Cylindrical-turnplate permanent magnet speed controller

A technology of permanent magnet speed governor and turntable, which is applied in the direction of asynchronous induction clutch/brake, etc., which can solve the problems of large axial force, high bearing requirements, and small area, so as to avoid axial thrust, simple installation and debugging, and increase Effect of Coupling Area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

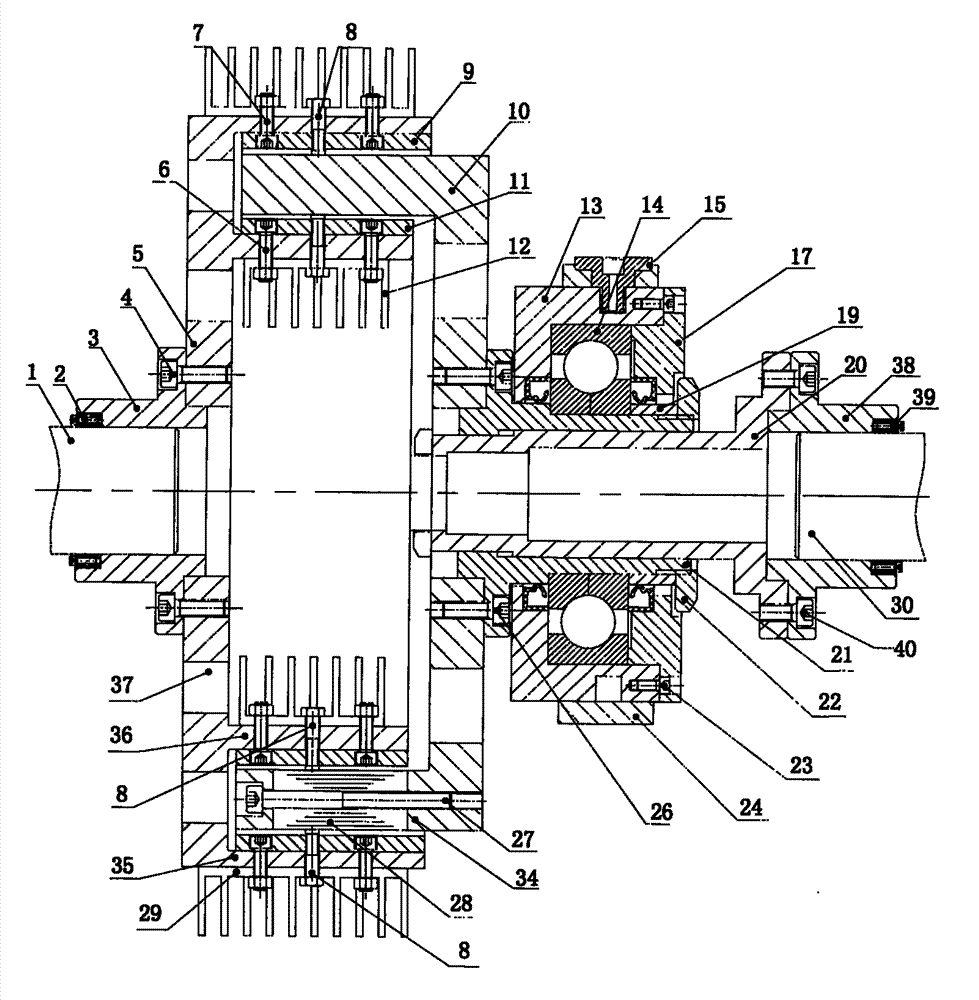

[0026] Referring now to the accompanying drawings of the description, the cylindrical turntable permanent magnet governor of the present invention will be further described in conjunction with specific embodiments.

