Finish-milling clamp for automobile steering knuckles and application method

A technology for steering knuckles and steering knuckles of automobiles, applied in clamping, milling machine equipment, manufacturing tools, etc., can solve the problems of poor tolerance of fixtures, troublesome replacement of fixtures, and fluctuations in order quantities, so as to improve flexibility, improve precision, and reduce vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be clearly and completely described below in conjunction with specific embodiments.

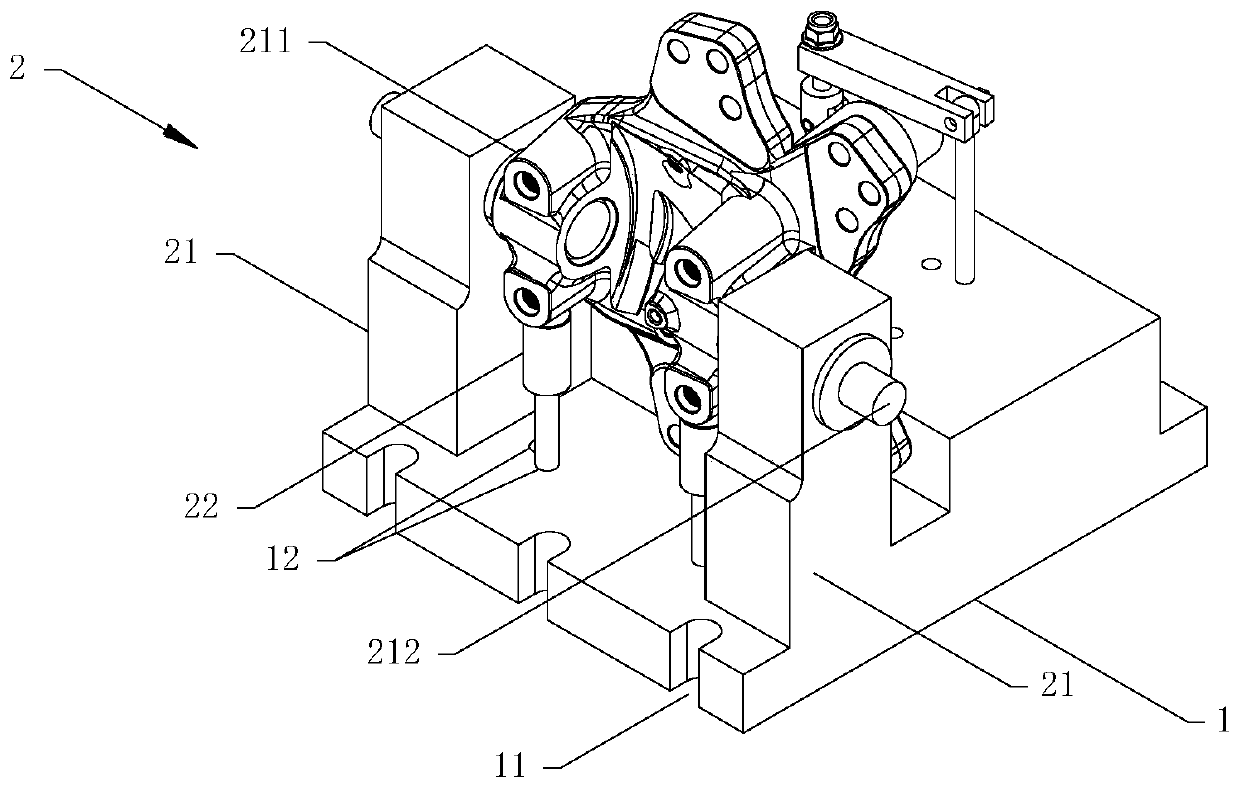

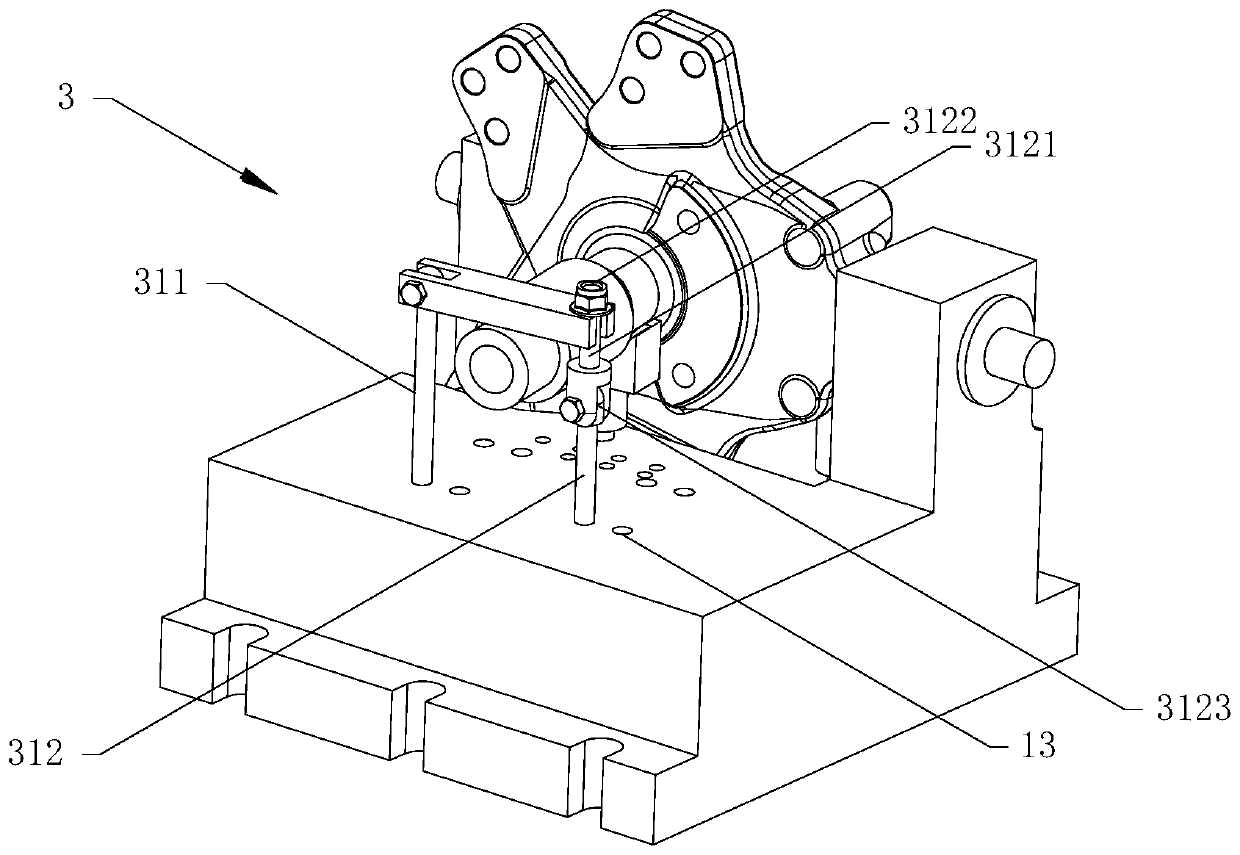

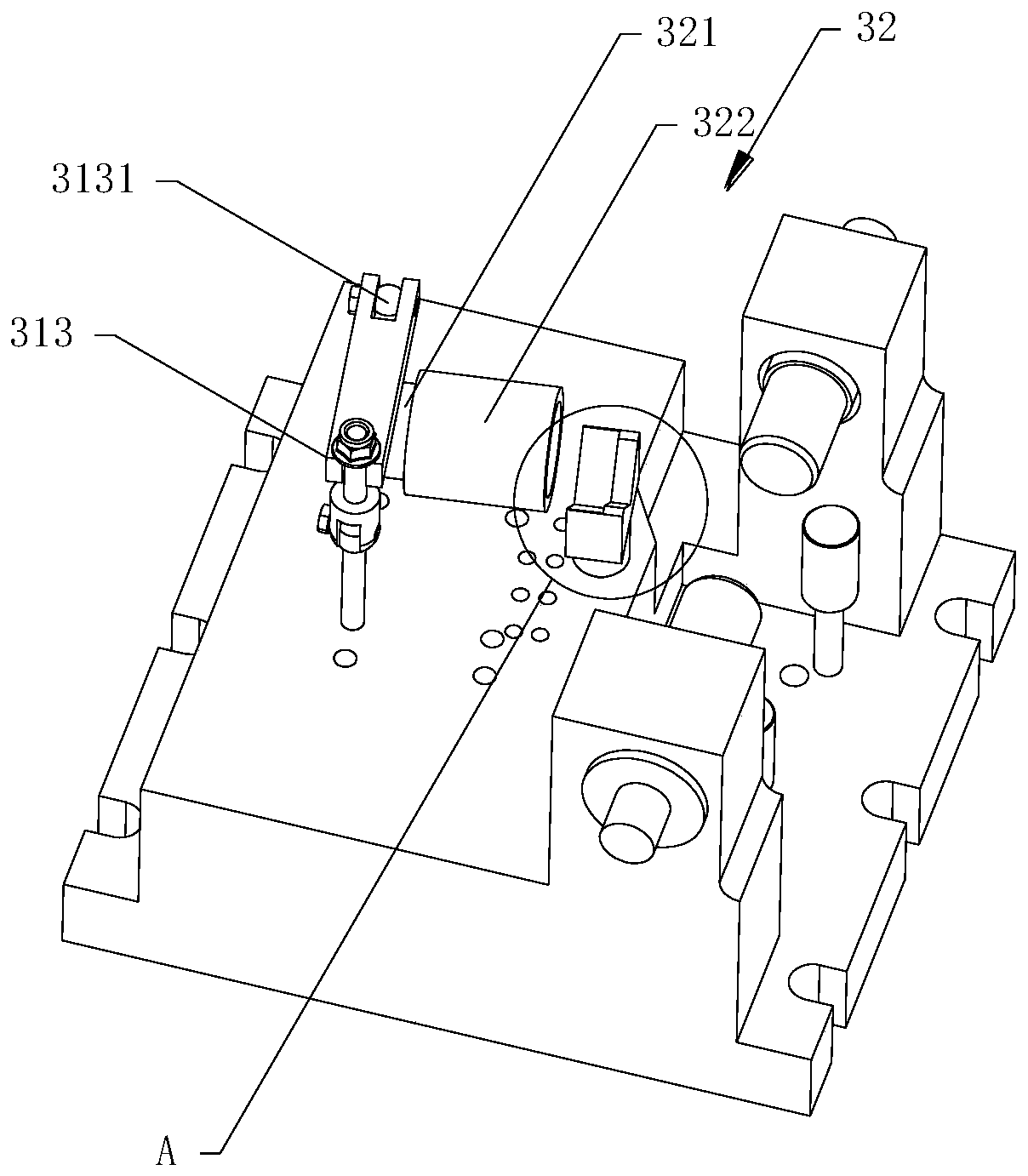

[0033] A precision milling fixture for an automobile steering knuckle, such as Figure 1-4 As shown, it includes a base 1, a fastening device 2 and a pressing device 3, and it is characterized in that: the fastening device 2 is arranged on one side of the base 1, and the pressing device 3 is arranged on the other side of the base 1; The fastening device 2 includes positioning piles 21 arranged on both sides of the base 1, a positioning hole 211 is opened on the positioning pile 21, and a mandrel 212 is arranged in the positioning hole 211 for connecting the positioning pile 21 and the steering knuckle. The fastening device 2 is also provided with a support rod 22, and the base 1 is provided with several support holes 12 near the side of the fastening device 2. The support rod 22 and the support hole 12 are connected by threads. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com