Method for in situ construction of a wind power plant

A technology for wind power generation equipment and on-site assembly, which is applied in the directions of wind turbine components, wind turbine assembly, wind power generation, etc., and can solve problems such as reducing the service life of components and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

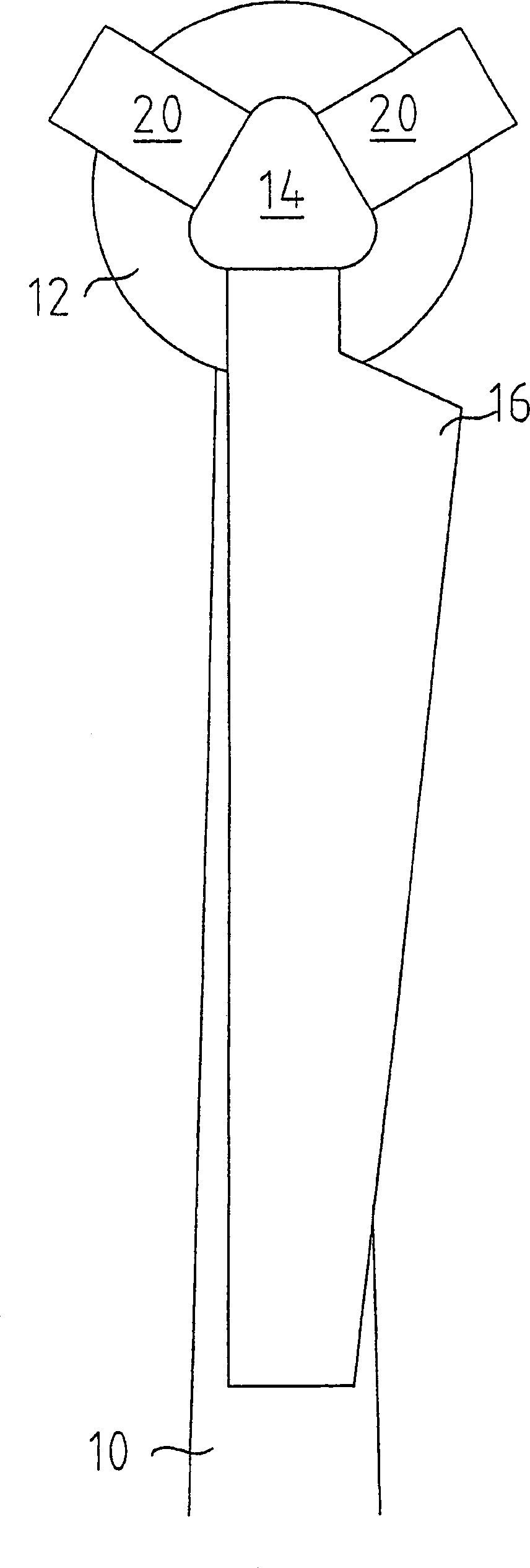

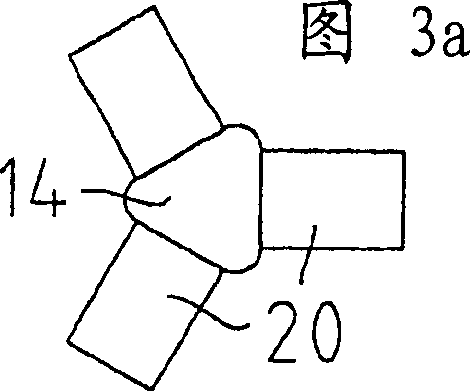

[0021] figure 1 The upper part of a steel tower 10 is shown, at the top of which a nacelle 12 is arranged, in which are arranged mechanical brackets for accommodating all mechanically moving parts of the wind power plant. Arranged centrally in the nacelle 12 (of the mechanical carrier) is a rotor hub 14 , on which rotor blades 16 can be mounted via a flange connection. One of the rotor blades 16 is shown in the installed position.

