Damper

A damper and flow resistance technology, applied in the direction of liquid resistance brakes, brake types, liquid shock absorbers, etc., can solve the problems of increased assembly man-hours, increased manufacturing costs, time lag, etc., to achieve fewer parts, lower manufacturing costs, The effect of reducing assembly man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A damper according to an embodiment of the present invention will be described.

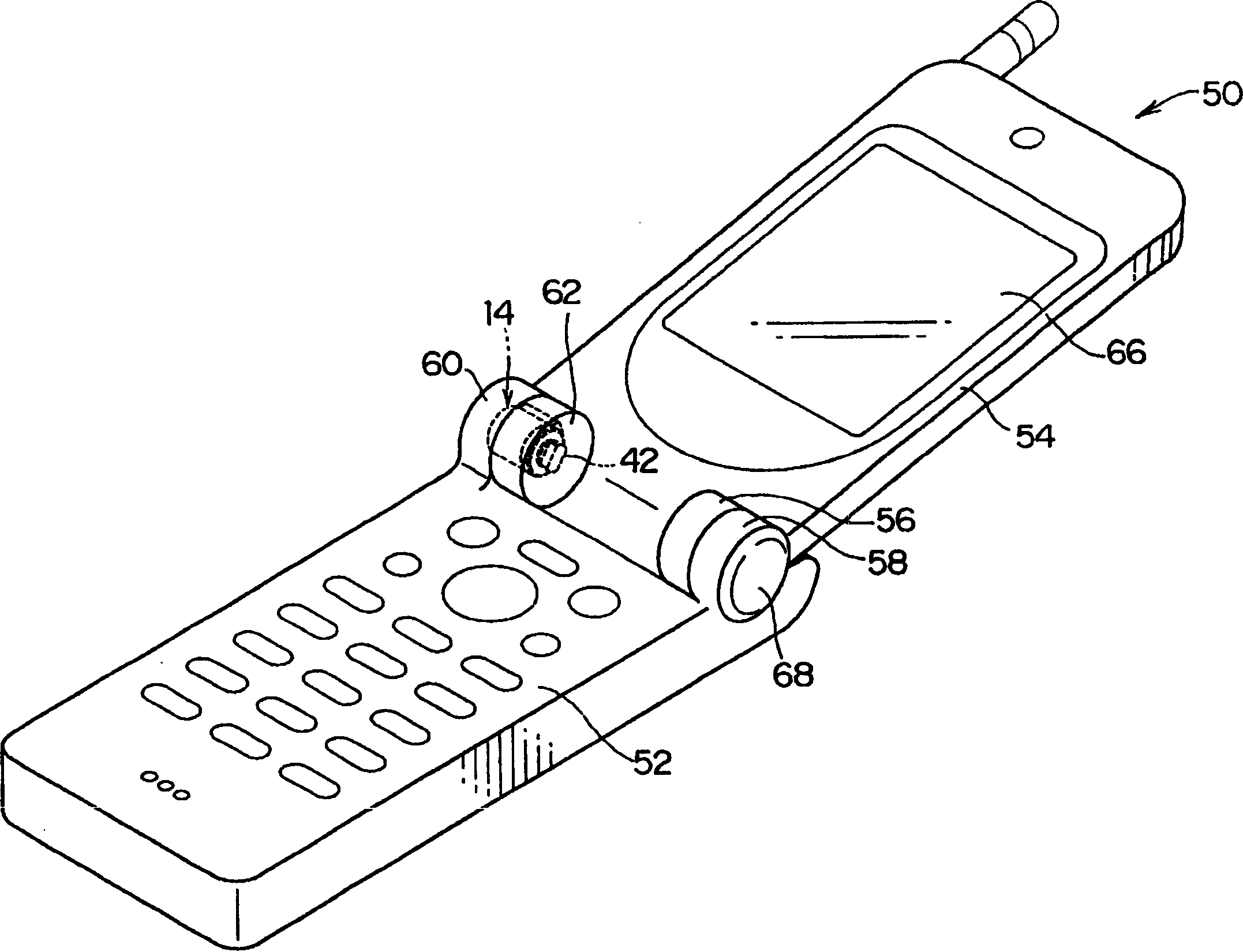

