Patents

Literature

309results about How to "Play a locking role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

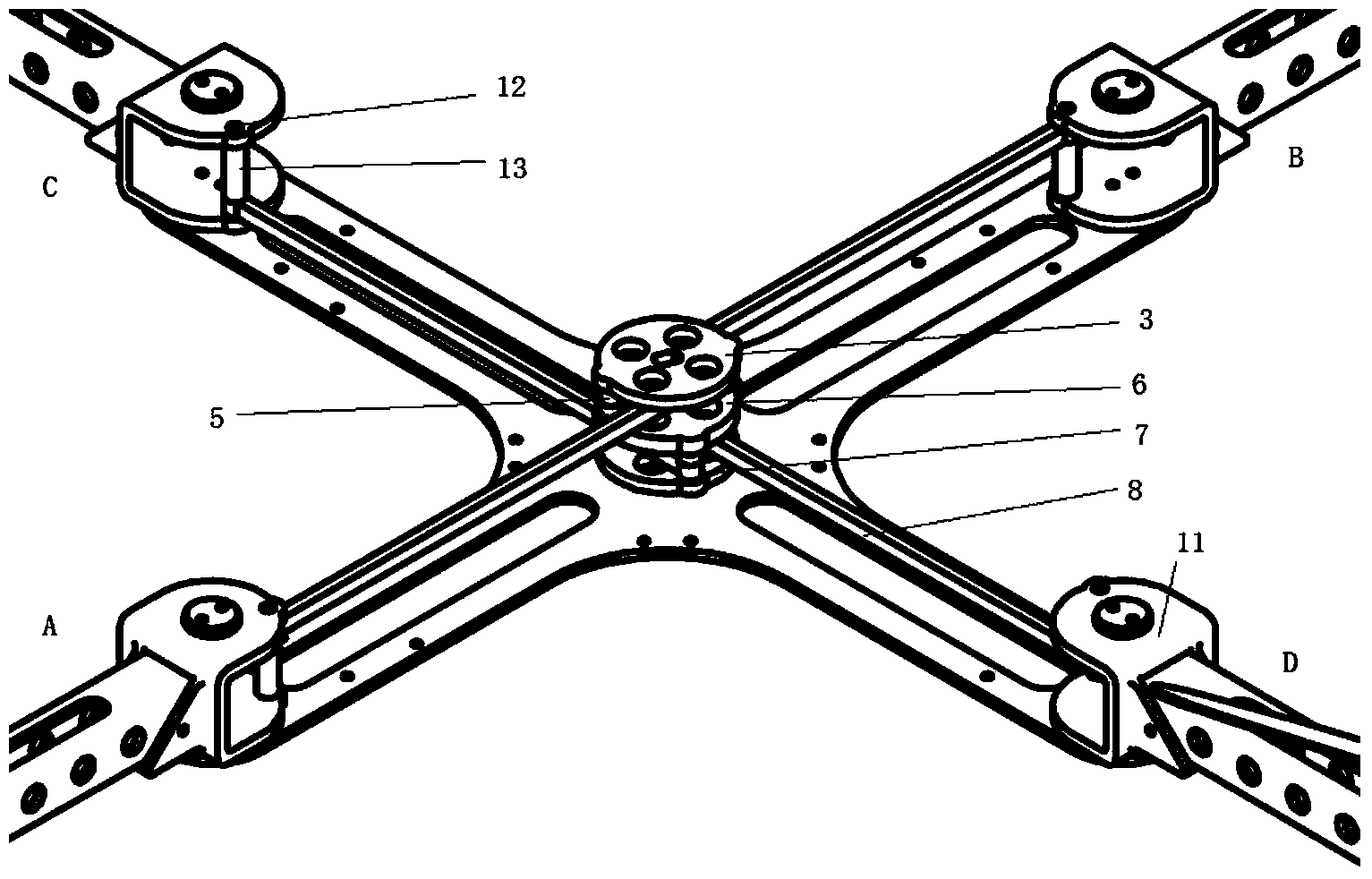

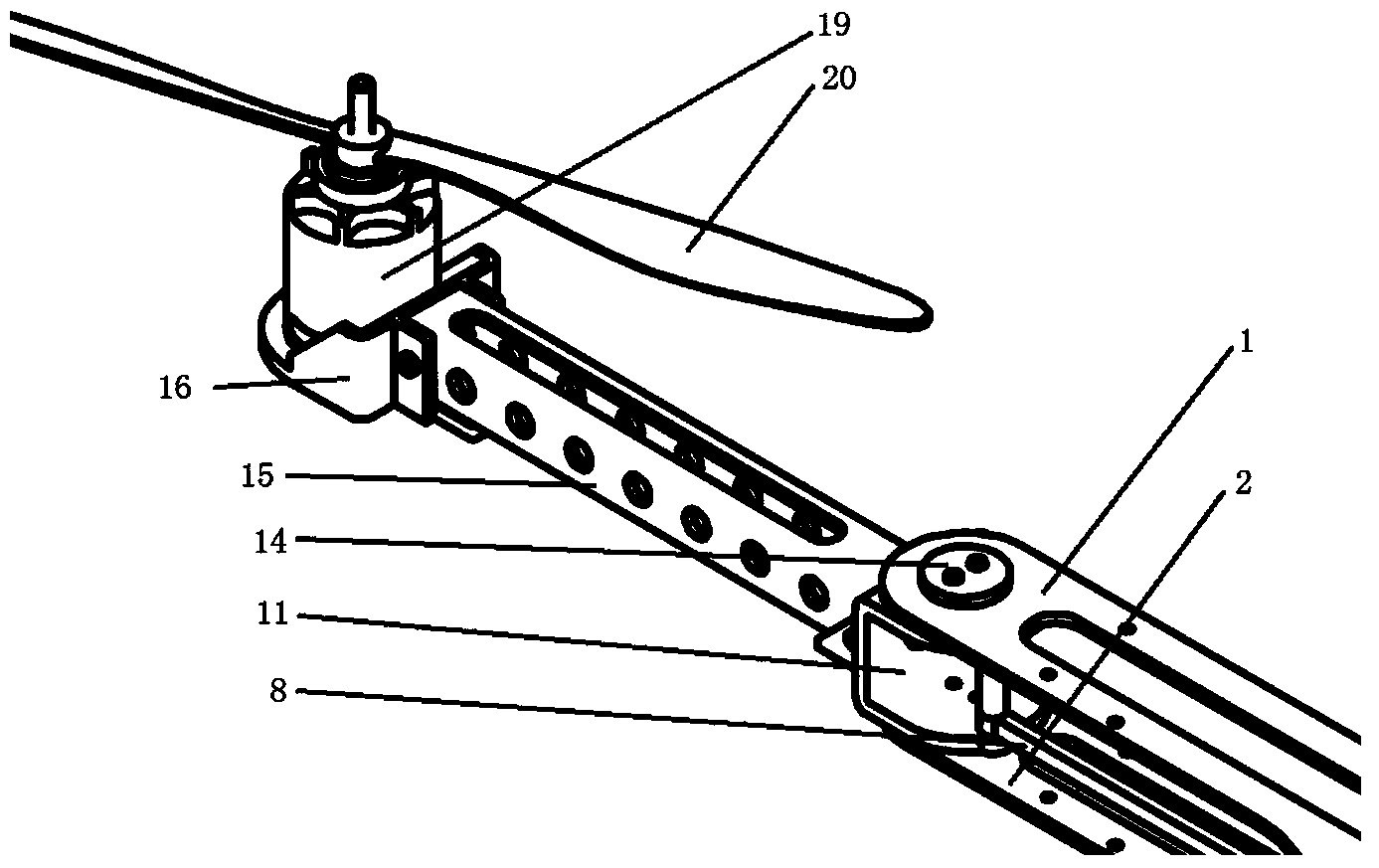

