Permanent magnet speed governor

A permanent magnet governor and permanent magnet technology, applied in the direction of permanent magnet clutches/brakes, etc., can solve problems such as electromagnetic interference, short life cycle, and insufficient stability, and achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

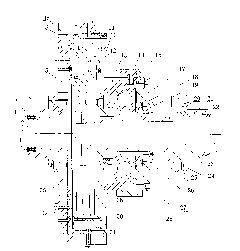

[0026] Referring now to the accompanying drawings in the description, the permanent magnet governor of the present invention will be further described in conjunction with specific embodiments.

[0027] Working principle: The magnets on the permanent disk and the side cylinder are arranged adjacently with N and S poles, and the magnetic field lines pass through the corresponding conductor disk and conductor cylinder. When the two move relative to each other, the conductor disk and conductor cylinder are cut separately. The magnetic lines of force generate eddy currents in the conductor disk and the conductor cylinder, and the eddy currents then generate an anti-magnetic field to prevent the relative movement between the two, thereby realizing the torque transmission between the two. The greater the strength of the magnetic field passing between the two, the greater the transmitted torque; the faster the relative movement, the greater the transmitted torque; the greater the speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com