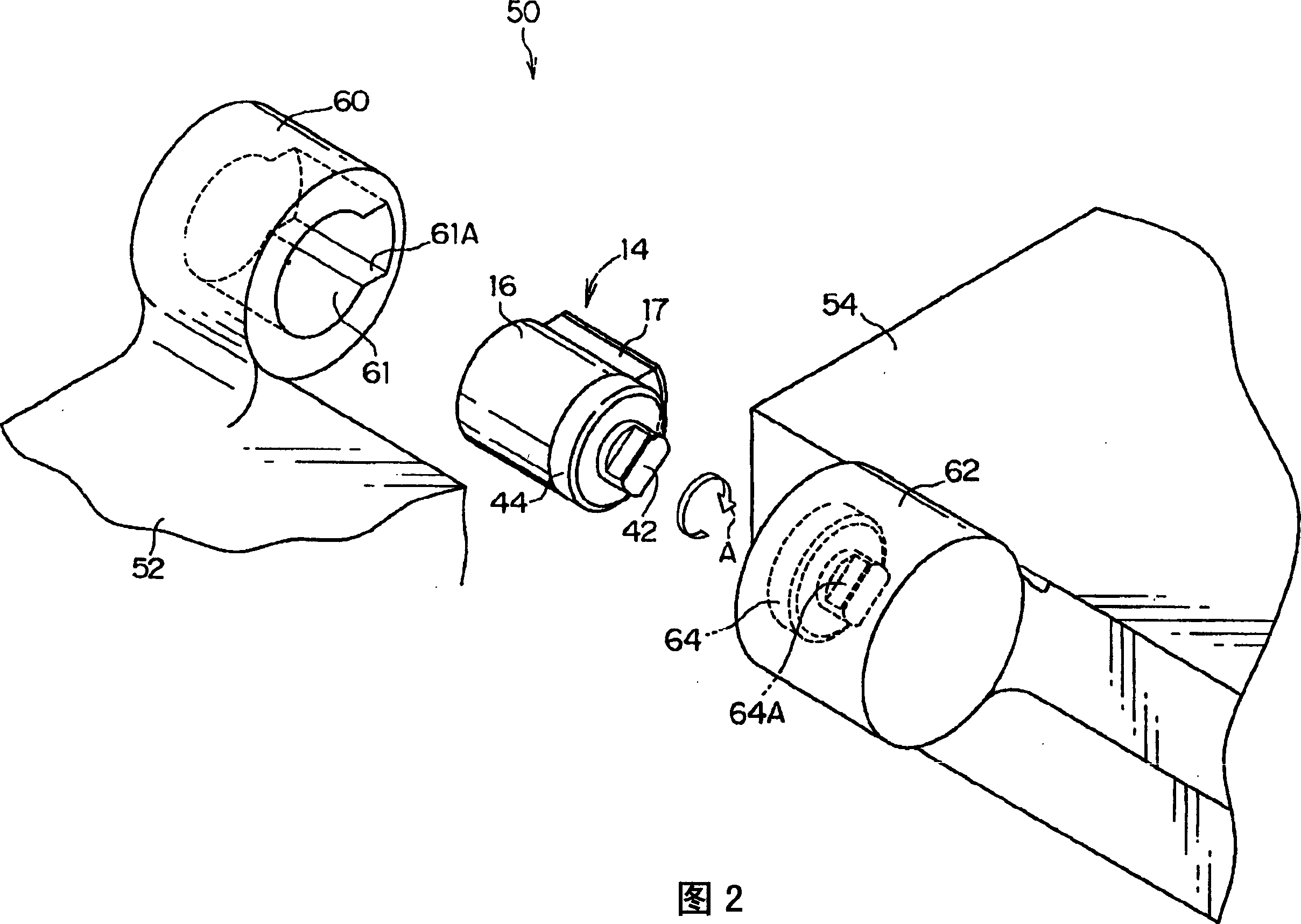

[0043] figure 1 A mobile phone 50 using the damper 14 according to the embodiment of the present invention is shown. This mobile phone 50 is constituted by a transmitting side main body 52 and a receiving side main body 54 , and a pair of shaft parts 56 and 58 and shaft parts 60 and 62 are provided on the mobile phone 50 . Therefore, the receiving-side body 54 can be rotated relative to the transmitting-side body 52 , and the mobile phone 50 can be folded with the receiving-side body 54 closed.

