Patents

Literature

119results about How to "Change torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

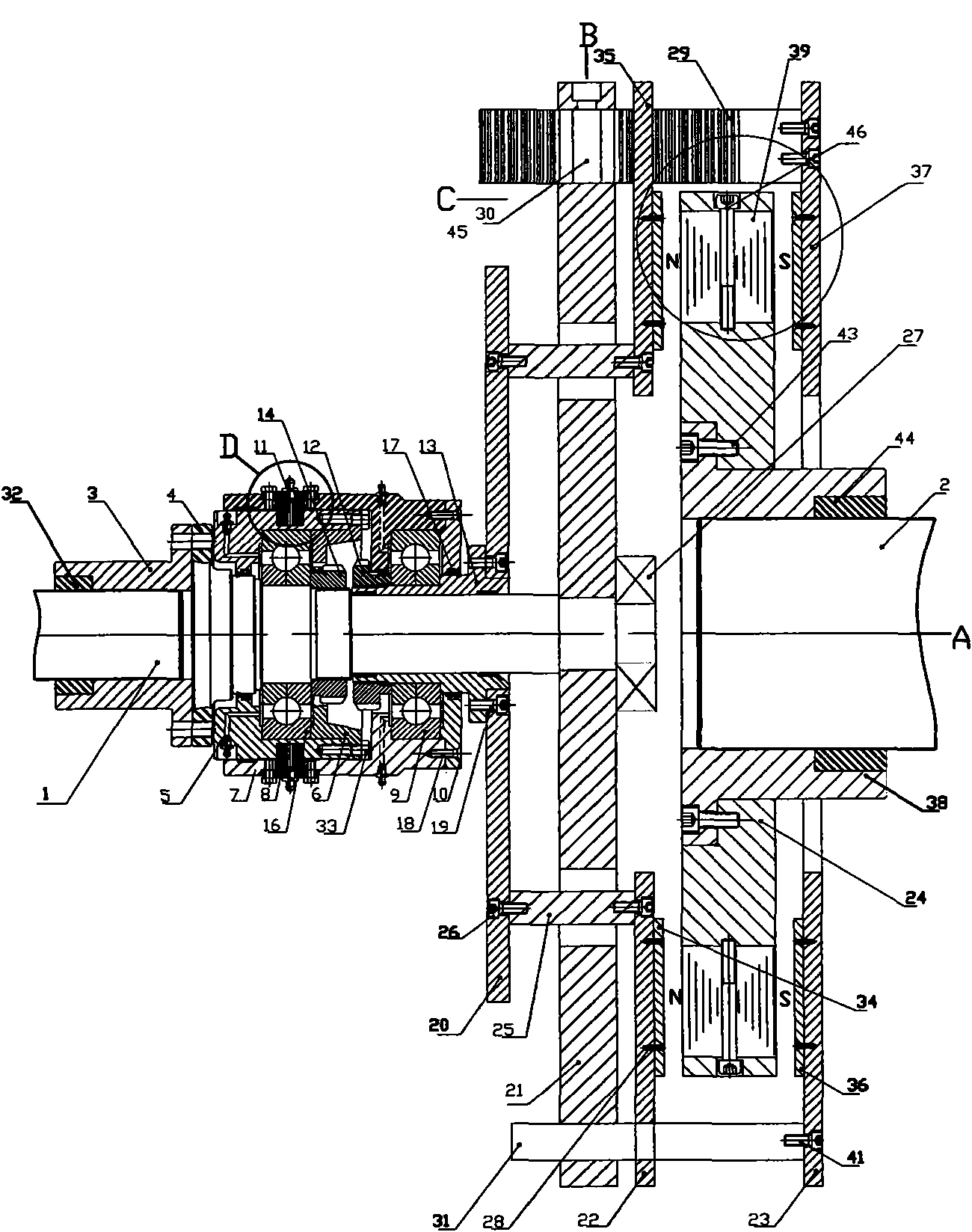

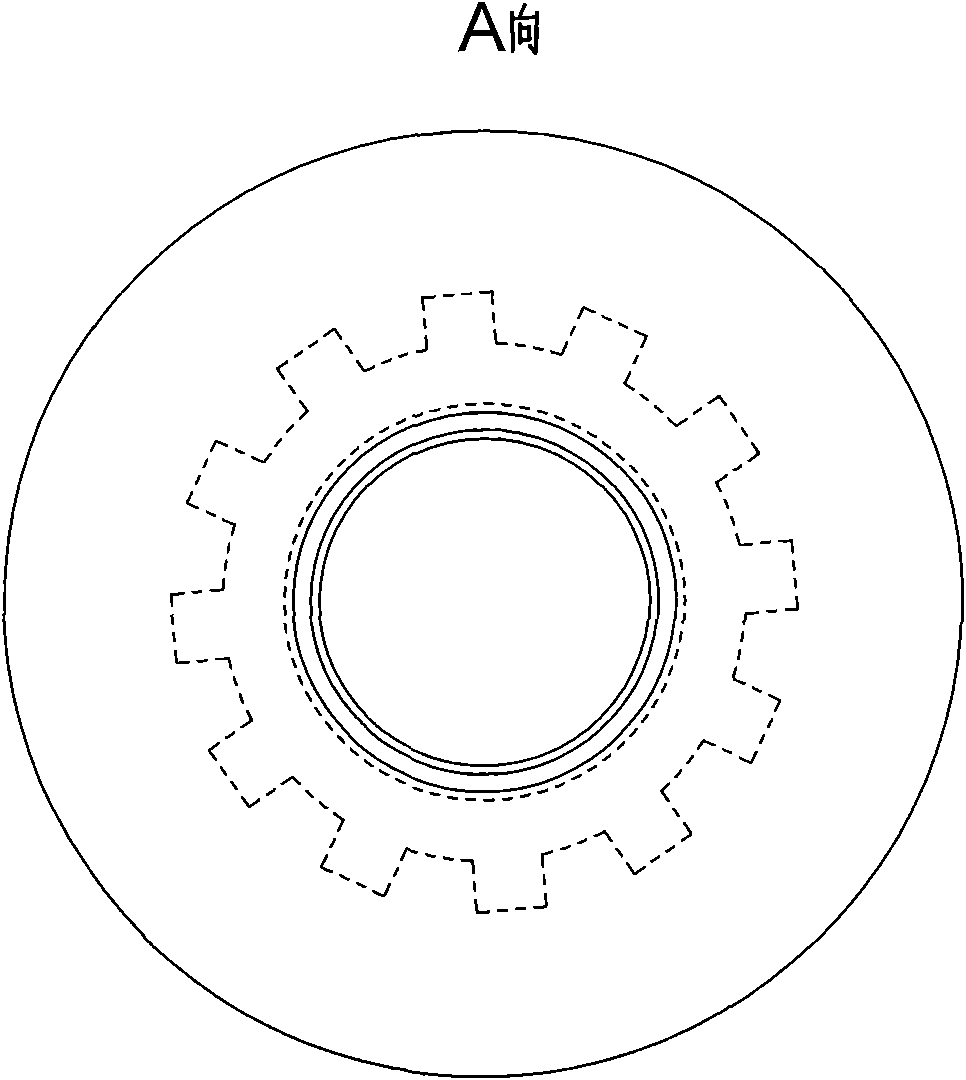

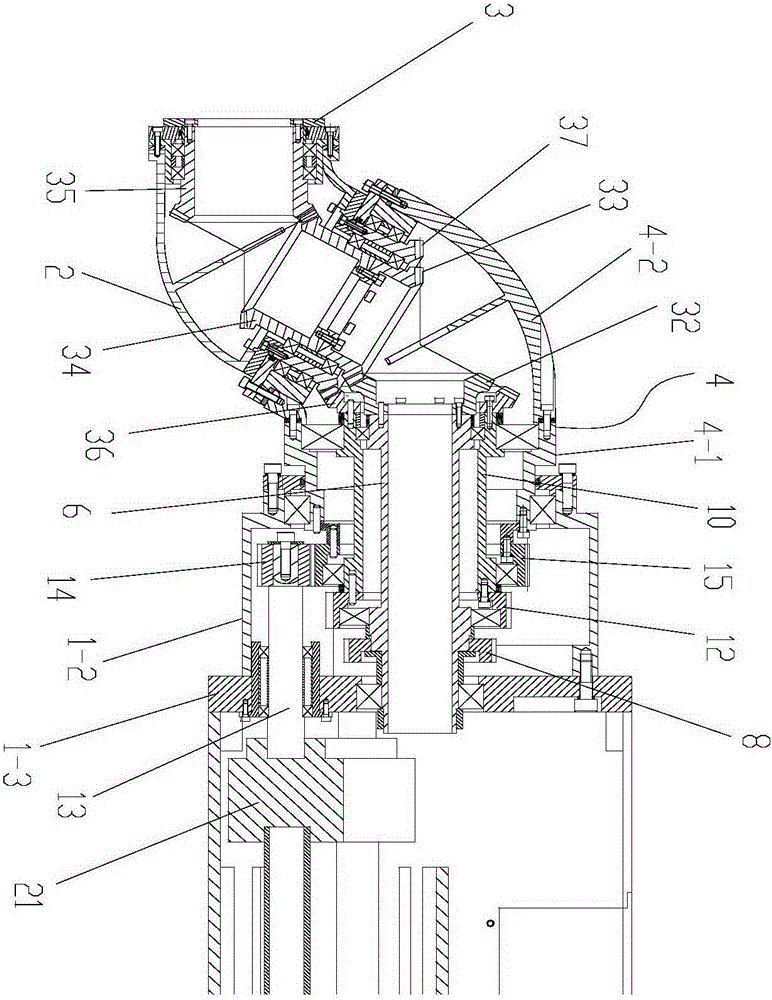

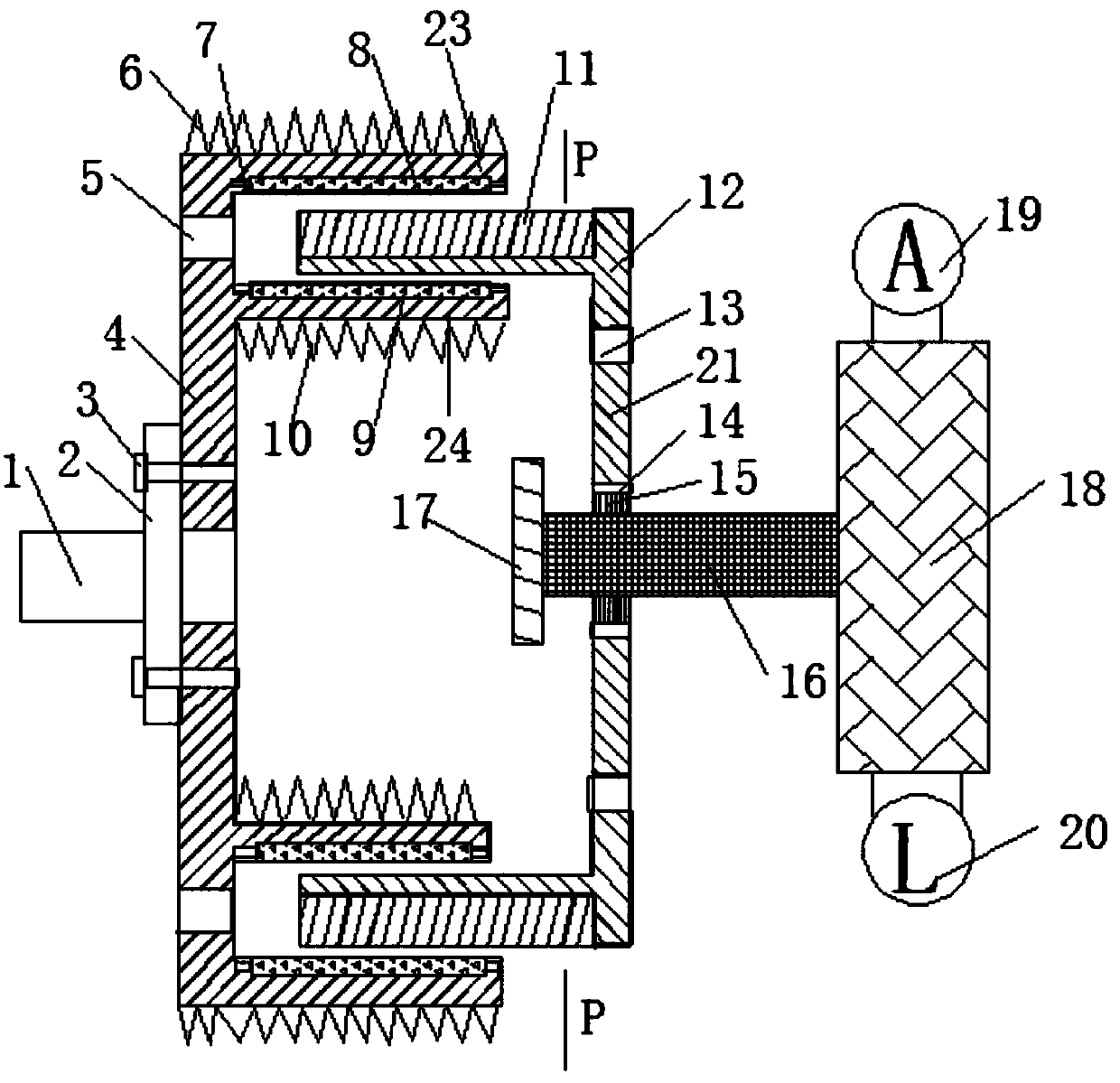

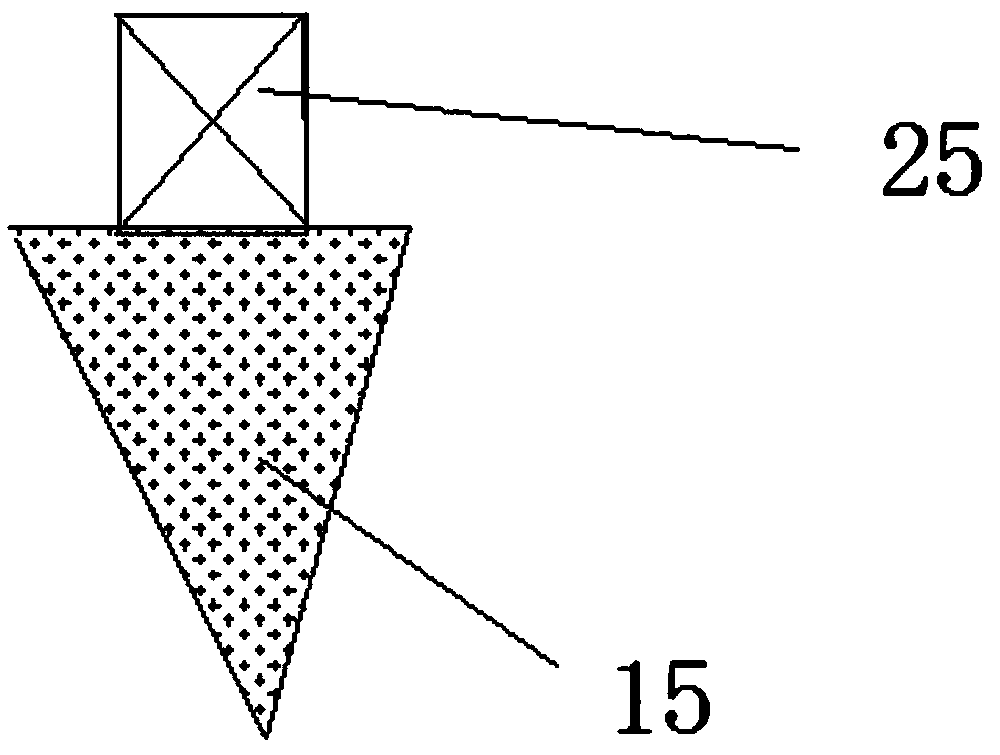

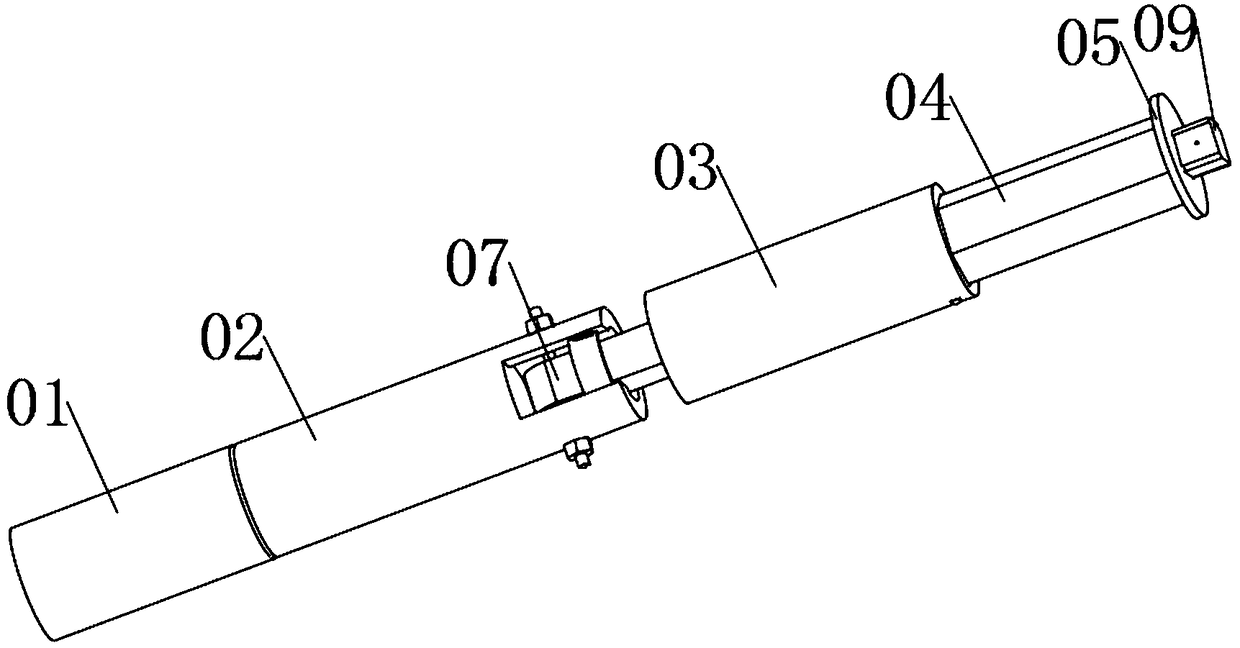

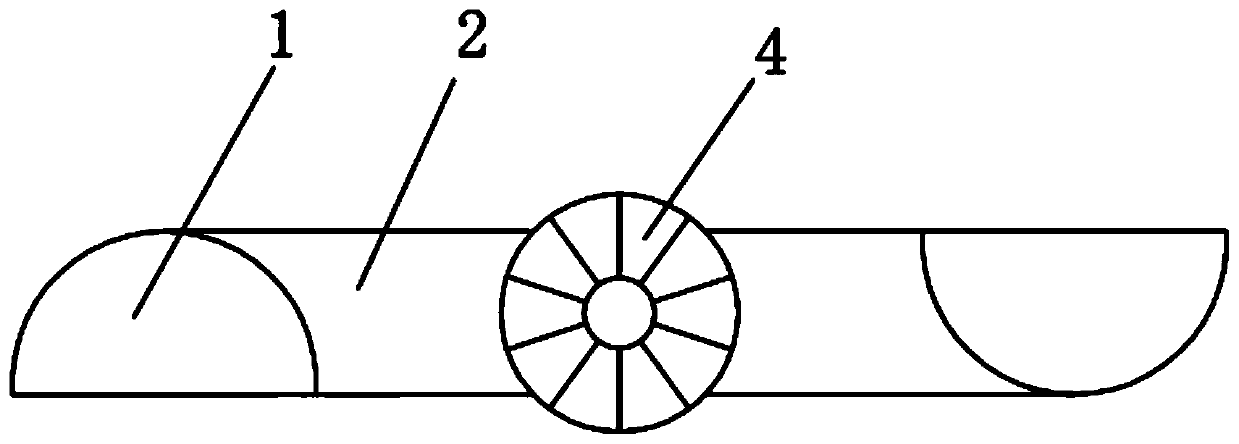

Permanent-magnetic drive speed adjustor

ActiveCN101814820ARealize no-load startChange torqueAsynchronous induction clutches/brakesElectrical conductorMechanical engineering

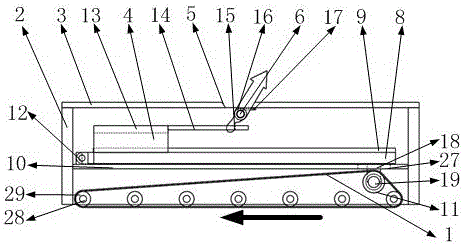

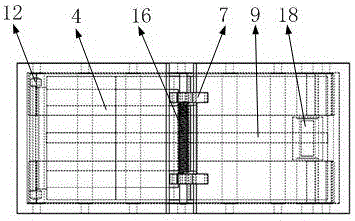

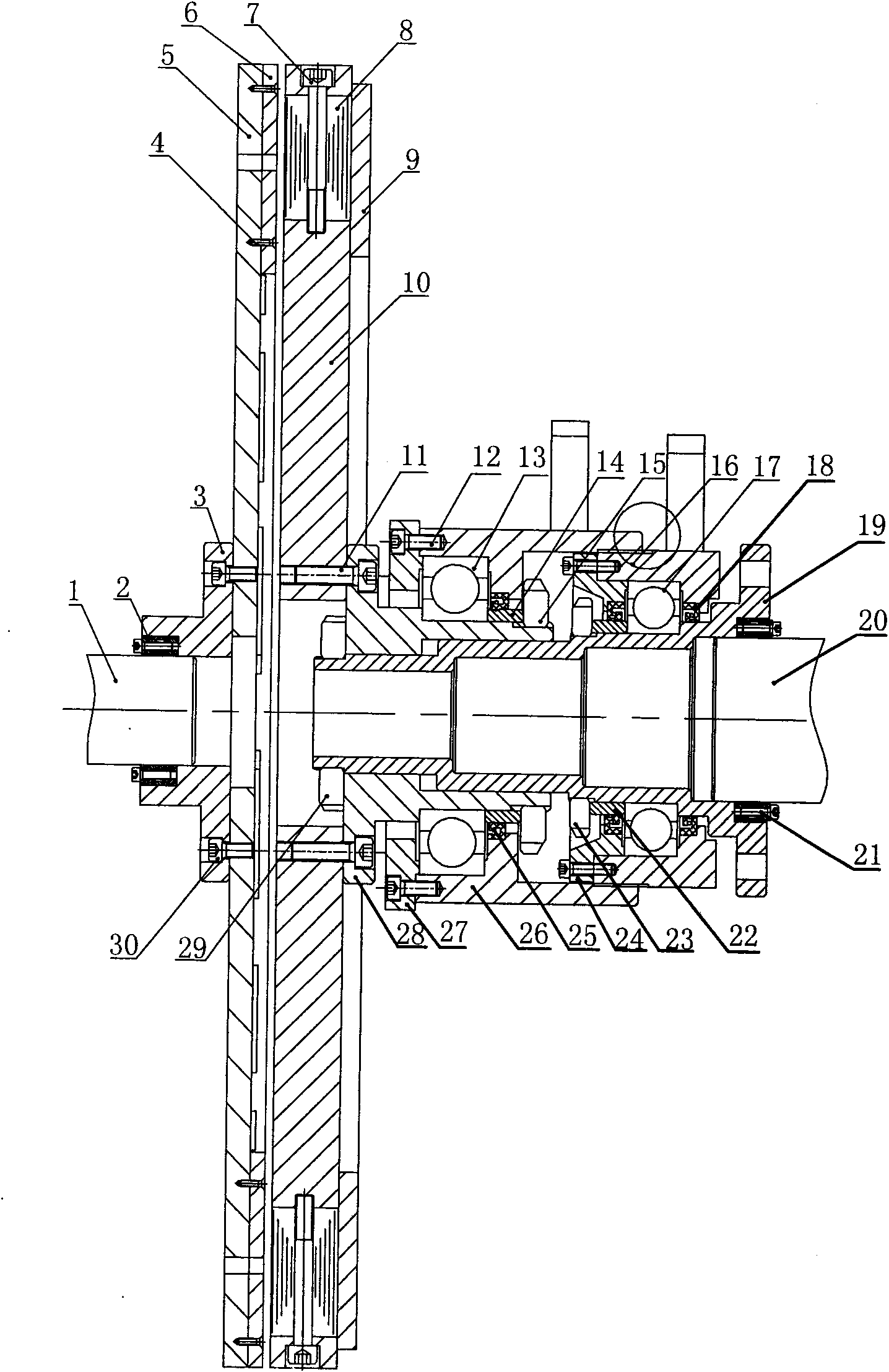

The invention provides a permanent-magnetic drive speed adjustor, which comprises a first shaft, a second shaft and an extension shaft, wherein the second shaft is connected with a permanent-magnetic turntable; the first shaft is connected with the extension shaft; the extension shaft is provided with a bearing, a shaft sleeve and an outer sleeve and connected with a cage-shaped rotor; the cage-shaped rotor consists of turntables, and two conductor discs are arranged on two sides of the permanent-magnetic turntable; the left small turntable is fixedly connected with the left conductor disc, the left second turntable is provided with a gear, and the two conductor discs are provided with a rack respectively; the right conductor disc is provided with a pin shaft which passes through the left conductor disc and penetrates the left second turntable; the conductor discs on two sides realize synchronous reverse equidistance motion through a gear and rack mechanism; and the first shaft and the second shaft can be connected with a motor or a load. The permanent-magnetic drive speed adjustor has the advantages of realizing non-contact power transfer of power, reducing vibration, starting the motor without load, changing the torque transferred between the conductor disc and the permanent-magnetic turntable, and repeatedly, adjustably and controllably outputting the torque and the rotational speed to fulfill the purposes of speed adjustment and energy conservation.

Owner:QINGDAO SPRING ENERGY TECH

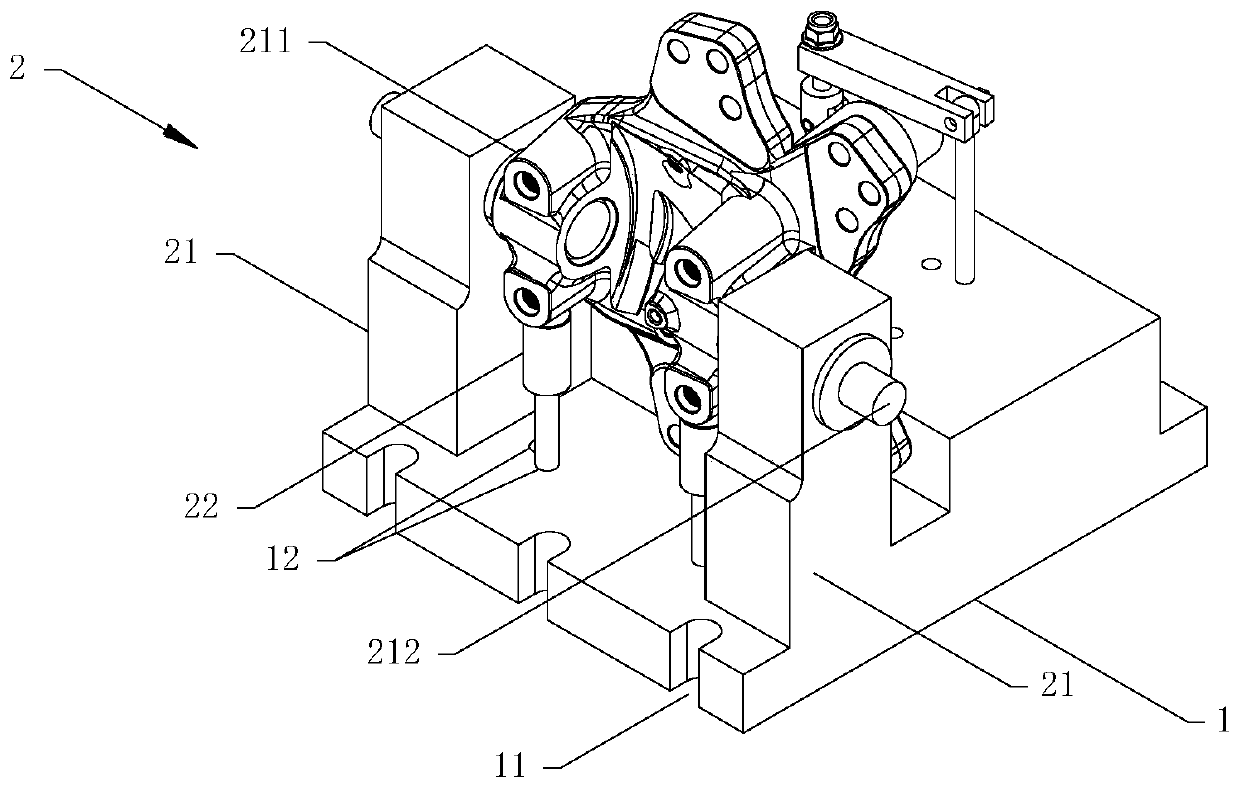

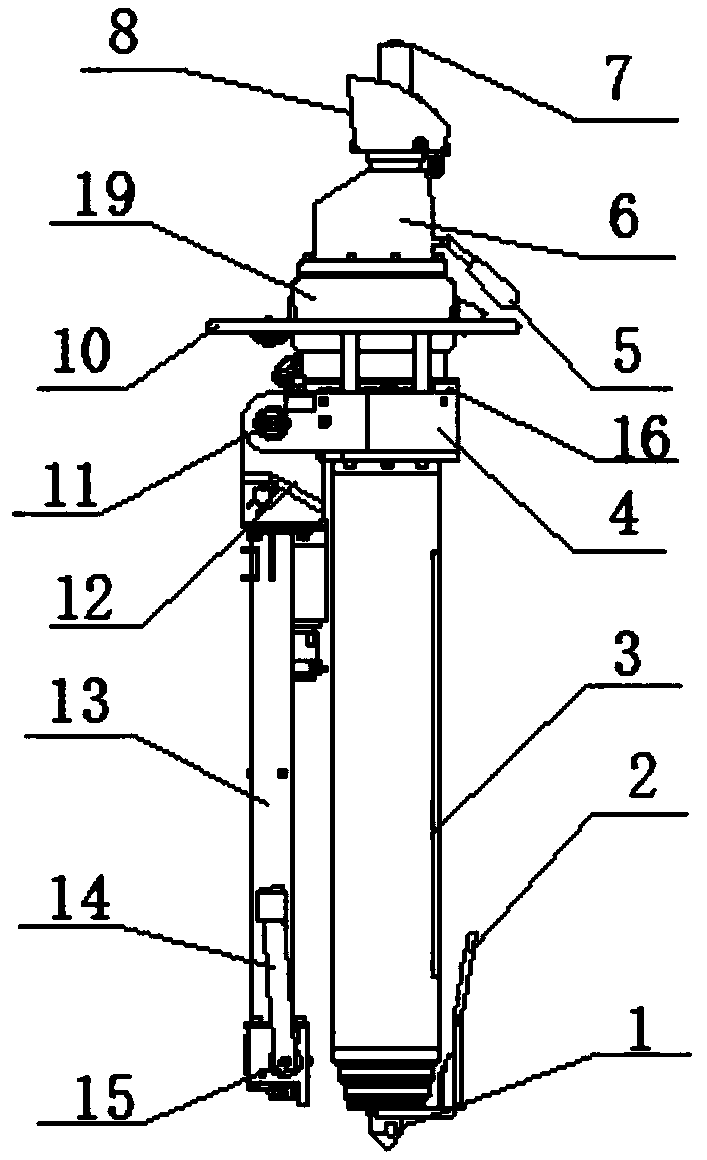

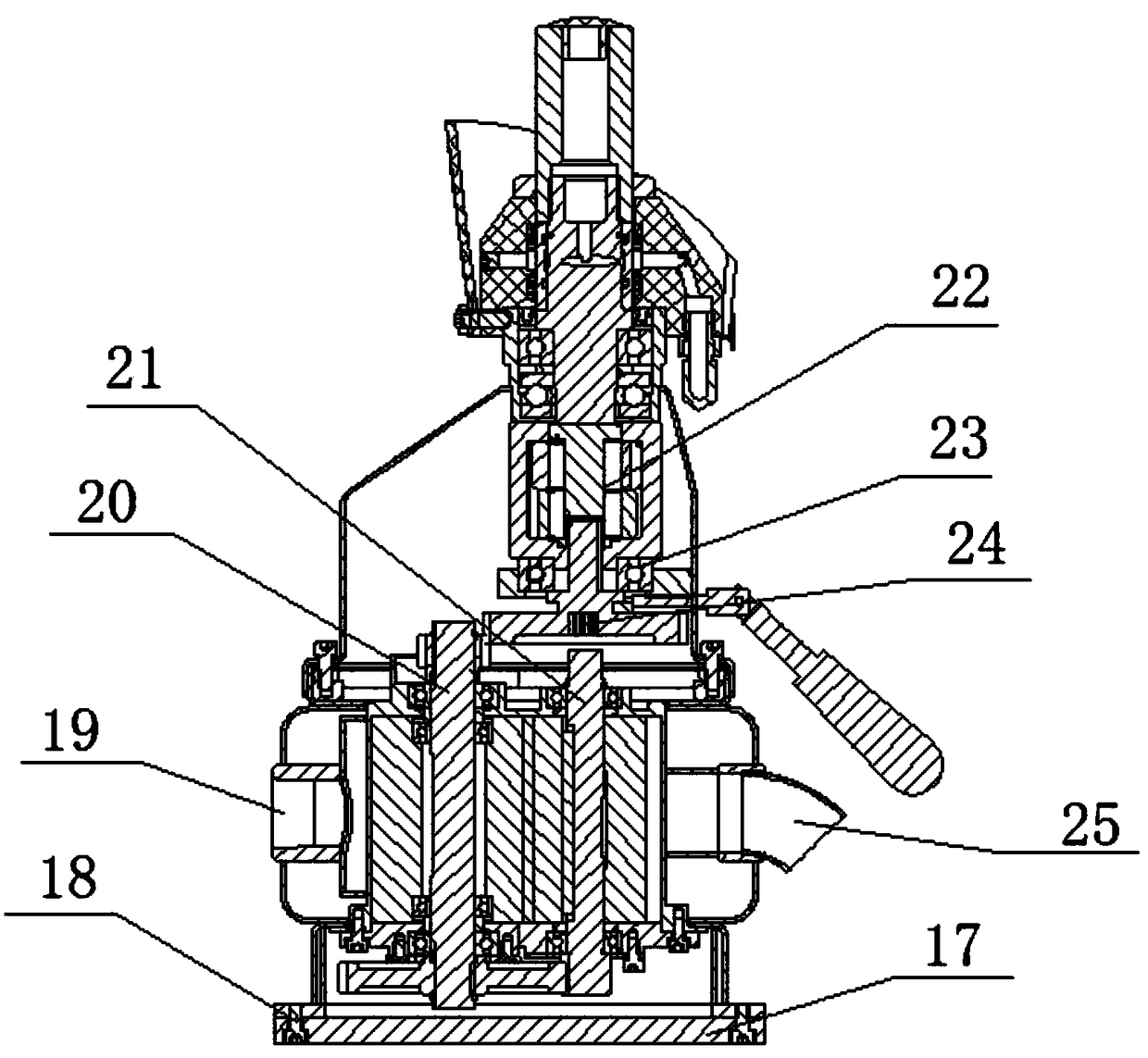

Arm unit of spraying robot

InactiveCN105216009AEliminate errorsGuaranteed accuracySpraying apparatusArmsRelative displacementDrive shaft

The invention discloses an arm unit of a spraying robot. The arm unit comprises a supporting arm, a wrist, and a tail end arm in rotational connection with the wrist, as well as a connecting piece in rotational fit with a tail end of the supporting arm and the wrist; the arm unit further comprises a first driving mechanism for driving the tail end arm to rotate, a second driving mechanism for driving the wrist to rotate and a third driving mechanism for driving the connecting piece to rotate; each driving mechanism is provided with a power input assembly matched with a transmission shaft to input power, and then the power is further accurately input into a driving assembly for directly driving the unit to rotate through power transfer of the power input assembly; by means of stepping, errors caused by long-distance transmission coaxiality can be eliminated; meanwhile, in the operating process of the spraying robot, a relative displacement between the wrist and the elbow joint of the tail end mechanical arm is compensated to ensure the accuracy of spraying; meanwhile, a rotating speed and a torque can be changed to reduce the working strength.

