Permanent magnet governor

A permanent magnet governor and permanent magnet technology, applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of small relative area, many electrical components, large axial force, etc., and achieve controllable output torque and The effect of rotating speed, increasing the coupling area, and avoiding axial thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

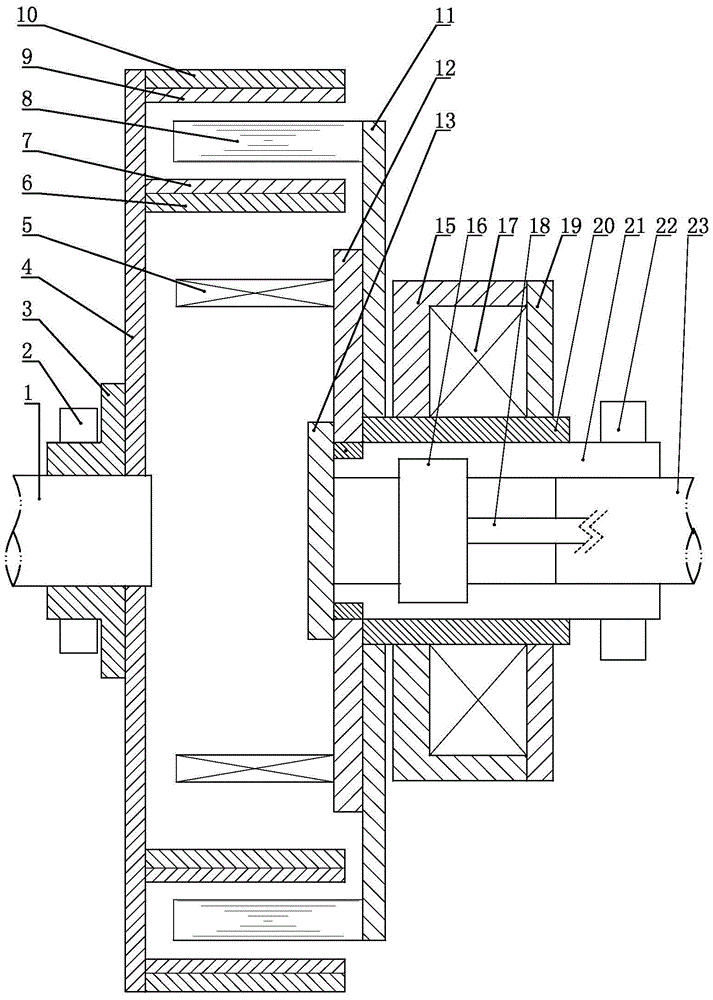

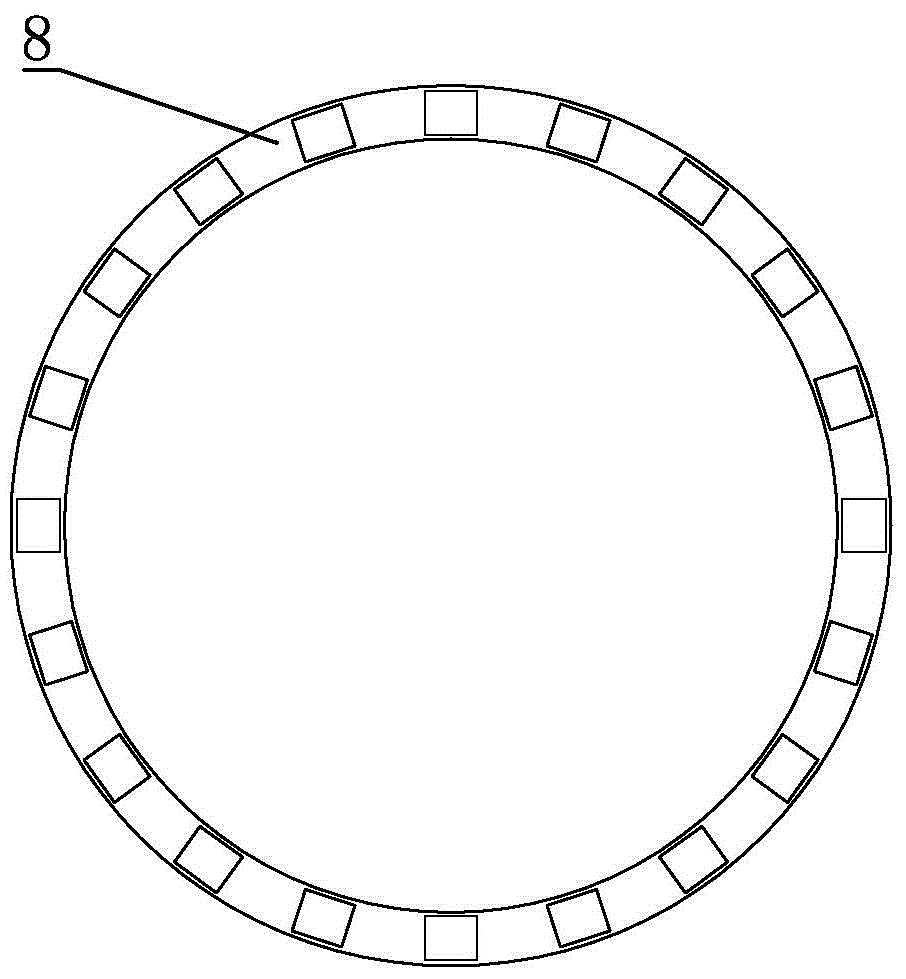

[0023] Such as figure 1 As shown, the present invention includes: a split and coaxial first shaft 1 and a second shaft 23, the first shaft 1 is fitted with an annular permanent magnetic turntable 4, and the second shaft 23 is fitted with An annular shaft sleeve 21, the sleeve 21 is covered with a cylindrical inner ring sleeve 20, and the inner ring sleeve 20 is covered with a ring-shaped conductor turntable 11. It is characterized in that: the permanent magnet turntable 4 There are two coaxial cylindrical protrusions fixedly connected to the outer edge: the outer tube 10 away from the first axis 1 and the inner tube 6 close to the first axis 1, the outer tube 10 and the inner tube 6 There is a gap between them, the inner surface of the outer layer cylinder 10 and the outer surface of the inner layer cylinder 6 are respectively fixed with an outer conductor cylinder 9 and an inner conductor cylinder 7; the outer edge of the conductor turntable 11 is fixedly connected with a cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com