Power assembly of full-hydraulic reverse circulation drilling machine

A powertrain and reverse circulation technology, applied in rotary drilling rigs, earth-moving drilling, drilling equipment, etc., can solve the problem that the torque of the drill pipe cannot be changed with the change of working conditions, the auxiliary time is increased, and the required time is prolonged, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

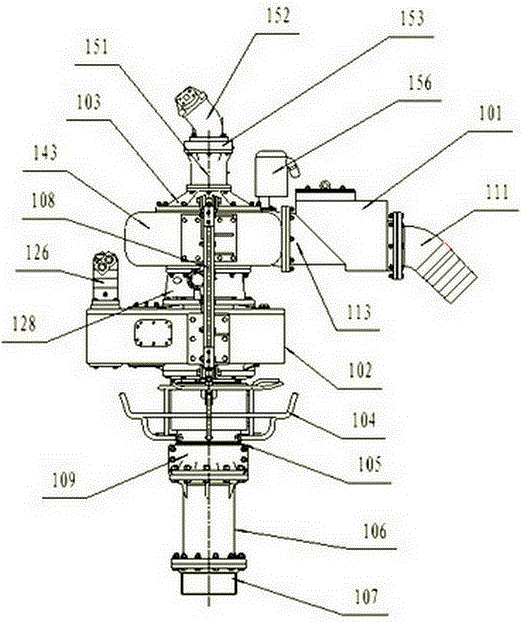

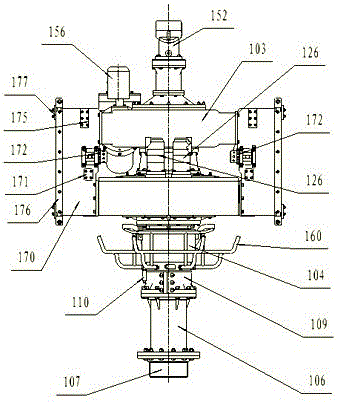

[0104] Example 1 The invention provides a power assembly of a full hydraulic reverse circulation drilling rig. said Powertrain Including slag discharge chamber 101, reduction box assembly 102, mud pump assembly 103, rotary joint assembly 104, shaft pad 105, main shaft adapter rod 106, main buckle head 107, assembly joint plate assembly 108, main shaft drive clamp tile 109 , stop pin assembly 110 (such as Figure 1-2 shown);

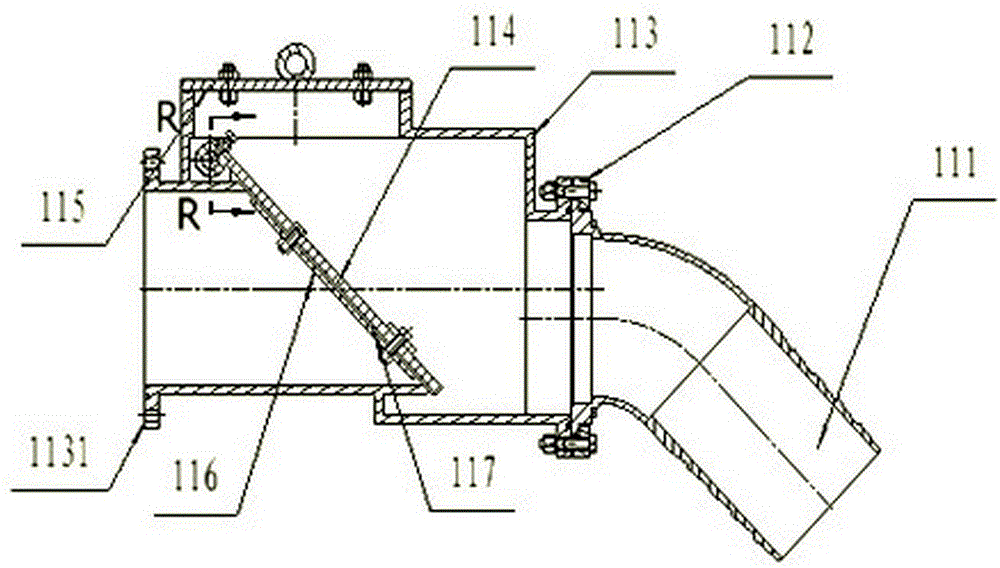

[0105] said Slag chamber 101 includes outlet joint 111, looper flange 112, slag discharge chamber housing 113, cover plate 114, upper cover 115, splint 116, rubber plate 117, bushing 118, pin shaft 119 (see Figure 3-5 ) ;

[0106] Put an O-shaped rubber ring into the ring groove on the upper surface of the circular column at the top of the slag discharge chamber casing 113, and fix the upper cover 115 on the top of the slag discharge chamber casing 113 with bolts and nuts;

[0107] One end of the circular tubular outlet joint 111 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com