Lathe sliding box

A technology of sliding crate and lathe, which is applied in the field of lathe crate and lathe, and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

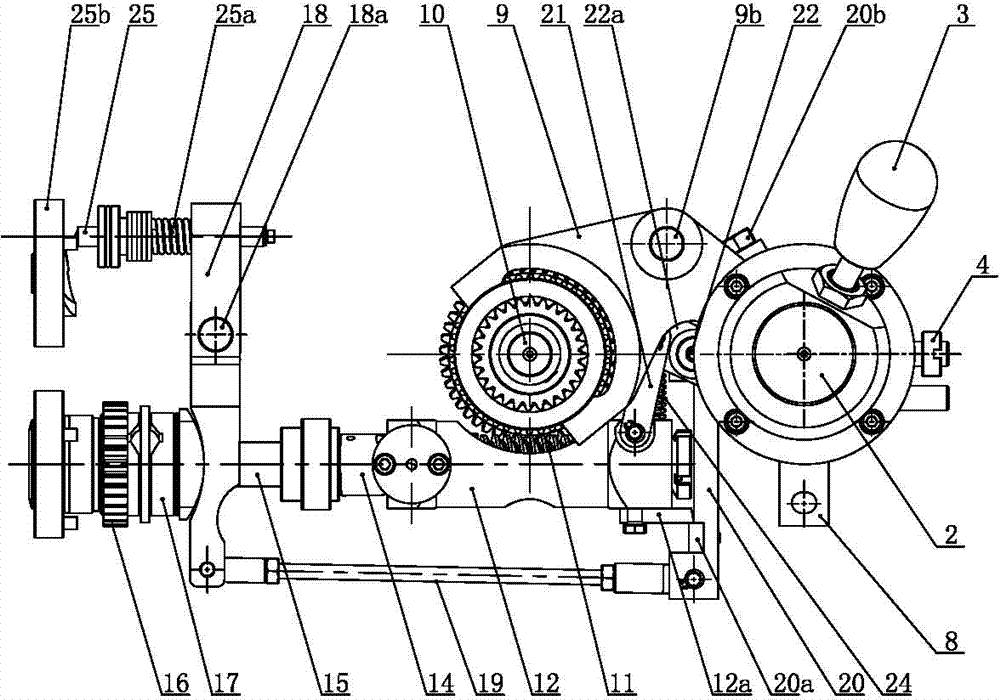

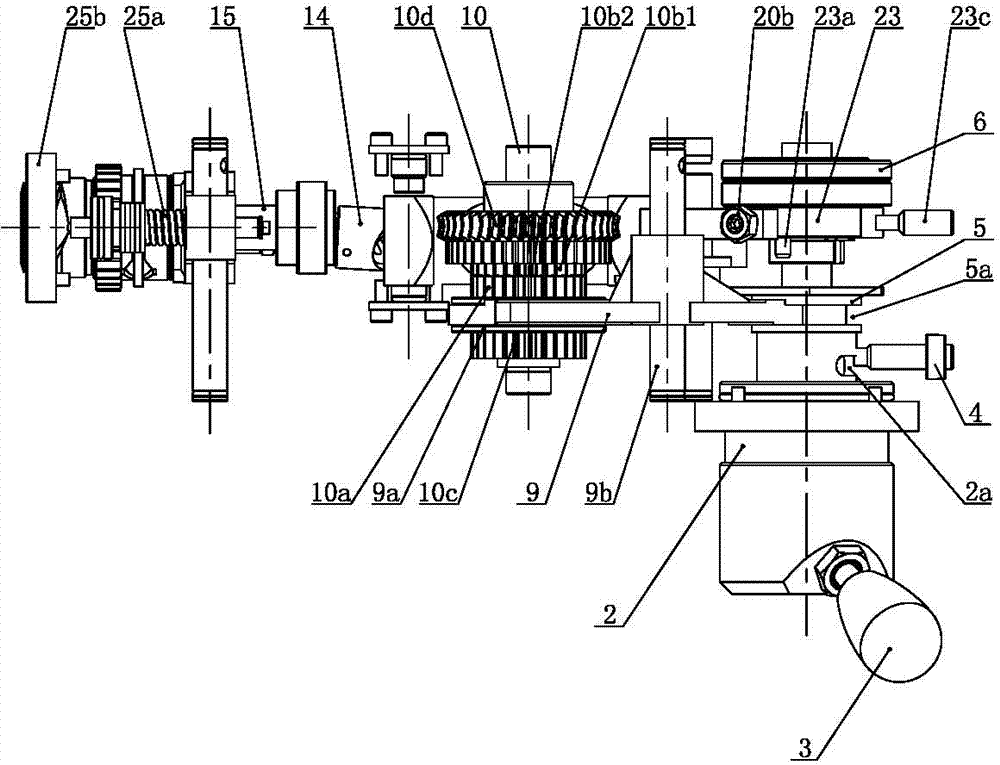

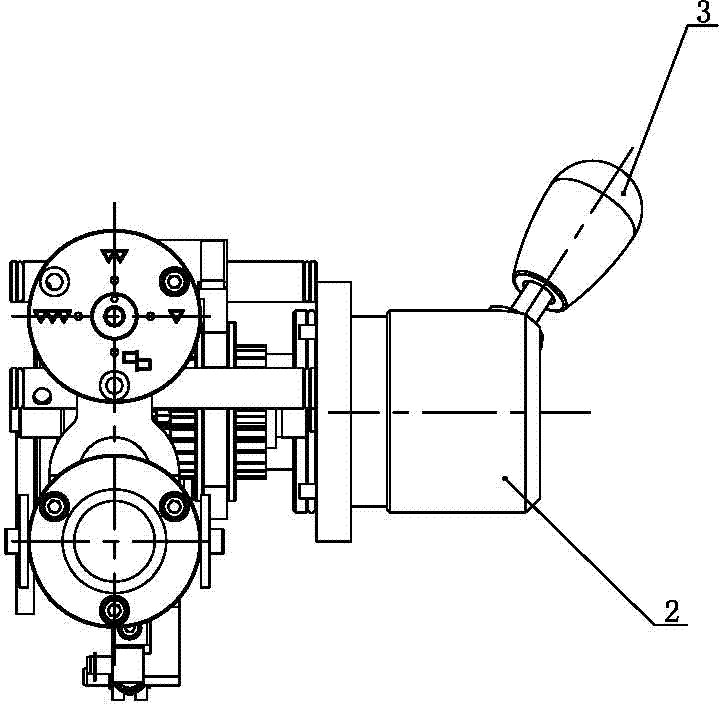

[0056] Such as Figure 1 to Figure 10 As shown, the lathe slide box of the present invention includes a box body, on which a wheel shaft 10 is fixedly installed, and an intermediate gear 10a is fixedly installed in the middle part of the wheel shaft 10, and the front and rear sides of the intermediate gear 10a are equipped with longitudinal tool gears 10c and transverse The cutting gear 10b1, the transverse cutting gear 10b1 and the longitudinal cutting gear 10c can rotate on the axle 10 respectively, and the intermediate gear 10a, the horizontal cutting gear 10b1 and the longitudinal cutting gear 10c can be meshed with the inner ring gear 9a respectively.

[0057] The lathe slide box also includes a joystick shaft 2, the middle part of the joystick shaft 2 is located in the joystick seat 1 and can rotate or slide back and forth in the joystick seat 1, the axis of the joystick shaft 2 is parallel to the axis of the wheel shaft 10, One end of the joystick shaft 2 is installed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com