Owner:CHONGQING CHANGJIANG COATING EQUIP

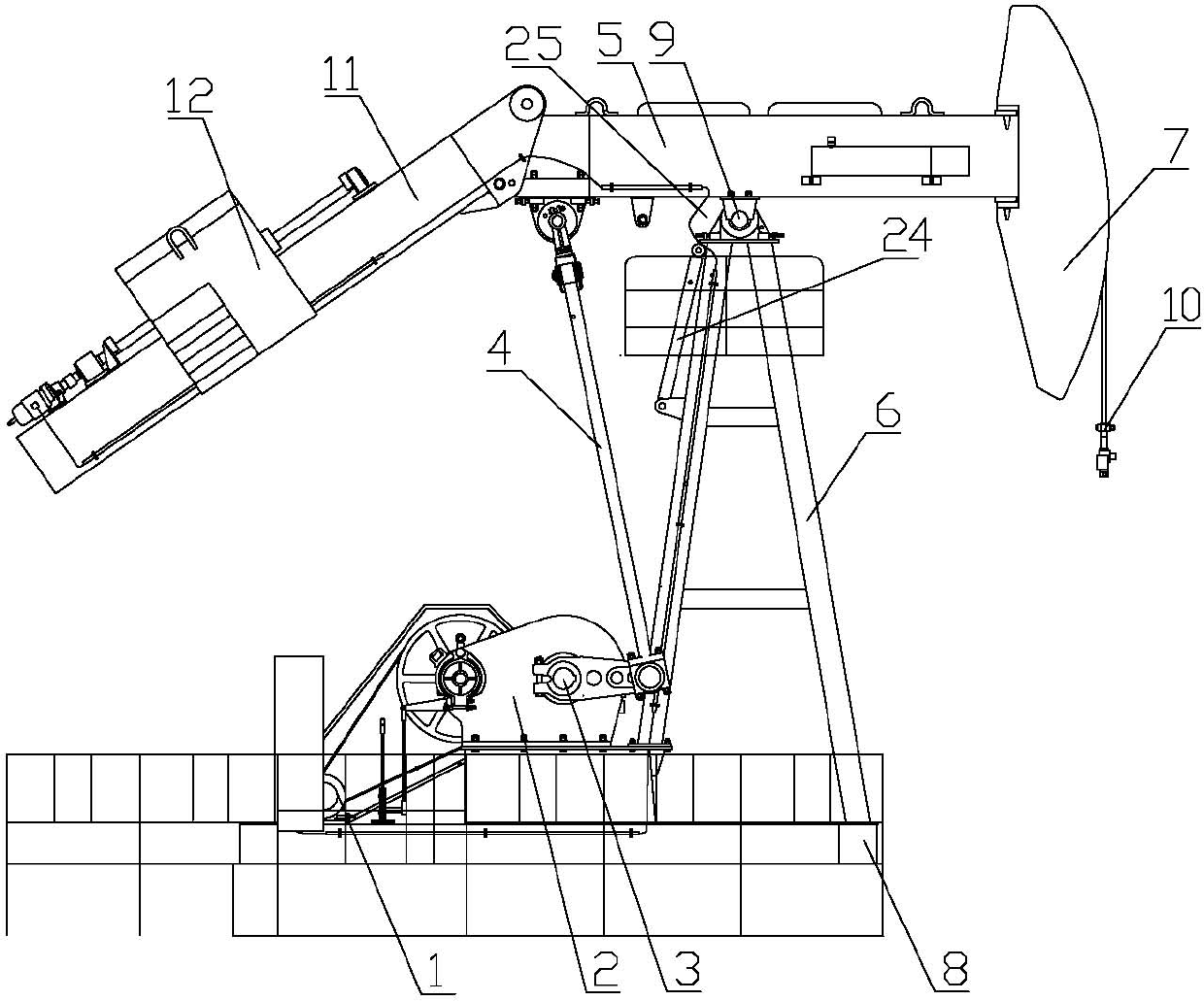

Walking beam type electric manually-balanced pumping unit

The invention disclosed a walking beam type electric manually-balanced pumping unit, relating to the technical field of walking beam type pumping units. The walking beam type electric manually-balanced pumping unit comprises a motor, a speed reducer, a crank, a connecting rod, a walking beam, a bracket, a horse head and a base. The motor, the speed reducer and the bracket are fixedly arranged on the base, a power output shaft of the speed reducer is provided with the crank, the crank is hinged with the lower end of the connecting rod, the walking beam capable of swinging up and down is hinged at the top end of the bracket through a middle bracket bearing block, the upper end of the connecting rod is hinged with the left part of the walking beam, the horse head is fixedly arranged at the right end of the walking beam and is provided with a polished rod eye, and a suspension arm is arranged at the left end of the walking beam. According to the walking beam type electric manually-balanced pumping unit disclosed by the invention, the structure is reasonable and compact, and the use is convenient; in addition, a movable adjustable counterweight device can move forwards and backwards on the suspension arm by an adjustable counterweight device driving device, thus the moment of a weight box is changed, the balance on a suspension point load is realized, and the efficiency and the effect of balance adjustment of a whole machine are greatly improved.

Owner:XINJIANG UYGUR AUTONOMOUS REGION NO 3 MACHINE TOOL WORKS

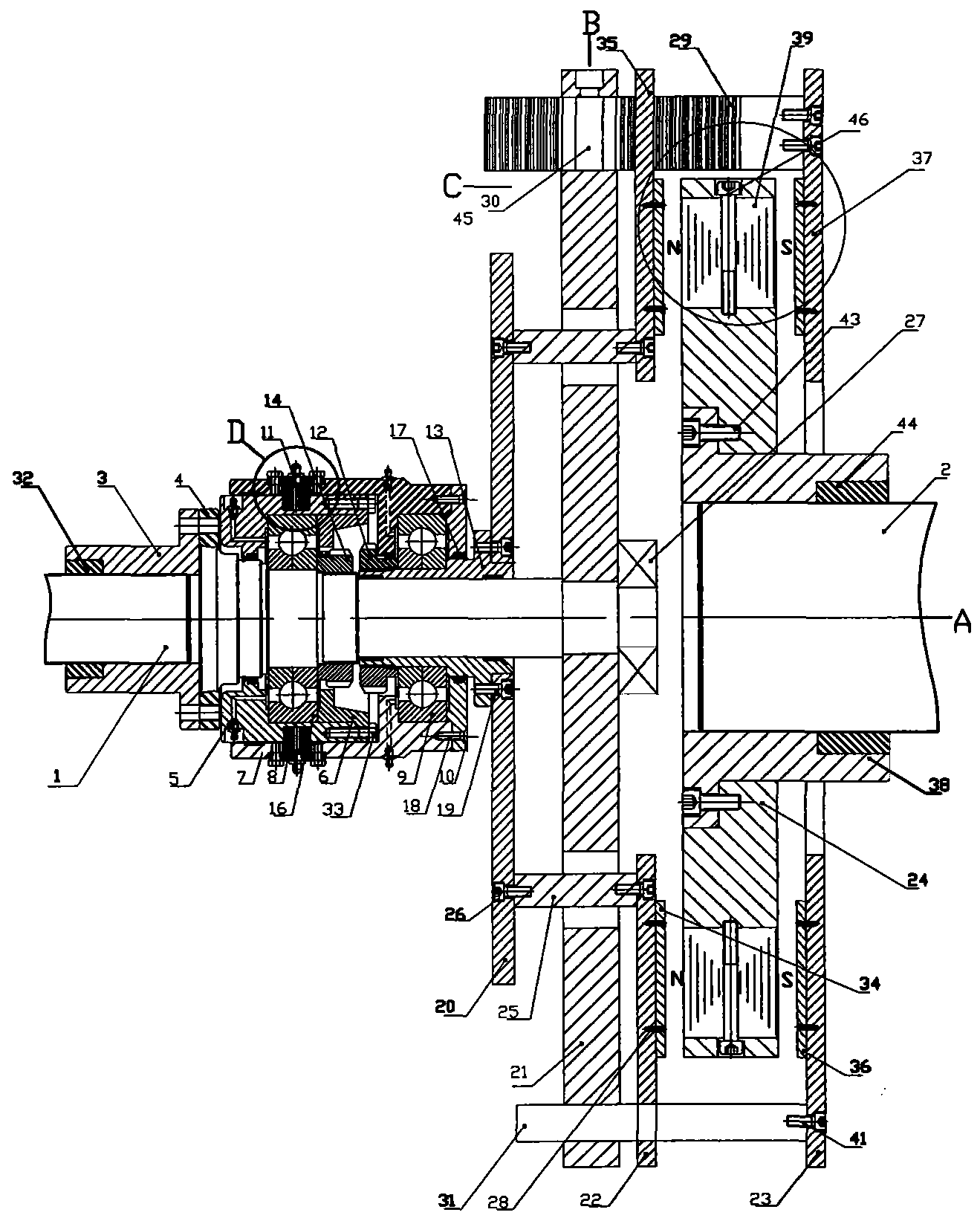

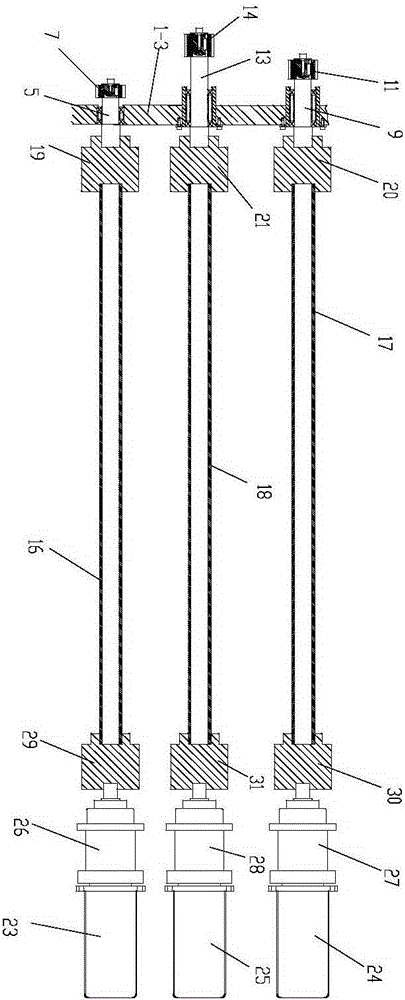

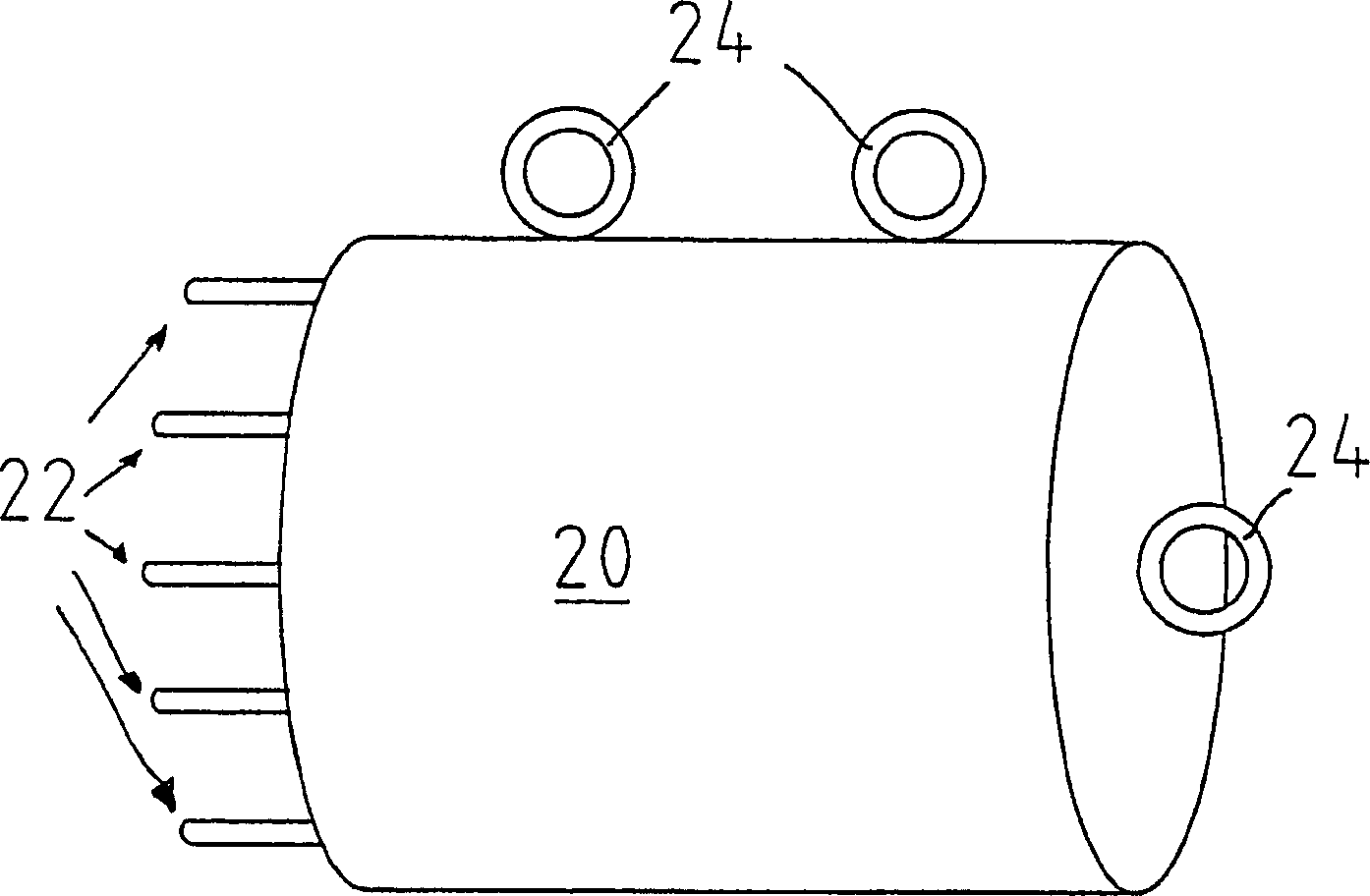

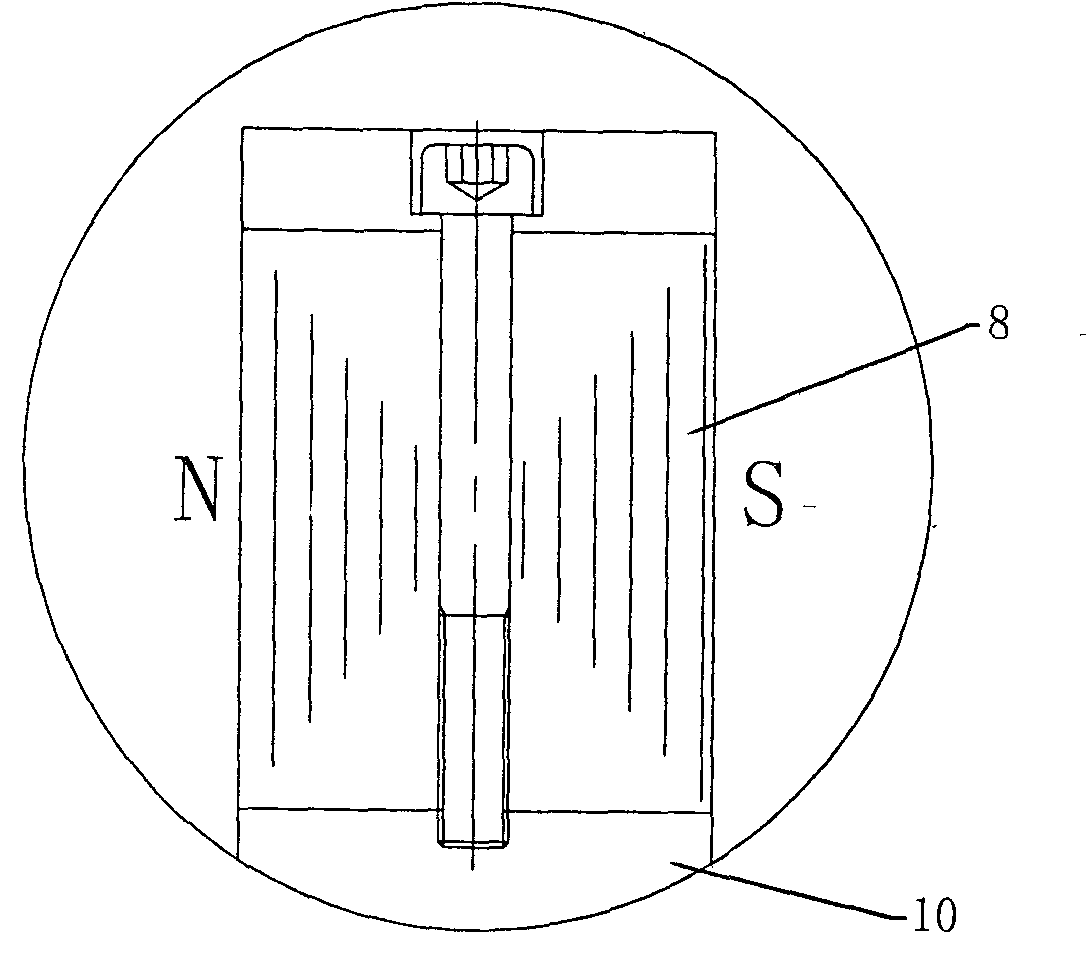

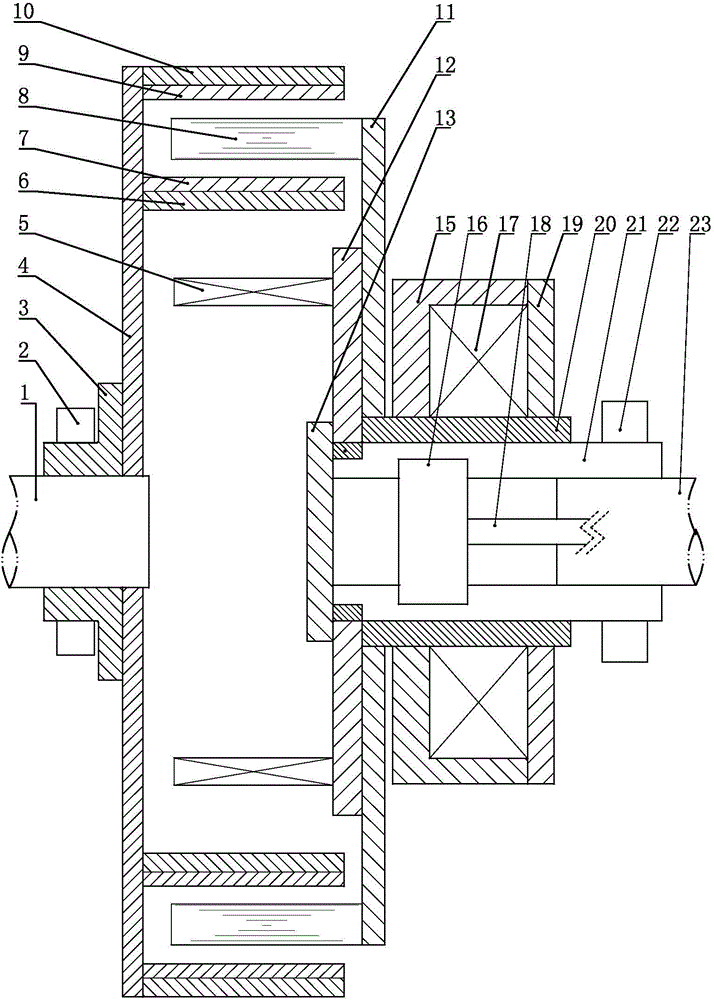

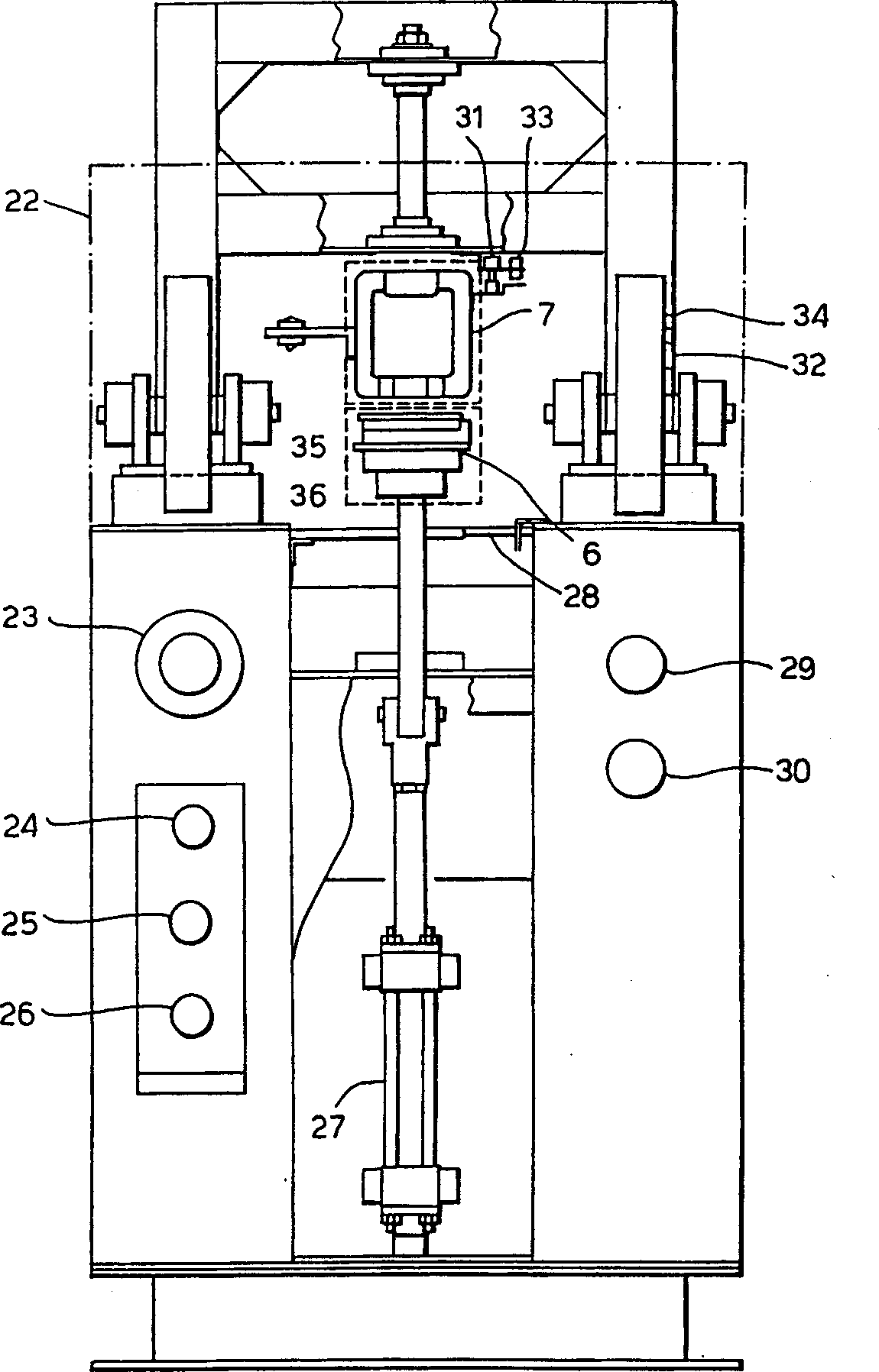

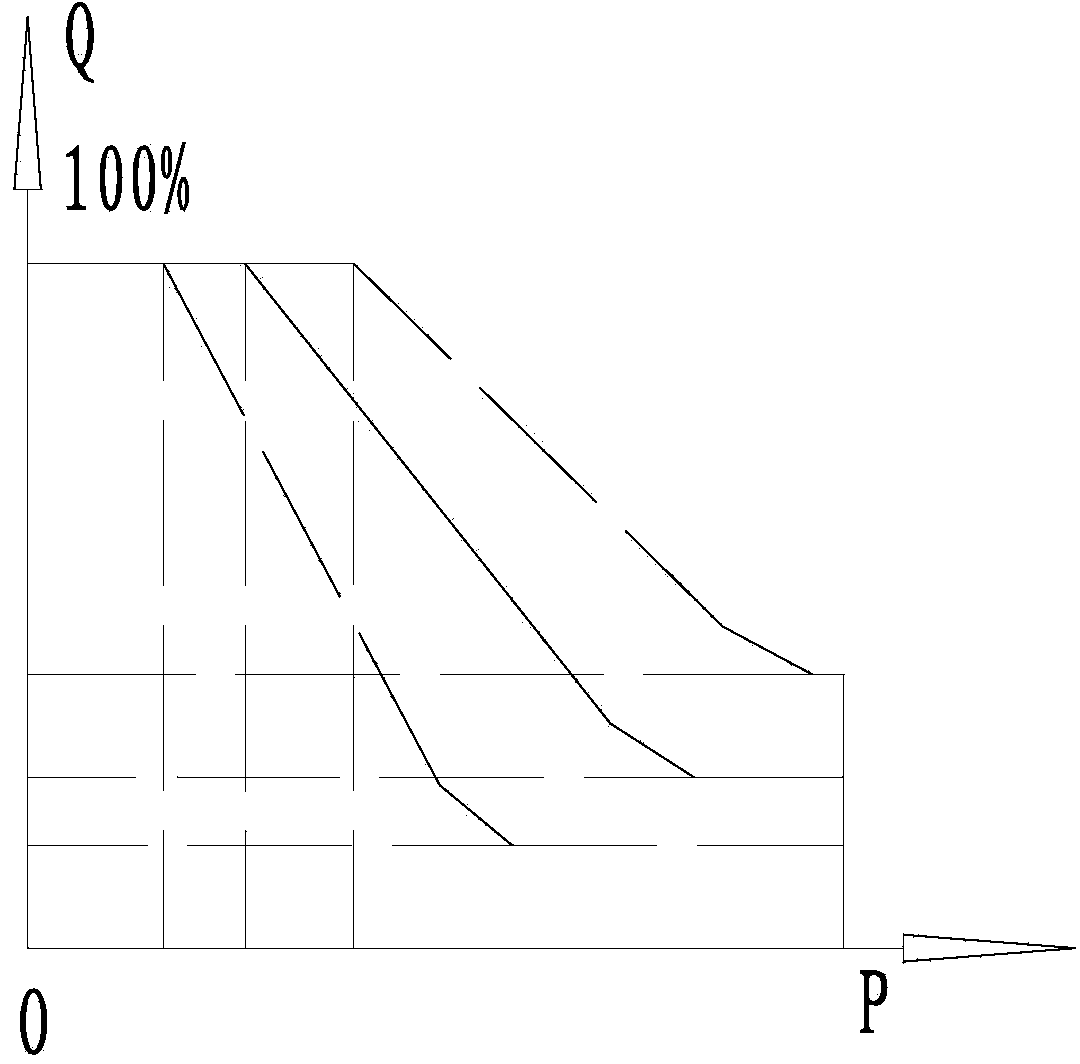

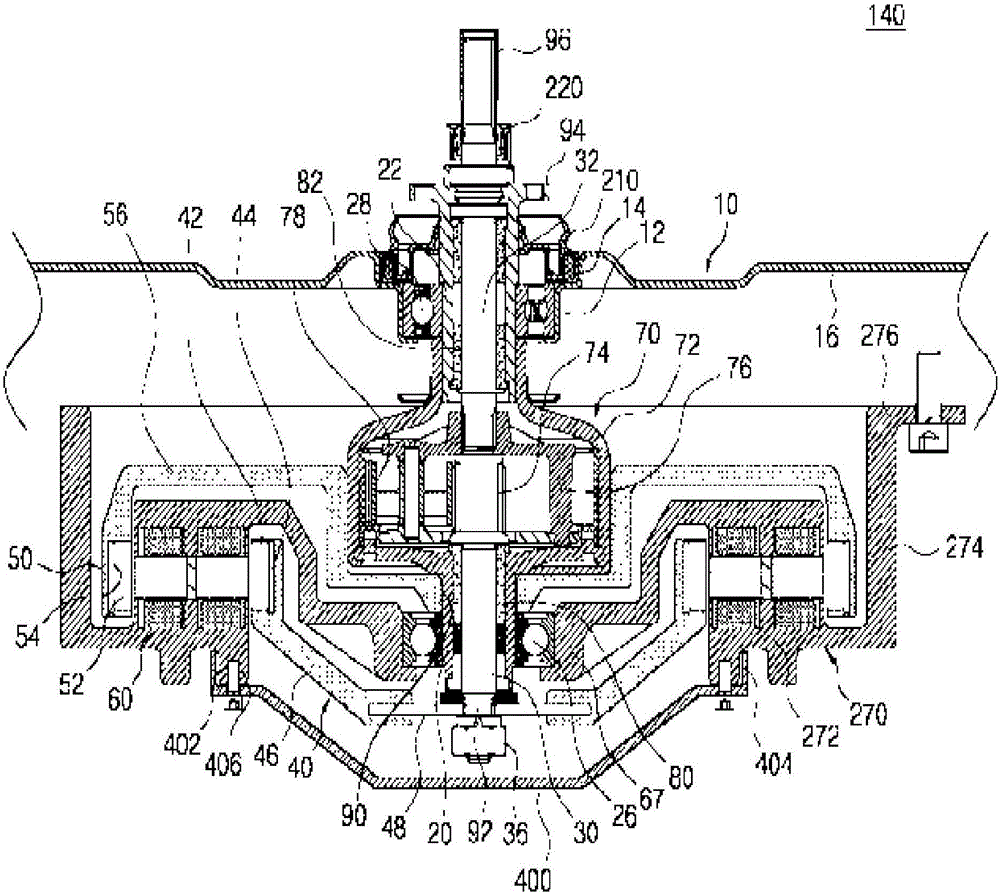

Permanent magnet speed governor

ActiveCN101800465AAchieve complete no-load startChange the air gapPermanent-magnet clutches/brakesElectrical conductorCoupling

The invention relates to a permanent magnet speed governor. A first shaft is provided with a single-layer edge cylinder conductor turnplate, and a second shaft is connected with a single-layer edge cylinder permanent magnet turnplate, wherein the permanent magnet turnplate is in the conductor turnplate; an annular conductor plate and a conductor cylinder are arranged in the conductor turnplate; the edge cylinder of the permanent magnet turnplate is provided with an outer permanent magnet ring and an inner permanent magnet ring; a gap is preserved between the conductor plate and the inner permanent magnet ring, and a gap is also preserved between the outer permanent magnet ring and the conductor cylinder; and a regulating mechanism mainly comprising a shaft sleeve, an addition shaft, an inner circle sleeve and an outer circle sleeve is arranged between the second shaft and the permanent magnet turnplate. The cylindrical turnplate permanent magnet speed governor replaces single-surface coupling by cylindrical and planar dual coupling and has a big coupling surface, and thereby, the non-contact transfer of the power is realized, and the transfer torque force is big; moreover, the permanent magnet turnplate can move along the axial direction, the transferred torque between the conductor plate and the conductor cylinder can be changed as long as the distance between the permanent magnet turnplate and the conductor plate and an effective part meshed with the conductor cylinder are changed; the permanent magnet speed governor can realize repeatable, regulable and controllable output torque and rotating speed to achieve the goals of speed regulation and energy saving.

