Split-type supercharger for a turbocharged engine

A turbocharger and engine technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as increased manufacturing costs and after-sales maintenance costs, adverse effects on vehicle driving comfort, and complex structures. The effect of improving NVH performance, solving the problem of outgassing noise, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

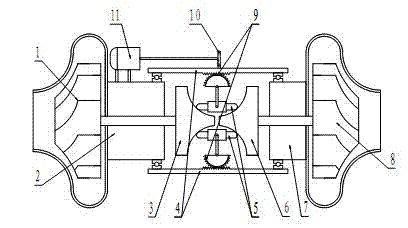

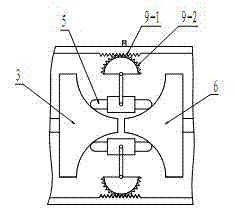

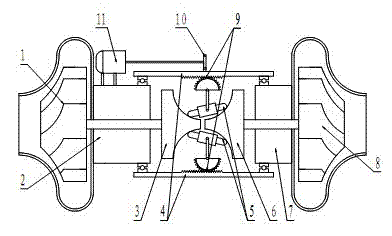

[0020] See Figure 1, figure 2 , the present invention consists of a compressor 1, a turbine 8 and an intermediate body, the intermediate body is a split structure, which includes a compressor end intermediate body 2, a turbine end intermediate body 7, an intermediate body shell 4, a roller turntable stepless The transmission and the drive motor 11, the compressor end intermediate body 2 and the turbine end intermediate body 7 are connected through the intermediate body housing 4, and the intermediate body housing 4 is connected with the drive motor 11 through the gear meshing mechanism 10, and the intermediate body housing The inner cavity of the body 4 is provided with a roller turntable continuously variable transmission; the roller turntable continuously variable transmission is composed of an input turntable 6, an output turntable 3, a power roller 5 and a worm gear mechanism 9, and the input turntable 6 is fixed on the turbine 8 on the rotating shaft, the output rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com