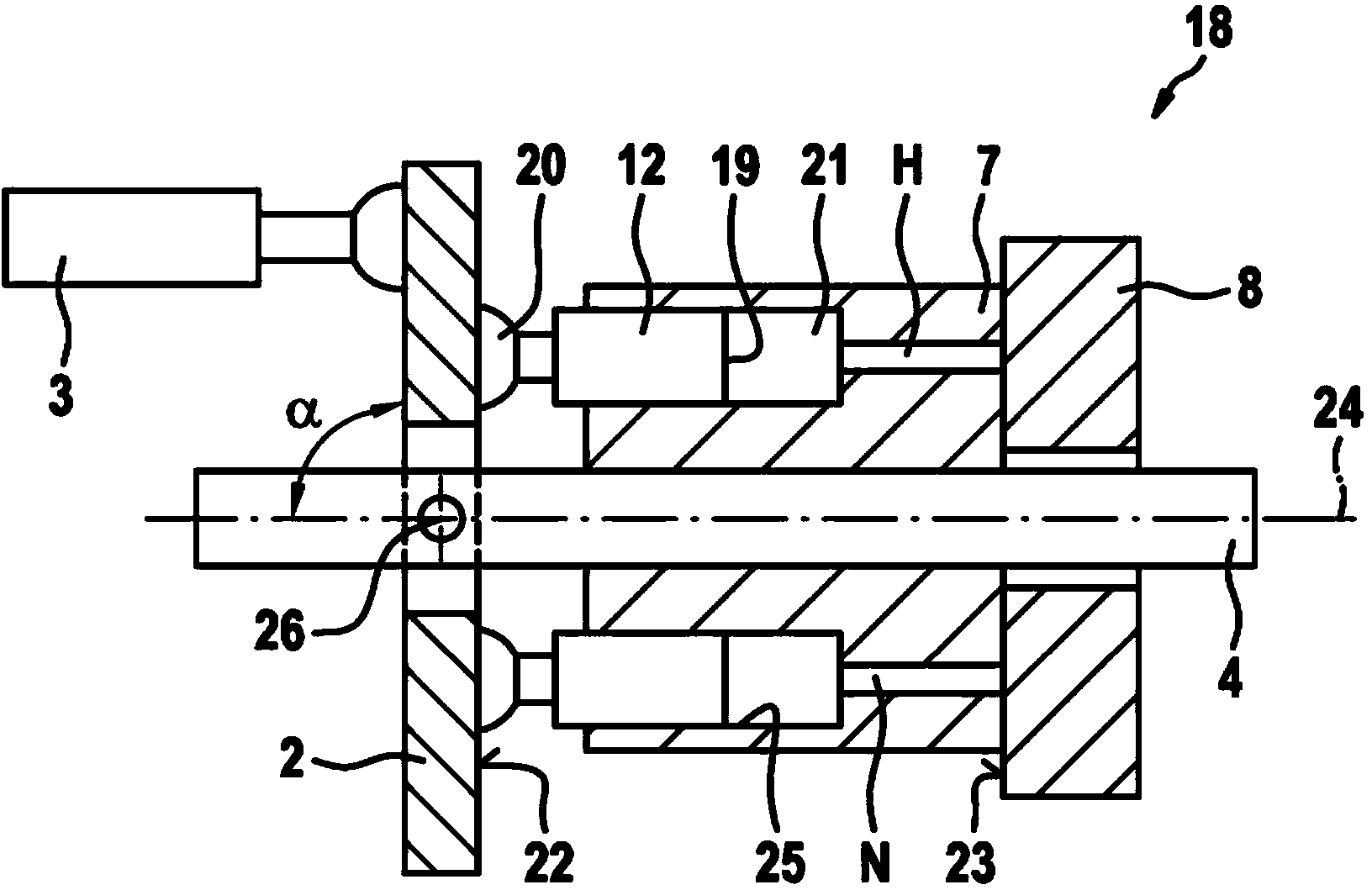

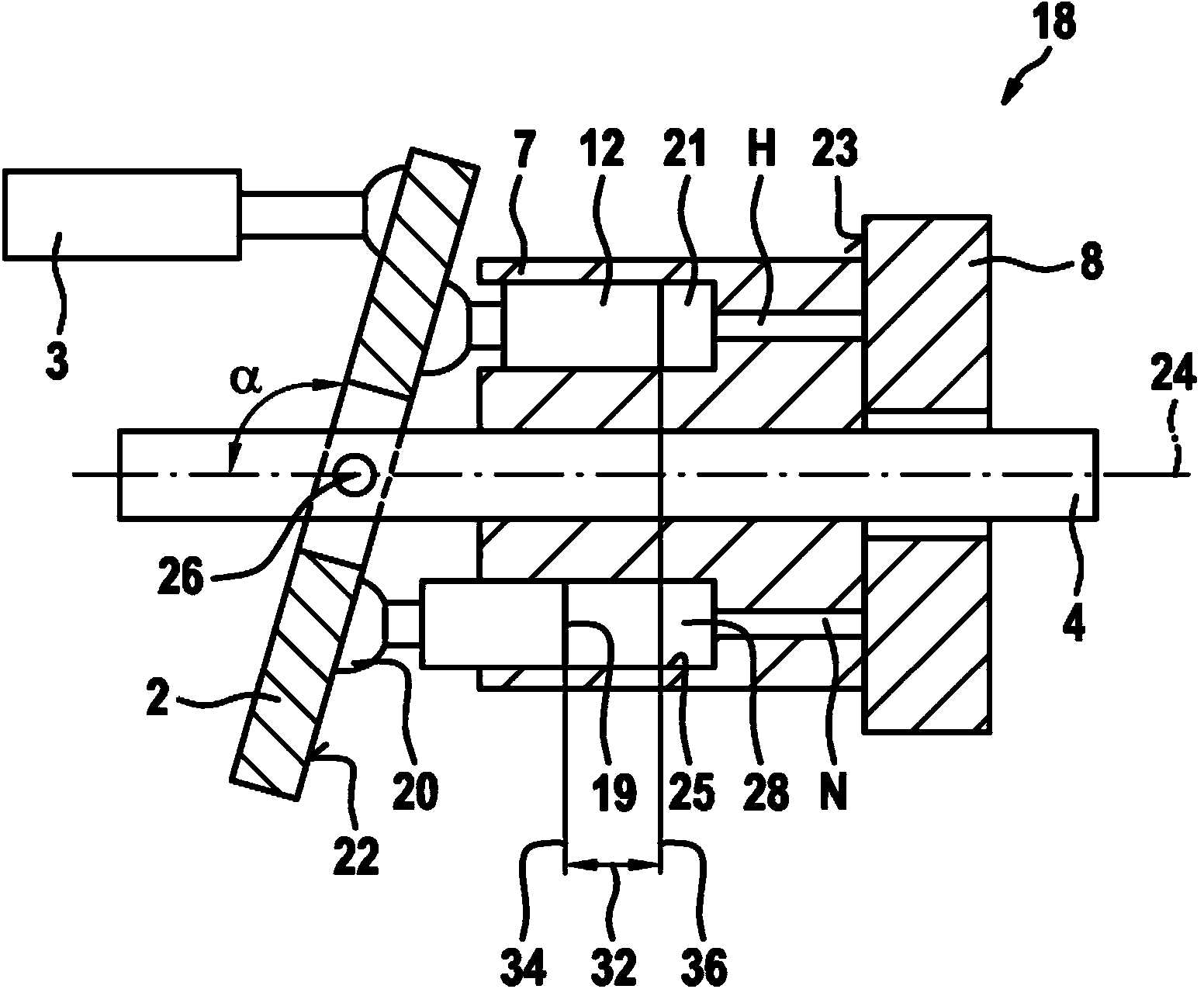

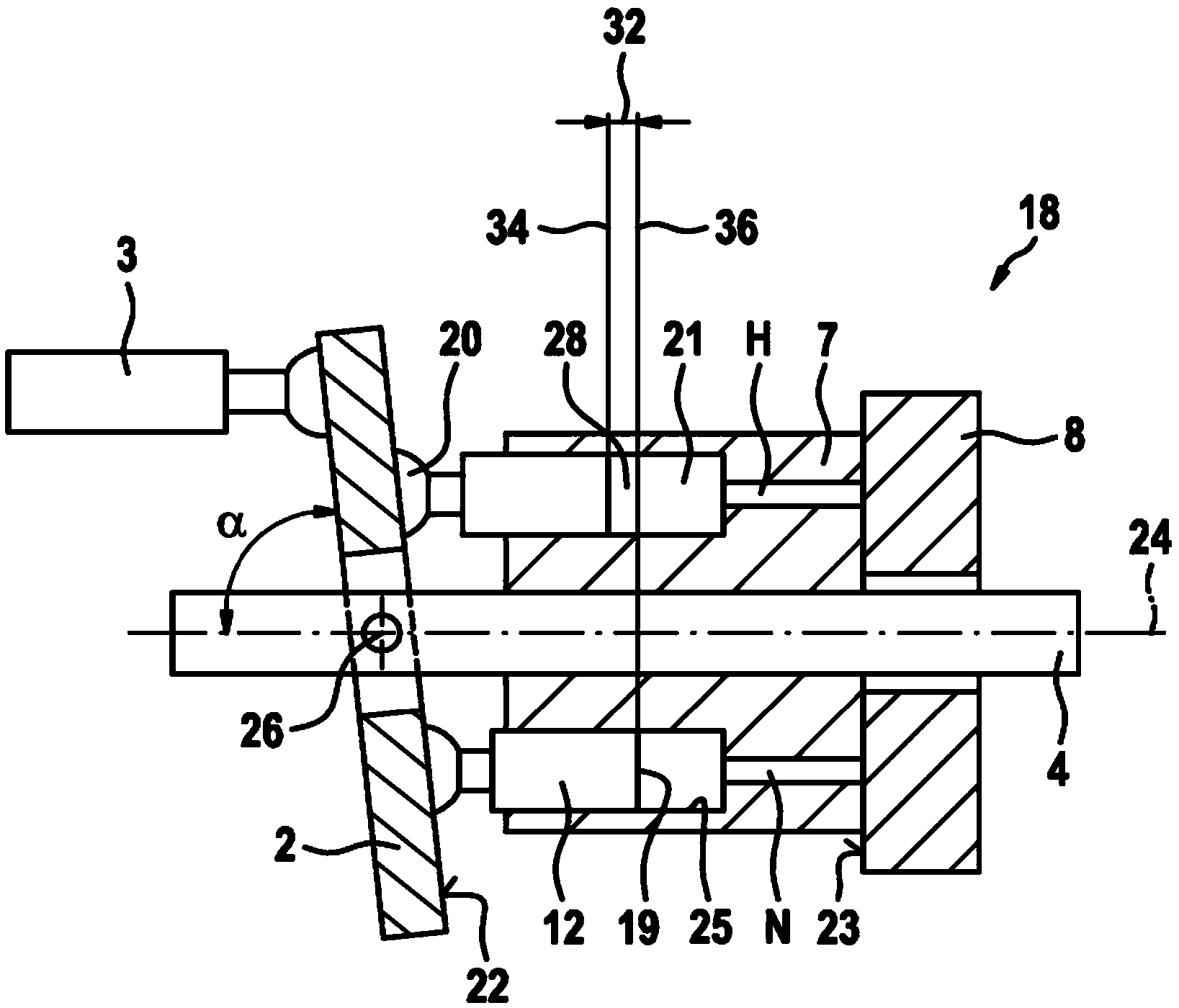

[0034] with the help of figure 1 , 2 and 3 illustrate the operating principle of the axial piston machine 18 in a swash plate construction according to the prior art. exist figure 1 The main components of the axial piston machine 18 are shown by way of example. The swivel cradle 2 can be mounted rotatably about a pivot point 26 , wherein the pivot point 26 can intersect the axis 24 . The cradle is also known as a slew plate or a slant plate. Above the axis 24 is shown an adjusting device 3 in the form of a (telescopic) adjusting piston, which is fixedly connected to a housing, not shown here. By adjusting the adjustment device 3, the cradle 2 is deflected relative to the axis 24, which can be achieved, for example, in figure 2 and 3 As seen in the cradle, the cradle is in figure 1The center is perpendicular to the axis 24 and accordingly has an inclination angle α of 90°. In this case, the adjusting device 3 is connected to the cradle 2 in such a way that a movement i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com