Owner:QINGDAO SPRING ENERGY TECH

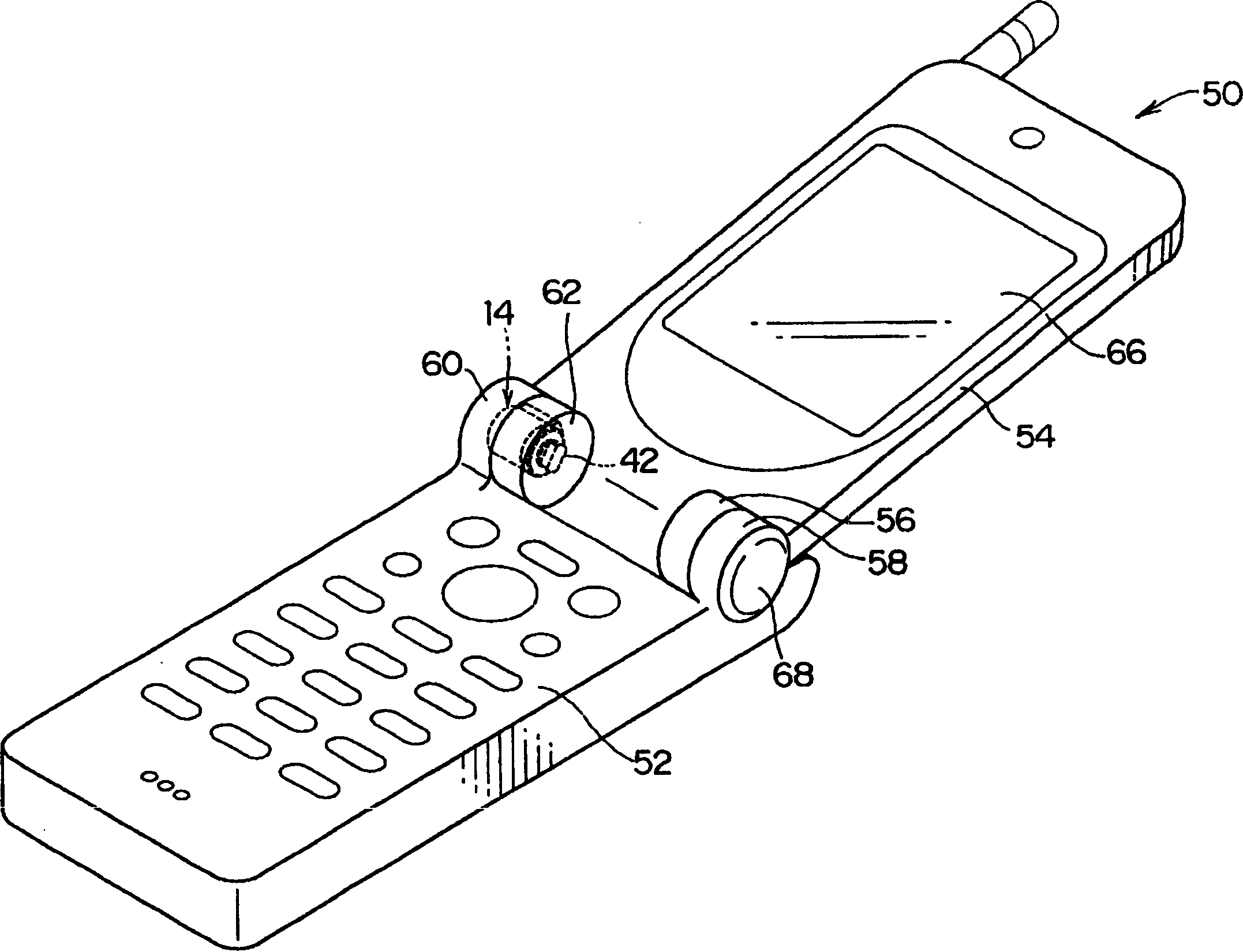

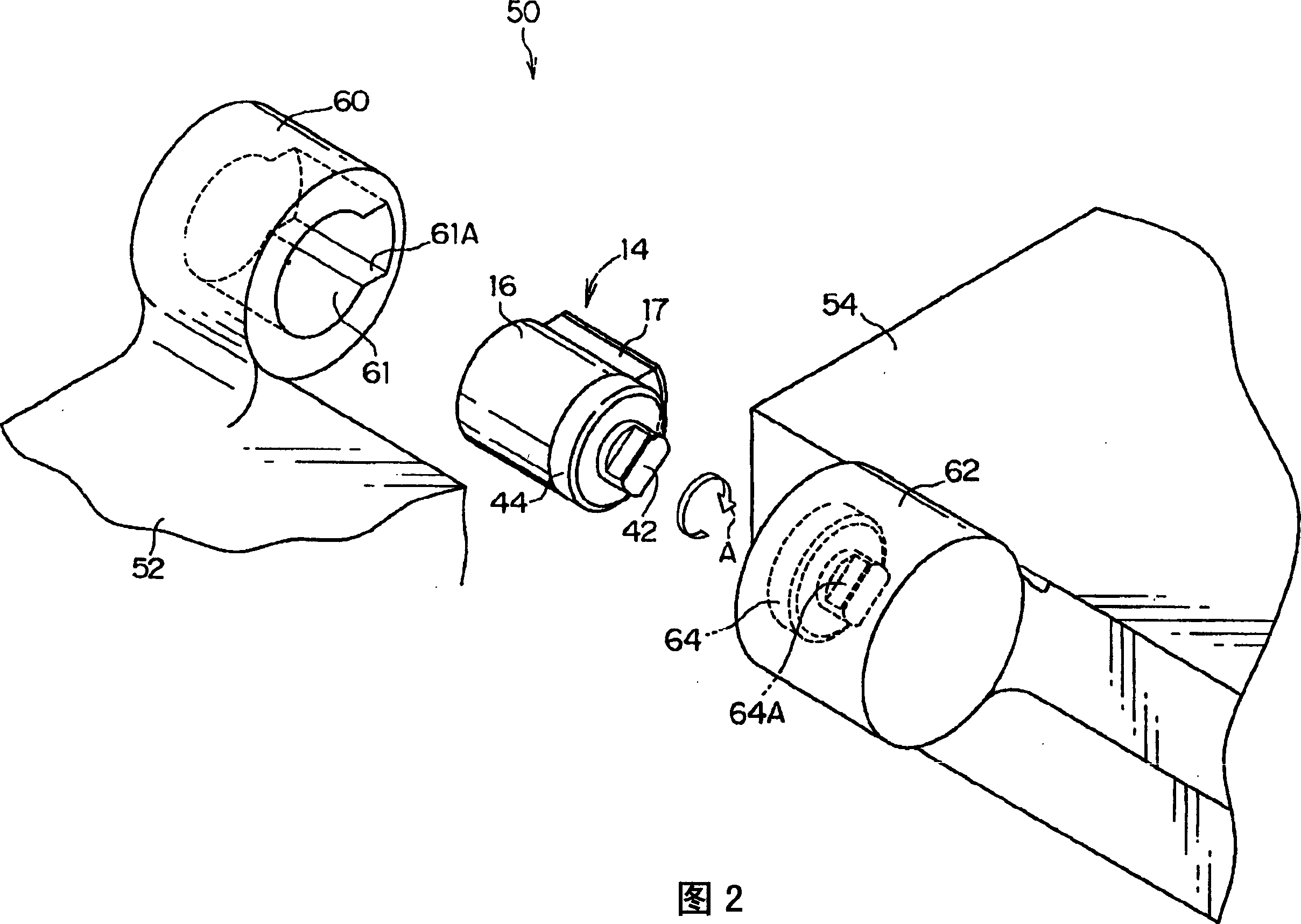

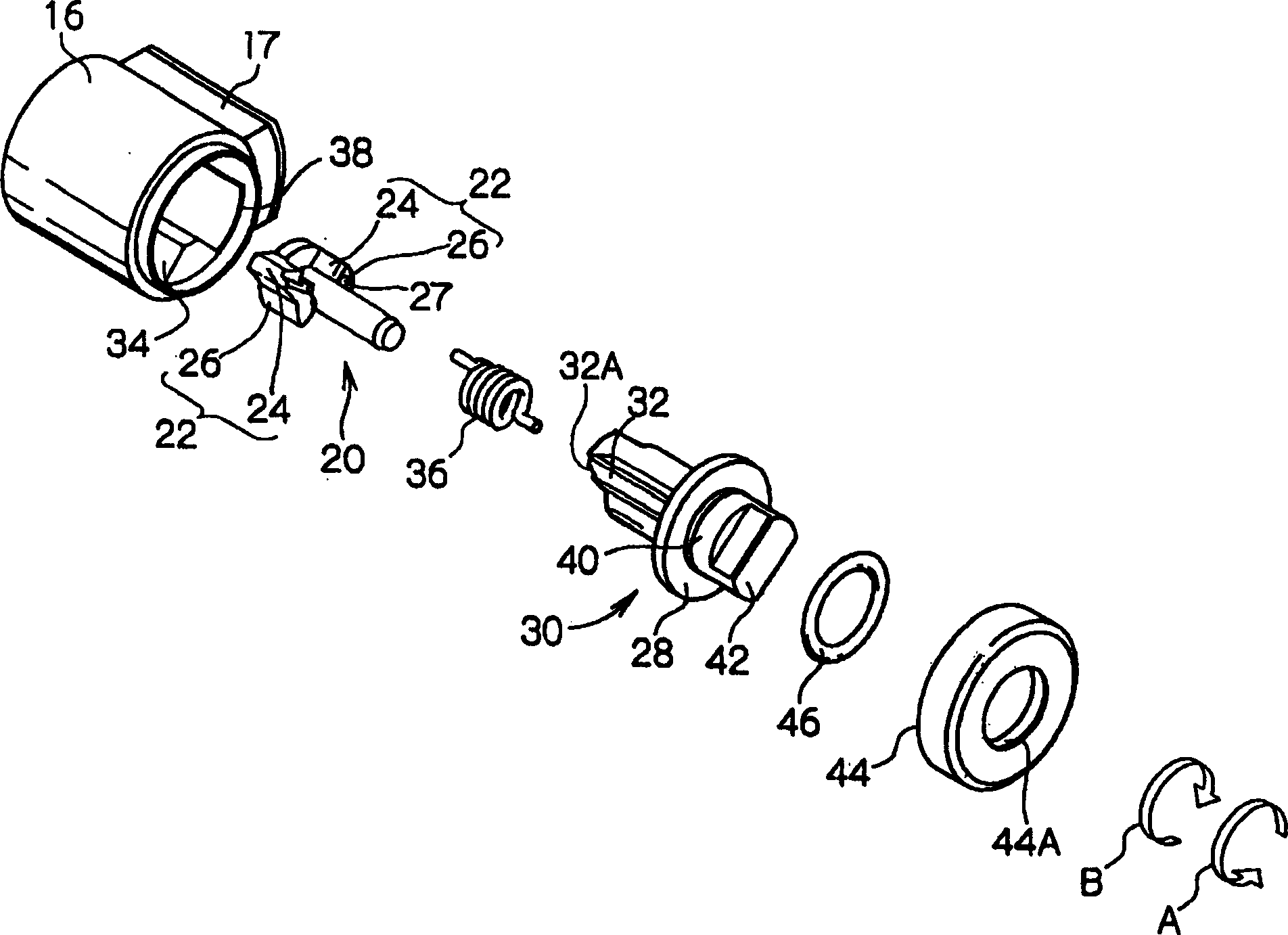

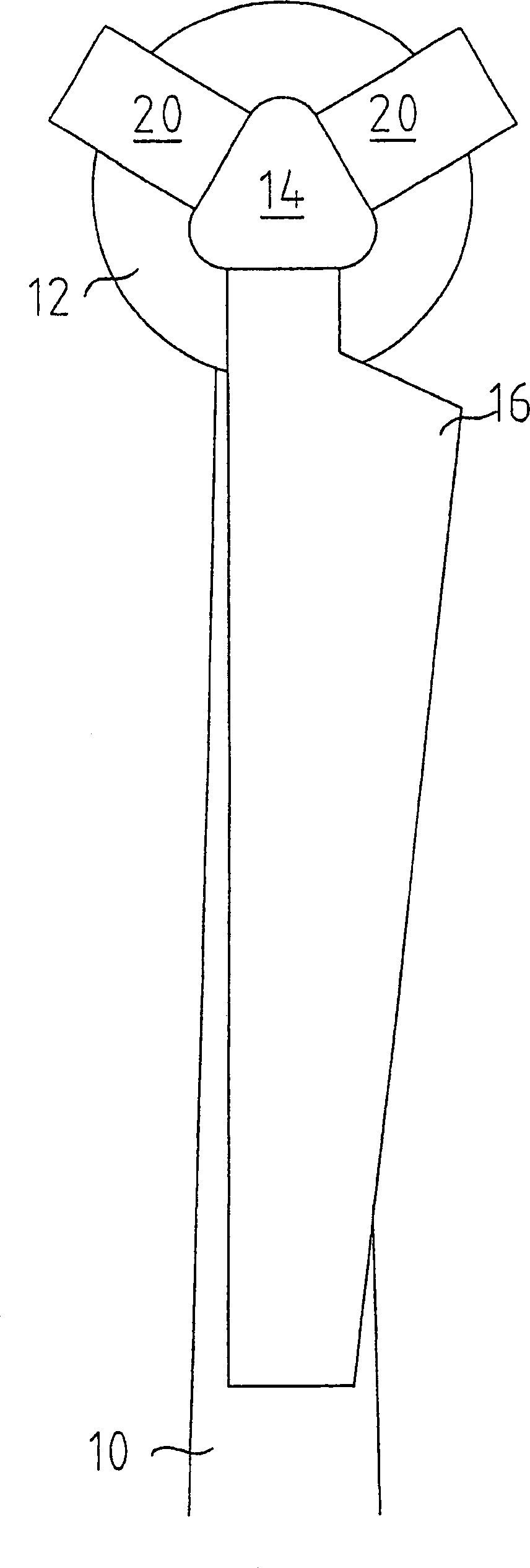

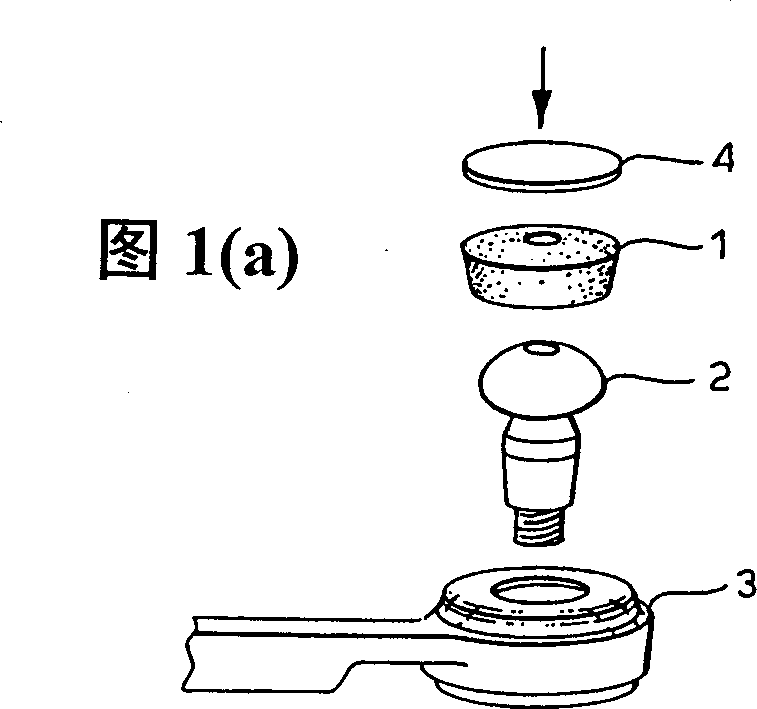

Damper

InactiveCN1502832AImprove shear resistanceUniform resistanceLiquid resistance brakesLiquid based dampersEngineeringShock absorber

When an upper 30 is rotated in the direction of an arrow B, the connection of the upper 30 to a bottom 20 is released, and a clearance is formed between the upper 30 and the bottom 20. Accordingly, a braking force acting on the upper 30 can be reduced by passing viscous fluid through the clearance to reduce a fluid resistance caused by the viscous fluid. Also, when the upper 30 is rotated in the direction of an arrow A, the upper 30 is connected to the bottom 20 and they are integrally rotated. Thus, the braking force acting on the upper 30 can be increased by shearing resistances caused by the viscous fluid applied to a projectedly installed part 32 and a connection part 24 and the viscous fluid passed through the clearance thereof from the inner peripheral surface of a housing. As a result, the torque can be varied according to the rotational direction.

Owner:NIFCO INC

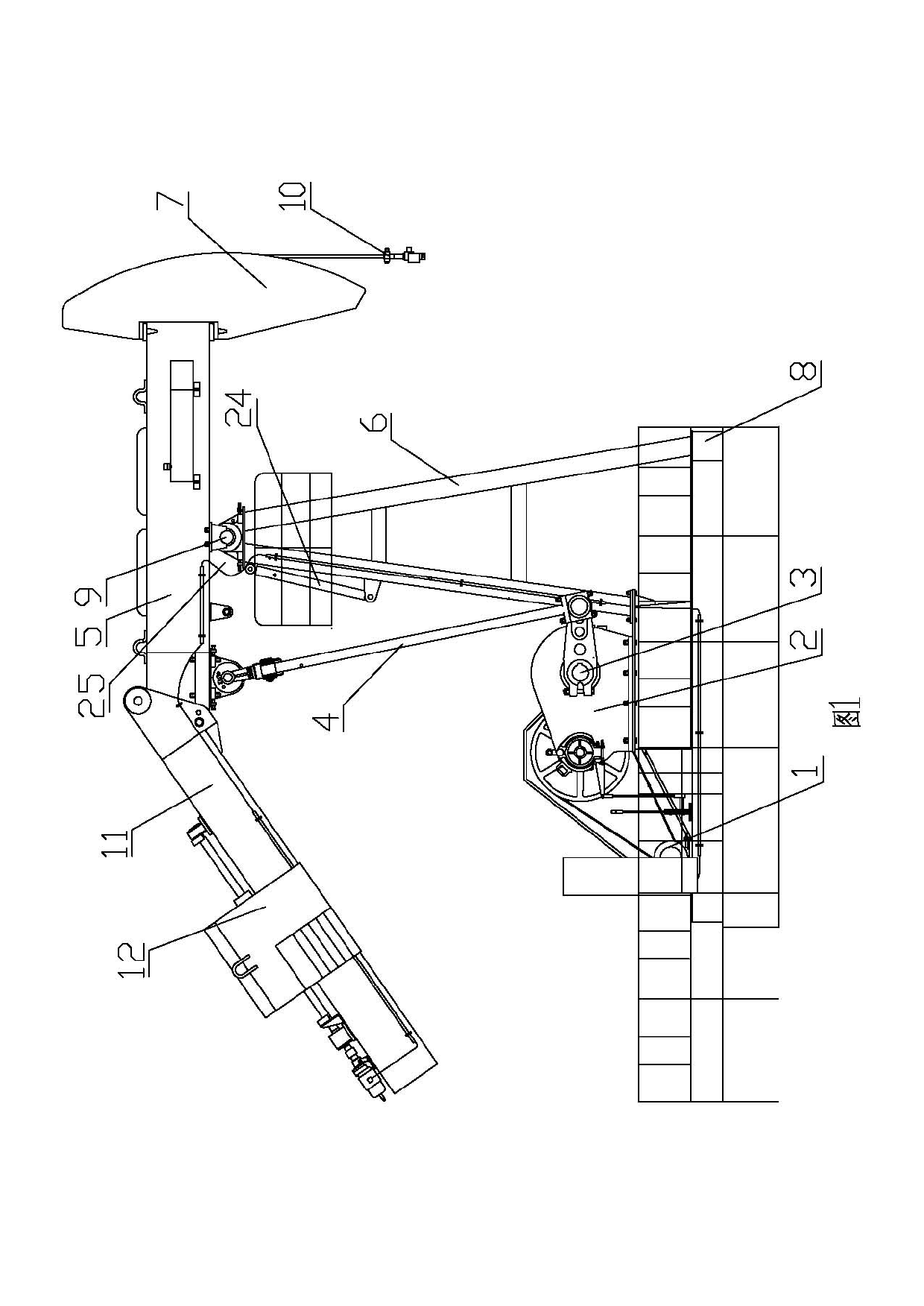

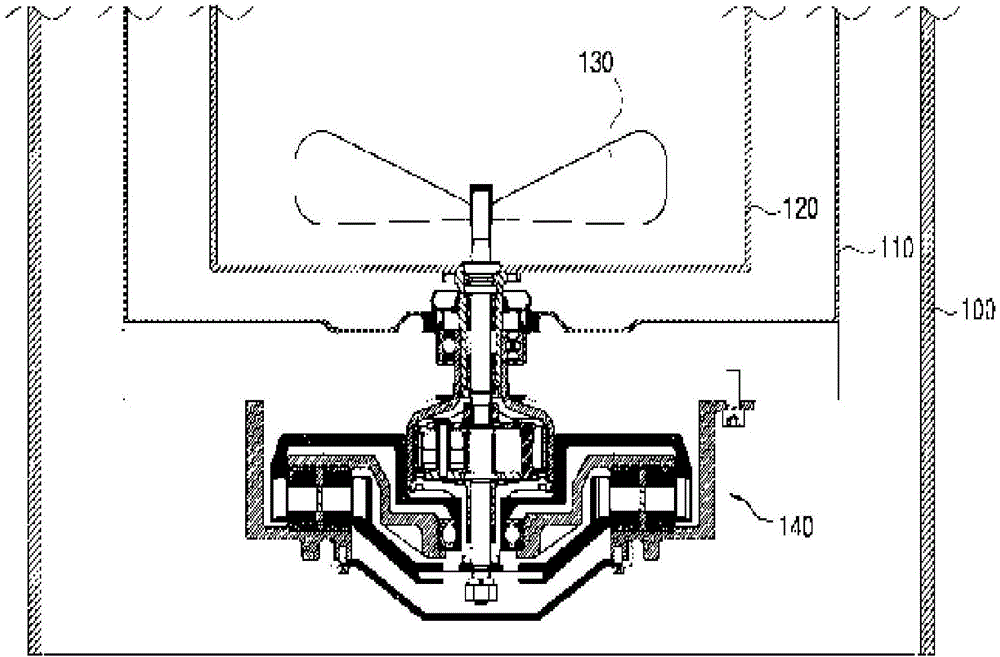

Method for in situ construction of a wind power plant

InactiveCN1551949AAvoid damagePrevent rotationWind motor assemblyMachines/enginesEngineeringHigh torque

One aspect of the present invention concerns a process for mounting rotor blades to a rotor hub of a wind power installation in situ. In order to avoid high torques in the mechanical train of the wind power installation in the operation of mounting the rotor blades, a process according to one aspect of the invention includes the following steps: mounting a weight to at least one flange of the rotor hub; mounting the rotor blade in the installation situation; rotating the rotor hub into a predeterminable position; and exchanging the weight arranged on the flange of the rotor hub for a rotor blade by removing the weight and then mounting the rotor blade to the rotor hub.

Owner:阿洛伊斯沃本

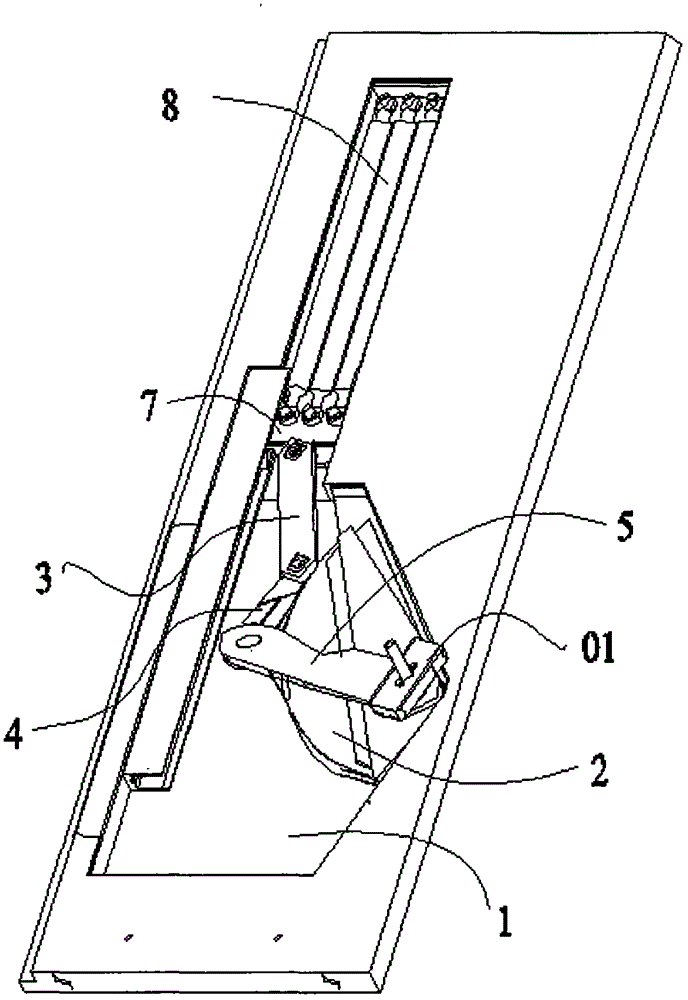

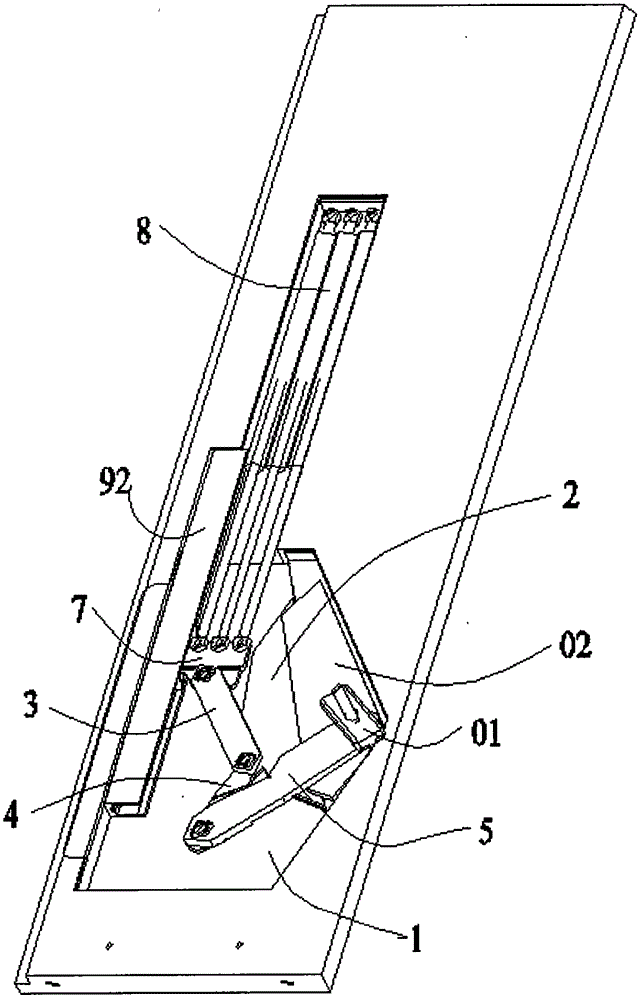

Overturning mechanism and cabinet-type overturning bed

The invention discloses an overturning mechanism and a cabinet-type overturning bed, and belongs to the technical field of overturning mechanisms and overturning beds. The overturning mechanism comprises a torque conversion mechanism which is mounted on a bottom plate, a power-assisting mechanism which is used for providing force for the torque conversion mechanism, a curve torque adjusting device and a torque transmission output device; the torque conversion mechanism comprises a first connecting rod, a second connecting rod and a third connecting rod which are rotatably connected in sequence; the first connecting rod is connected with the power-assisted mechanism; the end, close to the first connecting rod, of the second connecting rod is tightly adhered to the curve torque adjusting device and can move along the curve torque adjusting device; the torque transmission output device used for connecting a heavy objet is fixed to the other end of the third connecting rod. By adopting the technology, the torque output of the power-assisted mechanism can be automatically adjusted according to the change of load torque in the overturning process of the loaded heavy object, so that the device can be automatically kept in balance with the load torque; the operation is easy and flexible; the space is saved; the function of saving labor and being safe are achieved.

