Disc-shaped rotating disc permanent magnet adjustment device

A regulator, permanent magnet technology, applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of many fault points, short life cycle, many electrical components, etc., to achieve controllable output torque and speed, installation and debugging. Simple, effect of increasing coupling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

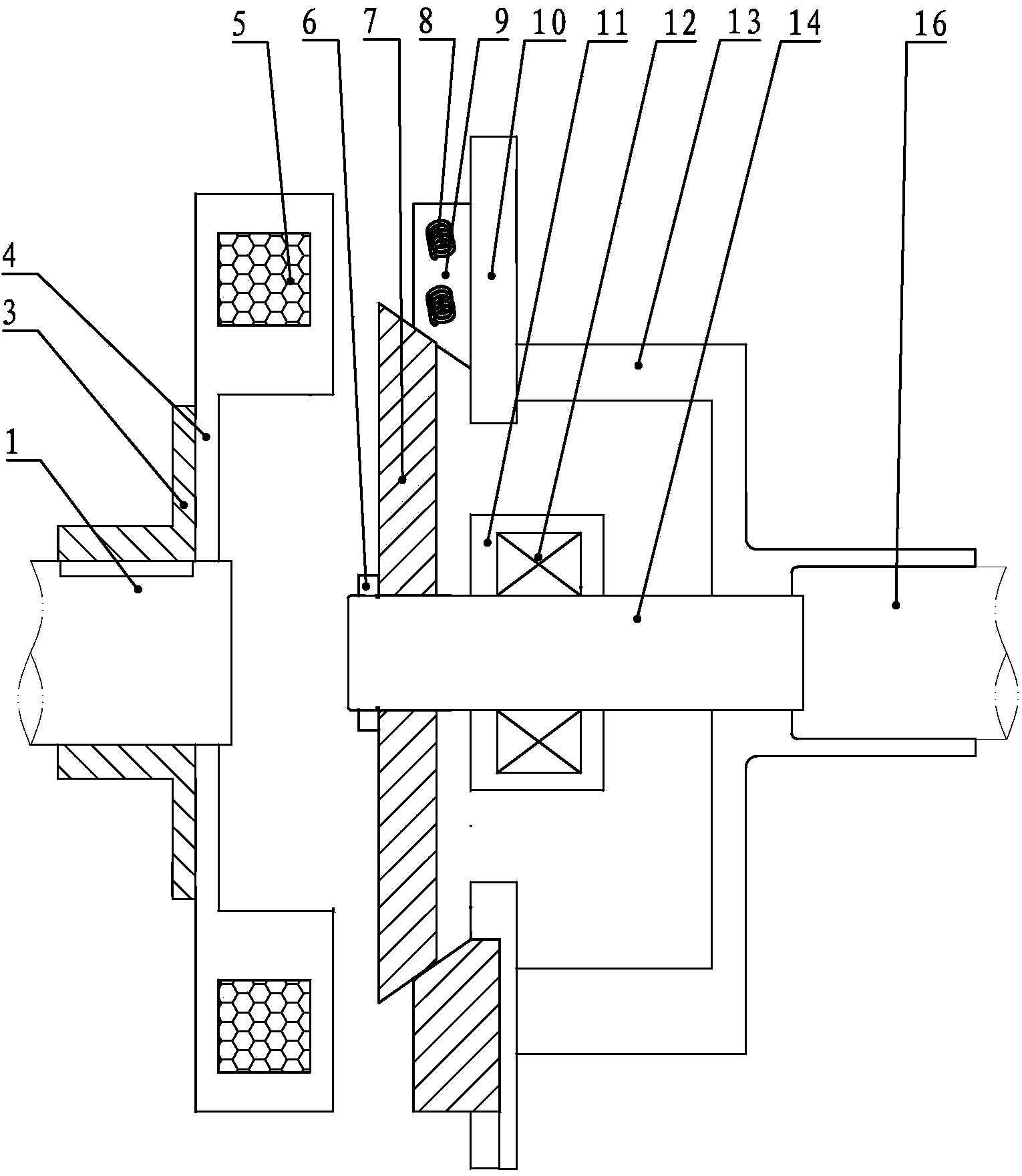

[0018] Such as figure 1 As shown, the present invention includes: a split and coaxial first shaft 1 and a second shaft 16, the first shaft 1 is covered with a permanent magnetic turntable 4 and a hub 3, and the hub 3 includes a The interference-fit cylindrical fixing part and the ring-shaped connecting part fixedly connected with the permanent magnet turntable 4 by bolts, the second shaft 16 is fitted with a shaft sleeve 13, and the shaft sleeve 13 is fitted with a conductor turntable 10 , it is characterized in that: a circle of permanent magnets 5 is installed outside the outer diameter edge of the permanent magnet turntable 4, and the magnetic pole direction of the permanent magnets 5 is perpendicular to the surface of the permanent magnet turntable 4, and different poles are installed between adjacent permanent magnets 5; the shaft There is an extension shaft 14 coaxial with the second shaft 16 in the sleeve 13, and one end of the extension shaft 14 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com