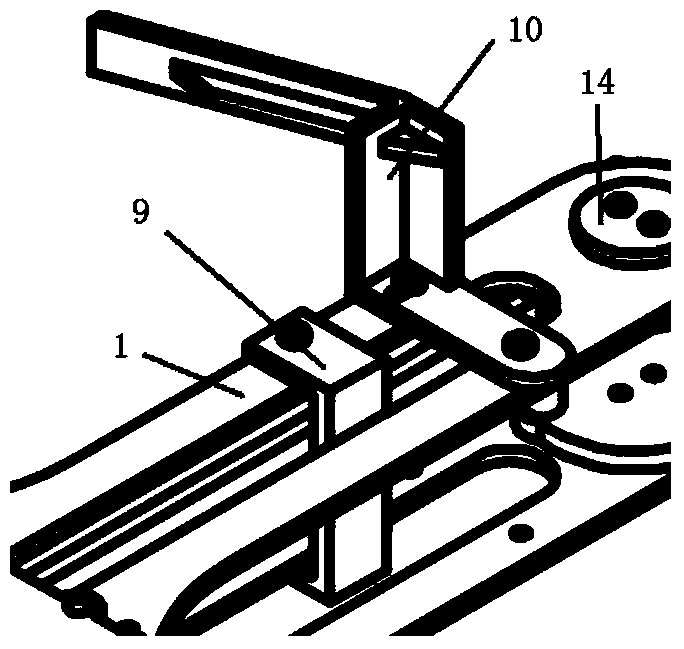

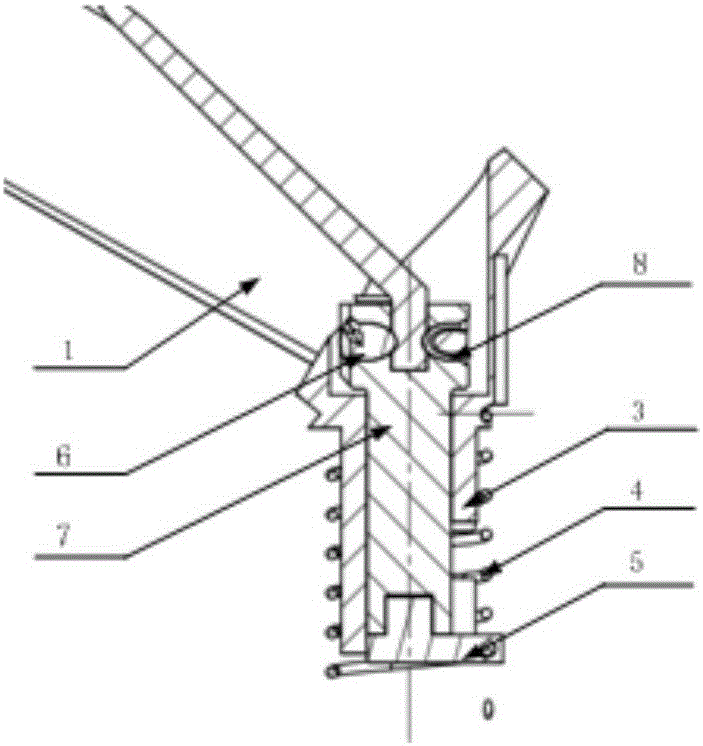

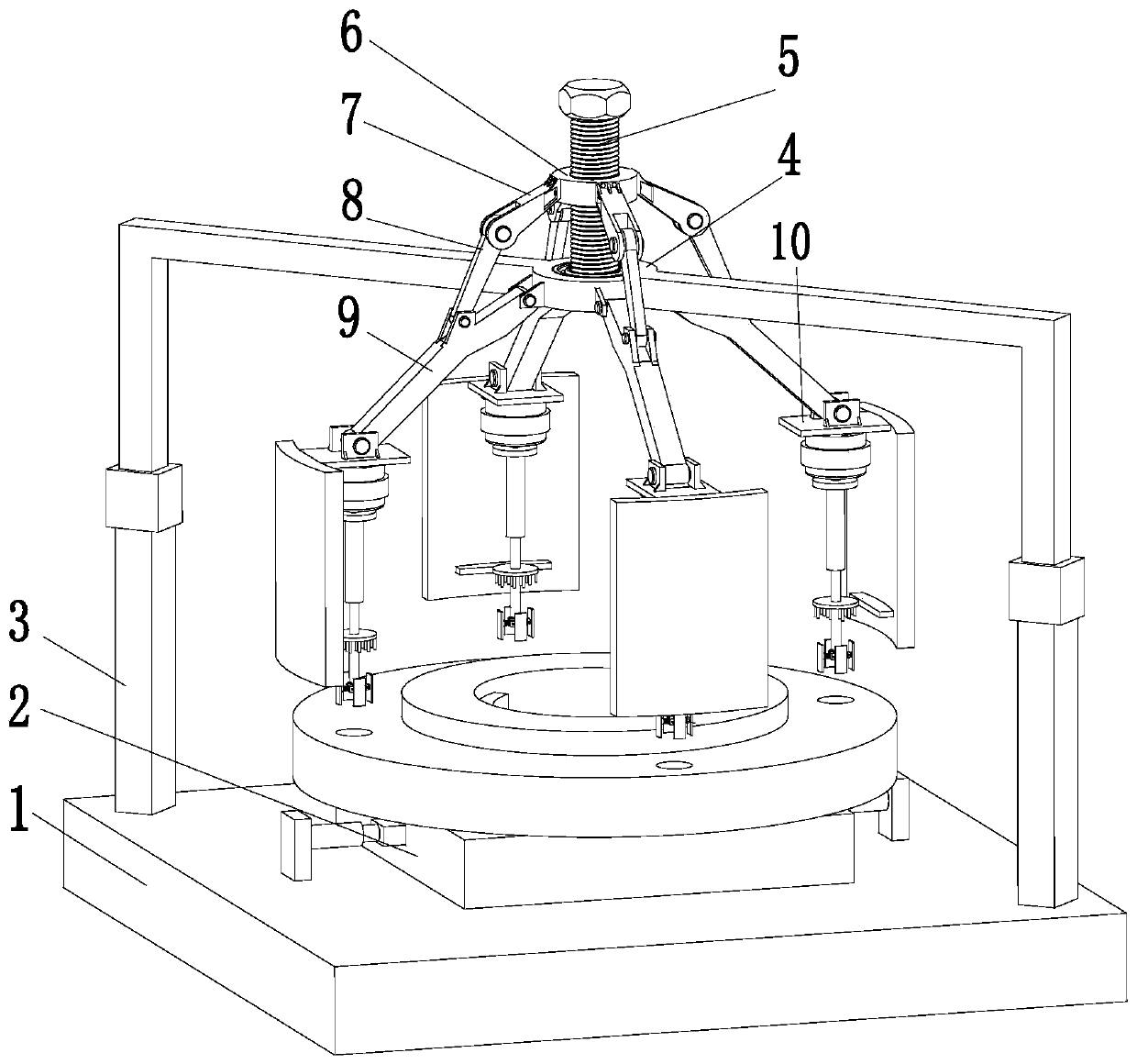

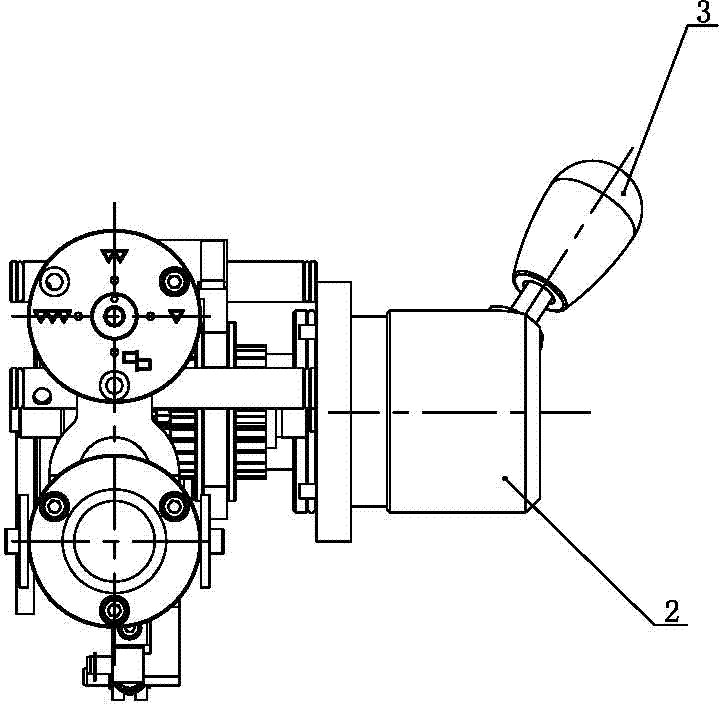

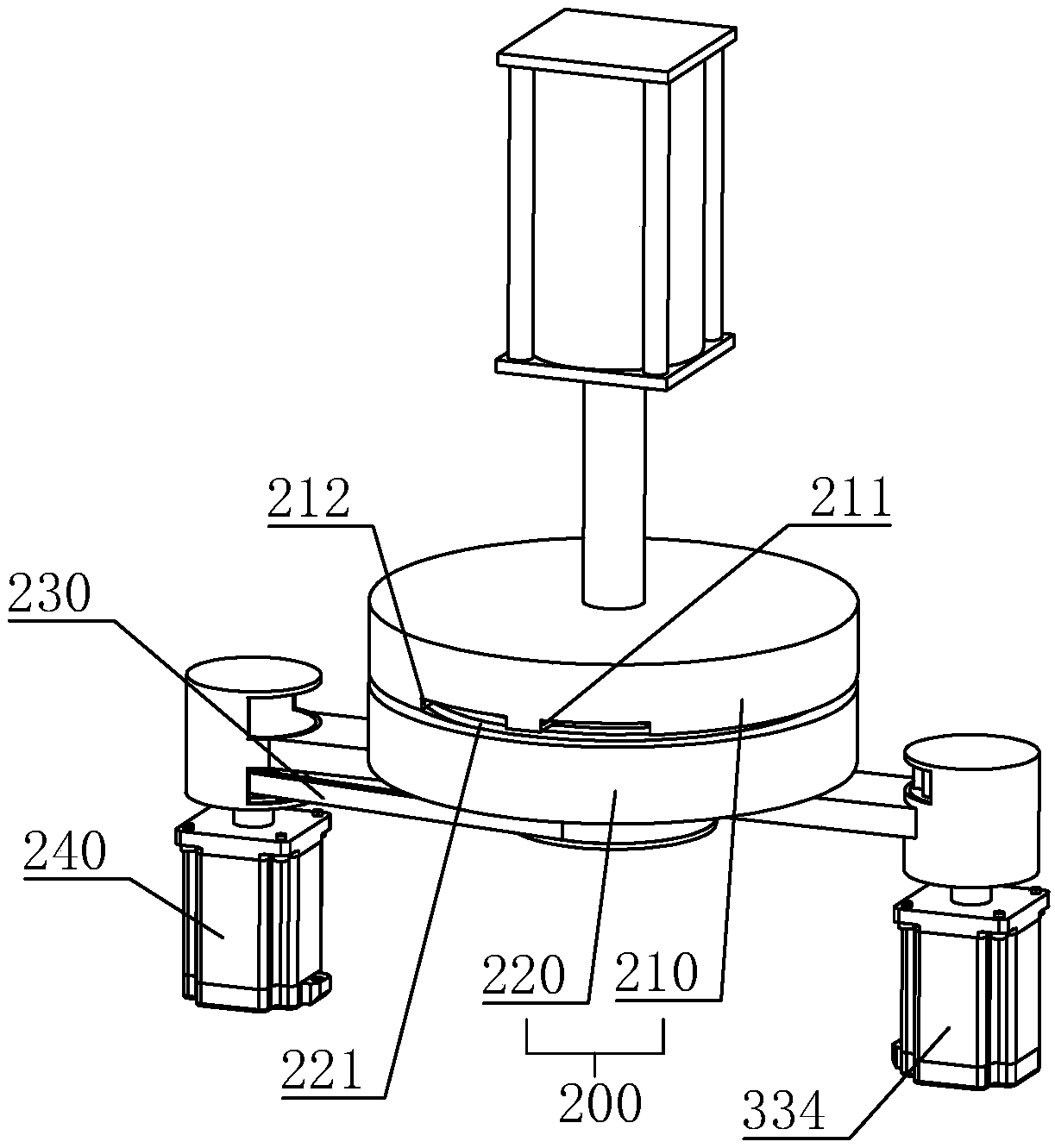