Owner:林永忠

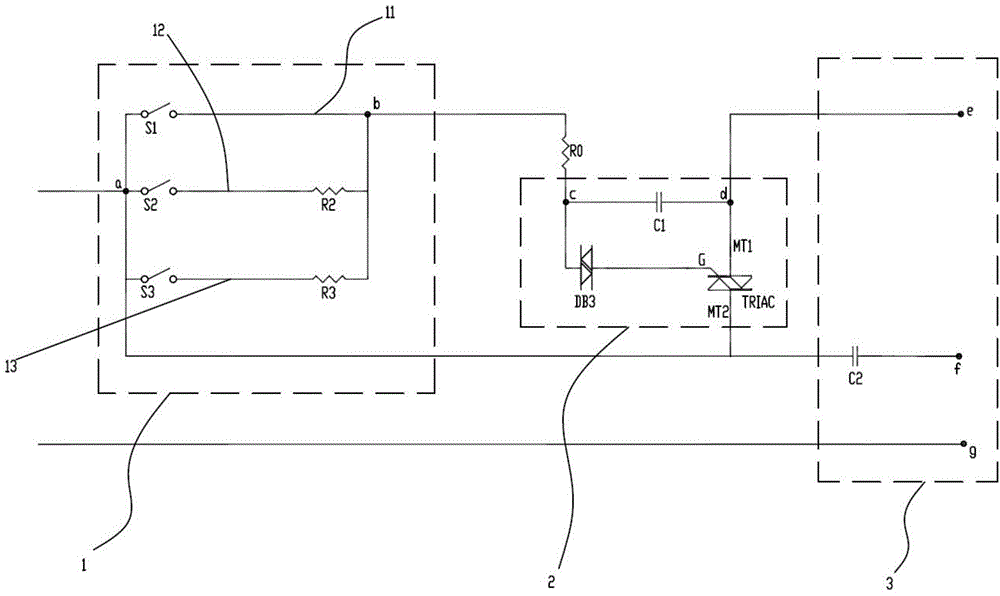

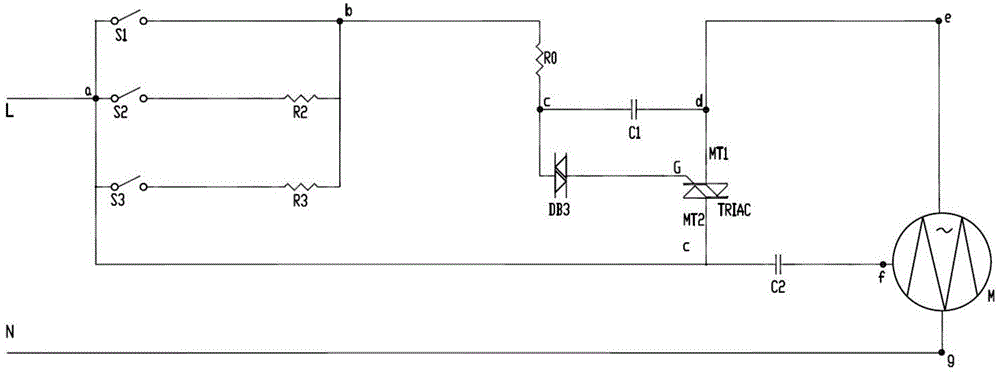

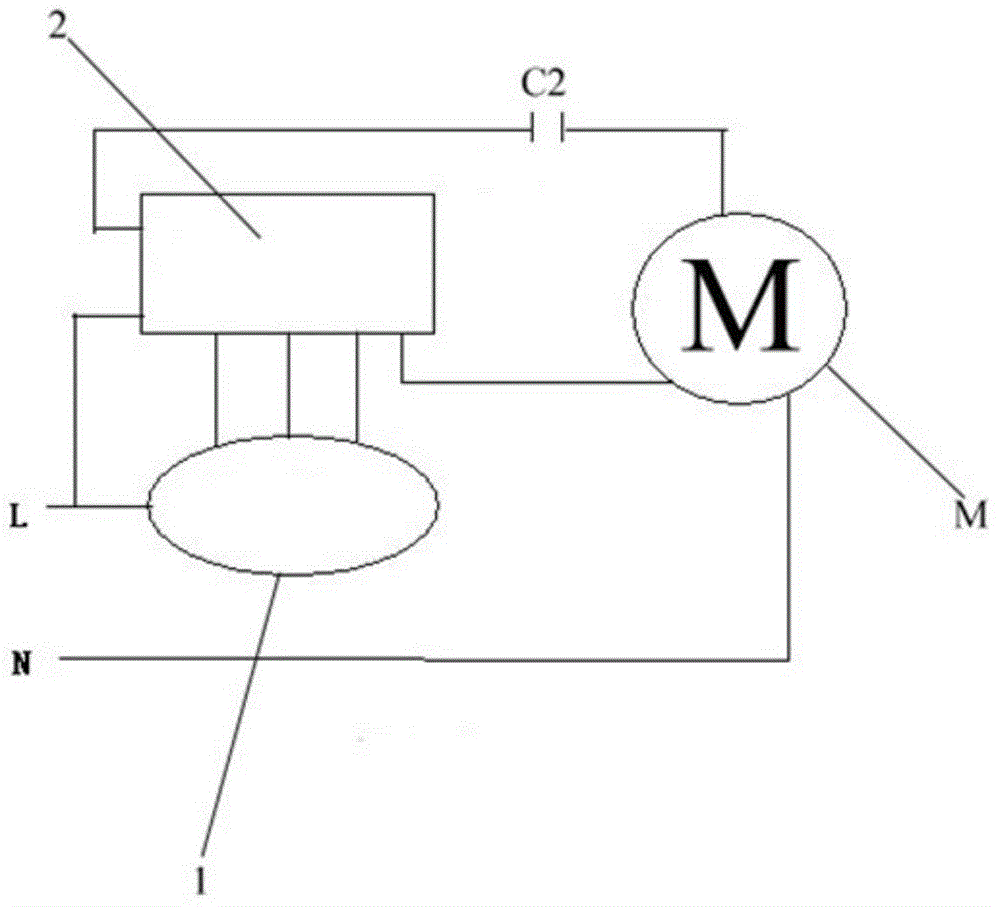

Fan motor speed adjusting device, fan with same and fan motor

InactiveCN104467623AChange torqueExtended service lifeAC motor controlMechanical energy handlingMaximum torqueCapacitance

The invention relates to a fan motor speed adjusting device, a fan with the fan motor speed adjusting device and a fan motor. The fan motor speed adjusting device comprises a switch control circuit, a speed adjusting circuit and a starting circuit. According to the fan motor speed adjusting device, firstly, the torque force of the motor is determined through the phase shifting effect of a starting capacitor in the starting circuit, and then the speed of the motor is adjusted through the speed adjusting circuit. The starting capacitor shares voltage with the motor and relieves impacting force of current on the motor, and therefore fluctuation is greatly reduced when the current torque force of the motor is stable. According to the fan motor speed adjusting device, the fan with the fan motor speed adjusting device and the fan motor, the advantages of an electronic speed adjusting method and the advantages of a capacitor speed adjusting method are combined, and on the premise that it is guaranteed that each speed adjusting gear can obtain maximum torque force generated by a motor winding, the motor is intelligently controlled through electronic speed adjustment; thus, impacting force of current on the motor is relieved, the current torque force of the motor can be stable, the service life of the motor is prolonged, and aging of all devices is relieved; the circuit structure is simple, and maintenance is convenient.

Owner:陈伟禧

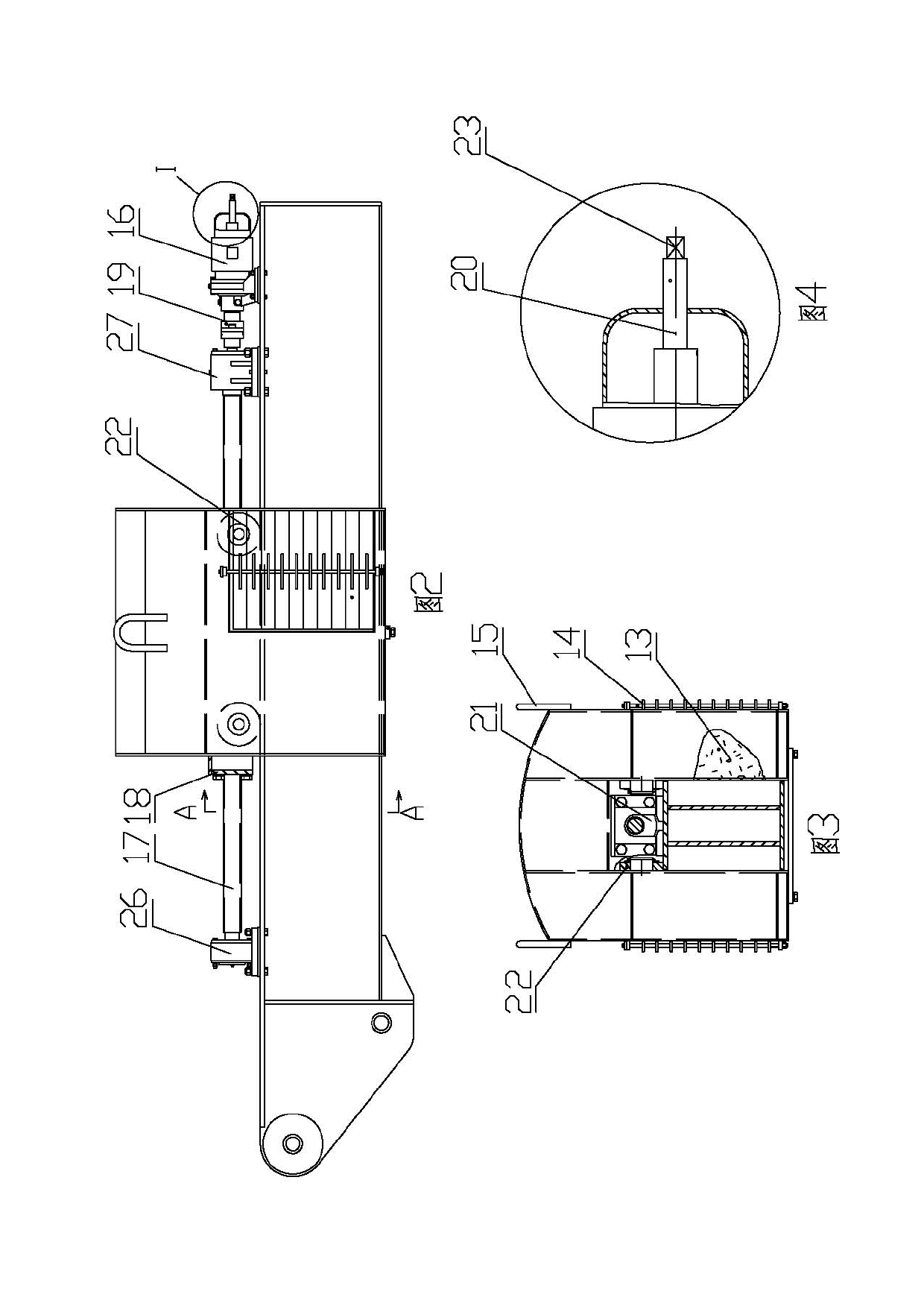

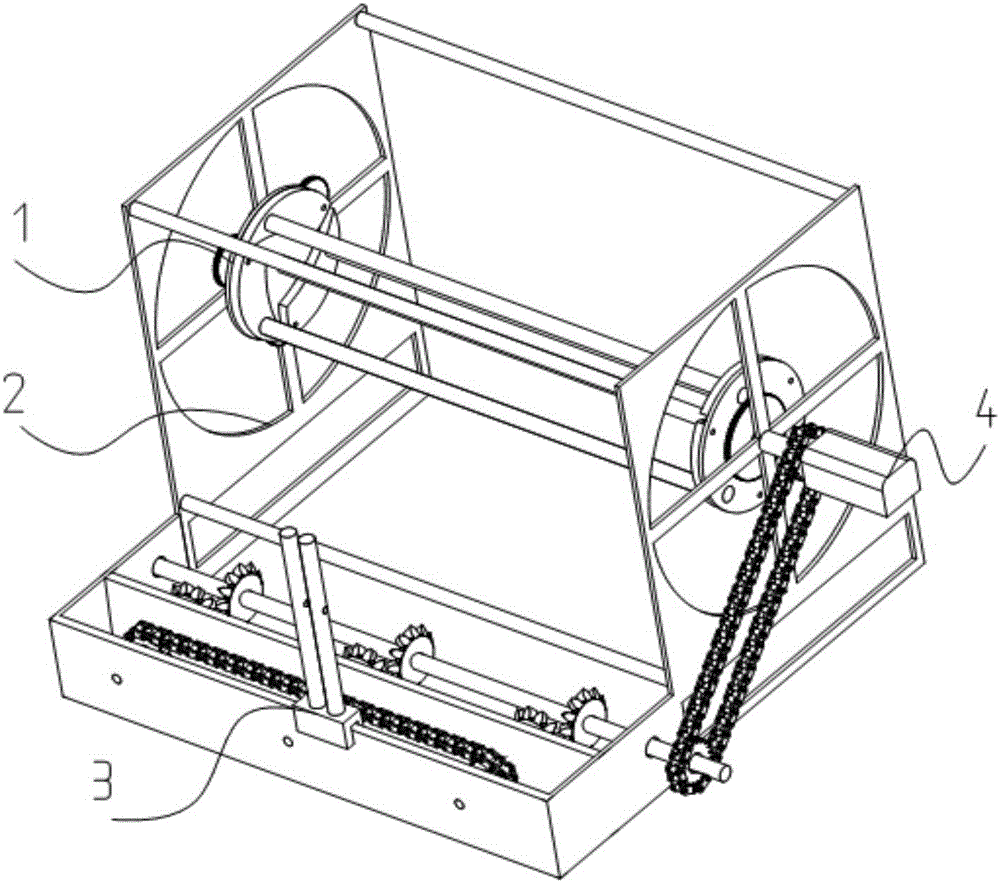

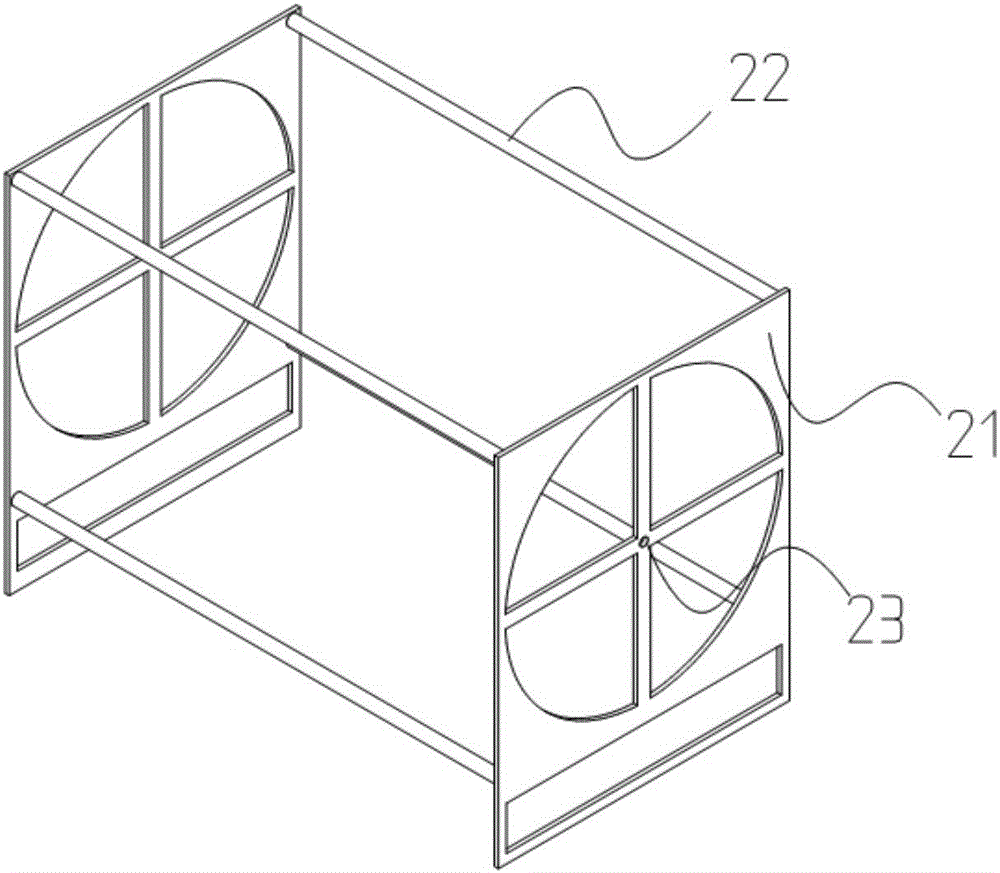

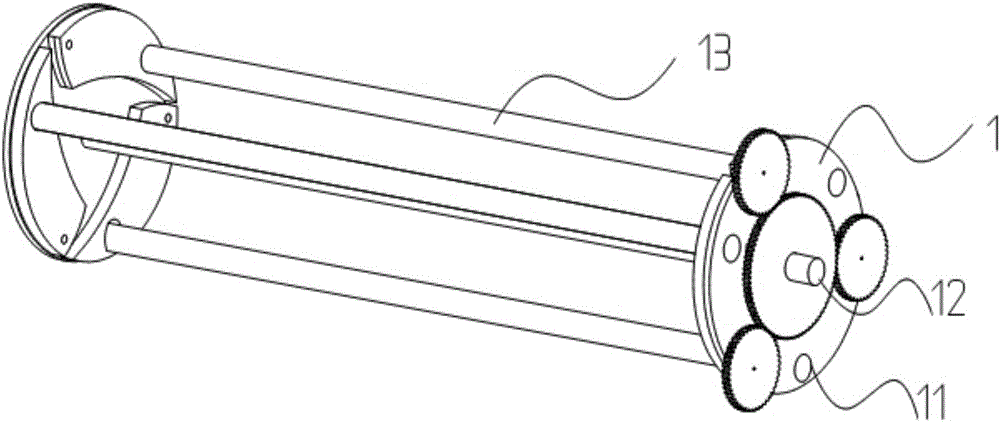

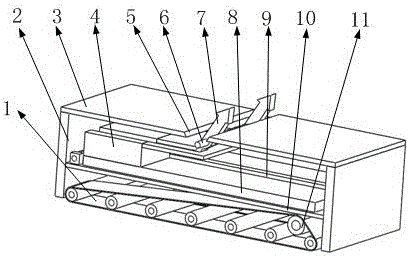

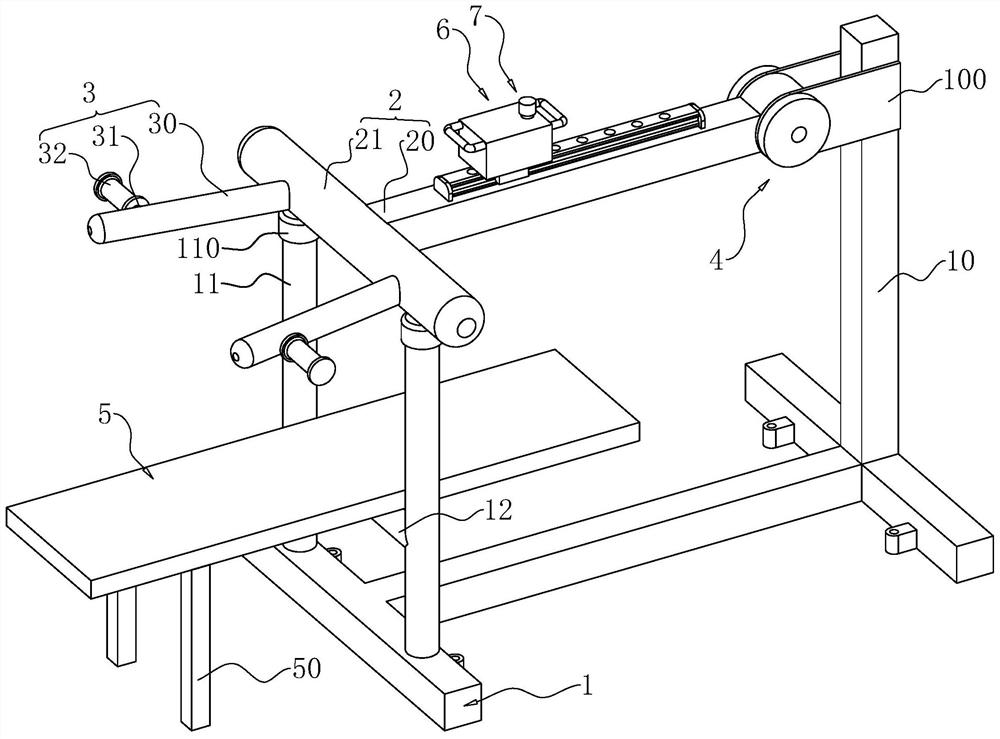

Roller-adjustable multipurpose winding device

A roller-adjustable multipurpose winding device comprises a bracket, a roller adjusting device and a motor. The bracket comprises bracket supporting boards and transverse rods, wherein the bracket supporting boards are two parallel vertical boards, the transverse rods are four transverse long rods, one ends of the four transverse rods are fixedly arranged at the four corners of one of the bracket supporting boards correspondingly, and the other ends of the four transverse rods are fixedly arranged at the four corners of the other bracket support board correspondingly. The roller adjusting device is arranged in the bracket and comprises two adjusting device bodies, a center shaft and a movable shaft. The two adjusting device bodies are arranged beside the two bracket supporting boards correspondingly. Each adjusting device comprises a rotating plate, a movable block, a driven gear, a movable shaft hole and a driving gear. The center shaft is a long rod, the two ends of the center shaft penetrate through the two adjusting device bodies and are arranged in center shaft holes in the bracket separately, and the motor is arranged at one end of the center shaft. Three movable rods are used for replacing traditional rollers, the positions of the movable rods are changed by rotating the driving gear, then the diameter of the roller is changed, different wires can be wound by changing the diameters of the rollers, and operation is easy.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

Mechanical joint and robot arm comprising same

ActiveCN103722562AReduce the effect of backlashSpace saving configurationProgramme-controlled manipulatorJointsMotor driveRobotic arm

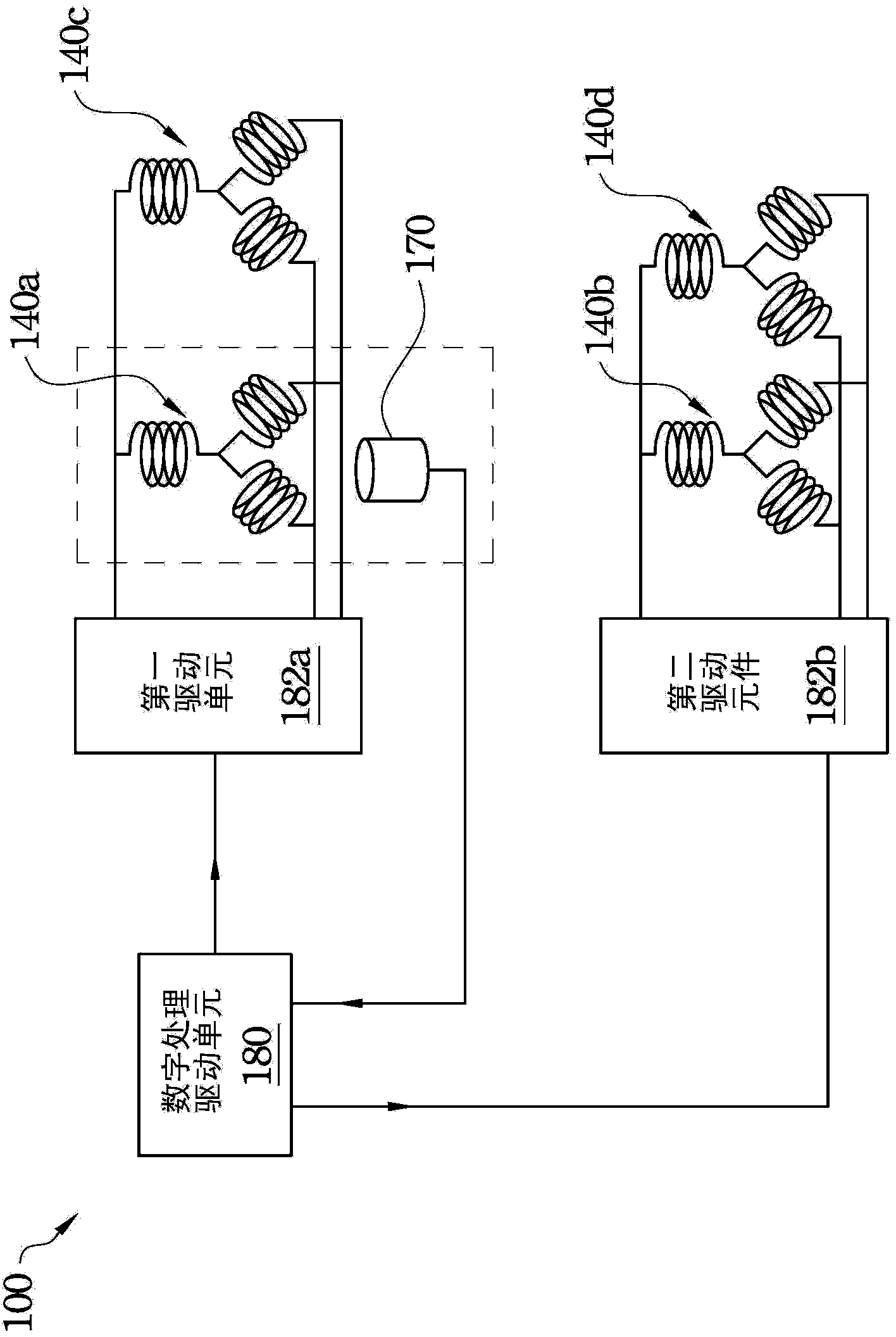

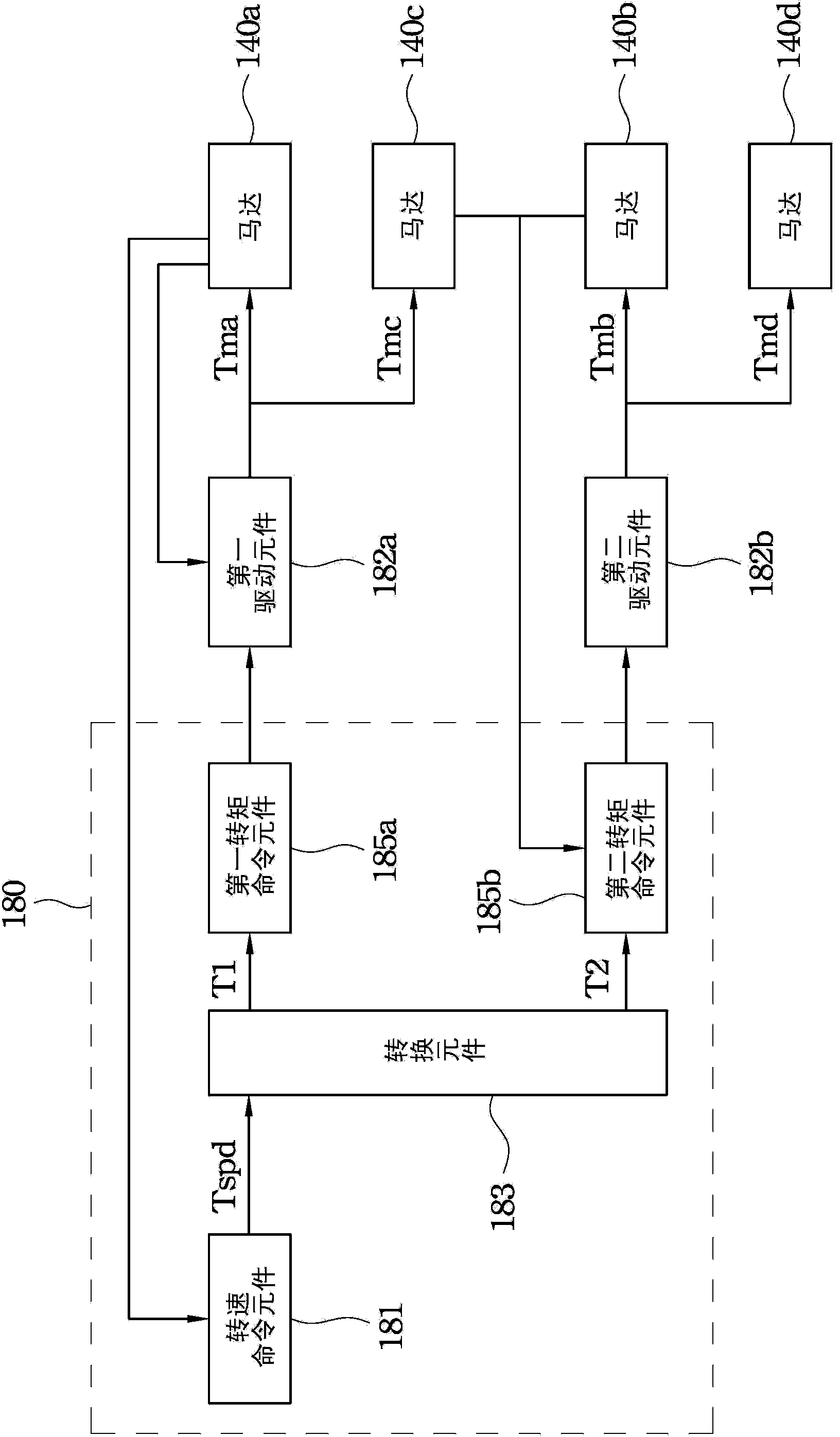

The invention discloses a mechanical joint and a robot arm comprising the mechanical joint. The mechanical joint comprises a hollow shaft, a first gear, a plurality of motors, a plurality of second gears, an encoder and a digital processing and driving unit. The first gear is fixed to the hollow shaft. The motors surround the hollow shaft and are respectively provided with a rotating shaft. The second gears are fixed to the rotating shafts and meshed with the first gear. The motors drive the second gears to rotate the hollow shaft. The encoder is arranged at the side, opposite to the corresponding second gear, of one motor. A signal of the encoder is transmitted back to the digital processing and driving unit to drive the motors. According to the mechanical joint, as the motors drive the hollow shaft to rotate in cooperation with the gears, output torsion of the hollow shaft can be effectively increased, and magnitude of deceleration is lowered. A user can adjust the number of the motors according to different requirements to change torsion and rotating speed of the hollow shaft of the mechanical joint. Due to the fact that the encoder and the digital processing and driving unit are located on the same plane, space allocation can be effectively saved.

