PVC gel driven flexible mechanical tongs and preparing method thereof

A mechanical gripper and flexible technology, applied in the field of manipulators, can solve the problems of poor portability, slow response, poor medium and high frequency characteristics, etc., and achieve the effect of simple driving form and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

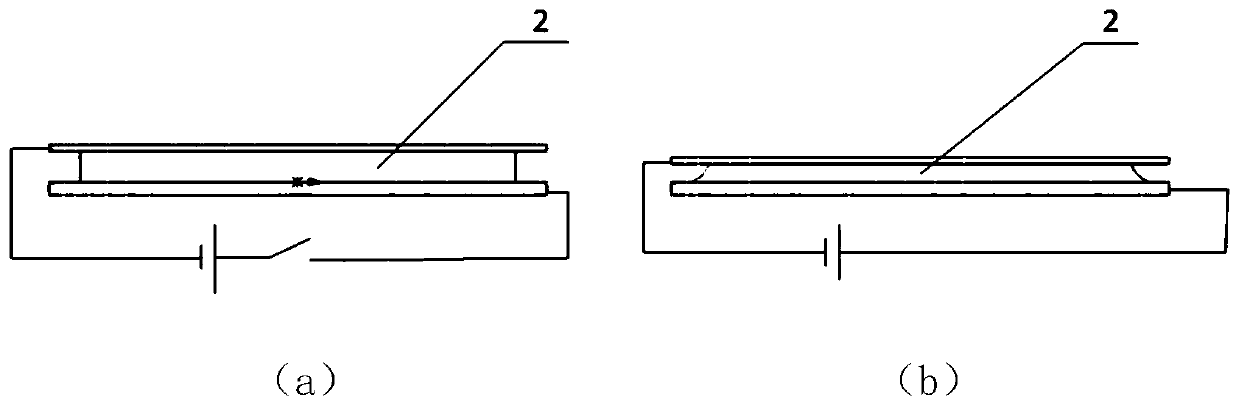

[0066] Please combine image 3 and Figure 4 , first make PVC gel film 2, take PVC granule and plasticizer dibutyl adipate (DBA) and mix with the ratio of mass ratio 1:2, add organic solvent tetrahydrofuran after mixing and dilute, the mixture quality and tetrahydrofuran The mass ratio is 1:3, and it is configured into a polymer solution, and a 100 μm thick PVC gel film 2 is prepared through a film casting process;

[0067] The anode mesh electrode 1 uses poly 60-mesh stainless steel metal mesh, and the cathode plane electrode 3 uses copper foil with a thickness of 0.02mm;

[0068] Taking the PVC gel film 2 as the core layer, laminating the anode mesh electrode 1, the PVC gel film 2 and the cathode plane electrode 3 in a sandwich structure to obtain a single-layer PVC driver 4;

[0069] The single-layer PVC driver 4 is stacked to obtain a five-layer PVC driver 5 .

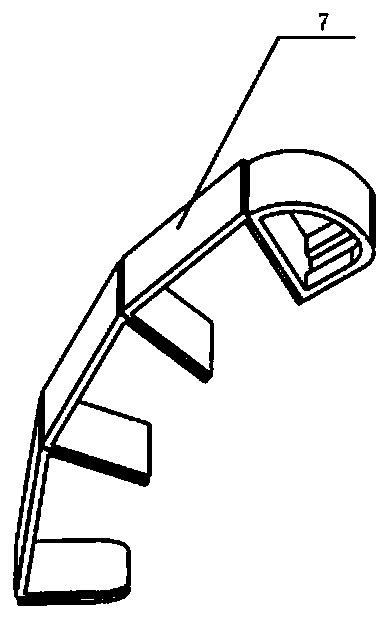

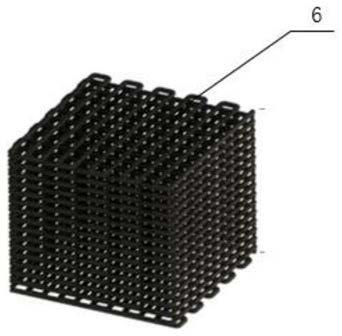

[0070] A three-dimensional grid structure of a carbon nanotube and silicone rubber mixture was printed using ...

Embodiment 2

[0073] First make PVC gel film 2, take by weighing PVC granule and plasticizer dibutyl adipate (DBA) and mix with the ratio of mass ratio 1:8, add organic solvent tetrahydrofuran after mixing and dilute, the mixture quality and tetrahydrofuran The mass ratio is 1:12, configured as a polymer solution, and a 300 μm thick PVC gel film 2 is prepared through a casting process;

[0074] The anode mesh electrode 1 uses poly 80-mesh stainless steel metal mesh, and the cathode plane electrode 3 uses copper foil with a thickness of 0.08mm;

[0075] Using the PVC gel film 2 as the core layer, the anode mesh electrode 1, the PVC gel film 2 and the cathode flat electrode 3 are stacked in a sandwich structure to obtain a single-layer PVC driver 4;

[0076] The single-layer PVC drivers 4 are stacked to obtain 50-layer PVC drivers 5 .

[0077] A three-dimensional grid structure of a carbon nanotube and silicone rubber mixture was printed using 3D direct-writing printing technology as a flexi...

Embodiment 3

[0082] First make PVC gel film 2, take by weighing PVC particle and plasticizer dibutyl adipate (DBA) mix with the ratio of mass ratio 1:12, add organic solvent tetrahydrofuran after mixing and dilute, the mixture quality and tetrahydrofuran The mass ratio is 1:8, configured as a polymer solution, and a 500 μm thick PVC gel film 2 is prepared through a casting process;

[0083] The anode mesh electrode 1 uses poly 70-mesh stainless steel metal mesh, and the cathode plane electrode 3 uses copper foil with a thickness of 0.06mm;

[0084] Using the PVC gel film 2 as the core layer, the anode mesh electrode 1, the PVC gel film 2 and the cathode flat electrode 3 are stacked in a sandwich structure to obtain a single-layer PVC driver 4;

[0085] The single-layer PVC driver 4 is stacked to obtain a 35-layer PVC driver 5 .

[0086] A three-dimensional grid structure of a carbon nanotube and silicone rubber mixture was printed using 3D direct-writing printing technology as a flexible ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com