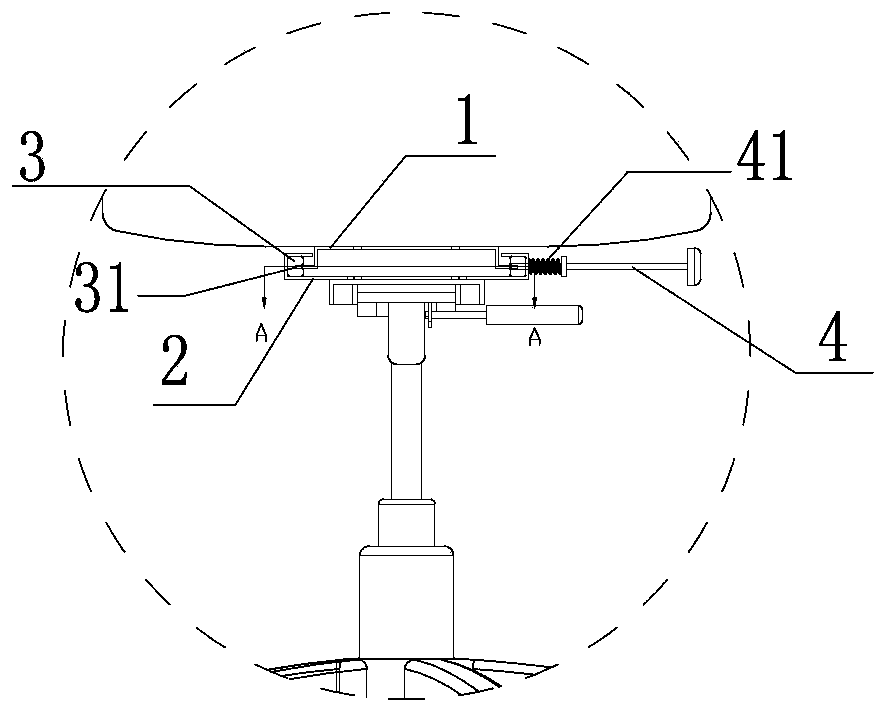

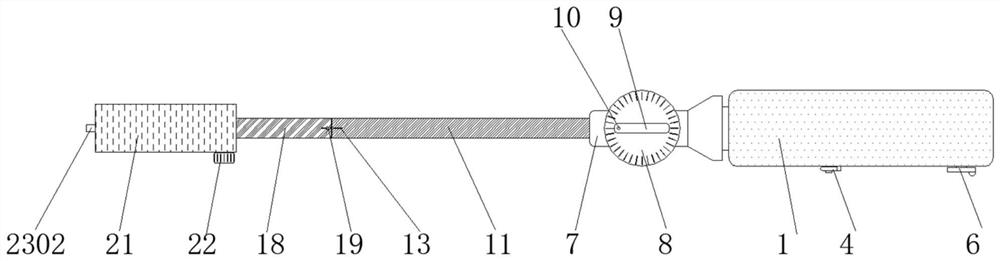

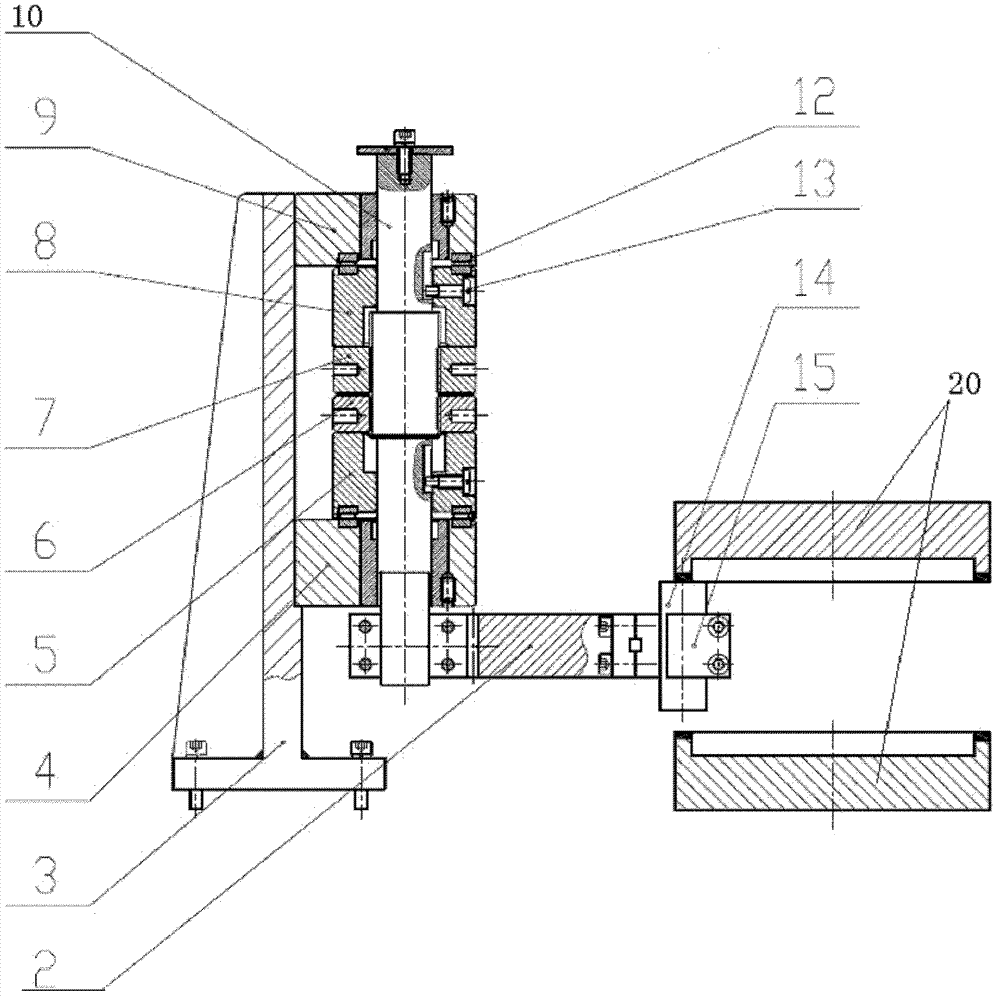

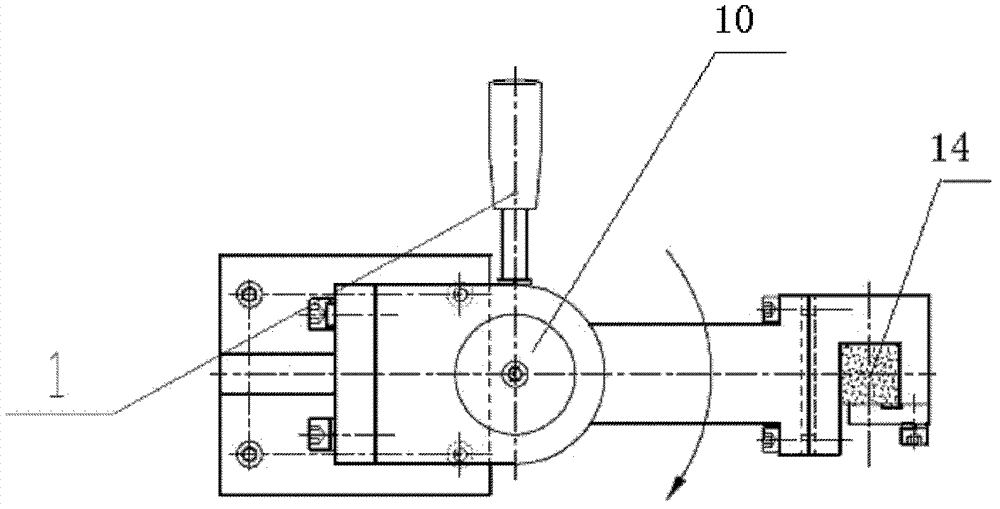

Four-rotor aircraft rack with capacity