Lubricant composition and his use in a ball joint

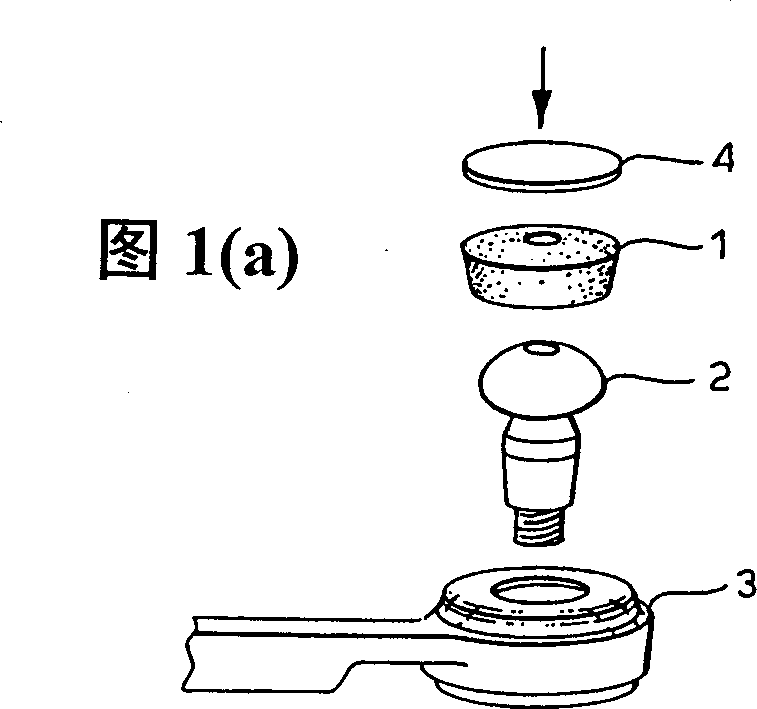

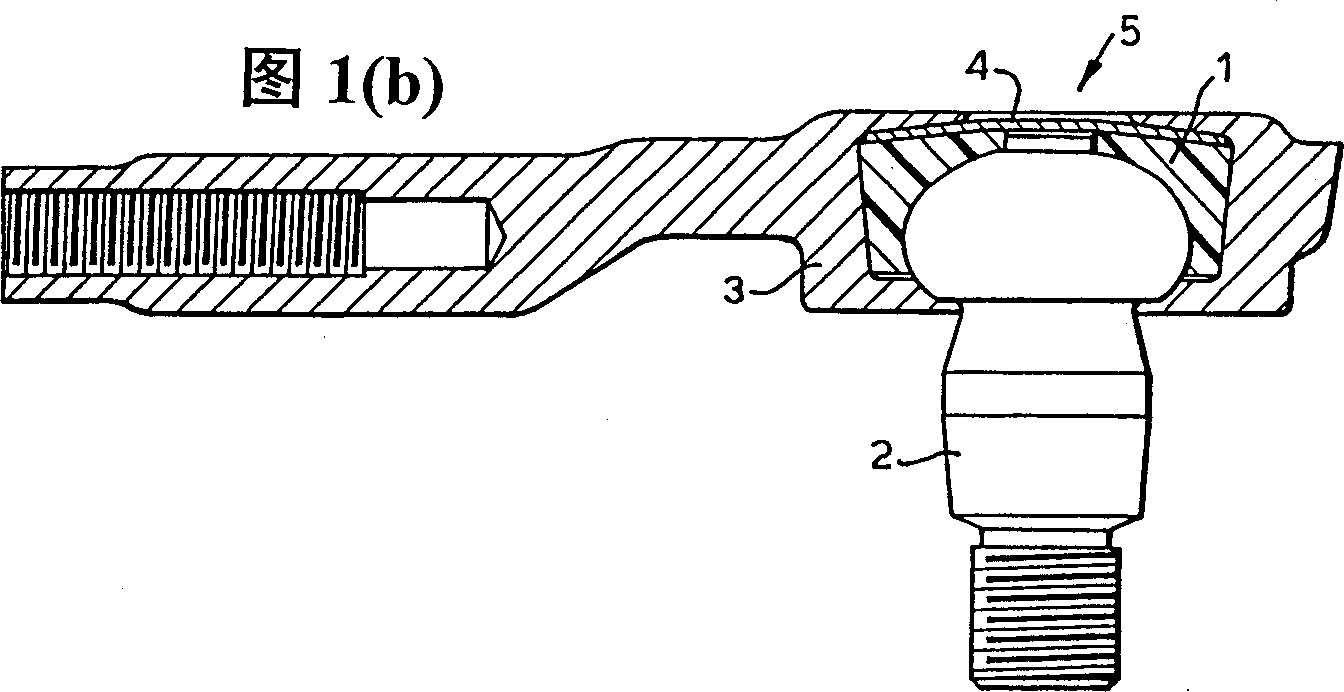

A technology for lubricants, ball joints, applied in the field of application of lubricant components in such a ball joint, able to solve the problems of direct contact, enlargement, ball socket wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

