Long-gauge coaxial multi-sleeve packaged fiber grating sensor for measuring tensile-compressive strain

A technology of fiber grating and multiple casings, which is used in measuring devices, instruments, optical devices, etc., can solve the problems of not reflecting the stress state of the entire structure, small measurement range, etc. Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] The protection scope of the present invention is not limited by the specific examples, but shall prevail in the claims. In addition, on the premise of not violating the technical solution of the present invention, any modification or change made to the present invention that can be easily realized by those skilled in the art will fall within the scope of the claims of the present invention.

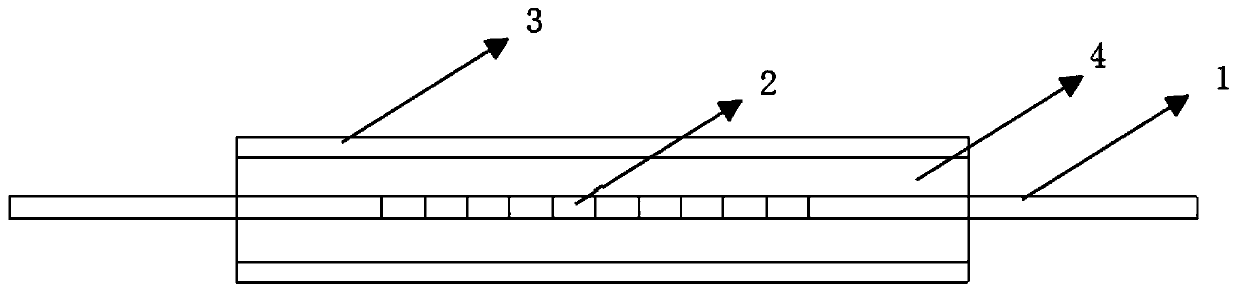

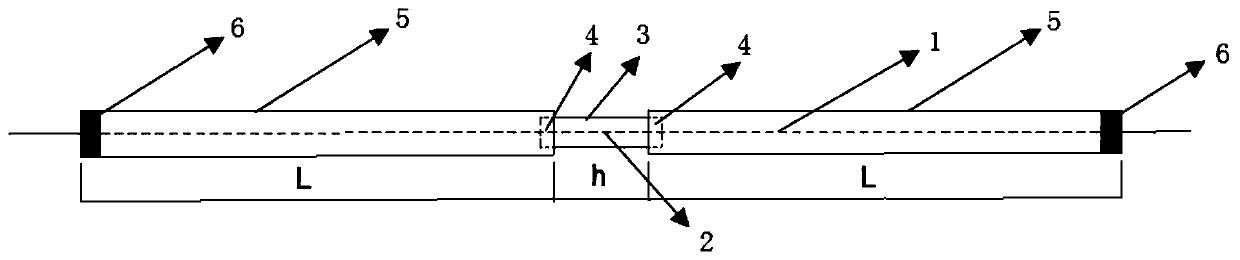

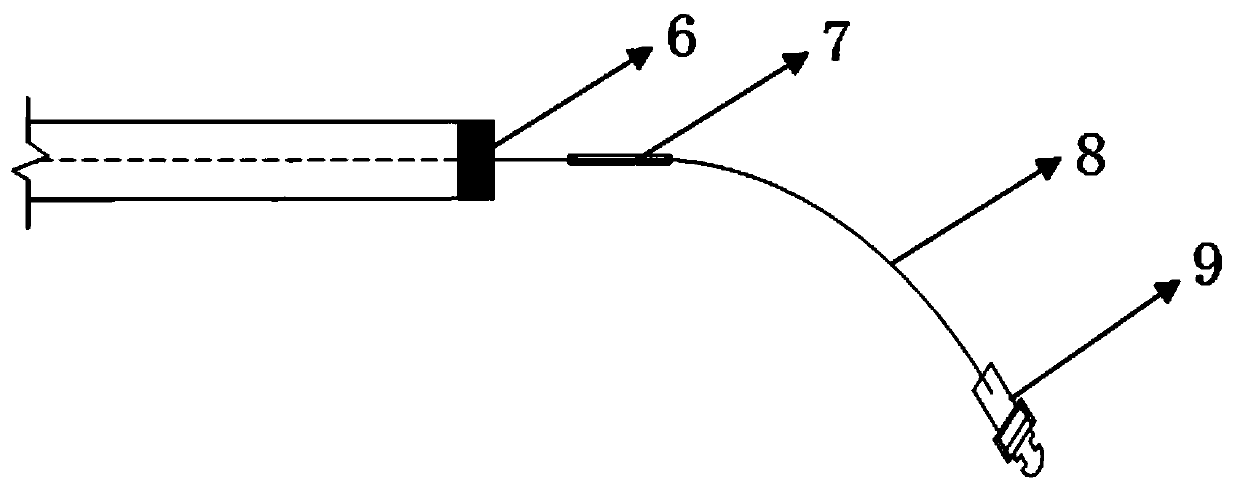

[0019] A long gauge strain sensor based on fiber grating sensing technology, including bare optical fiber 1, fiber grating 2, short sleeve 3, optical fiber adhesive 4 (using 353ND glue), packaging long tube 5, silicone rubber 6 (using 704 glue), polyethylene transparent semi-hard tube 7, single-mode single-core optical fiber jumper 8, connecting flange 9;

[0020] Both ends of the fiber grating 2 are connected to the bare optical fiber 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com