Rotary engine

A rotary engine, a new type of technology, applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problems of complex structure, large heat loss, short maintenance cycle, etc., and achieve simple manufacturing process, sufficient combustion, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

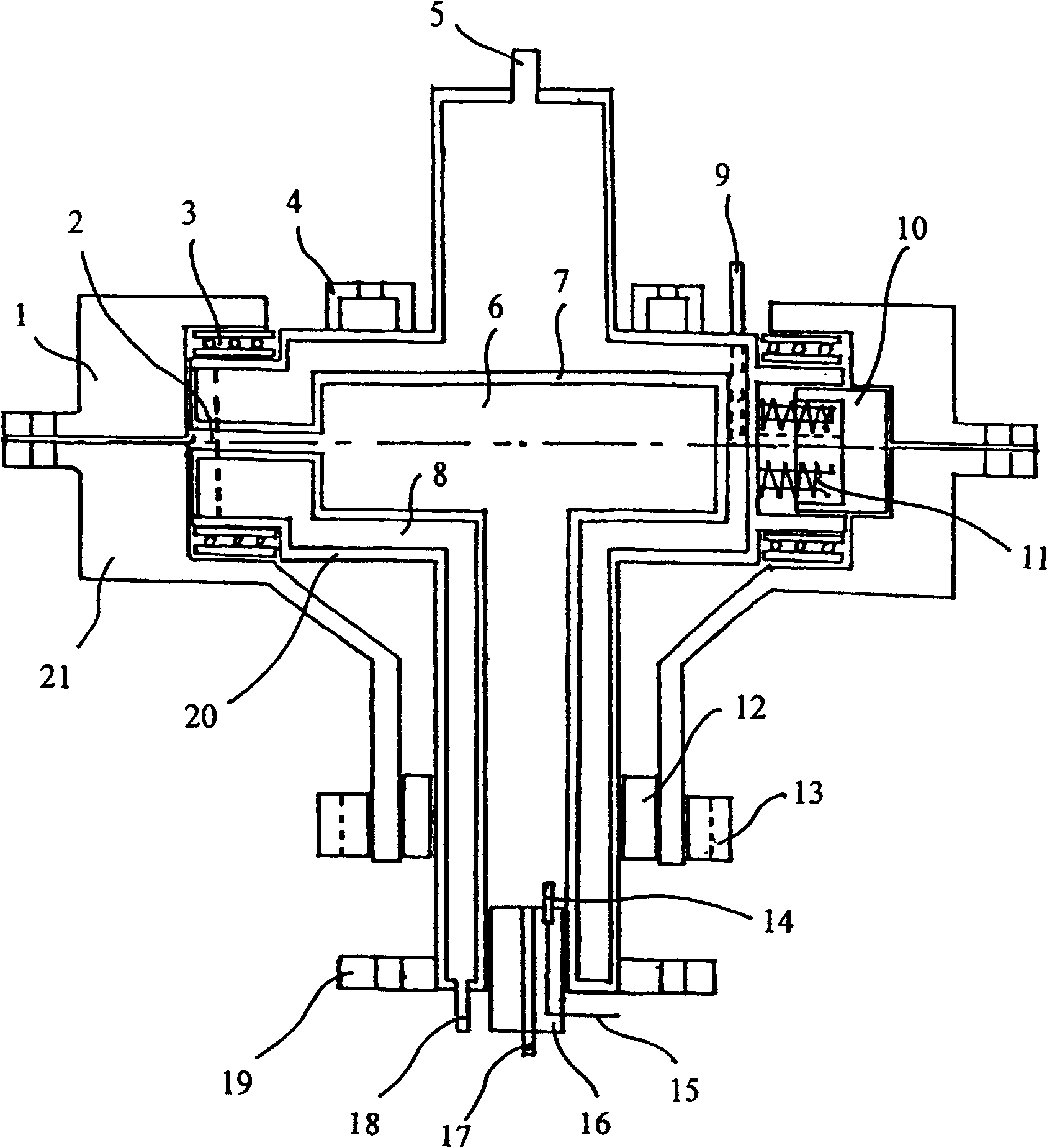

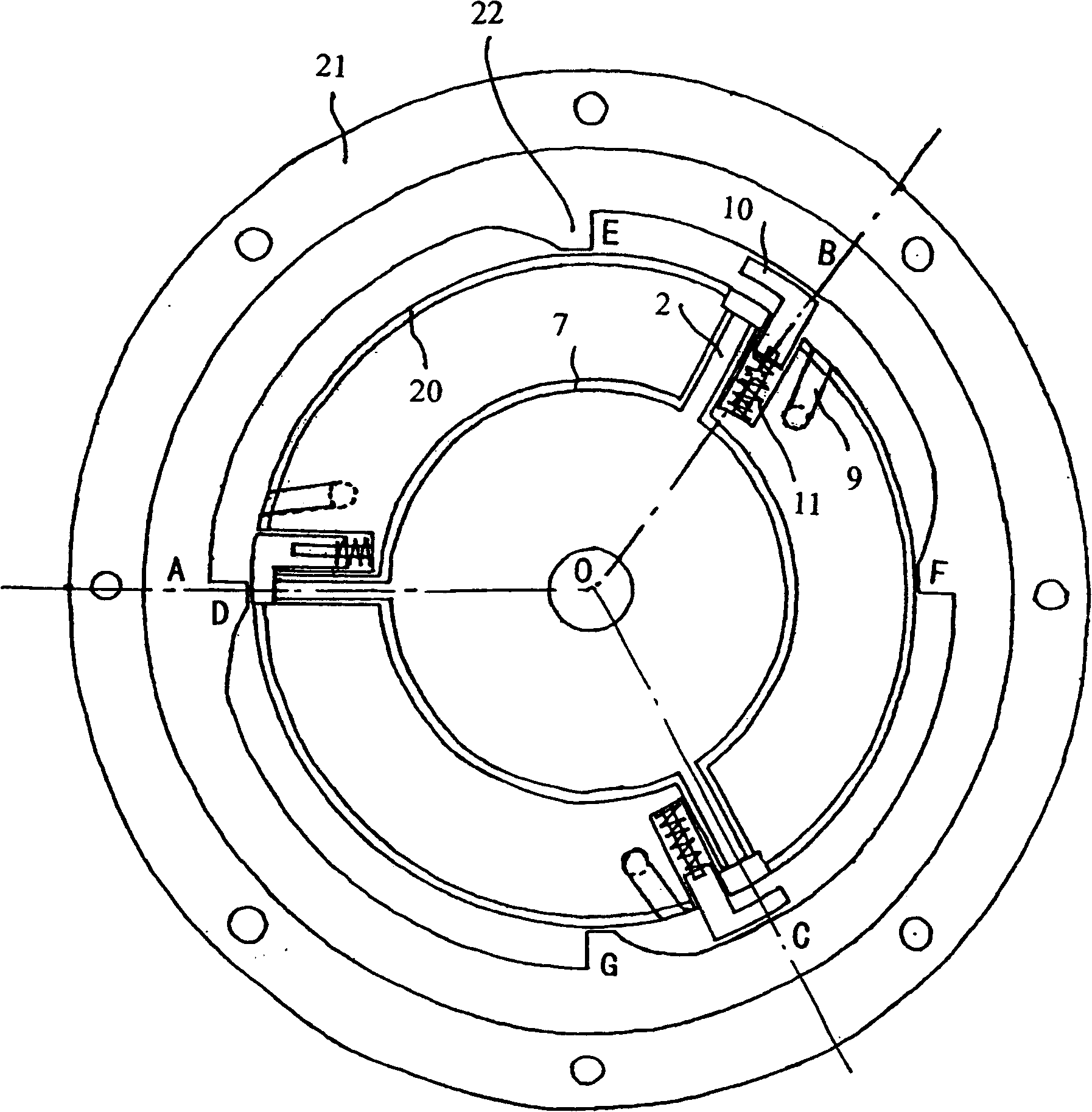

[0014] As shown in Figures 1 and 2, the new rotary engine consists of an energy conversion device and a power output device.

[0015] The energy conversion device is a fixed two-layer structure, which is supported and fixed by the upper bracket 4 and the lower bracket 19. The inner layer is a dish-shaped burner 7 formed by welding metal pipes. The combustion chamber 6 of the burner has a free space for thermal expansion. Complete combustion, the burner is equipped with a sealing plug 16 at the fuel inlet, the fuel injection pipe 17 and the spark plug 14 are installed in the sealing plug, the mixture of fuel and air injected by the fuel injection pipe 17 is already a mixture of high-pressure fuel and air, and the spark plug 14 passes through The wire 15 is connected to the external power supply, and the burner 7 has three gas injection pipes 2 (A, B, C) uniformly distributed along the circumference, and the cooler 20 surrounded by the burner 7 is provided with a gas injection po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com