Piezoelectric micro-thruster

A thruster and piezoelectric technology, which is applied in the direction of the propulsion system of the aerospace vehicle, can solve the problems of unadjustable thrust, long response time and short life, and achieve the effect of good sealing performance, fast response speed and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

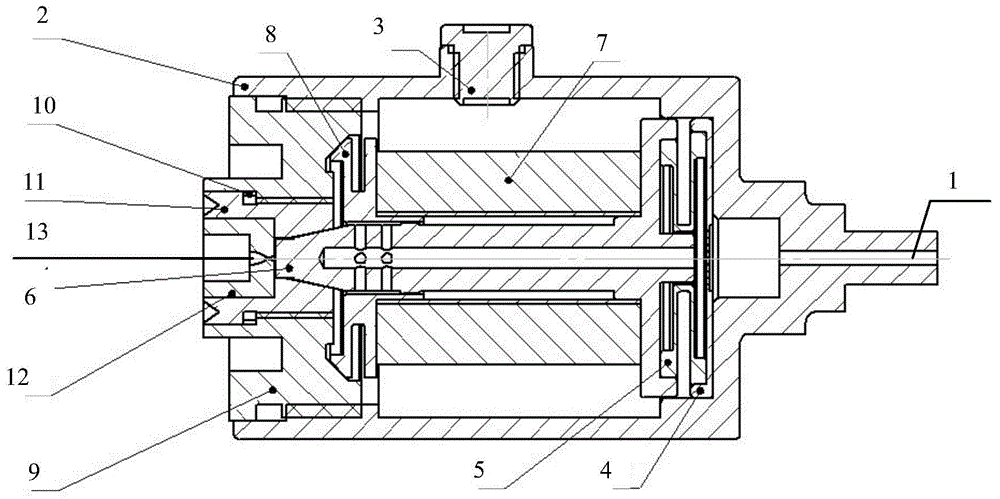

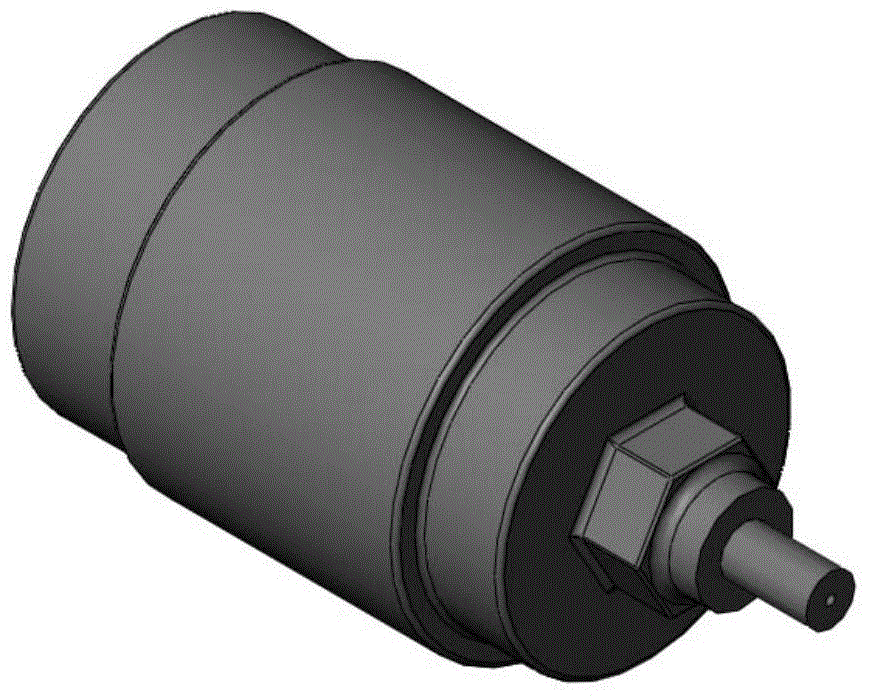

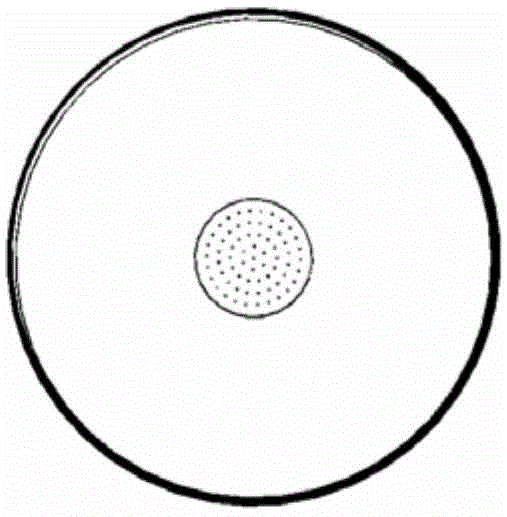

[0027] The piezoelectric micro thruster of the present invention will be further described below in conjunction with the working principle and the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention.

[0028] The piezoelectric drive device utilizes the deformation characteristics of the piezoelectric stack under the action of an electric field, and combines the action of the return spring and the washer spring to push the T-shaped valve core to move to realize the switch function of the thruster. The working principle of the piezoelectric micro thruster of the present invention is as follows: under a given voltage, the piezoelectric stack will increase the micro scale along the axial direction of the micro thruster, push the valve core to move towards the air inlet, and squeeze the reset spring and The gasket spring deforms it. At this ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com