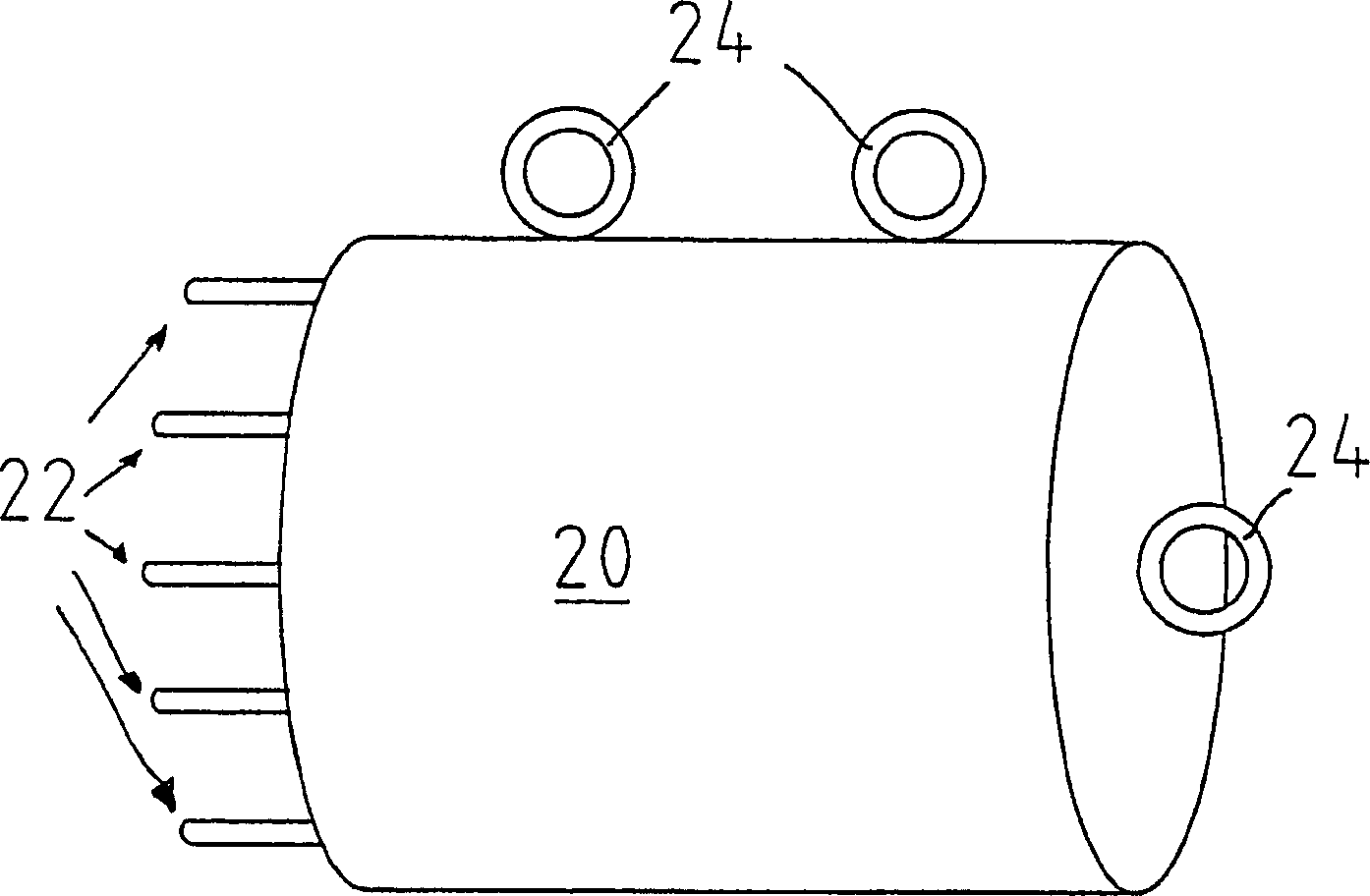

[0022] Arranged on the holding flange connection is a counterweight 20 , which imposes on the rotor hub 14 the load conditions that occur when the three rotor blades 16 are mounted in place. In this case, the torque produced is zero. In this way, the rotor hub 14 can be turned into a desired position. One of the counterweights 20 can then be removed and replaced by a rotor blade 16 . As a result, the load conditions remain unchanged, so that a further rotation and replacement of the remaining counterweight 20 by a rotor blade 16 does not presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com