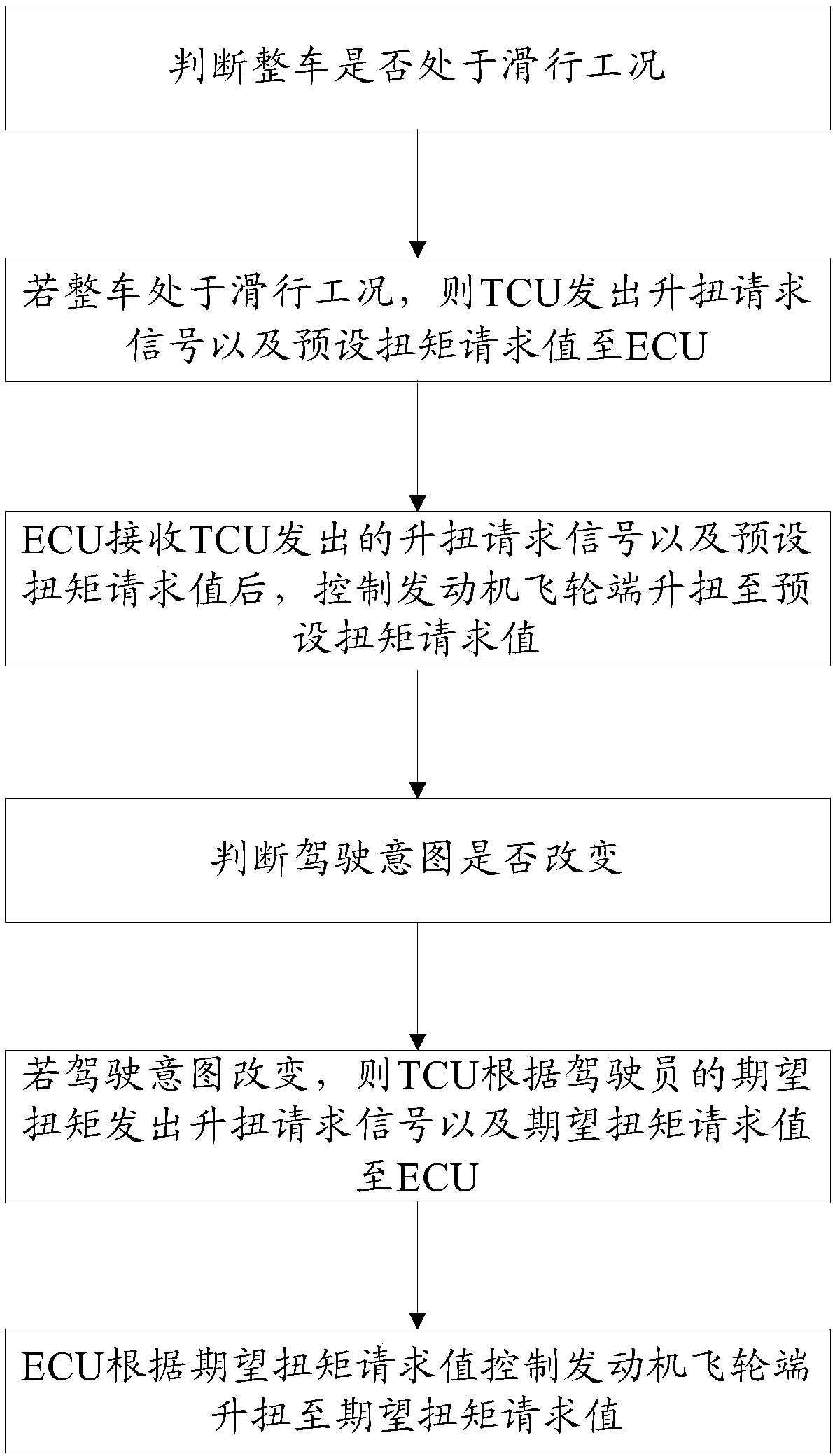

Sliding working condition torque control method

The invention discloses a sliding working condition torque control method. The sliding working condition torque control method comprises the following steps of judging whether a whole vehicle is in asliding working condition or not; if the whole vehicle is in a sliding condition, TCU sends a torque raising request signal and a preset torque request value to ECU; after receiving the torque raisingrequest signal and the preset torque request value from the TCU, the ECU controls the torque of the flywheel end of an engine to be raised to the preset torque request value; judging whether a driving intention is changed or not; if the driving intention is changed, the TCU sends a torque raising request signal and a desired torque request value to the ECU according to a torque desired by a driver; and the ECU controls the torque of the flywheel end of the engine to the desired torque request value according to the desired torque request value. By means of the sliding working condition torquecontrol method, because the torque of the engine in the sliding working condition is adjusted to the preset torque request value, when the driving intention is changed, the torque of the flywheel endof the engine is not changed greatly or rapidly, and impacts or setback can be effectively avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Self-adjusting static friction type vehicle stopping mechanism

ActiveCN106758964APrevent forward rollStabbed smoothlyTraffic restrictionsStatic frictionFriction tape

The invention belongs to the technical field of vehicle stopping and particularly relates to a self-adjusting static friction type vehicle stopping mechanism. The self-adjusting static friction type vehicle stopping mechanism comprises a plurality of wheel constraint mechanisms, wherein each wheel constraint mechanism comprises a friction belt, a balance block, spiked nails, a force applying board, resistance wheels and a friction wheel and can constrain the wheel of a running vehicle. After the wheels are constrained by the wheel constraint mechanisms, the car drags the wheel constraint mechanisms to move forwards along with the vehicle, static friction force between the ground each friction belt is generated to drive the friction belt to rotate due to the fact that the friction belt is arranged on the bottom surface of the wheel constraint mechanism, and the resistance wheels on the friction belt generate appropriate resistance to allow the resistance of the resistant wheels to constantly keep the static friction state between the ground the friction belt. In addition, the balance block is added into each wheel constraint mechanism, the positions of the balance body in the wheel constraint mechanism are adjusted according to vehicle speed, the faster the vehicle is, the more rear the balance block is, forward turning, driven by the vehicle, of the wheel constraint mechanism is prevented, fast vehicle braking is achieved, and a good use effect is achieved.

Owner:HEBEI ZONGSHEN GEMEILI AGRI MACHINERY MFG CO LTD

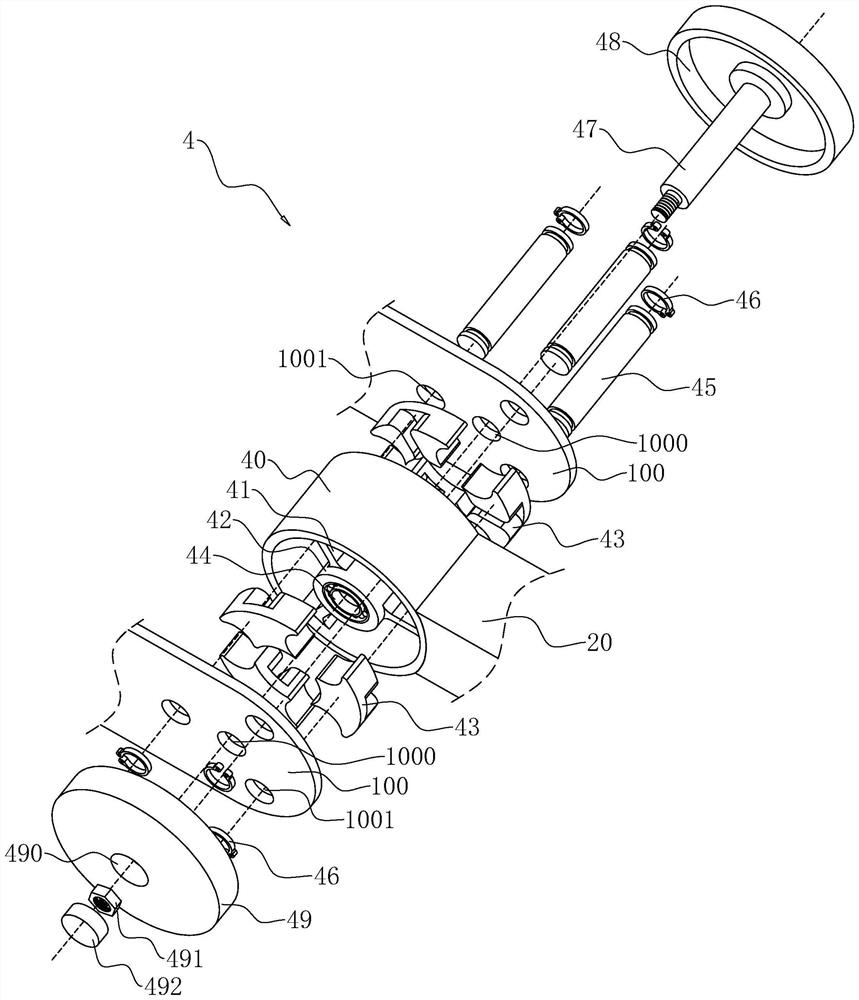

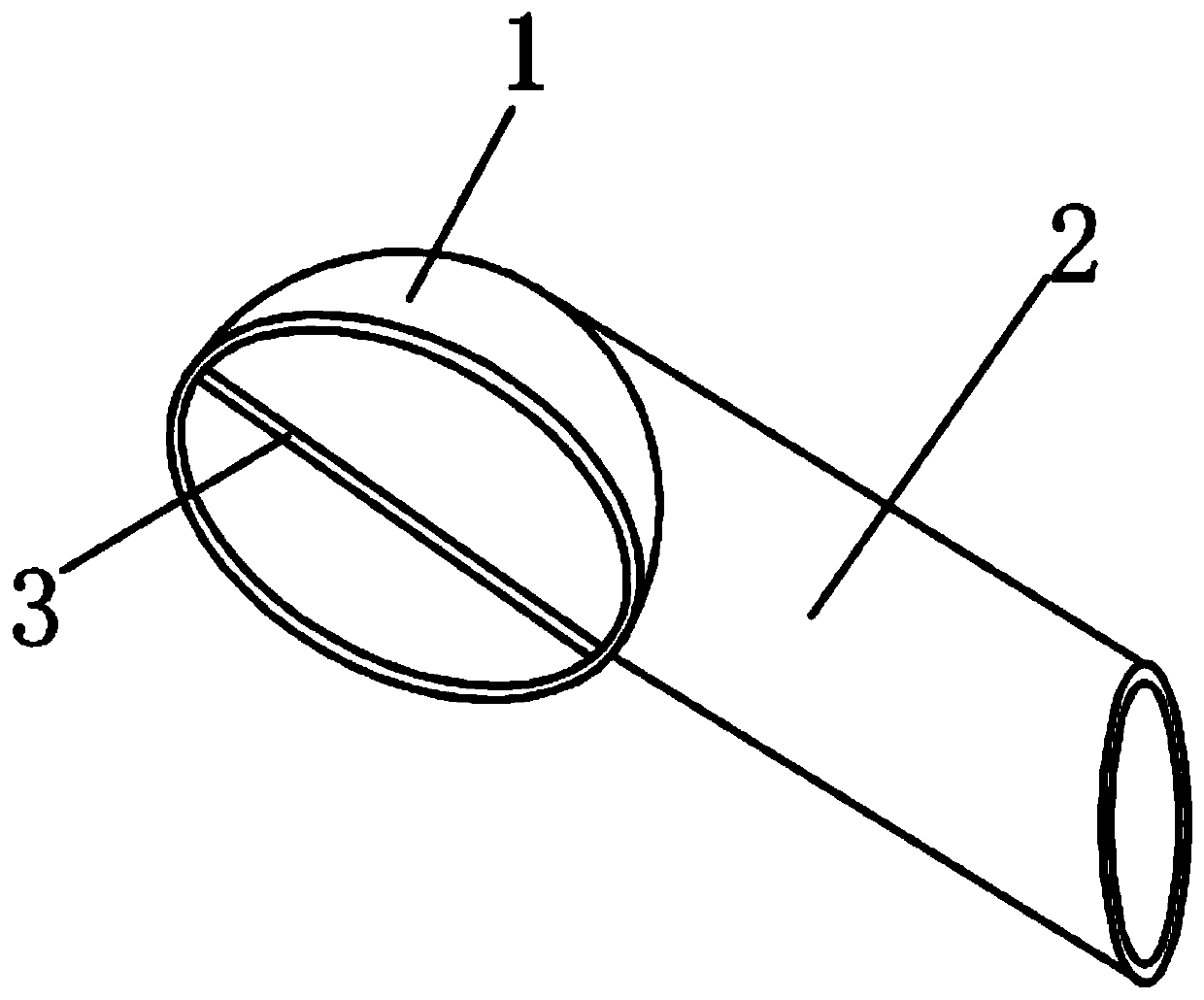

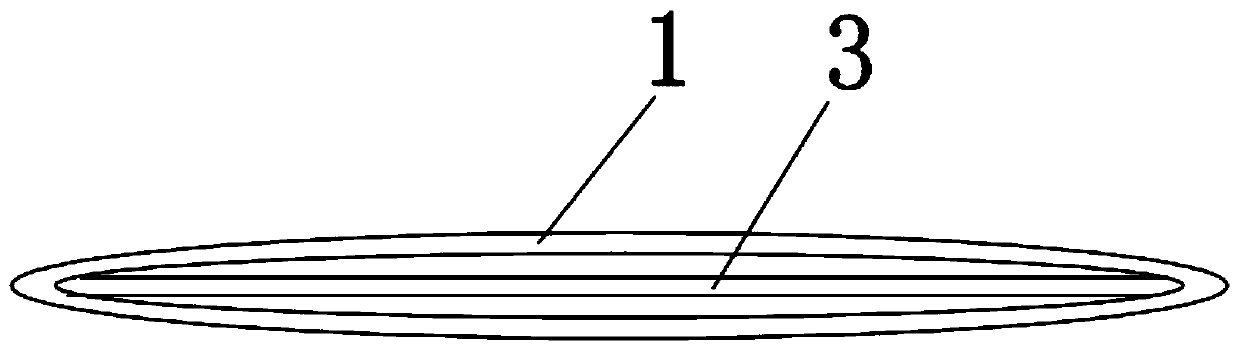

Permanent-magnet speed governor

InactiveCN101783576AAchieve complete no-load startChange the air gapAsynchronous induction clutches/brakesPush and pullElectrical conductor

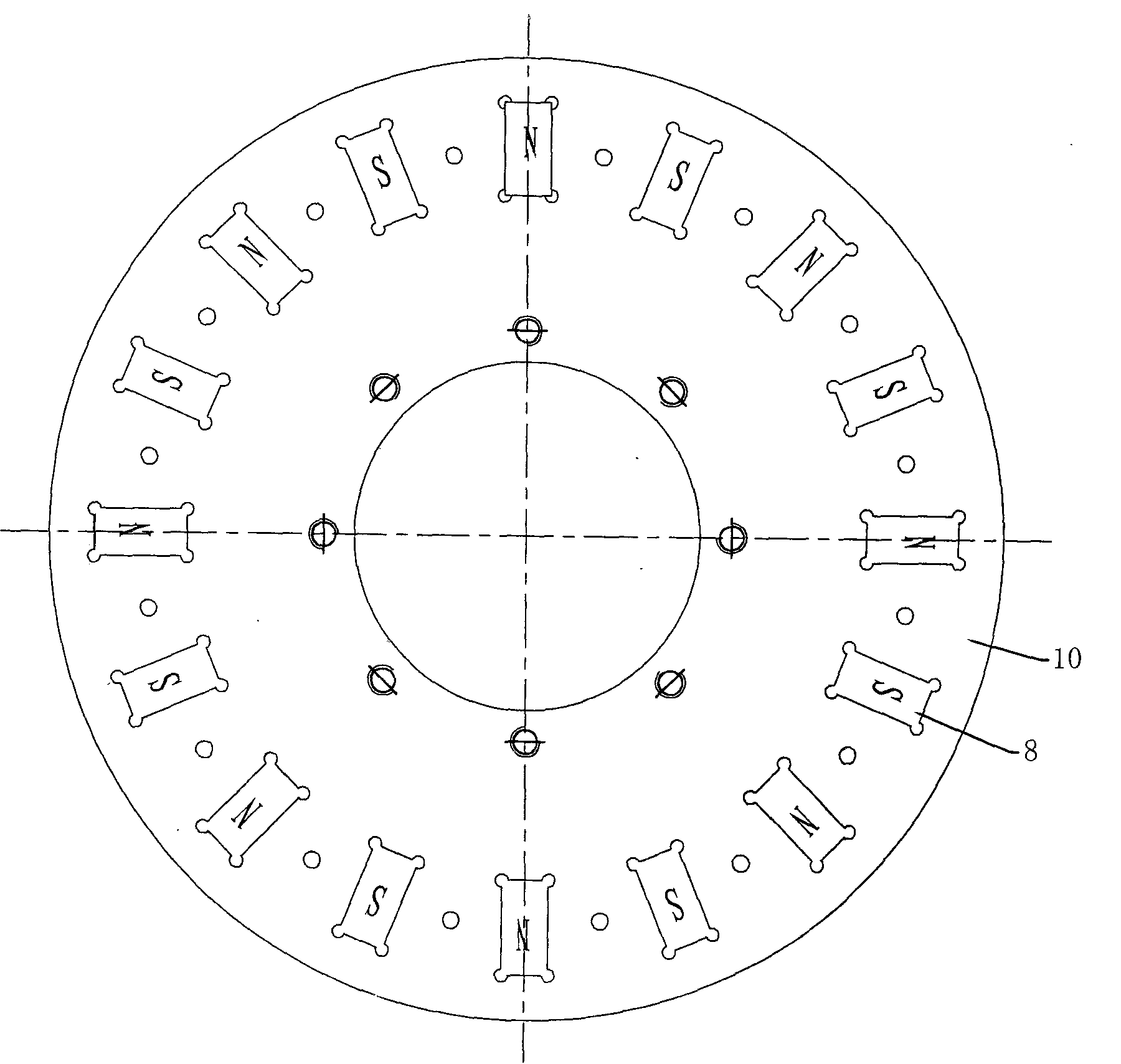

The invention relates to a permanent-magnet speed governor, which comprises a first shaft and a second shaft, wherein the first shaft and the second shaft are coaxial, a conductor disc is installed on the first shaft and the second shaft is connected with a permanent-magnet rotating disc. The conductor disc and the permanent-magnet are placed close to each other. The conductor disc is formed by an outer rotating disc made of ferromagnetic material and an inner rotating disc made of conductor material, wherein the outer rotating disc and the inner rotating disc are attached together. The permanent-magnet rotating disc is made of non-ferromagnetic material. A group of permanent magnets are annularly installed on the permanent-magnet rotating disc. The magnetic pole direction of the permanent magnets is in parallel with the axis of the rotating disc, and every two adjacent ends are heteropolar. The invention has the advantages that non-contact power transmission is realized, the vibration is reduced, the motor can be started up fully with no load during startup, the torque transferred between the permanent-magnet rotating disc and the conductor disc can be varied through adjusting a handle installed on an outer sleeve to push a bearing to axially move on the shaft, to push-and-pull the permanent-magnet rotating disc to axially move and to vary the air gap between the permanent-magnet rotating disc and the conductor disc, repeatable, adjustable and controllable output torque and rotating speed can be realized, and the goal of speed regulation and energy saving is obtained.