[0044] Springs (not shown) are disposed on the side of the shaft portions 56 and 58 so that the receiving-side main body 54 tends to open toward the transmitting-side main body 52 . On the other hand, the damper 14 is disposed on the side of the shaft portions 60 and 62 , and a braking force acts on the opening of the receiving-side main body 54 .

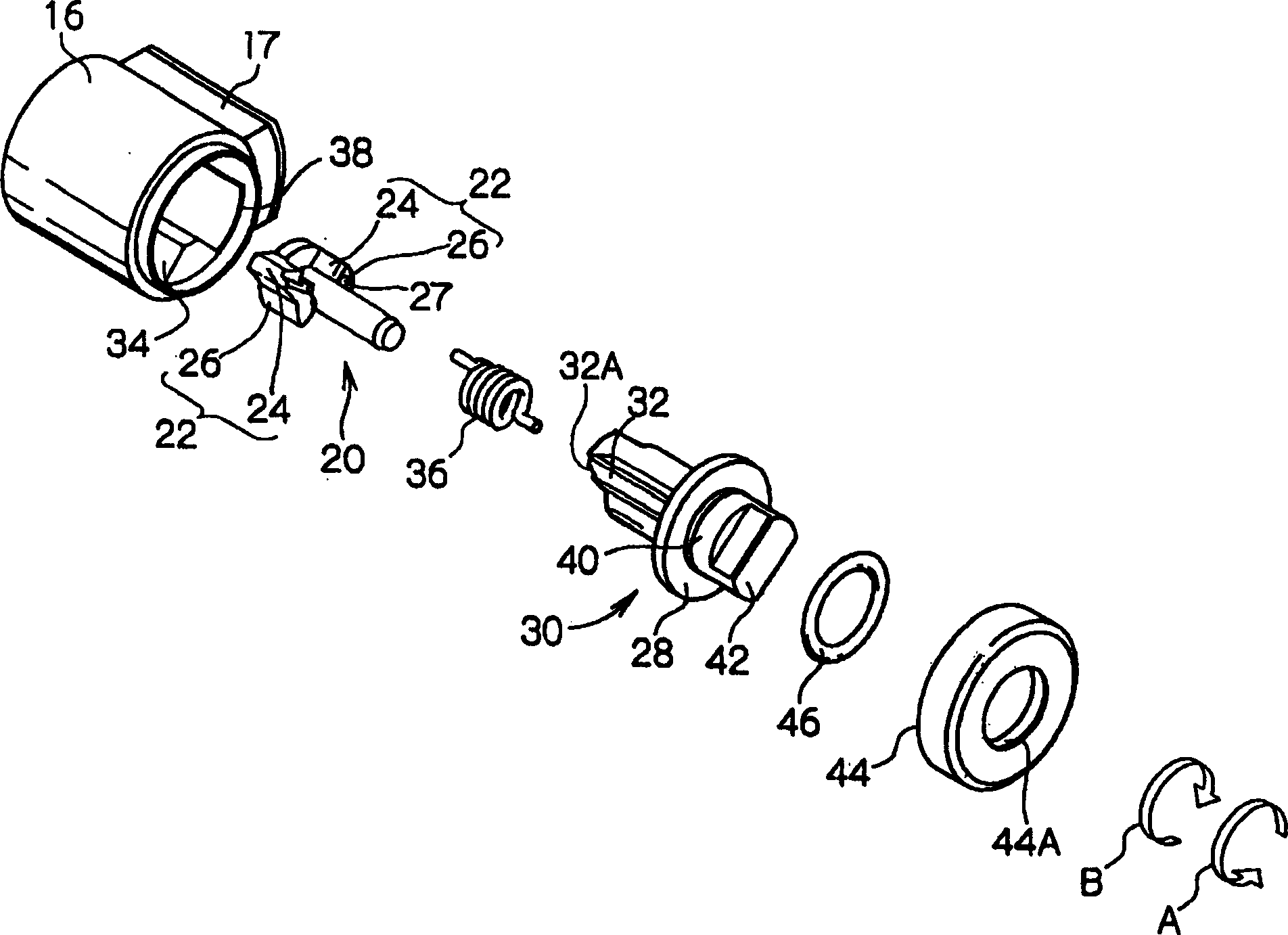

[0045] Here, the configuration of the damper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com