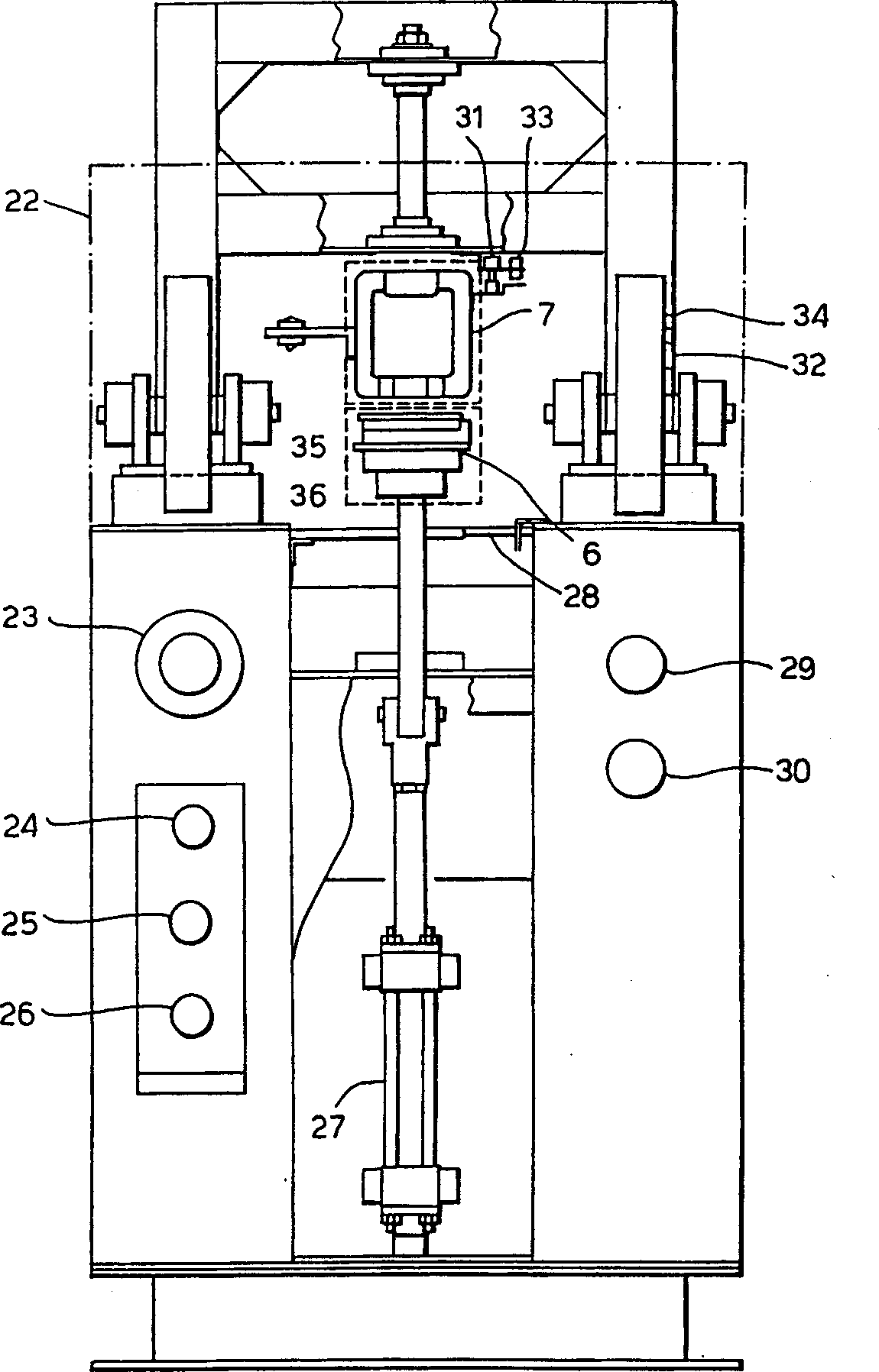

Method used

Image

Examples

example 1

[0038] Example 1 (the present invention)

[0039] A stainless steel container is filled with a viscosity of 5.2×10 at 25°C 4 mN·s / m 2 (cP) 200g of polyisoprene (hereinafter referred to as viscous medium A), 80g of ethylenebis-stearylamide (hereinafter referred to as amide A) and 30g of polyethylene wax, and stir to dissolve The charge was heated to 150°C. Stop heating when the contents melt and become transparent, add 1.0% amine-type antioxidant and cool to normal temperature. The contents are kneaded with a three-roll press to obtain a lubricated product. The penetration was 283 0.1 mm at 25°C, and the dropping point was 130°C in the lubricated product thus obtained.

example 2

[0040] Example 2 (the present invention)

[0041] By mixing at 25°C, the weight is 60%, the viscosity is 5.2×10 6 mN·s / m 2 (cP) polyisoprene and 40% by weight at 40°C, dynamic viscosity of 33.0mm 2 A viscous medium (hereinafter referred to as viscous medium B) was obtained from poly-α-olefin as a synthetic oil per sec. The viscosity of the viscous medium B is measured by a type B viscometer at 25°C as 8.0×10 4 mN·s / m 2 (cP). A stainless steel container was filled with 200 g of this viscous medium, 70 g of amide A and 30 g of paraffin, and the contents were heated to 150°C while being stirred. Heating was stopped when the content melted and became transparent, and after adding 1.0% of an amine type antioxidant to the content, it was cooled to normal temperature. The contents were homogenized by a three-roll press to obtain a lubricant product. The penetration was 2680.1 mm at 25°C and the dropping point for the product thus obtained was 124°C.

example 3

[0042] Example 3 (the present invention)

[0043] When mixed at 25°C, the weight is 40%, and the viscosity is 5.2×10 6 mN·s / m 2 (cP) polyisoprene and 60% by weight at 40°C with a dynamic viscosity of 23.5mm 2 / sec mineral oil to obtain a viscous medium (hereinafter viscous medium C). The viscosity of this medium is measured by a type B viscometer at 25°C as 1.1×10 4 mN·s / m 2 (cP). A stainless steel vessel was filled with 200 g of viscous medium C, 60 g of amide A and 40 g of microcrystalline paraffin. And the contents were heated to 150°C with stirring. Stop heating when the contents melt and become transparent, add 1.0% amine-type antioxidant and cool to normal temperature. After cooling, the contents are kneaded with a three-roll press to obtain a lubricated product. The penetration was 295 0.1 mm at 25°C, and the dropping point was 129°C in the lubricated product thus obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com