Owner:王荣松

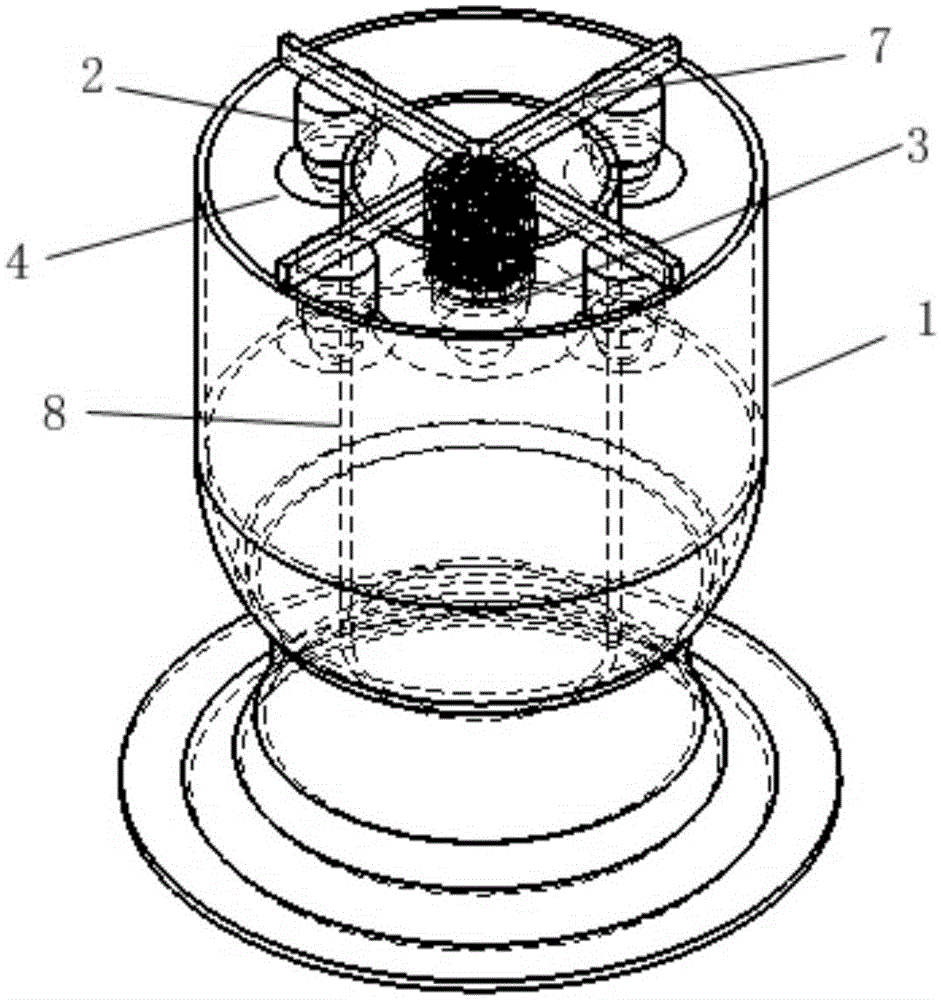

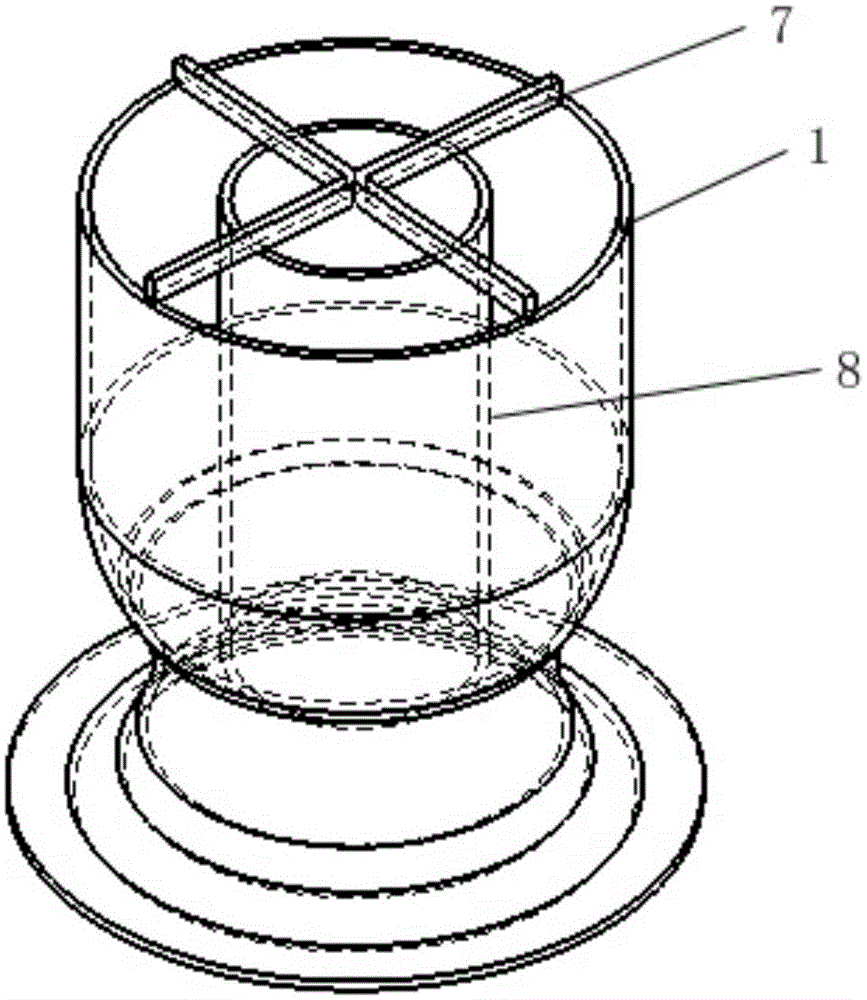

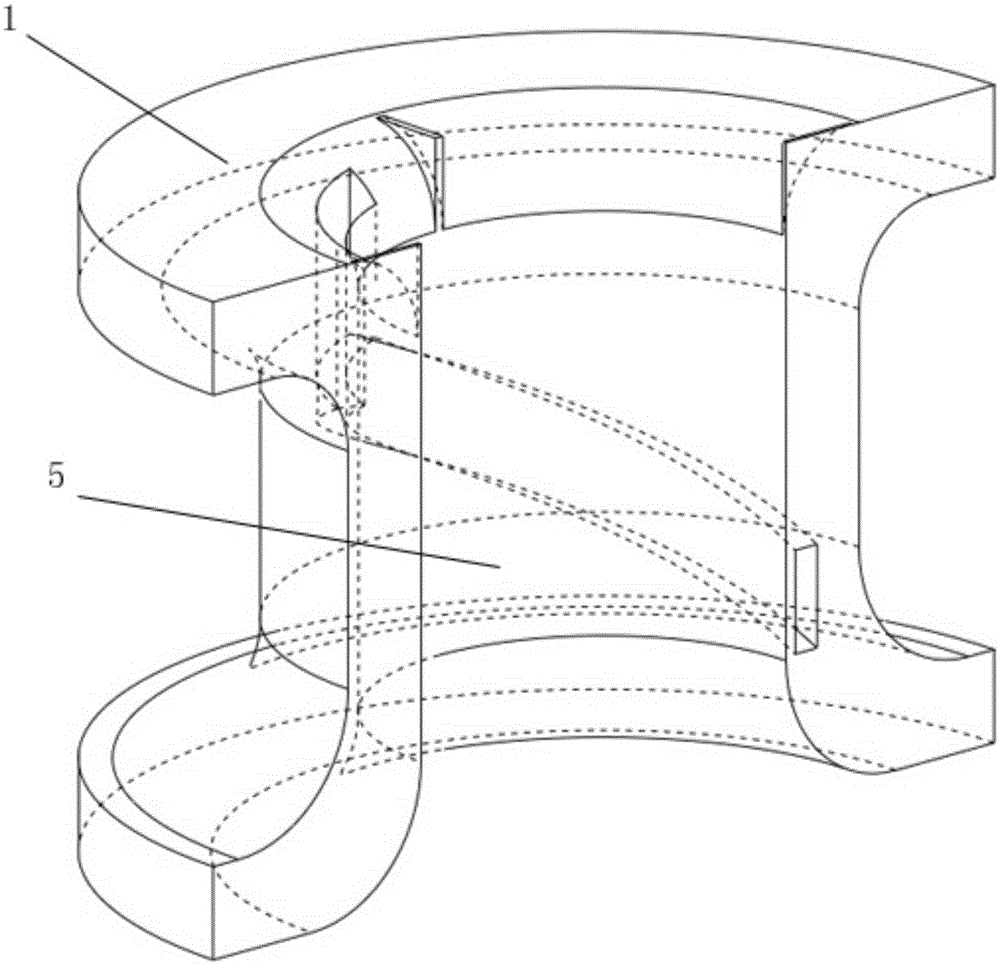

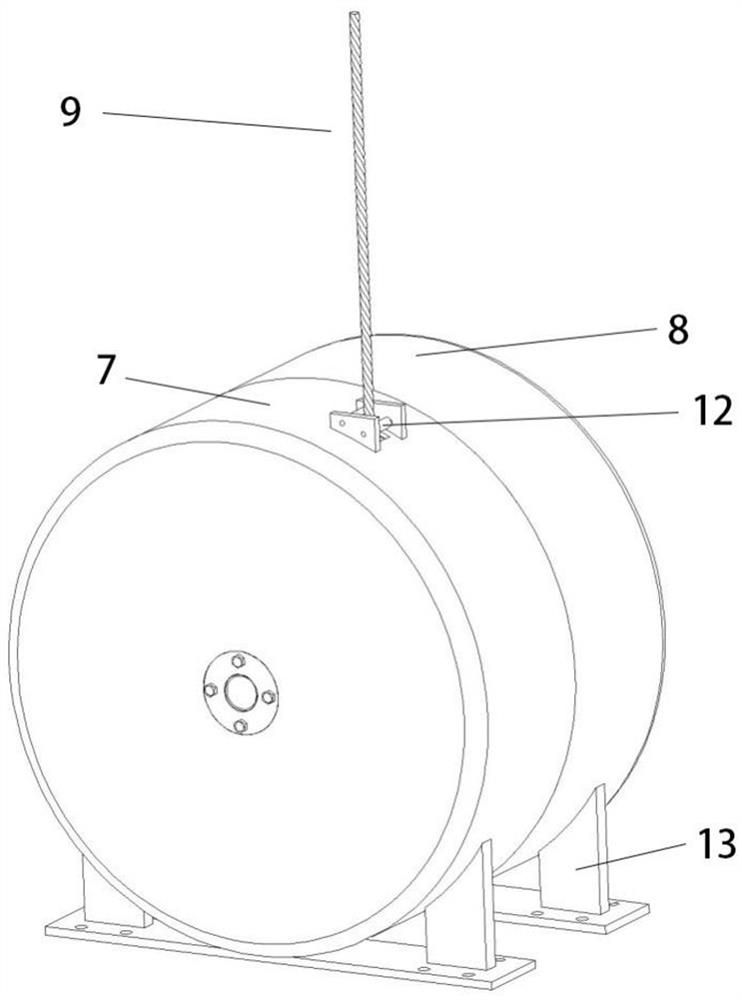

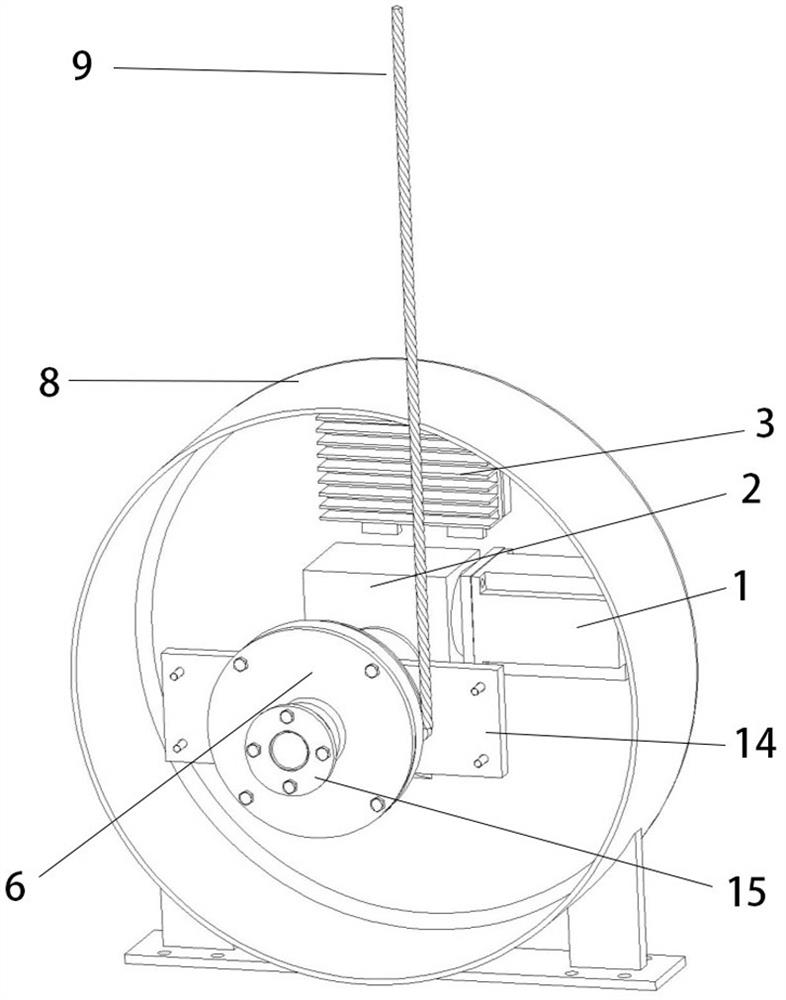

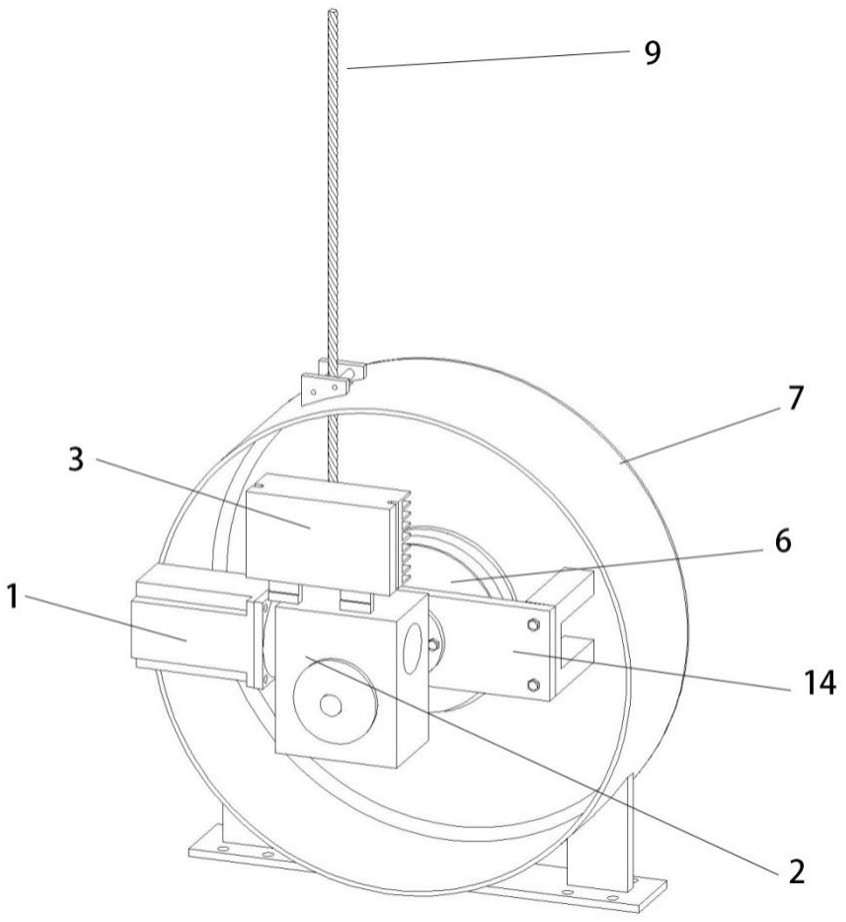

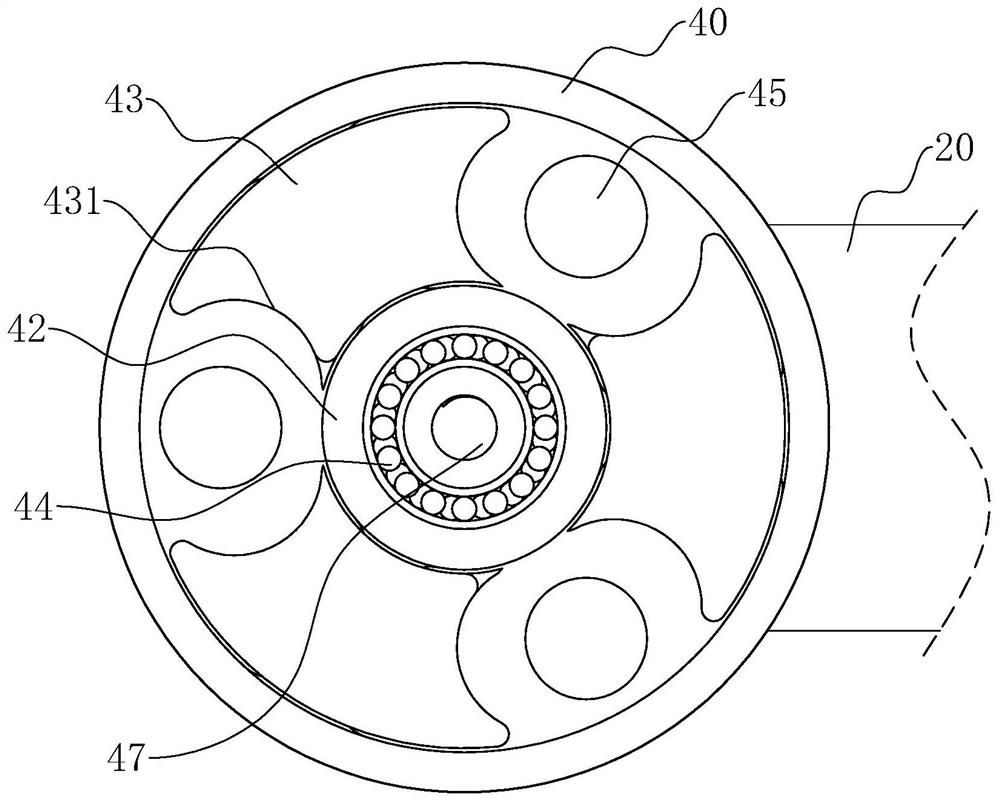

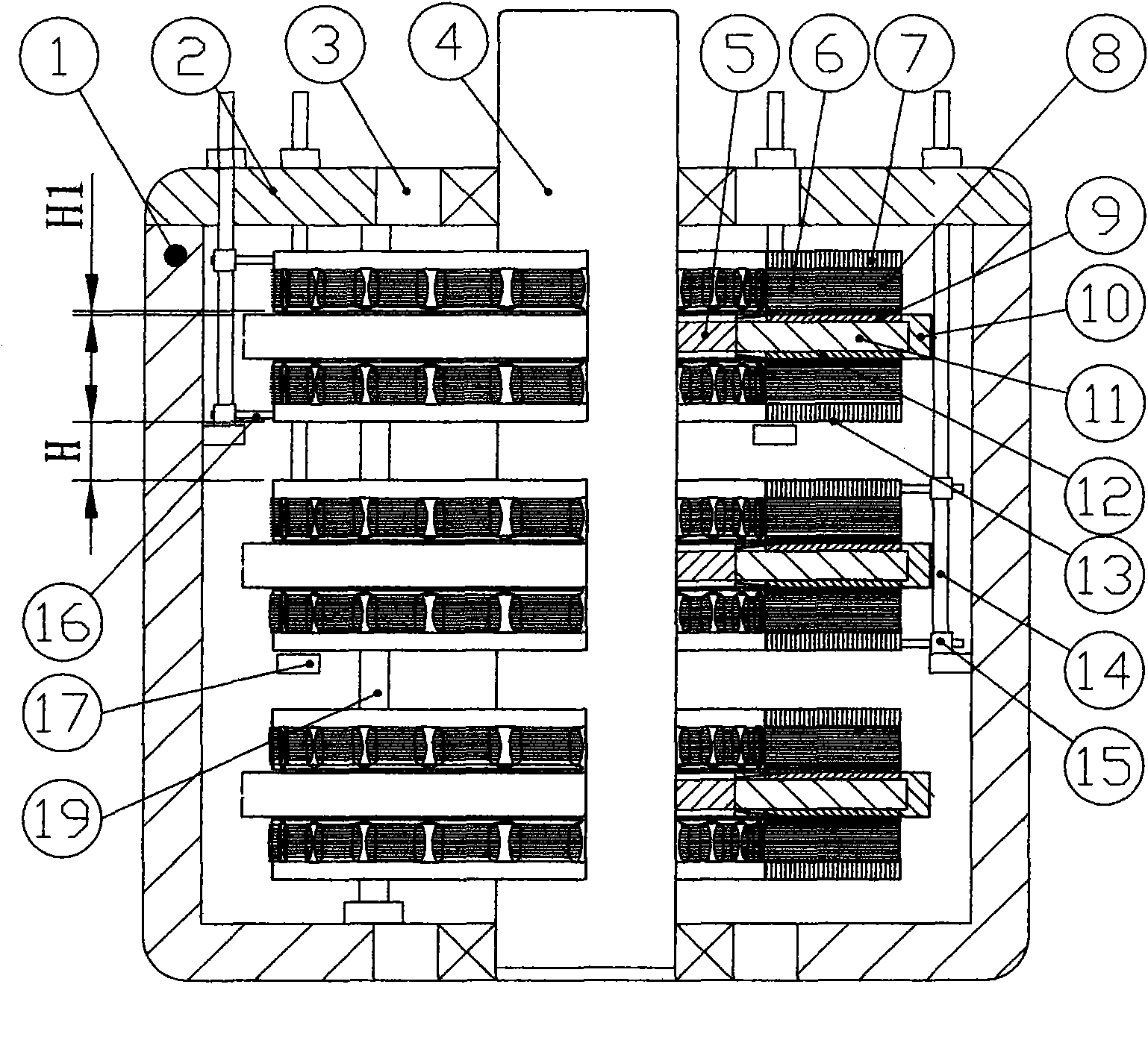

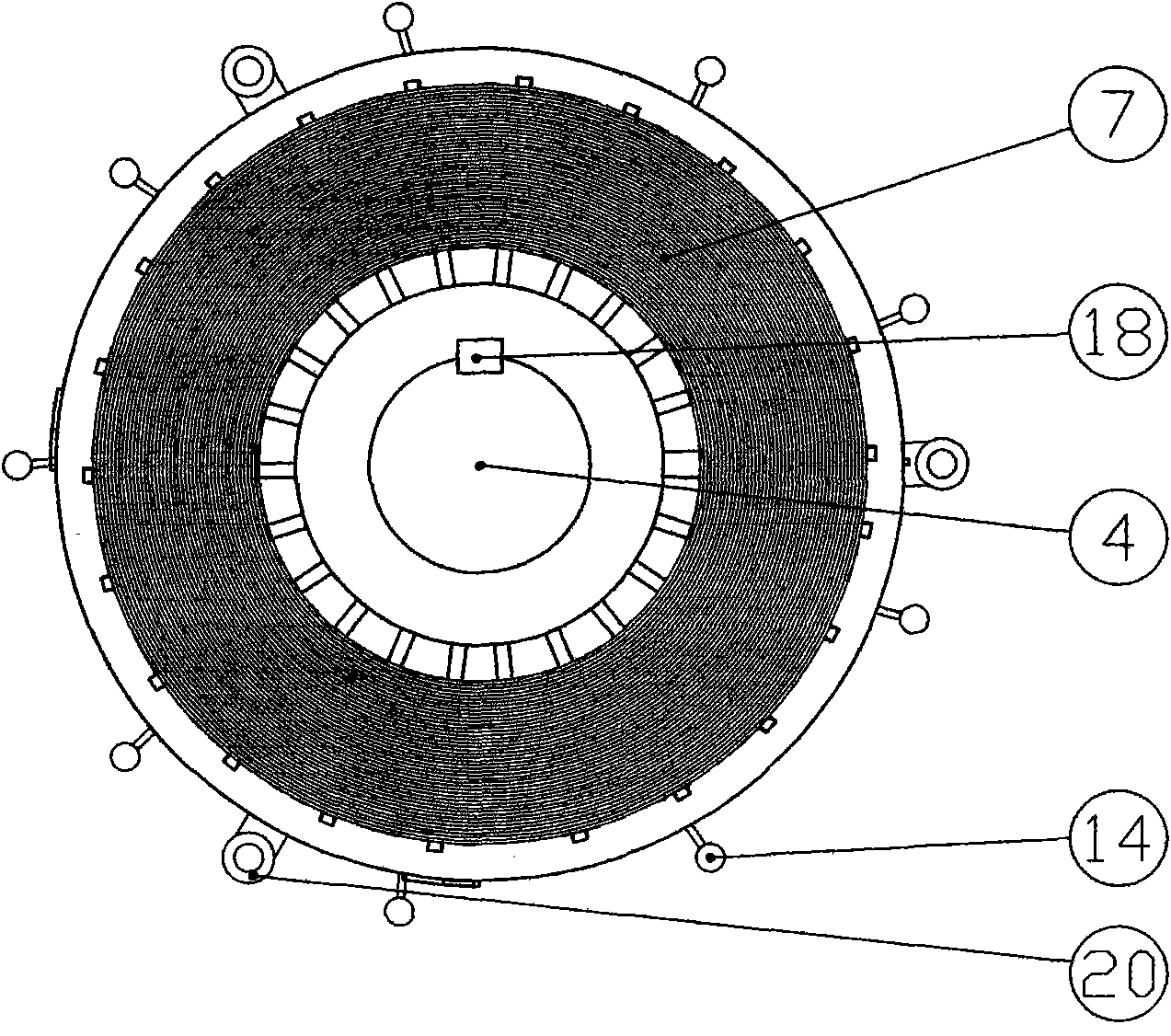

Cylindrical magnetic bracket-type permanent magnet governor

ActiveCN107612275AChange torqueChange speedAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesPermanent magnet rotorElectric machine

The invention discloses a cylindrical magnetic bracket-type permanent magnet governor, which comprises a cylindrical conductor rotor, a cylindrical permanent magnet rotor and a speed regulating device, wherein the cylindrical conductor rotor comprises an outer cylinder and an inner cylinder; the inner wall of the outer cylinder is connected with an outer conductor cylinder; the outer wall of the inner cylinder is connected with an inner conductor cylinder; the cylindrical permanent magnet rotor is provided with a magnetic bracket; a circle of magnetic holes are uniformly distributed in the outer wall of the magnetic bracket; a permanent magnet is arranged in each magnetic hole; an electromagnetic valve is arranged on a base of the cylindrical permanent magnet rotor; the base of the cylindrical permanent magnet rotor is hinged with the electromagnetic valve; the cylindrical permanent magnet rotor is connected with a driven shaft; the speed regulating device is connected with one end ofthe driven shaft and the other end of the driven shaft is connected with a baffle plate; and the cylindrical permanent magnet rotor slides between the baffle plate and the speed regulating device andis prevented from colliding with the conductor rotor, and the speed regulating range can be 0-98%, so that motor can be completely separated from load. The speed regulating device is connected with the electromagnetic valve through wireless communication, so that the driving force is not needed while non-contact transmission of power is achieved.

Owner:ANHUI WOLF POWER TECH

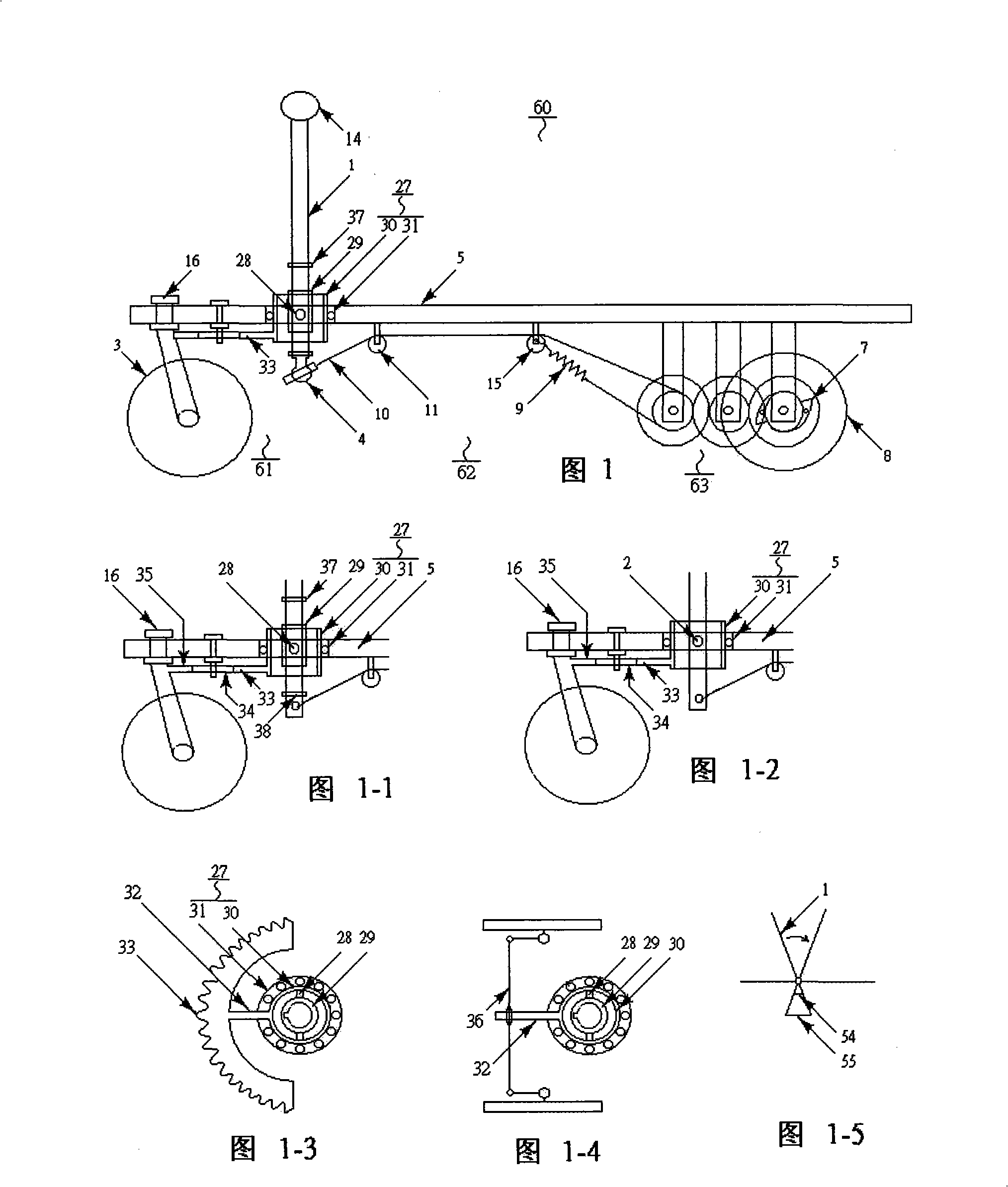

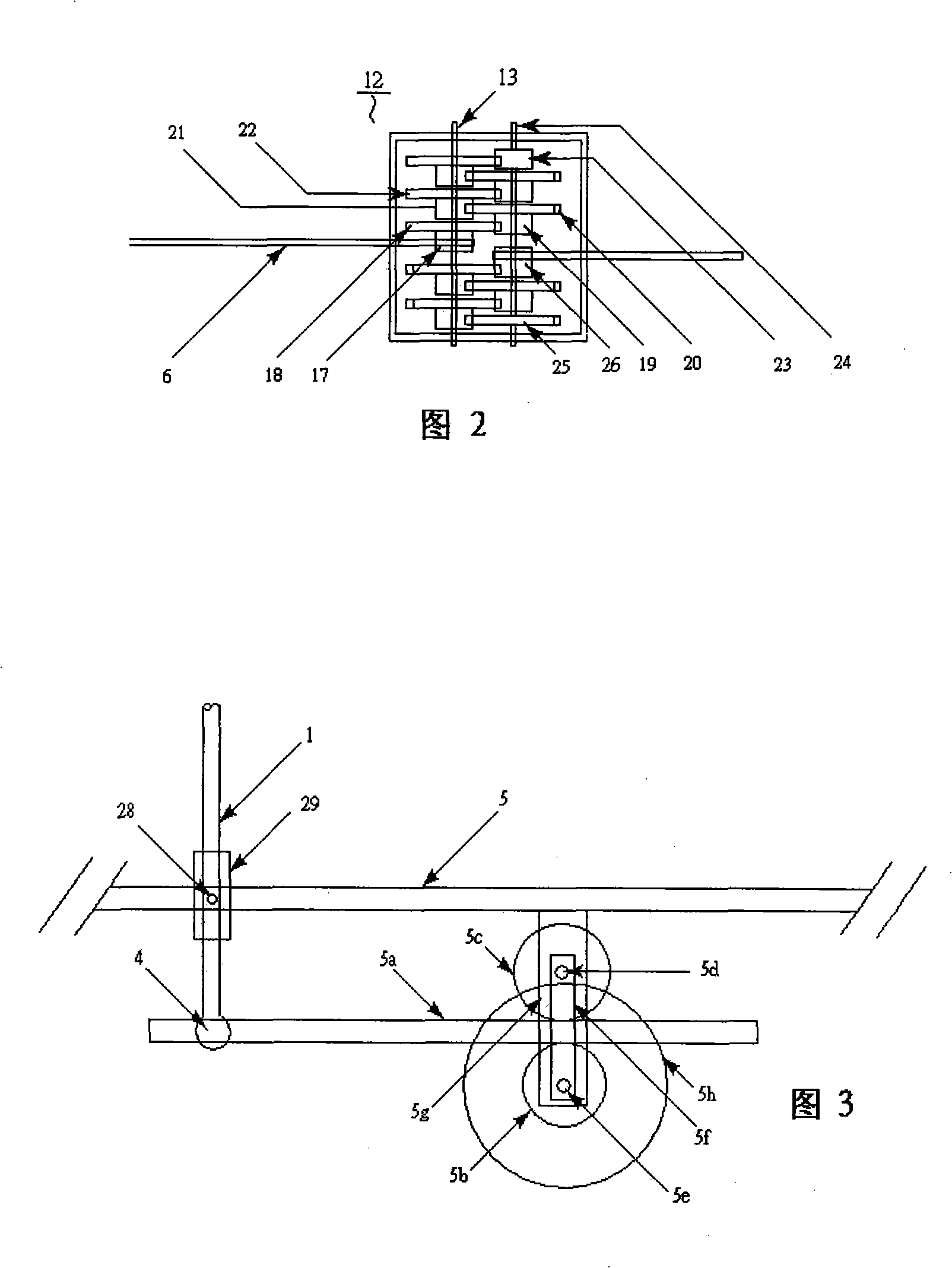

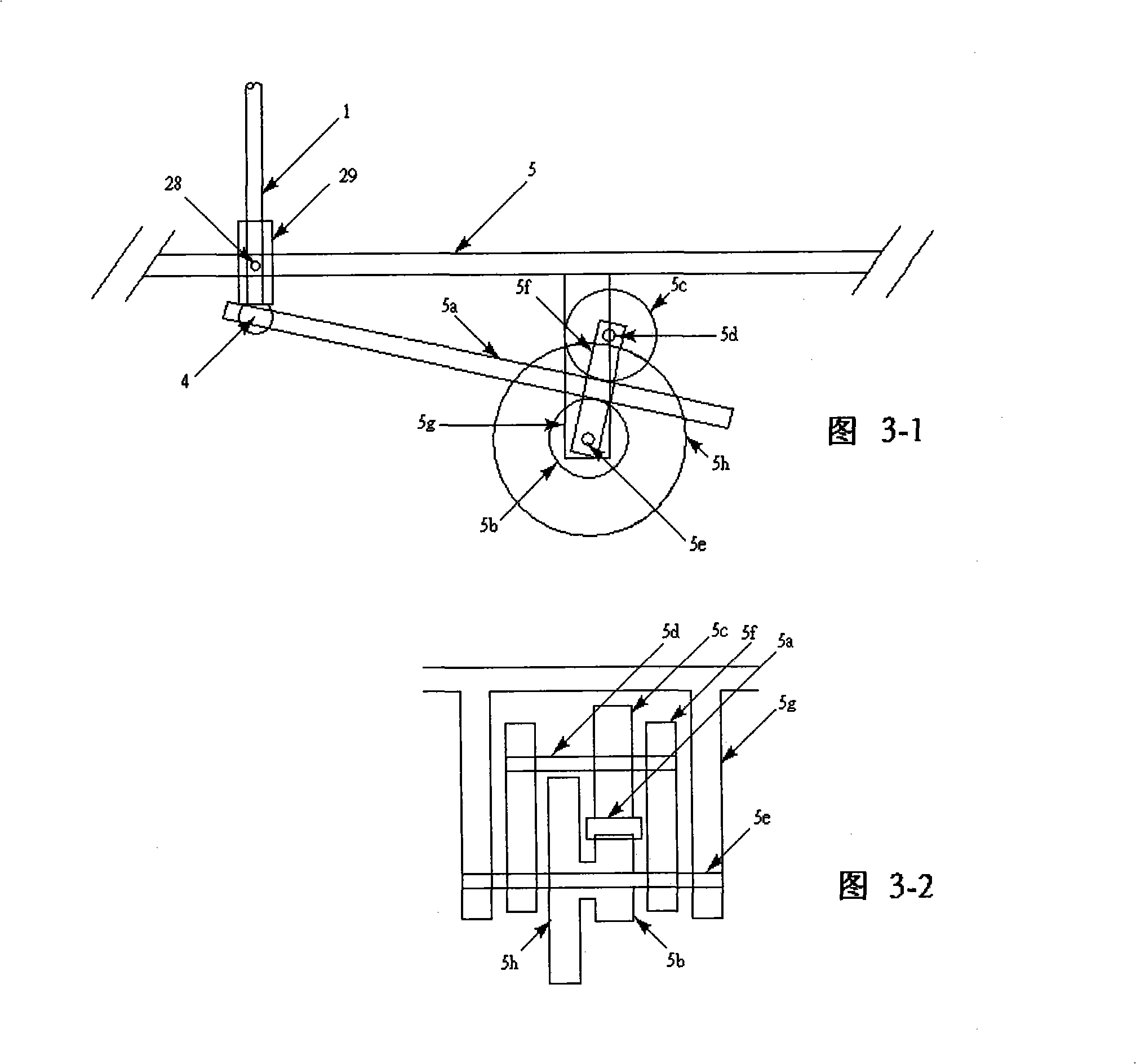

Rowing bicycle driven by push and pull

InactiveCN101244742AChange direction easilyGraceful movementCyclesWheel based transmissionPush and pullGear ratio

The invention relates to a rowing bicycle driven by push and pull includes a base panel, which aims to provide a transportation powered by hands instead of by feet. The rowing bicycle has a handlebar on top of a swing pole, with a center point which is supported by an inner ring of a bearing on a board; Using pulling or pushing action drives wheels move, at same time, the handlebar steers in the forward direction. The bottom of the swing pole drives an increasing gear ratio mechanism; and by positioning an idler gear to change speeds or by 2 chains. Furthermore using a rack and a passive gear makes this invention is able to use pushing or pulling or both actions to make vehicle move forward.

Owner:孙利庆

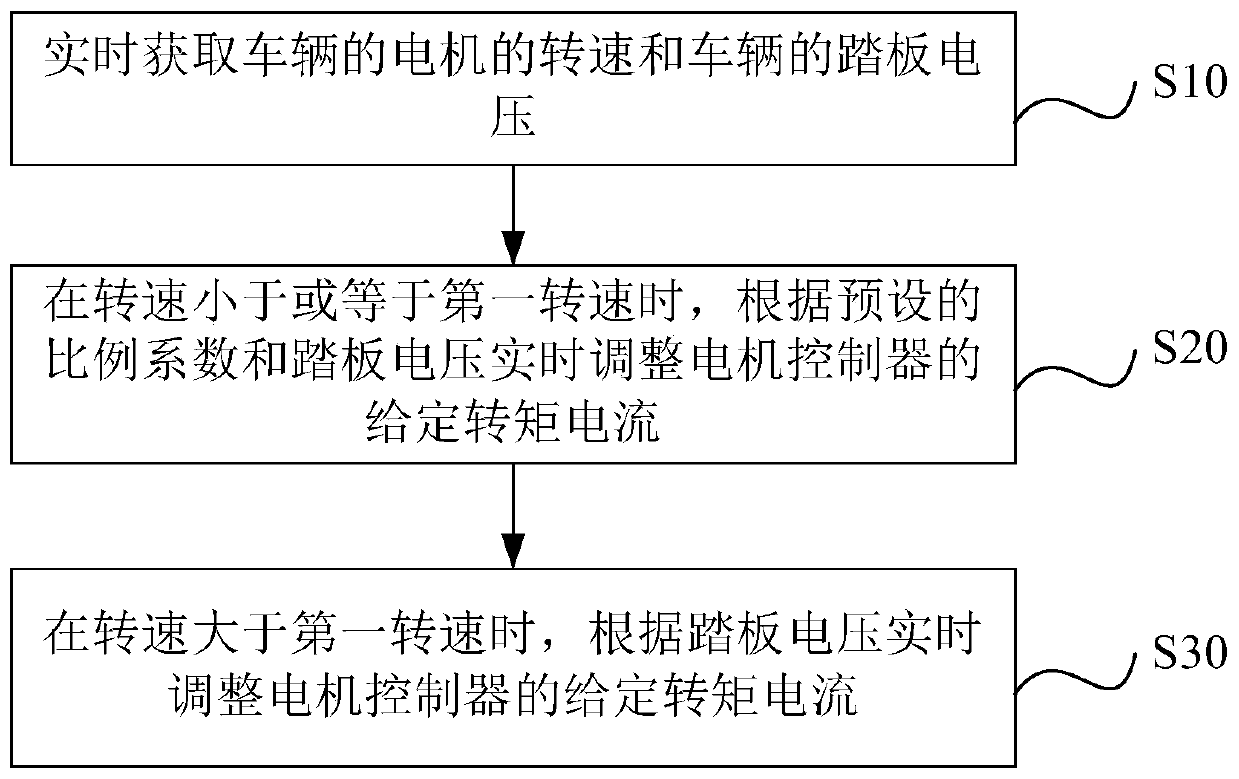

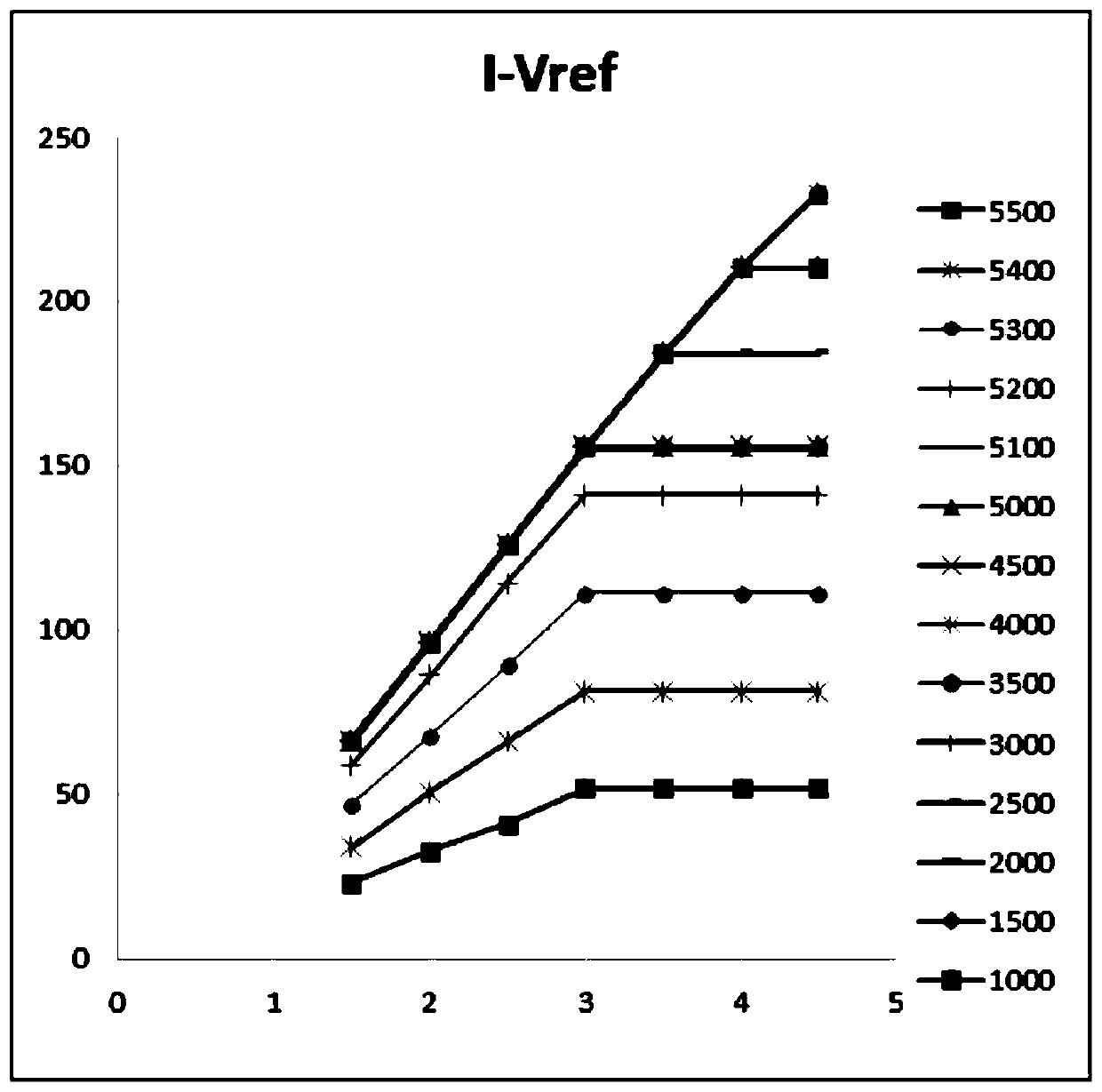

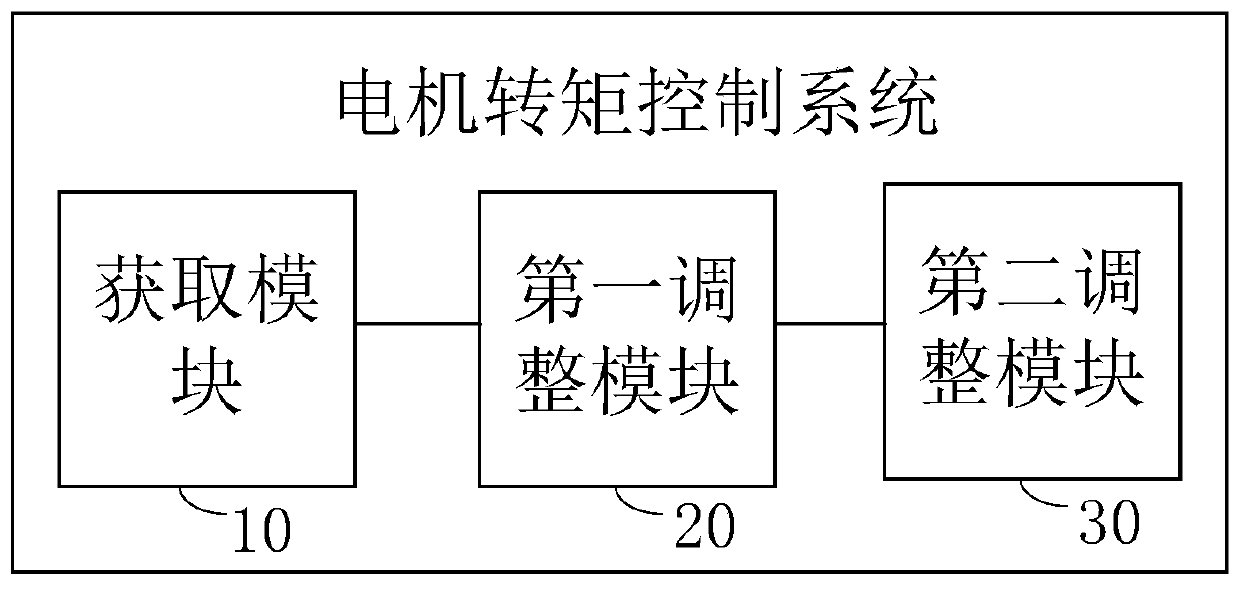

Motor torque control method, system and equipment and storage medium

ActiveCN110588365AChange torqueHigh sensitivitySpeed controllerElectric motor controlPower flowElectric machine

The embodiment of the invention discloses a motor torque control method, system and equipment and a storage medium. The motor torque control method comprises the steps of obtaining a rotation speed ofa motor of a vehicle and a pedal voltage of the vehicle in real time; when the rotation speed is less than or equal to a first rotation speed, adjusting a given torque current of a motor controller in real time according to a preset proportionality coefficient and the pedal voltage; and when the rotation speed is larger than the first rotation speed, adjusting the given torque current of the motor controller in real time according to the pedal voltage so as to improve the sensitivity of the torque control of the motor.

