Optical fiber grating sensor for long-term real-time monitoring of the corrosion on steel bars

A fiber grating and steel bar corrosion technology, which is applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problems of large individual differences in steel bars, etc., and achieve the effect of easy processing and manufacturing, simple production and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific embodiments, but the protection scope of the present invention is not limited by specific embodiments, and the claims shall prevail. In addition, under the premise of not violating the technical solution of the present invention, any modification or change made to the present invention that can be easily realized by a person of ordinary skill in the art shall fall within the scope of the claims of the present invention.

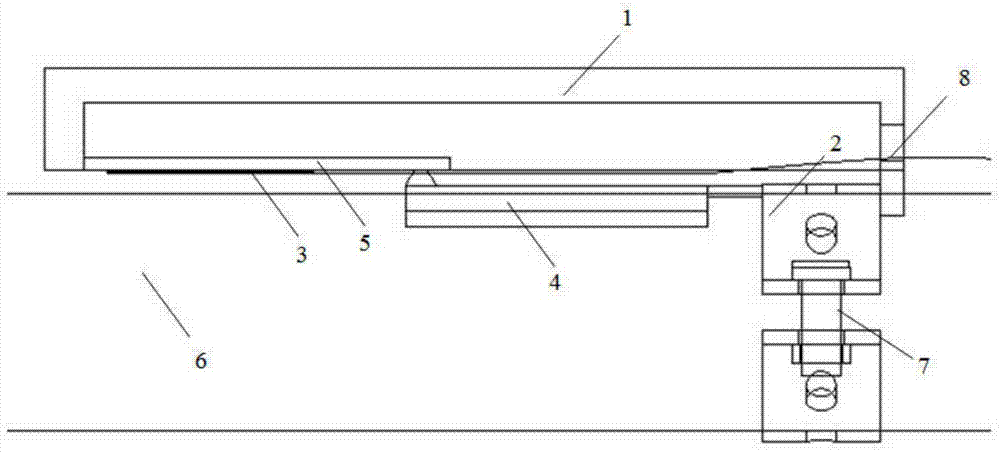

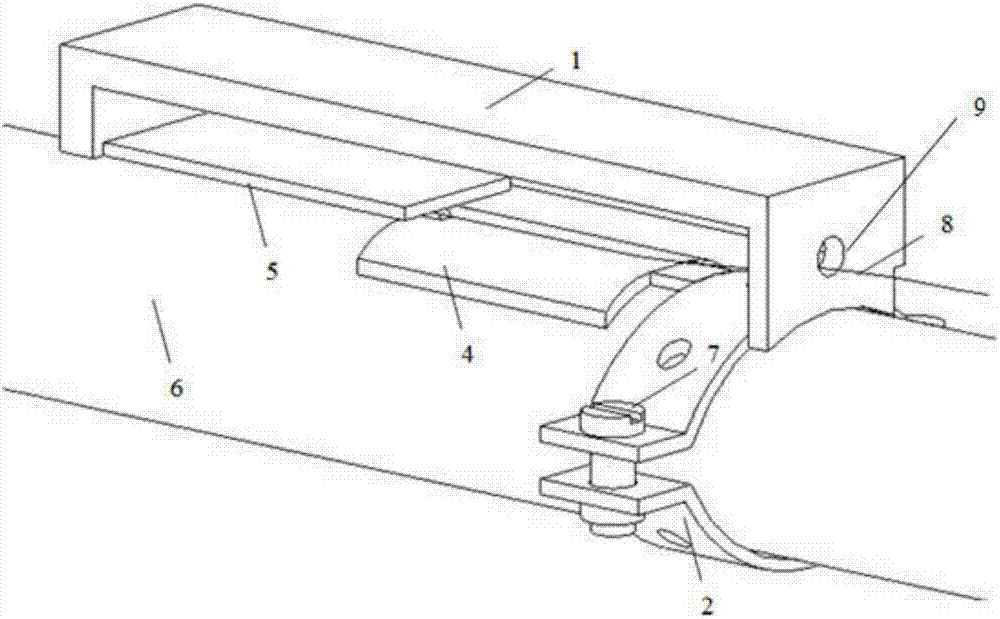

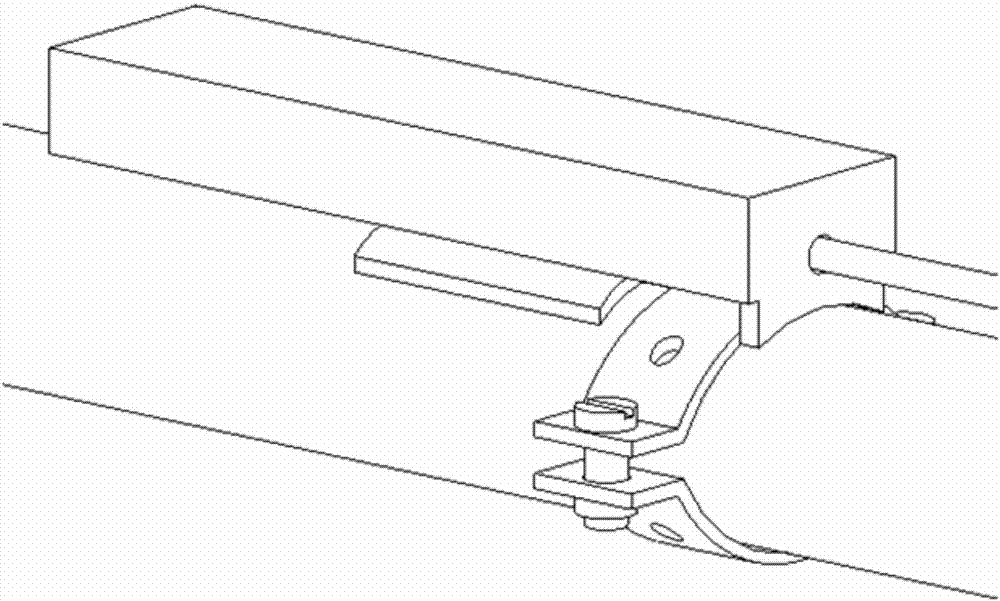

[0022] figure 1 , Shown in 2, 3; a fiber grating sensor for long-term real-time monitoring of steel corrosion, including: protective shell 1, fixed pipe buckle 2, fiber grating 3, conductive cantilever 4, monitoring cantilever 5

[0023] The protective shell 1 is a bottomless rectangular box structure, one side wall is provided with a round hole, and the protective shell 1 is fixed to the steel bar 6 through a fixed pipe buckle 2;

[0024] The protective shell 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com