Valve position correcting based efficiency monitoring method of full-life high-pressure cylinder of steam turbine

An efficiency monitoring, high-pressure cylinder technology, applied in safety devices, mechanical equipment, engine components, etc., can solve problems that cannot reflect the real-time real-time level and comparison of high-pressure cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A method for monitoring the efficiency of a steam turbine's full-life high-pressure cylinder based on valve position correction of the present invention will be further described in detail below with reference to the drawings and embodiments.

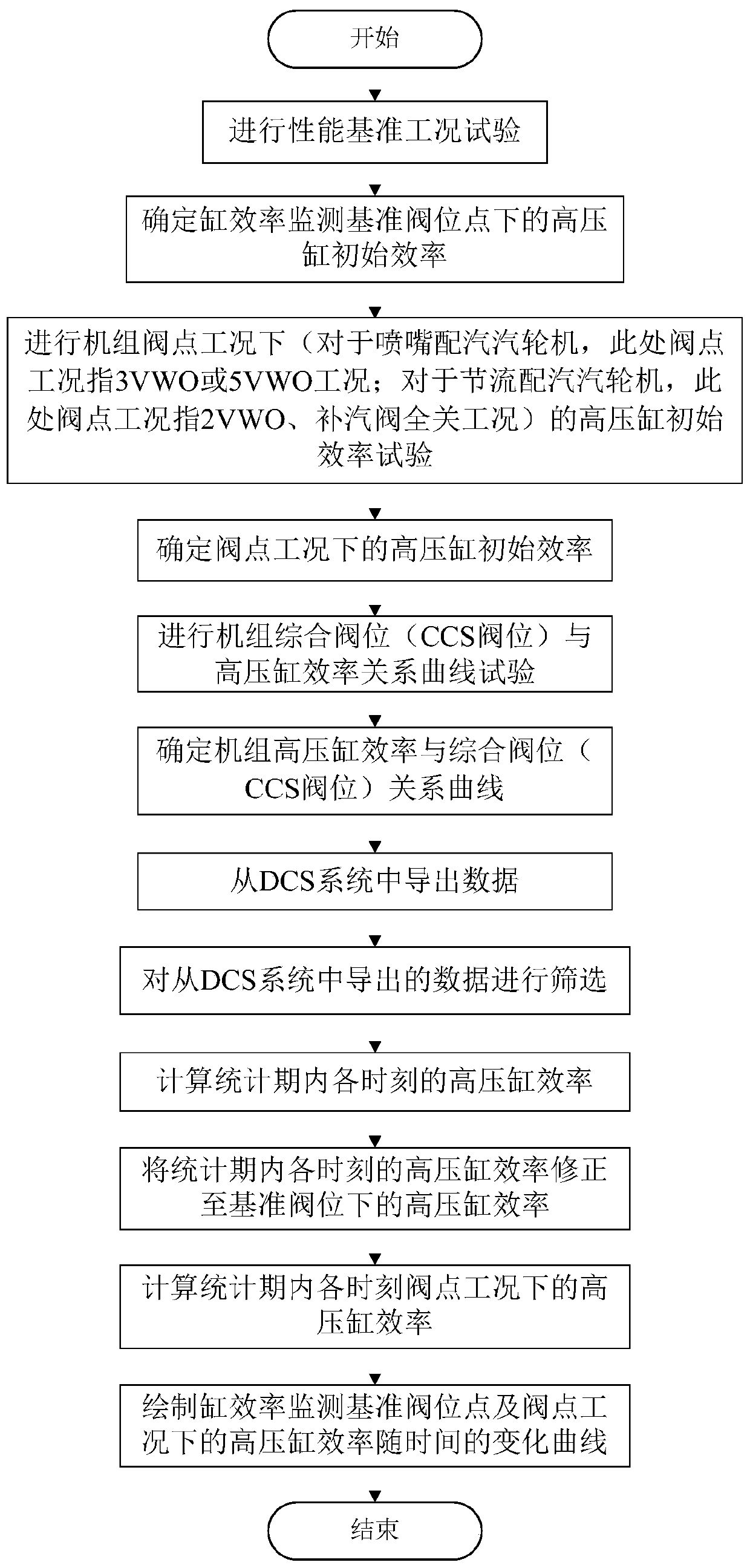

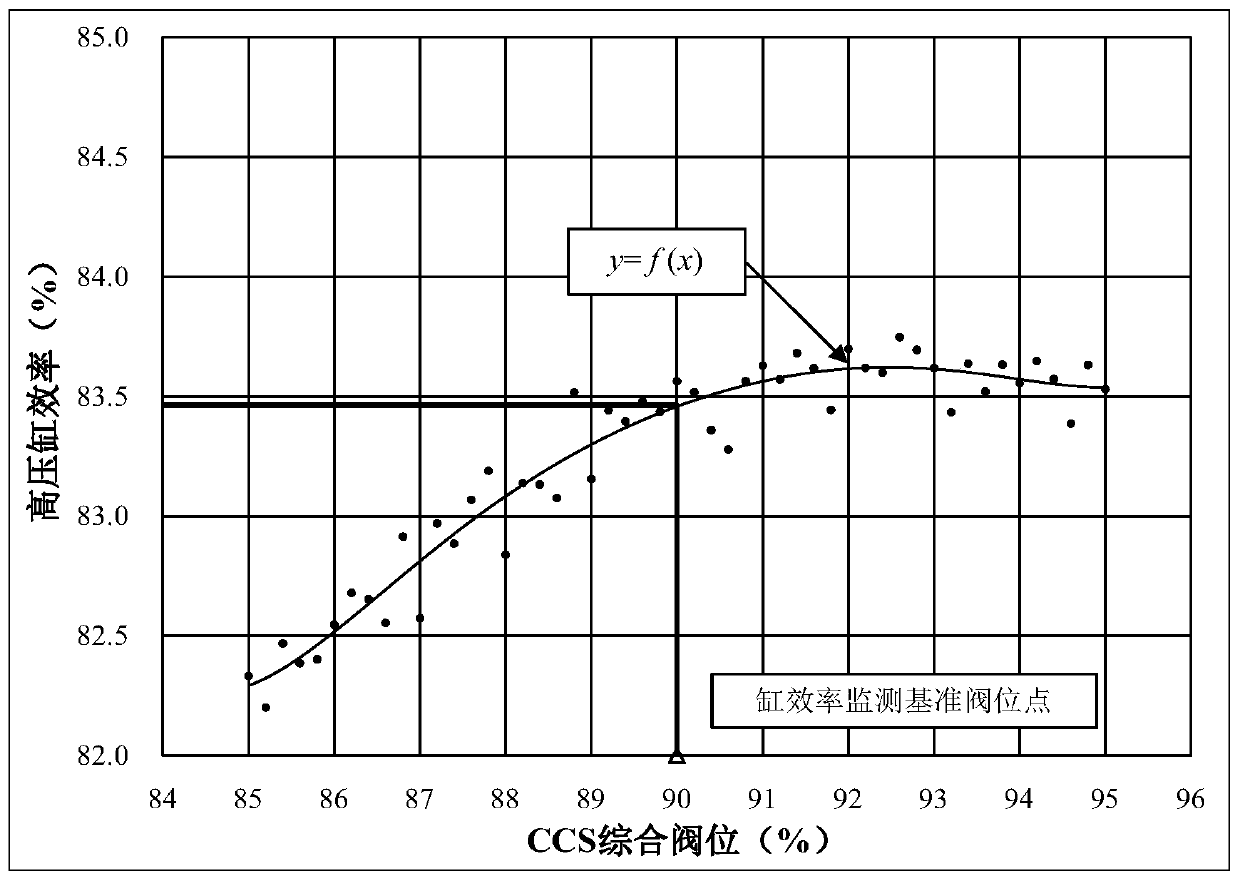

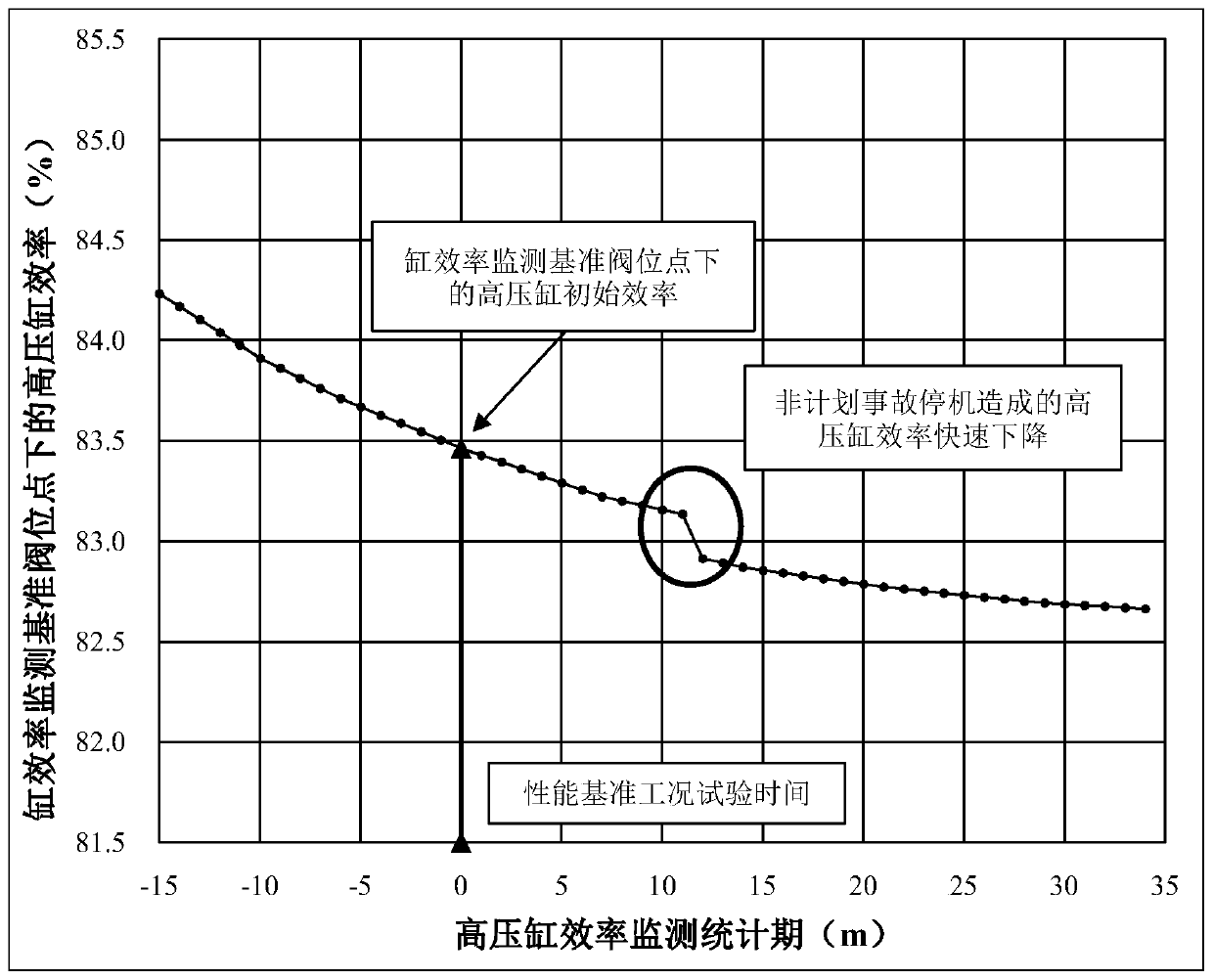

[0035] Such as figure 1 As shown, the present invention provides a valve position correction-based method for monitoring the efficiency of high-pressure cylinders throughout the life of a steam turbine, including the following steps.

[0036] 1. Carry out the performance benchmark working condition test. The test is carried out in the spring or autumn of the year. During the test, the main steam pressure, main steam temperature, high-pressure cylinder exhaust pressure, high-pressure cylinder exhaust temperature, unit comprehensive valve position (CCS valve position) and unit load are recorded. measuring point data. During the test, adjust the load of the unit to 100% of the rated load (±1.5%), adjust the main steam pressure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com