Owner:苏州云鹏控制科技有限公司

Underwater vector propeller for realizing flexible steering by utilizing coanda effect

ActiveCN105109649AFlexible propulsion controlImprove mobilityRotary propellersPropulsion power plantsSubmarineUnderwater robot

The invention relates to an underwater vector propeller for realizing flexible steering by utilizing coanda effect. The underwater vector propeller comprises a casing, a main propelling motor, vector motors, mainstream channels, a subsidiary stream channel, a main propeller stream channel and partition boards, wherein the main propelling motor is mounted in the main propeller stream channel; each of the vector motor is provided with a screw propeller; the connecting spaces of the casing and the main propeller stream channel through the partition boards are used as the mainstream channels; the subsidiary stream channel is a channel formed by the structure of the inner walls of the casing; the subsidiary stream channel is connected with the two symmetrical mainstream channels; the vector motors are respectively arranged in the mainstream channels; two ends of the casing are in an opening structure. The underwater vector propeller for realizing flexible steering by utilizing the coanda effect, disclosed by the invention, has the advantages that when ships, submarines, unmanned underwater robots and the like need to swerve, the vector propelling can be realized through changing the rotational speed of different vector motors, so that the flexible underwater propelling control can be realized.

Owner:OUBO INTELLIGENT TECH SHANGHAI CO LTD

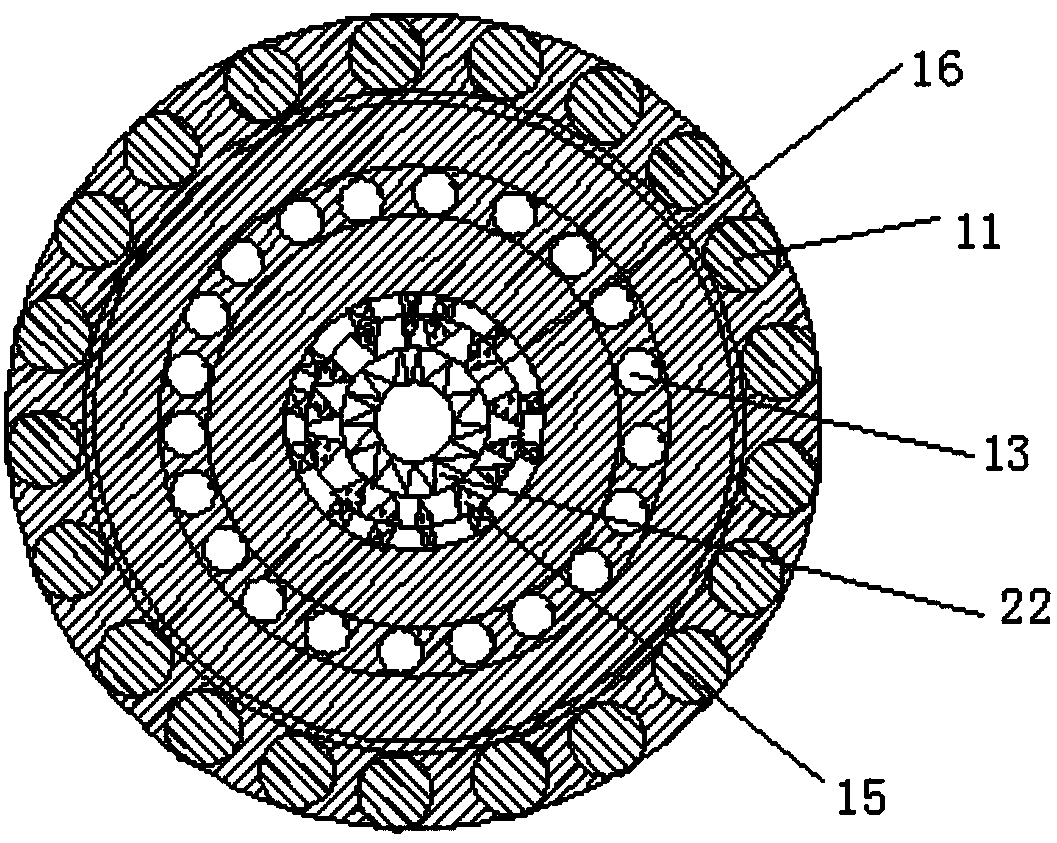

Permanent magnet speed controller

ActiveCN104158381AAchieve complete no-load startRealize the purpose of speed regulation and energy savingDynamo-electric gearsElectrical conductorMagnetic poles

Disclosed is a cylindrical permanent magnet speed controller, comprising a first shaft and second shaft which are separate and coaxial. The first shaft is sleeved with an annular permanent magnet rotating disc. The second shaft is sleeved with an annular shaft sleeve. The shaft sleeve is sleeved with a cylindrical inner circular sleeve. The inner circular sleeve is sleeved with an annular conductor rotating disc. The cylindrical permanent magnet speed controller is characterized in that the outer edge of the permanent magnet rotating disc is fixedly connected with two coaxial cylindrical projections which are an outer cylinder remote from the first shaft and an inner cylinder adjacent to the first shaft, a gap is left between the outer cylinder and the inner cylinder, and an outer conductor cylinder and an inner conductor cylinder are respectively fixed on the inner surface of the outer conductor cylinder and the outer surface of the inner conductor cylinder; and the outer edge of the conductor rotating disc is fixedly connected with a cylindrical magnet carrier of non-magnetic material, a plurality of permanent magnets are installed in a surrounding manner on the circumferential surface of the magnet carrier, the magnetic pole direction of each permanent magnet is perpendicular to the permanent magnet rotating disc, the adjacent permanent magnets are subjected to heterpolar installation, and the magnet carrier extends between the inner conductor cylinder and the outer conductor cylinder.

Owner:QINGDAO SPRING ENERGY TECH

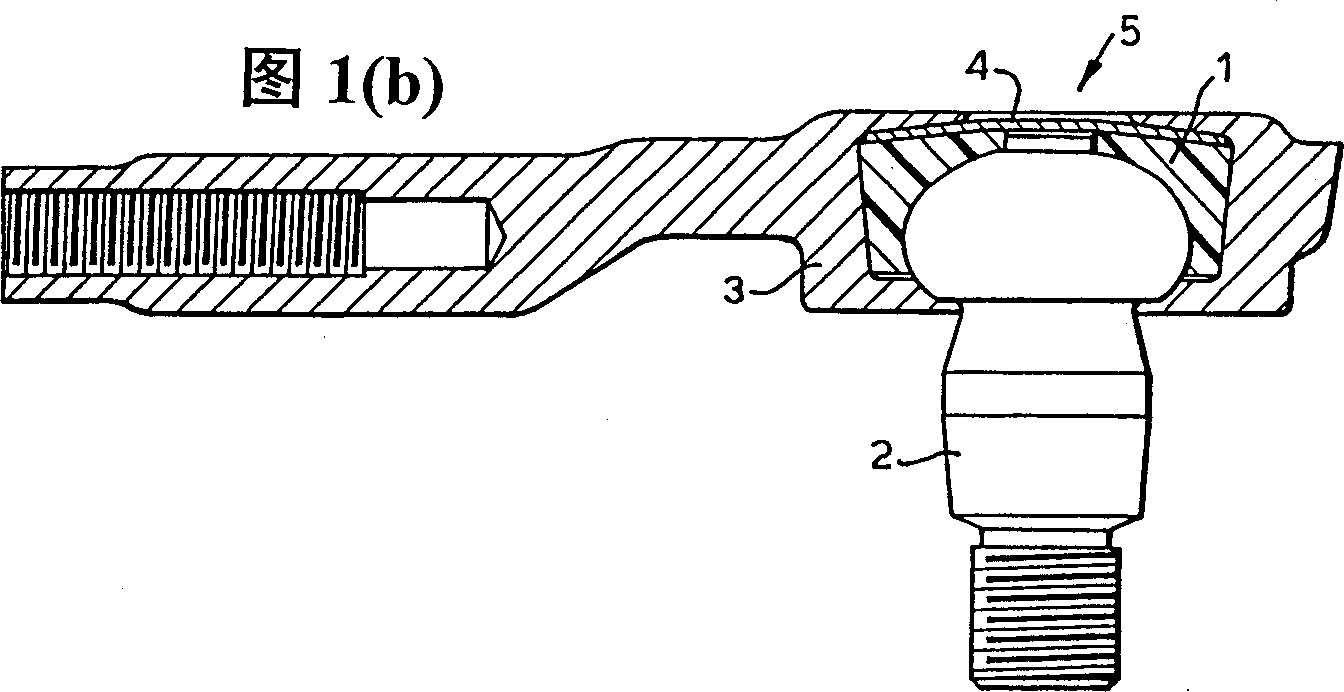

Lubricant composition and his use in a ball joint

InactiveCN1340092AIncreased durabilityReduce torqueAdditivesBase-materialsParaffin waxMicrocrystalline wax

Lubricant composition comprising: (A) 100 parts by weight of a viscous material having a viscosity from 3x103 to 105 mN.s / m2 (cP) at 25 ~C, which i s at least one member chosen from the group consisting of (i) polyisoprene rubber and (ii) viscous composition comprising polyisoprene rubber viscous substance; and (B) 15-45 parts by weight of at least one compound from a specific group of aliphatic amides and a specific group of aliphatic bisamid es and (C) 5-30 parts by weight of at least one wax chosen from the group of polyethylene wax, paraffin wax and microcrystalline wax; and ball joint comprising such lubricant composition, and use of such lubricant composition in a ball joint.

Owner:SHELL INT RES MAATSCHAPPIJ BV

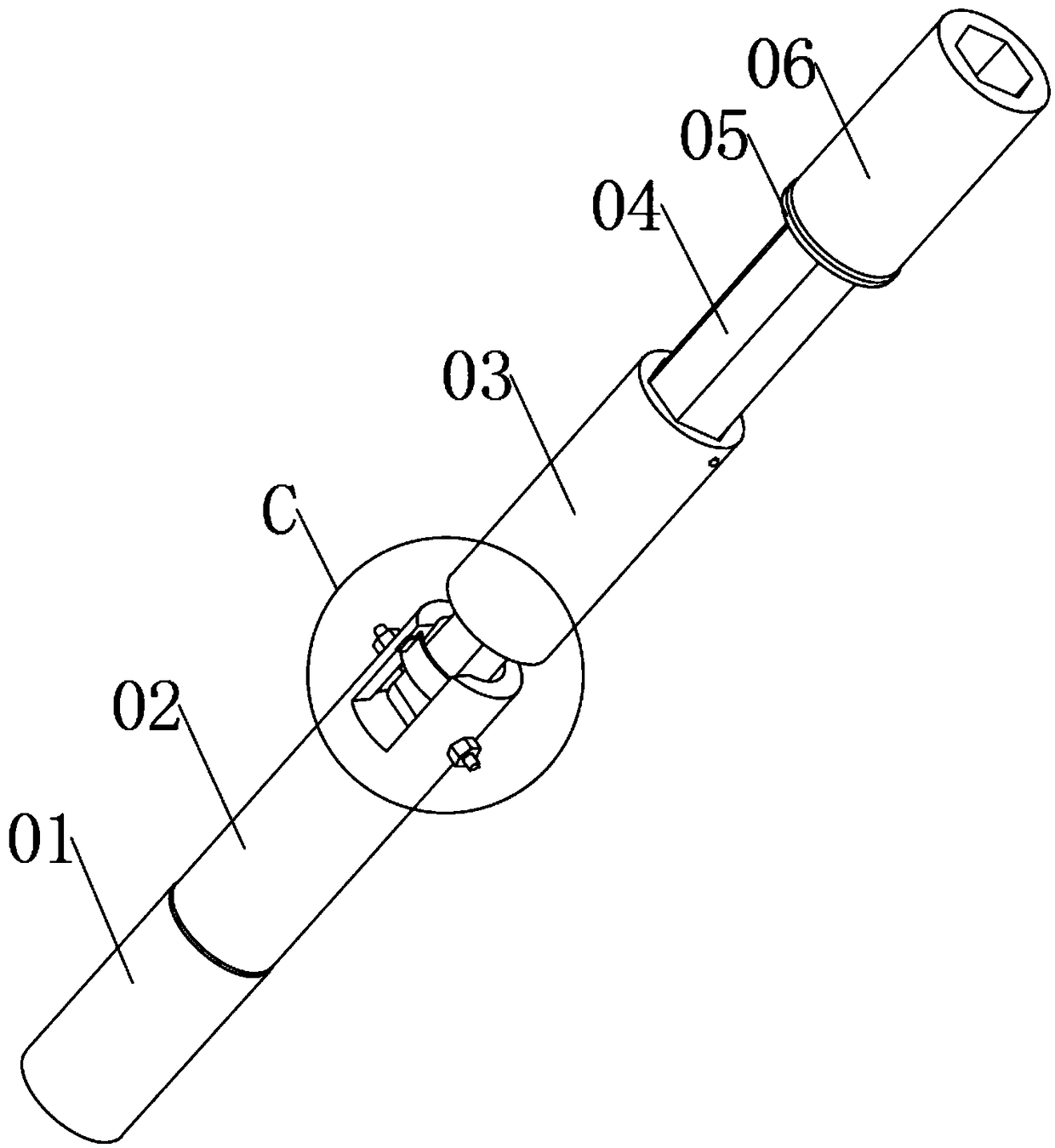

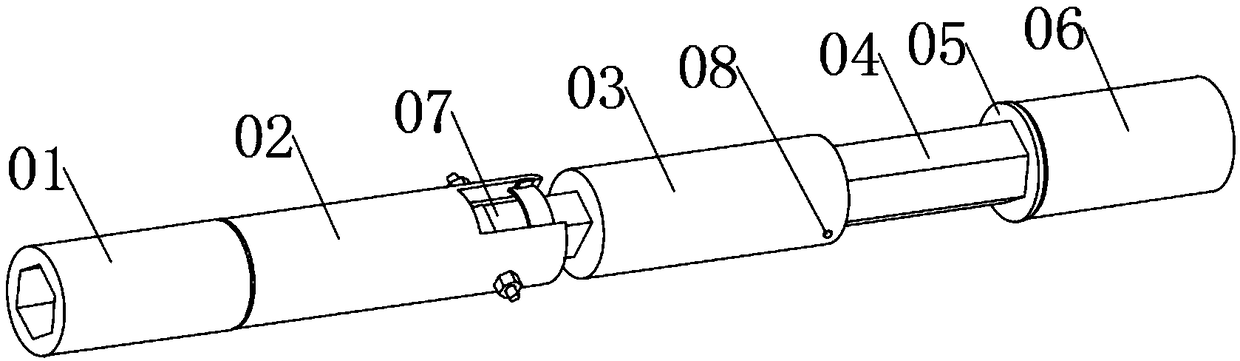

Easy-to-use connection sleeve

The invention discloses an easy-to-use connection sleeve, and relates to the technical field of sleeves. The easy-to-use connection sleeve comprises a sleeve wrench, a wrench fixing rod, a telescopingrotation cylinder, a telescoping rotation rod and a sleeve connecting cylinder which are arranged from bottom to top in sequence. A sleeve connector which is fixedly welded to the lower surface of the wrench fixing rod is sleeved with the sleeve wrench, the lower end of the telescoping rotation rod is movably sleeved with an inner cavity of the telescoping rotation sleeve, the telescoping rotation rod is of a hexagonal prism structure, the shape of the inner cavity in the telescoping rotation cylinder is matched with that of the telescoping rotation rod, and the lower end of the telescoping rotation rod and the upper end of the telescoping rotation cylinder are fixed with a pin. By means of the easy-to-use connection sleeve, the aim that the connection sleeve for removing a nut or a boltis changed into a vertical form or an L-shaped form is achieved, and the shape of the connection sleeve can be changed according to actual demands in use; when the connection sleeve is in an L shape,the torque can be changed, and when the nut or the bolt is removed, labor is saved.

Owner:NINGBO SNAICY METAL PROD CO LTD

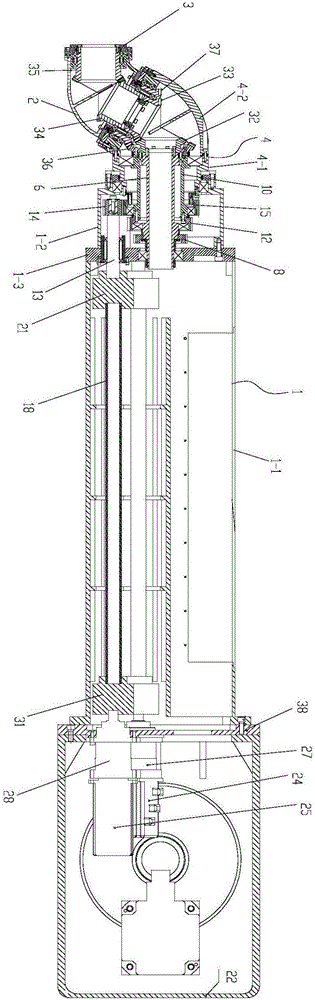

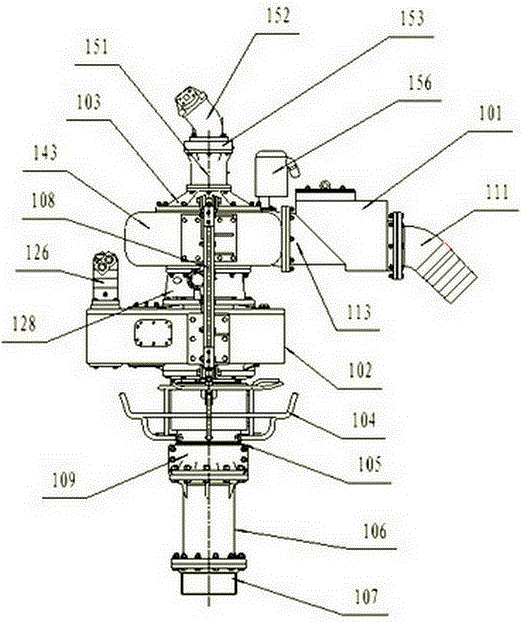

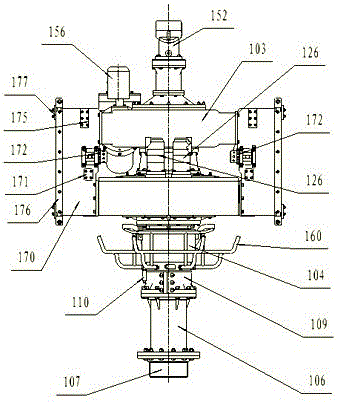

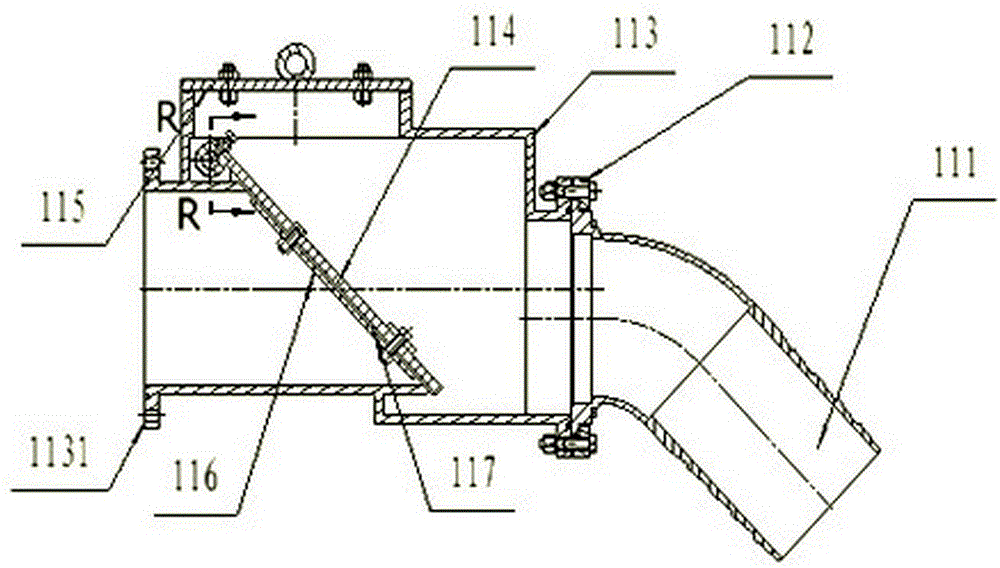

Power assembly of full-hydraulic reverse circulation drilling machine

The invention provides a power assembly of a full-hydraulic reverse circulation drilling machine. The power assembly comprises a residue discharge chamber, a reduction gearbox assembly, a mud pump assembly, a rotary connector subassembly, a shaft spacer, a spindle connecting rod, a main fastener, an assembly connecting plate subassembly, a spindle driving clamp slip and a stop pin subassembly. The power assembly has the advantages that two hydraulic motors are serially connected with each other or are connected with each other in parallel, so that two different rotational speeds can be implemented by a reduction gearbox, and the power assembly is adaptive to operation under different geological and aperture conditions; torque of drilling pipes can be changed along with change of the geological conditions of operation, and accordingly energy can be saved; a hydraulic system can be regulated, so that overload protection effects can be realized for drilling machine operation; the vacuumizing time can be shortened owing to sealing structures of the reduction gearbox and mud pumps; the hydraulic motors can be controlled by the hydraulic system and can drive the reduction gearbox with gears to directly drive drilling tools to rotate; flow of hydraulic pumps can be regulated, so that the rotational speeds and the lifting speeds of the drilling pipes and flow parameters of the mud pumps can be regulated; the power assembly is provided with rotary connector mechanisms, so that hole drilling operation can be implemented by impact drill bits or drill bits with rotor wings, and hole drilling operation on the scales larger than 200 meters can be implemented.

Owner:王乐康

Interval constant-force device capable of realizing stepless adjustment

InactiveCN112594347AModerate pullPulling force remains constantGearingChiropractic devicesPull forceReduction drive

An interval constant-force device capable of realizing stepless adjustment comprises a rope used for transmitting tension, a spring barrel, a spring shaft, a spring and an adjusting mechanism; the center end of the spring is connected to the spring shaft; the outer end of the spring is connected to the inner wall of the spring barrel; a cam is fixedly connected to one side of the spring barrel; one end of the rope is fixedly connected to the cam and is connected with an external stress mechanism after bypassing the cambered surface of the cam; the tightening degree of the spring is increased when the rope pulls the cam and the spring barrel to rotate around the spring shaft, and meanwhile, the corresponding radius vector on the cam is increased, so that the tension transmitted by the ropeis kept constant; the adjusting mechanism comprises a motor, a motor driver and a worm gear and worm reducer; the output end of the motor is connected with the input end of the worm gear and worm reducer; and the output end of the worm gear and worm reducer is connected with the spring shaft through a connecting assembly. According to the device, stepless adjustment of the tension on the cervicalvertebra of a patient can be realized, and the tension most suitable for the neck of the patient can be found.

Owner:LUOYANG INST OF SCI & TECH +1

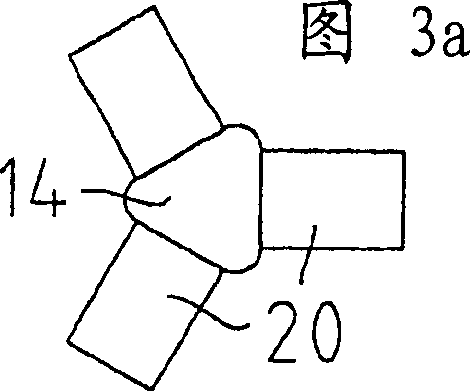

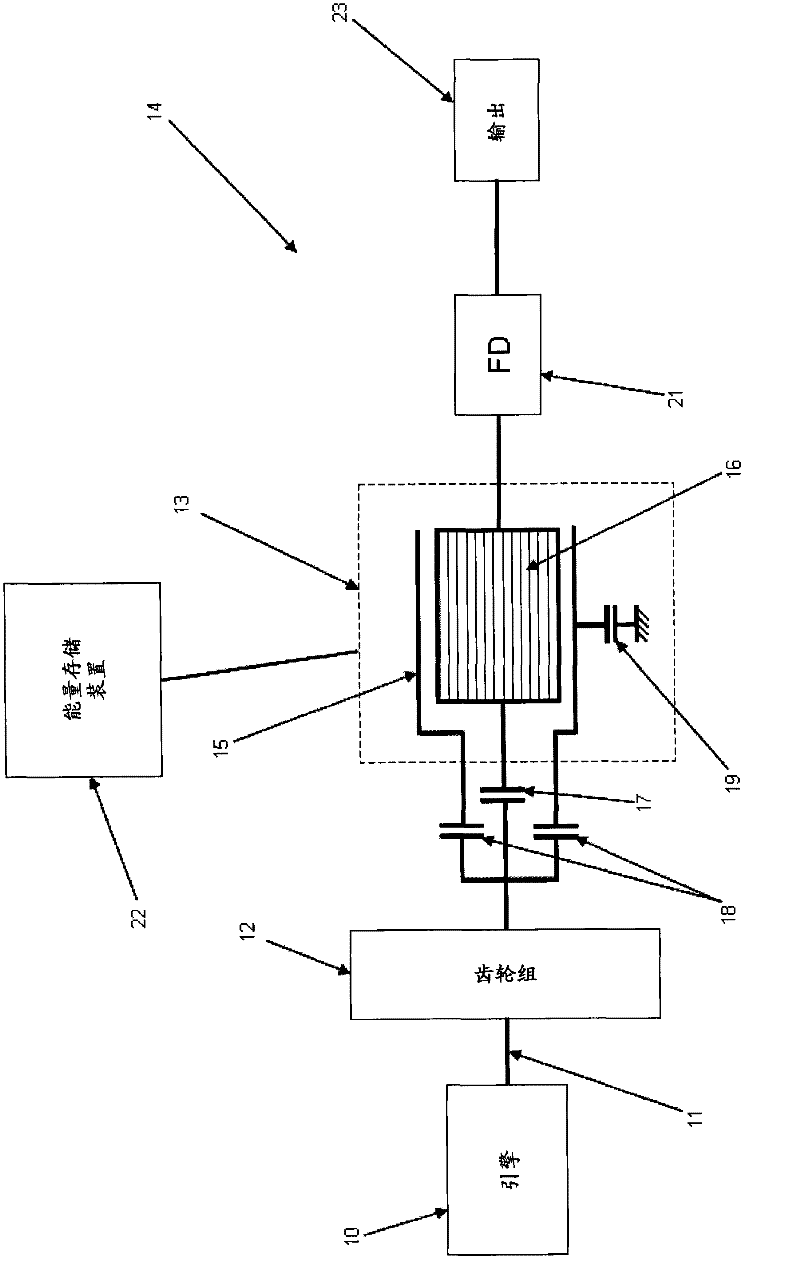

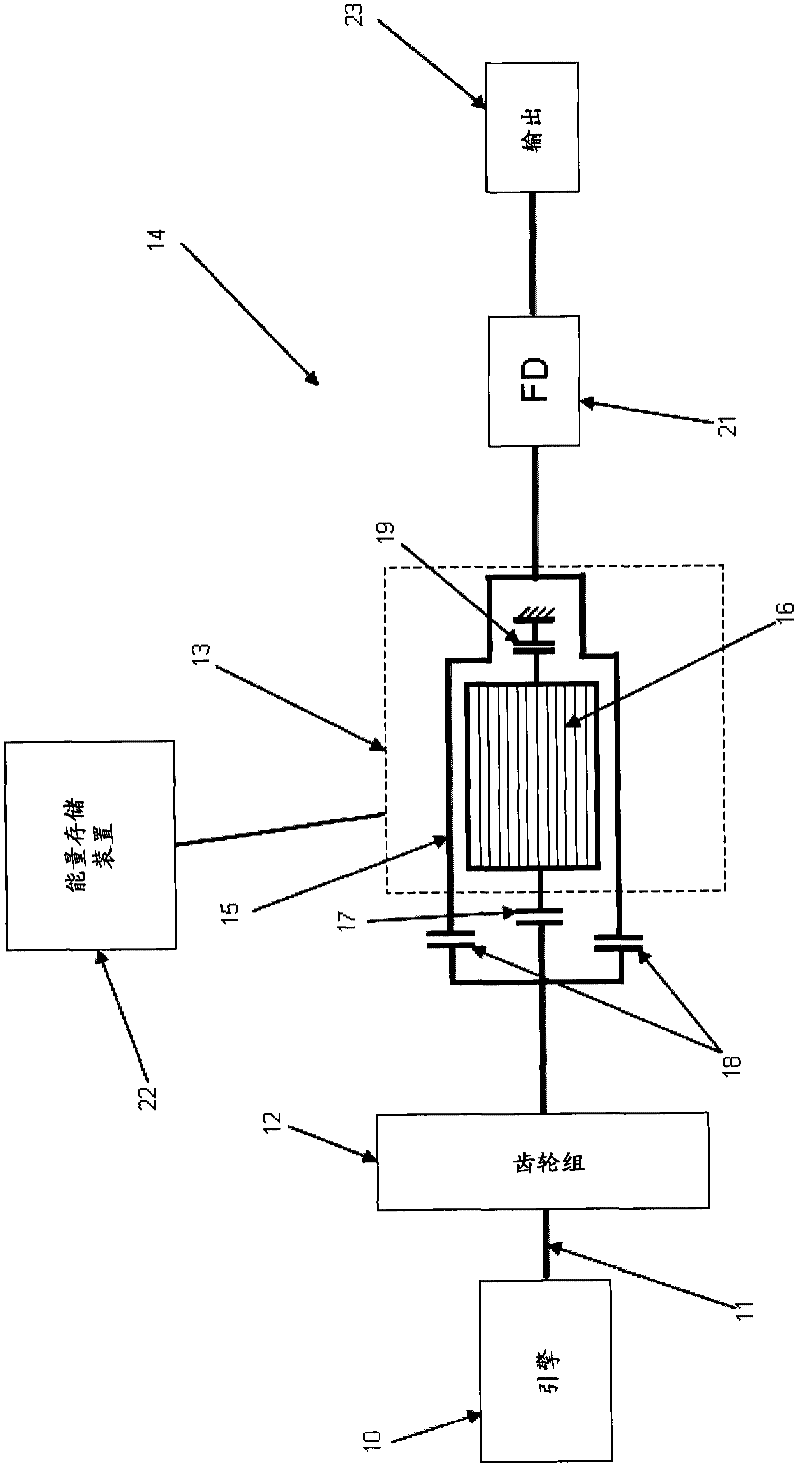

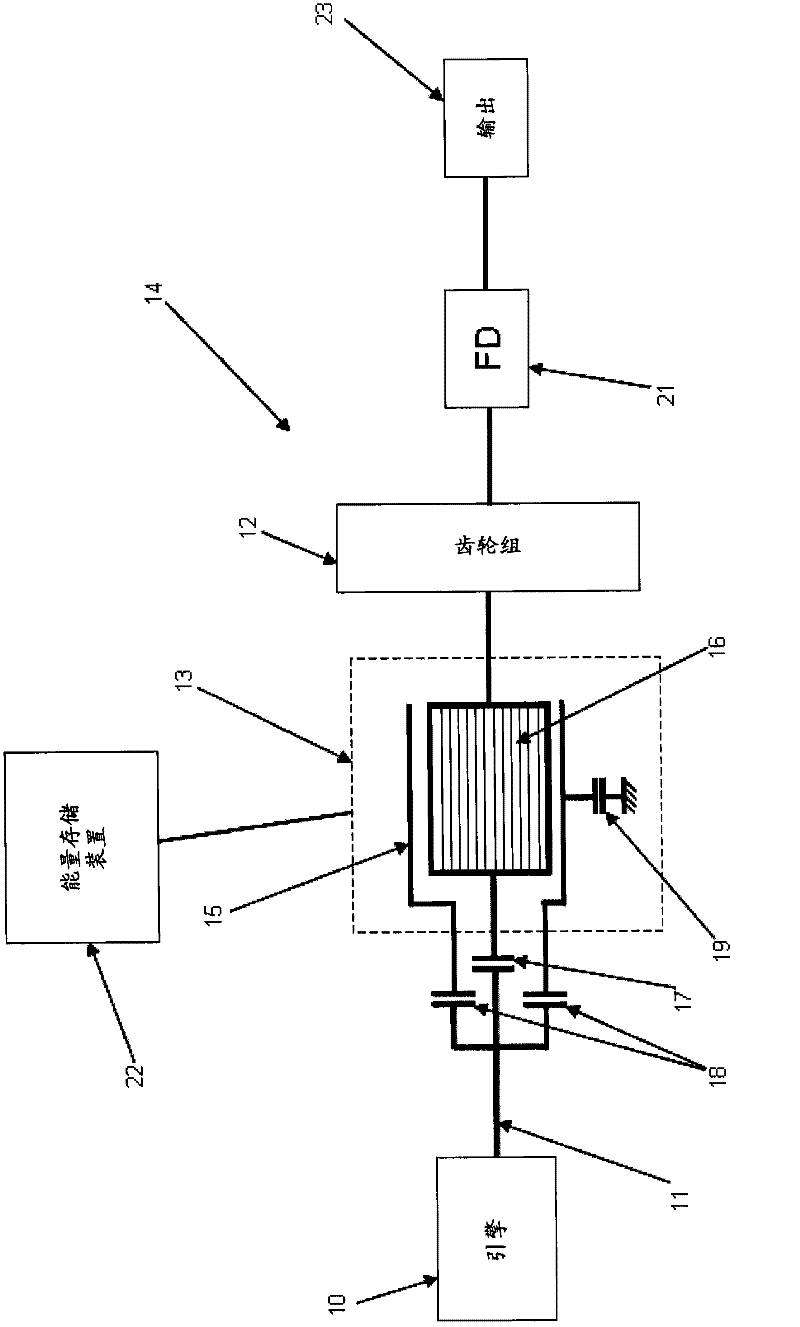

Hybrid power train

ActiveCN102398506AChange speedChange torqueGas pressure propulsion mountingElectric machinesElectric machineCoupling

A hybrid power train 14 including an electrical rotating machine 13 in the form of a rotatable stator electric machine having first 15 and second 16 rotatable members and an energy storage device 22 is described. First, second and third 17, 18, 19 mechanical coupling devices or clutches are capable of being selected to reversibly connect the first rotatable member 15 to the output of the engine, the second rotatable member 16 to the output of the engine and to connect one of the rotatable members to a ground point respectively. The hybrid power train operates in a mode according to which of the clutches are selected to connect. By changing between modes the efficiency of the source of rotational energy and the rotatable stator machine can be optimised based on the current required performance of the vehicle producing an overall efficiency gain across a wide range of driving conditions. Optionally, a planetary gear set is included.