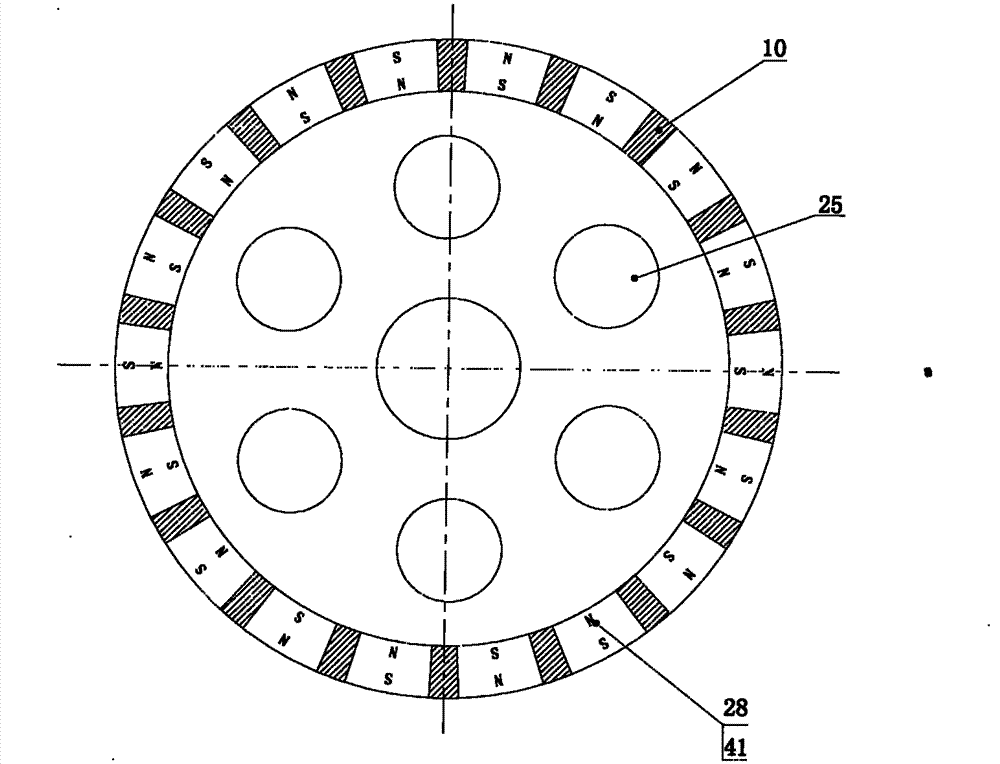

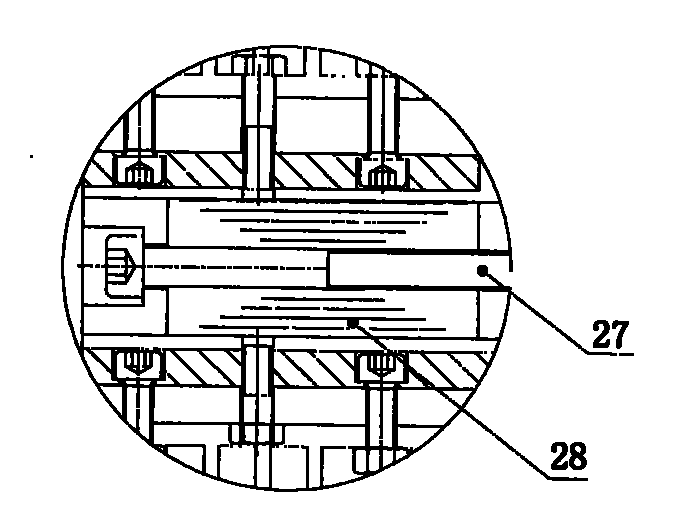

[0027] Working principle: The N and S poles of the magnets on the permanent disk are arranged adjacent to each other, and the magnetic field lines pass through the corresponding conductor cylinders. When the two move relative to each other, the conductor cylinders cut the magnetic force lines and generate eddy currents in the conductor cylinders. Eddy currents In turn, an anti-magnetic field is generated to prevent the relative movement between the two, so as to realize the torque transmission between the two. The greater the strength of the magnetic field passing between the two, the greater the transmitted torque; the faster the relative movement, the greater the transmitted torque; when the permanent magnet turntable is pushed and pulled by the bearing to move i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com