Owner:ROMAX TECH

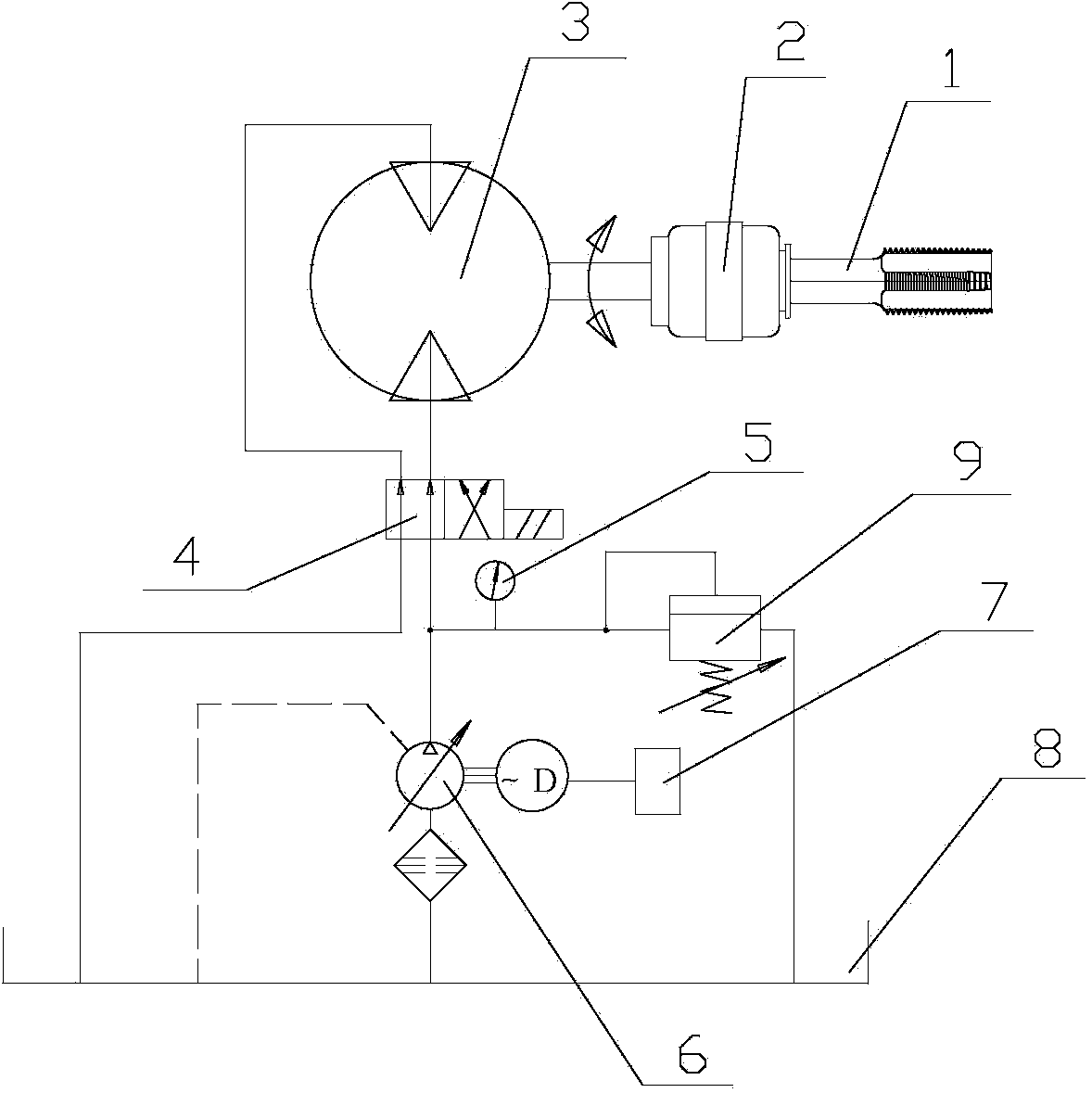

Independent-variable hydraulic tapping machine

The invention provides an independent-variable hydraulic tapping machine, relates to the technical field of tapping equipment and solves the problems that workpieces are not qualified according to requirements caused by the fact that a no-go fixed gauge is usually not fixed when an existing tapping machine meets screw tap accumulated crumbs or when the workpieces are hard in materials. The independent-variable hydraulic tapping machine comprises a tapping mechanism. The tapping mechanism comprises a hydraulic motor, a screw tap sleeve and a screw tap, and an output spindle of the hydraulic motor is connected with the screw tap sleeve which is connected with the screw tap through a tap chuck; a hydraulic circuit of the hydraulic motor is connected with an oil tank, a pressure control valve and a reversing valve are arranged on the hydraulic circuit, and both the pressure control valve and the reversing valve are connected with the oil tank; the reversing valve is further connected with a variable pump power unit which is connected with a control switch. The problem that when the torque of the independent-variable hydraulic tapping machine increases rapidly in case that the screw tap meets the accumulated crumbs during tapping and machining is solved by automatically slowing down the tapping speed through an independent-variable control system and correspondingly increasing the torque outputted in tapping.

Owner:QINGDAO XINKECHENG MACHINE TOOL

Bench press training instrument

PendingCN111840927AGood thrustImprove training effectResilient force resistorsWeightsPhysical medicine and rehabilitationBench pressing

Owner:北京冠之路科技集团有限公司

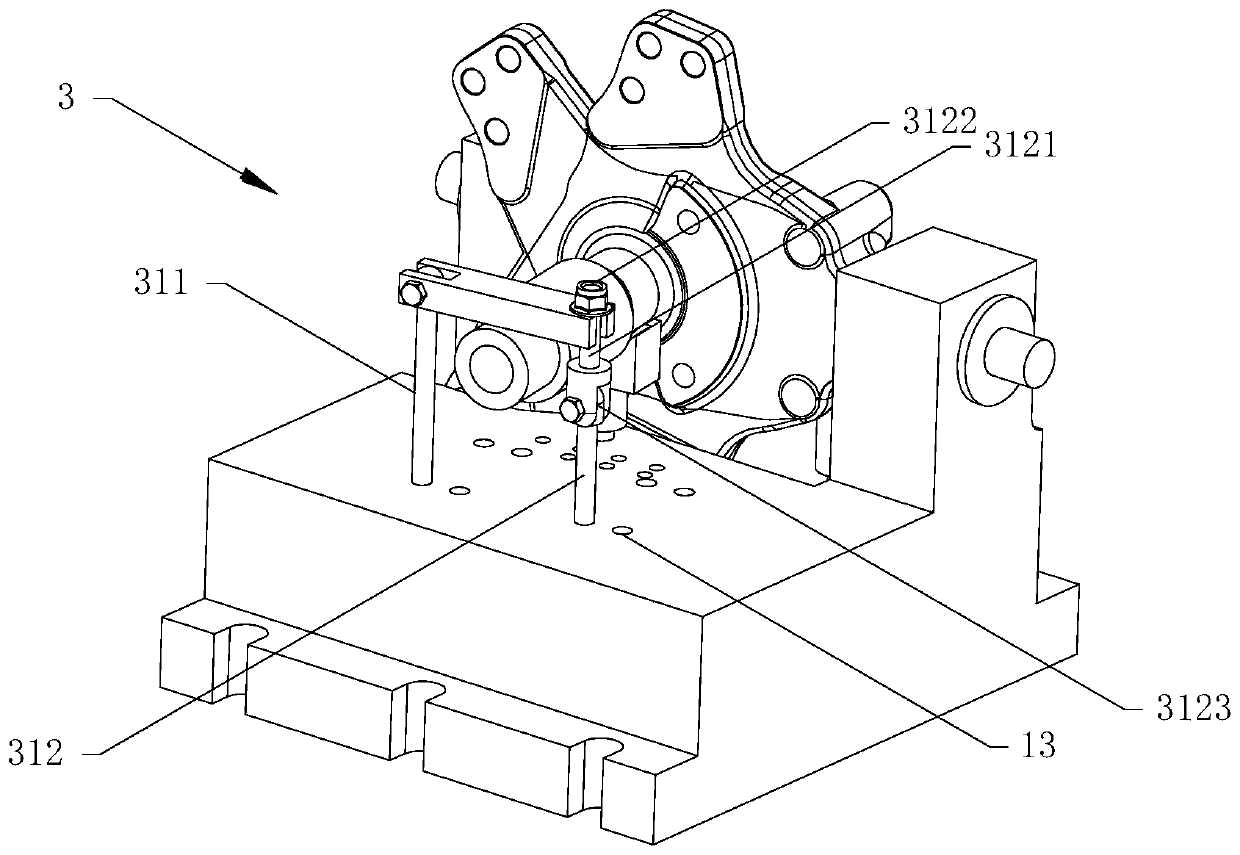

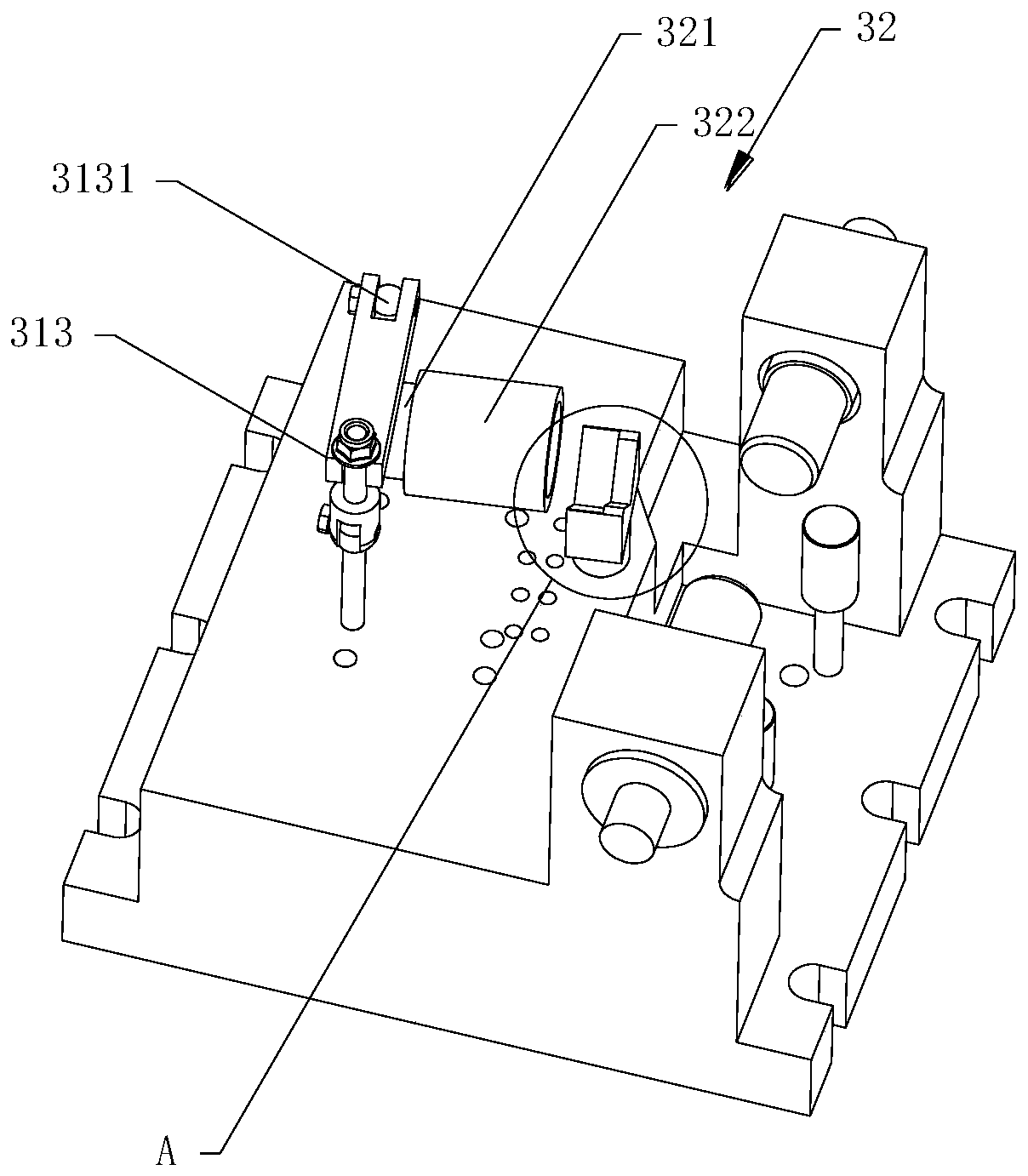

Finish-milling clamp for automobile steering knuckles and application method

InactiveCN110722198AChange torqueShorten the timeMilling equipment detailsPositioning apparatusEngineeringStructural engineering

The invention relates to the technical field of fine processing for steering knuckles and discloses a finish-milling clamp for automobile steering knuckles and an application method. The finish-milling clamp for the automobile steering knuckles is characterized by comprising a base, a fastening device and a compression device, the fastening device is arranged at one side of the base, and the compression device is arranged at the other side of the base; the fastening device comprises positioning piles arranged at the two sides of the base, the positioning piles are provided with positioning holes, and core shafts are arranged in the positioning holes and used for being connected with the positioning piles and the steering knuckles; the compression device comprises a compression plate, a sleeve arranged below the compression plate and a V-shaped top body close to the fastening device. By using a rotatable positioning device, the finish-milling clamp is self-adaptive to the angle of a workpiece, the flexibility of the clamp is improved, multiple products share one clamp, the replacement and assembly frequency is reduced, by further using a cushion block with a step, the fulcrum of theworkpiece is forward transferred, with assistance of the sleeve, the force arm is lengthened, the pressing force is increased, vibration of the workpiece is reduced, and the product precision is improved.

Owner:HUBEI TRI RING FORGING

Novel large torque roof bolter

The invention discloses a novel large torque roof bolter. The novel large torque roof bolter includes a tip, a handle, a landing leg, a fixing sleeve, a conversion handle, a reduction box shell, a drill sleeve, a water blocking sleeve, a motor shell, a support ring, a regulating shaft, a fixing sleeve, an operating arm, a support plate, a handle frame, a back cover plate, a cylinder head inner hexagon screw, an air inlet, an auxiliary shaft, a drive gear shaft, a main shaft, a bearing, and an air outlet. The tip is arranged at the bottom end of a base, equipment is convenient to fix. The landing leg is arranged at the top end of the base, the fixing sleeve is arranged at the top end of the handing leg, the fixing sleeve fastens the landing leg and the back cover plate, so that the equipment is steadier. The fixing sleeve is rotationally connected with the fixing sleeve through the regulating shaft, the operating arm is arranged in the fixing sleeve, and the equipment is convenient to operate. The air inlet is arranged at the top end of the back cover plate, and the air outlet is arranged at the position, depart from one end of the air inlet, of the top end of the base plate. The air outlet drives the auxiliary shaft and the drive gear shaft to rotate, the gear is arranged at the top end of the drive gear shaft, the angle of the conversion handle is rotated, and the position ofthe gear can be changed, so that the effect of changing torque is achieved.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

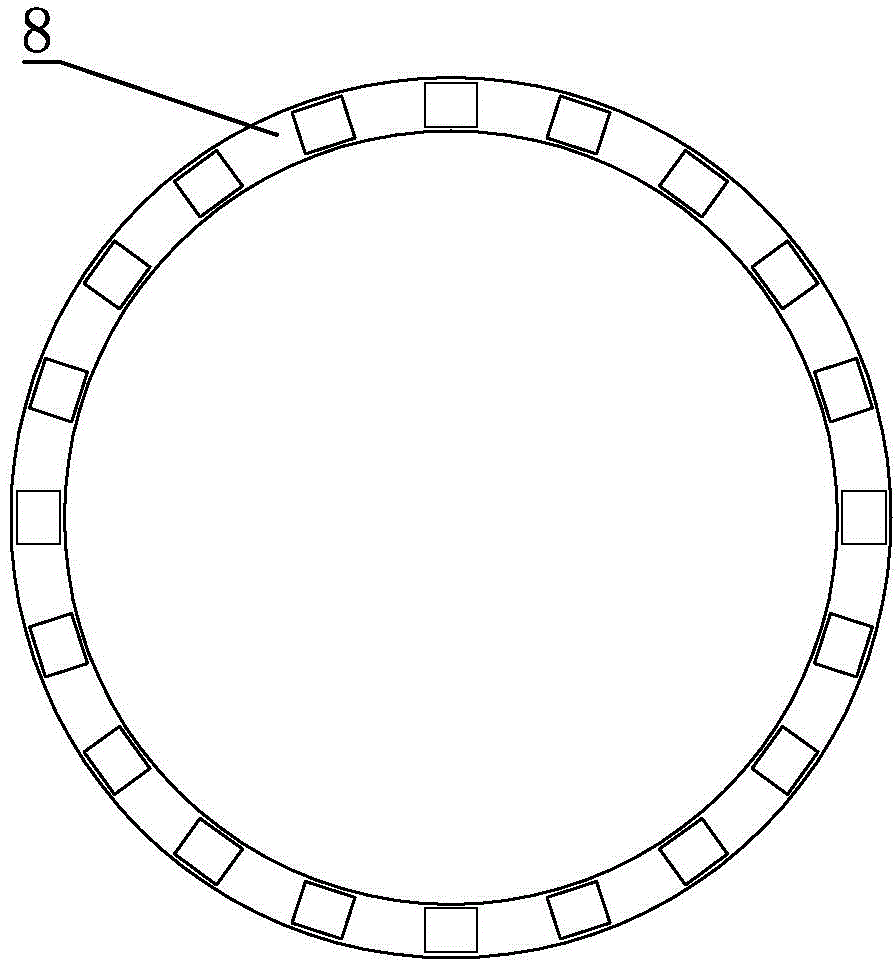

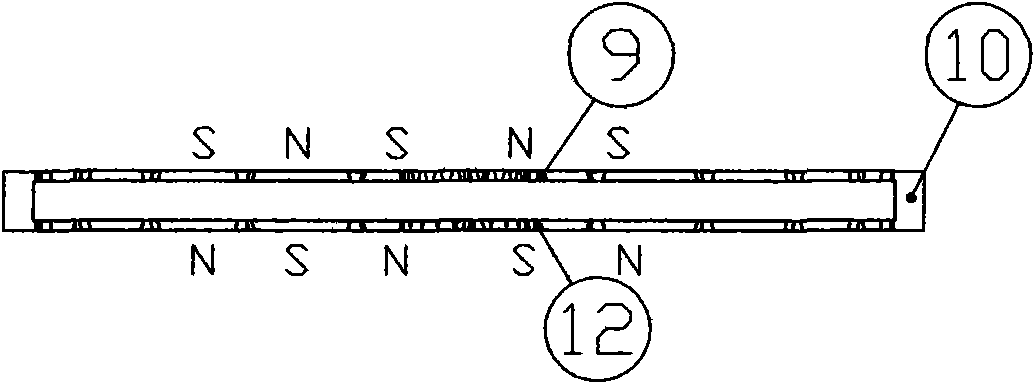

Multipolar serial flux-weakening motor

InactiveCN102255451AConvenient speed adjustmentChange torqueMagnetic circuit rotating partsElectric machinesFlux weakeningSteel plates

The invention belongs to a multipolar serial flux-weakening motor which comprises: a housing (1), an end cap (2) and a main shaft (4). The motor is characterized in that: three rotors are uniformly distributed on the main shaft (4), wherein the three rotors are fixed through a key (18); the rotors comprise the key (18) and a shaft sleeve (5), wherein the key (18) forms a tight fit connection with the shaft sleeve (5); a rotor core (11) is fixed on the shaft sleeve (5); N pole and S pole are uniformly distributed on upper and lower surfaces of the rotor core (11), and N dipole magnets (9) and S dipole magnets (12) are alternatively fixed on the N pole and the S pole; upper stators (6) are installed on upper sides of the rotors and lower stators (13) are installed on lower sides of the rotors; oriented silicon steel plates (7) are radially folded to form the stators; Three expanding gap supports (16) are uniformly distributed and fixed on a circumference of every stator; the expanding gap supports (16) are equipped with nuts (15); the nuts (15) is flexibly connected with a lead screw (14); the lead screw (14) is flexibly installed in a lead screw seat (17). The motor adjusts magnetic flux air gap through controlling a transmission mechanism so as to adjust a rotating speed and a torque. The motor is a first choice for an electric vehicle using new energy.

Owner:DALIAN HUAKONG INDAL EQUIP

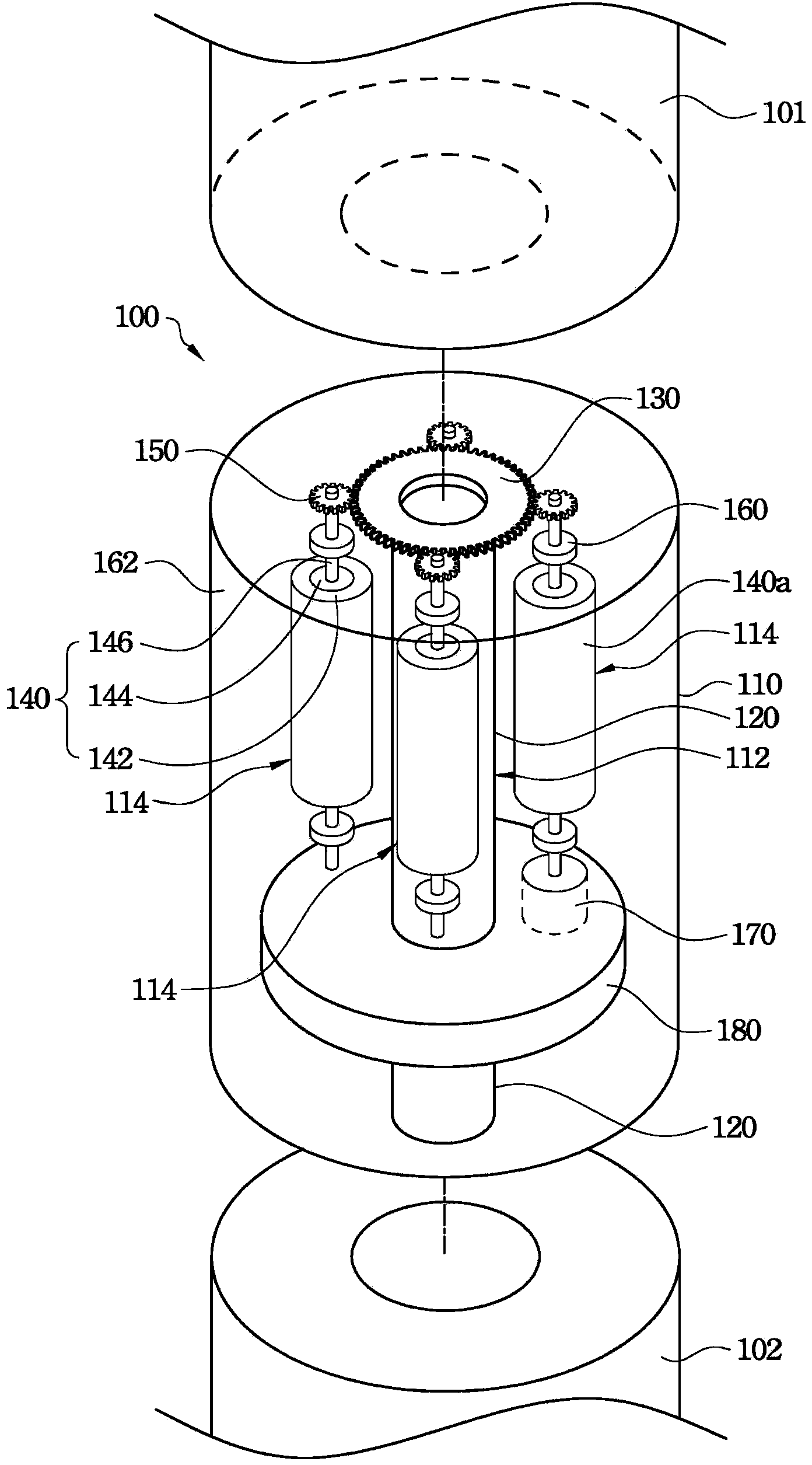

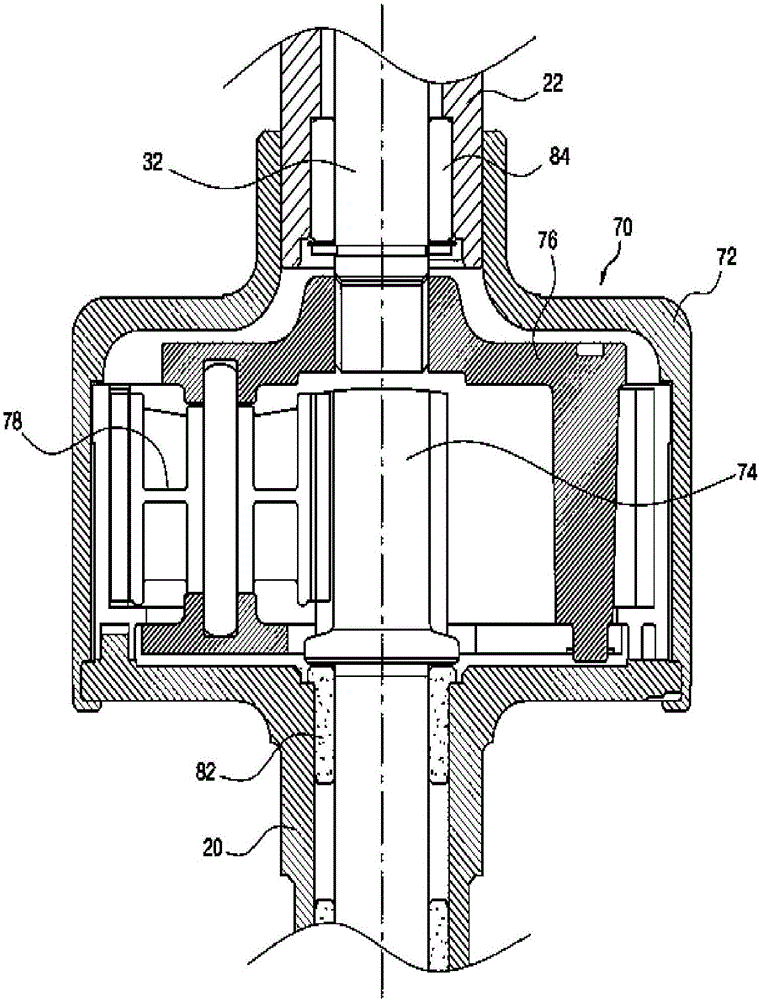

Washing Machine Driving Apparatus And Washing Machine Including Same

ActiveCN106464105AChange torqueAvoid interferenceOther washing machinesWashing machine with receptaclesDrive motorGear ratio

A washing machine driving apparatus of the present invention comprises: a double rotor-double stator type of drive motor that includes an inner rotor and an outer rotor that can be independently controlled by double stators and selectively generates an inner-rotor output and an outer-rotor output; a first inner shaft that transfers the inner-rotor output as a first input; a first outer shaft that is coupled to the outer periphery of the first inner shaft so as to be rotatable and transfers the outer-rotor output as a second input; a planetary gear device in which a gear ratio of a transmission output generated from a carrier when the first input is applied to a sun gear through the first inner shaft is controlled by the second input applied to a ring gear through the first outer shaft; and a protection unit for protecting the inner rotor, wherein the outer periphery of the protection unit is supported by the double stators. As a result, interference between the rotors and other components can be prevented so that the other components can be installed at a close location to the motor, thereby making better use of a space.

Owner:AMOTECH

High-power adjustable vertical-axis wind turbine generator system and control method

PendingCN111089032AReduce resistanceSmall drag coefficientWind motor controlRenewable energy generationElectric energyElectric generator

The invention discloses a high-power adjustable vertical-axis wind turbine generator system and a control method. The wind turbine generator system comprises a wind wheel and a generator; the generator is used for converting mechanical energy generated by rotation of the wind wheel to electric energy; the wind wheel comprises a blade and a hub; the blade comprises a handle and an end; one end of the handle is fixed on the hub and rotated through the hub, and the other end is fixedly connected with the end; the end is of a hollow semisphere structure; the end is provided with a hydraulic push rod in the diameter direction of the blade; the hydraulic push rod is connected with a control device; and the hydraulic push rod is controlled by the control device to extend or shrink so as to push the end to change the windward area of the end. The control method is realized through the wind turbine generator system. The high-power adjustable vertical-axis wind turbine generator system and the control method solve the problems of low power and incapability of adjusting a resistance vertical-axis wind turbine generator system.

Owner:李大伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com