of automatic folding and spreading

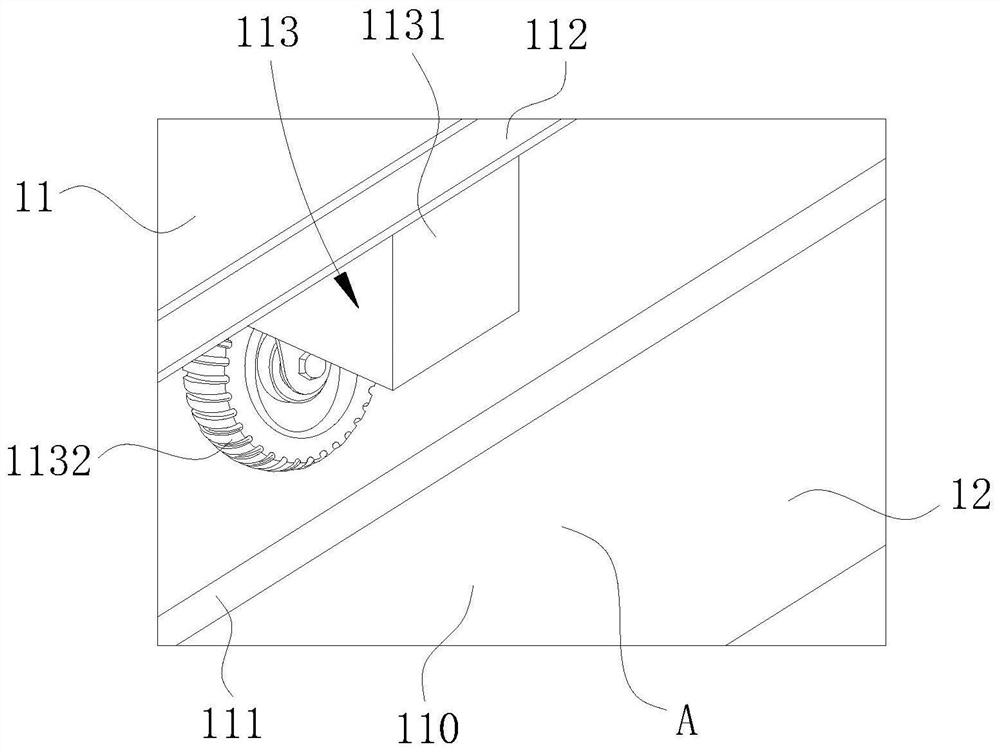

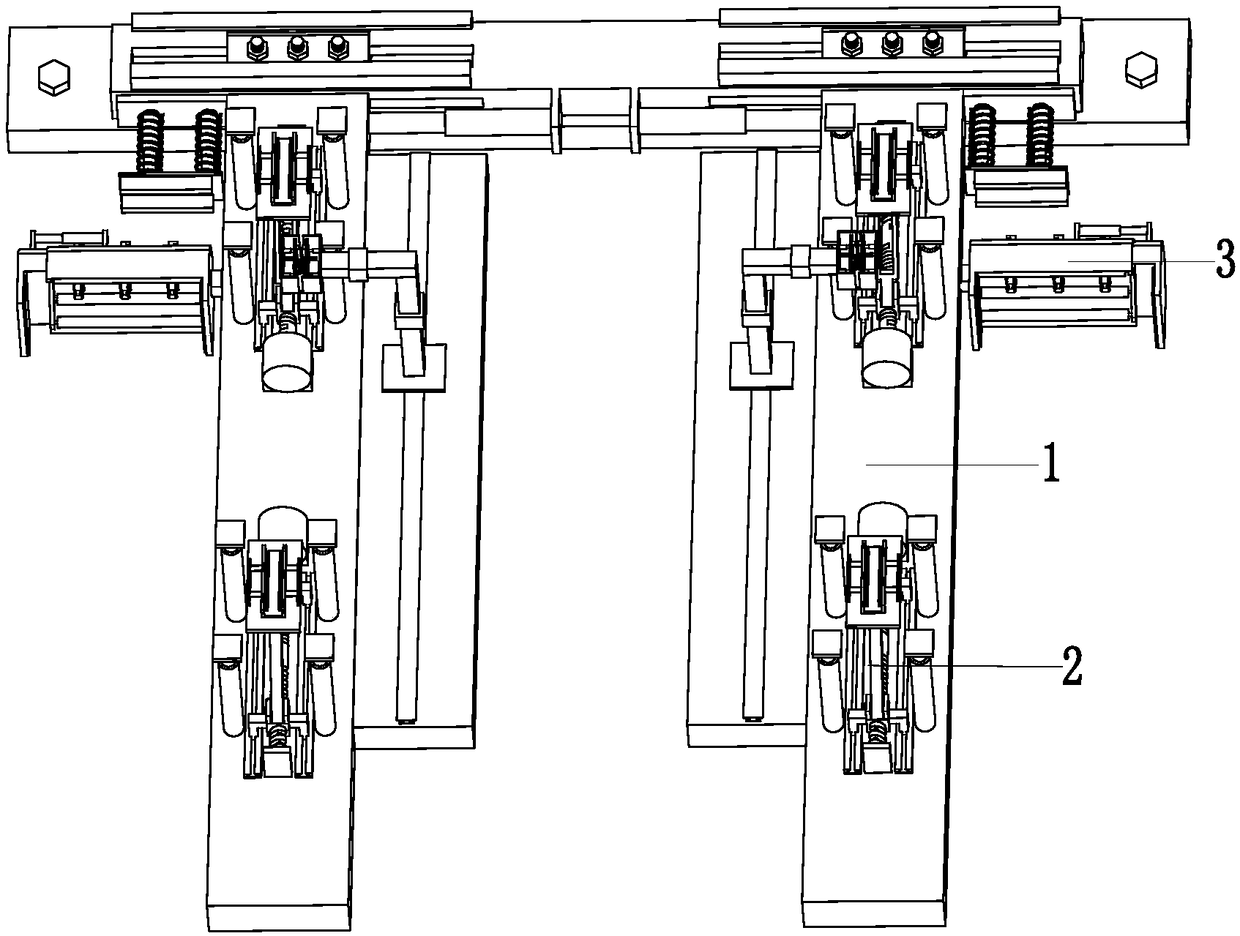

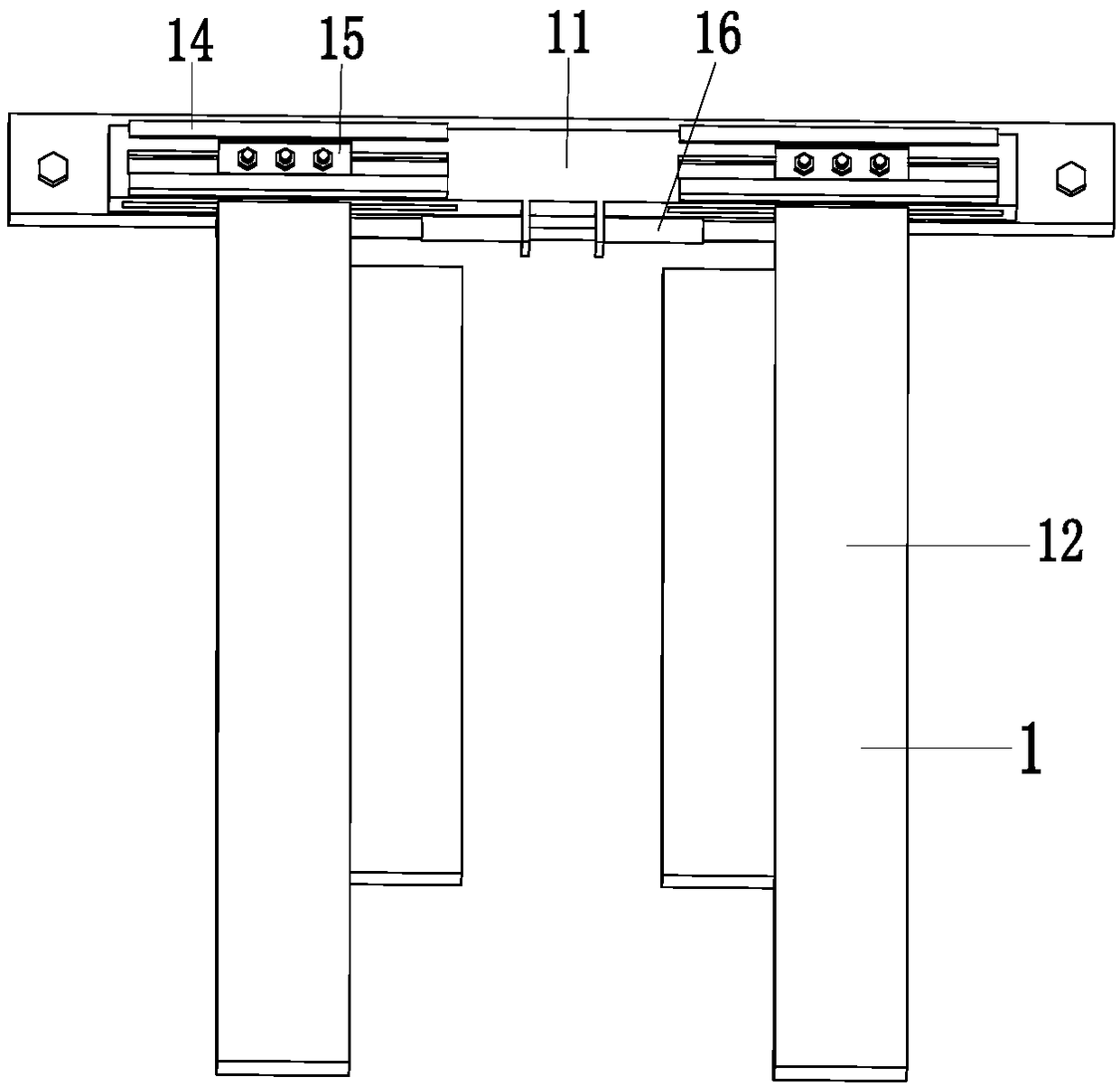

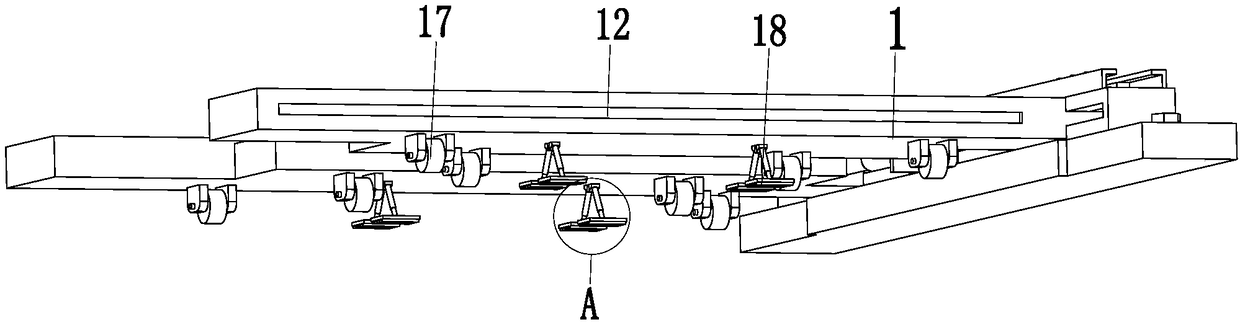

The invention acquires design inspiration from a mechanical aperture tuning mechanism of a camera lens, and designs an automatic folding rack comprising a central worm and gear speed reduction motor, an upper center plate, a lower center plate, a crank, connecting rods, support arms and rotor baffles. Therefore, a four-rotor aircraft can be folded to a compact square structure under the driving of the motor distributed in the center of the rack, end parts of adjacent rotors are close to the peak of the square as far as possible, positions of the rotors are relatively fixed, and accordingly, the geometric dimensioning of the four-axis aircraft is greatly reduced; and the four-rotor support arms can be spread automatically when the central motor rotates reversely.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

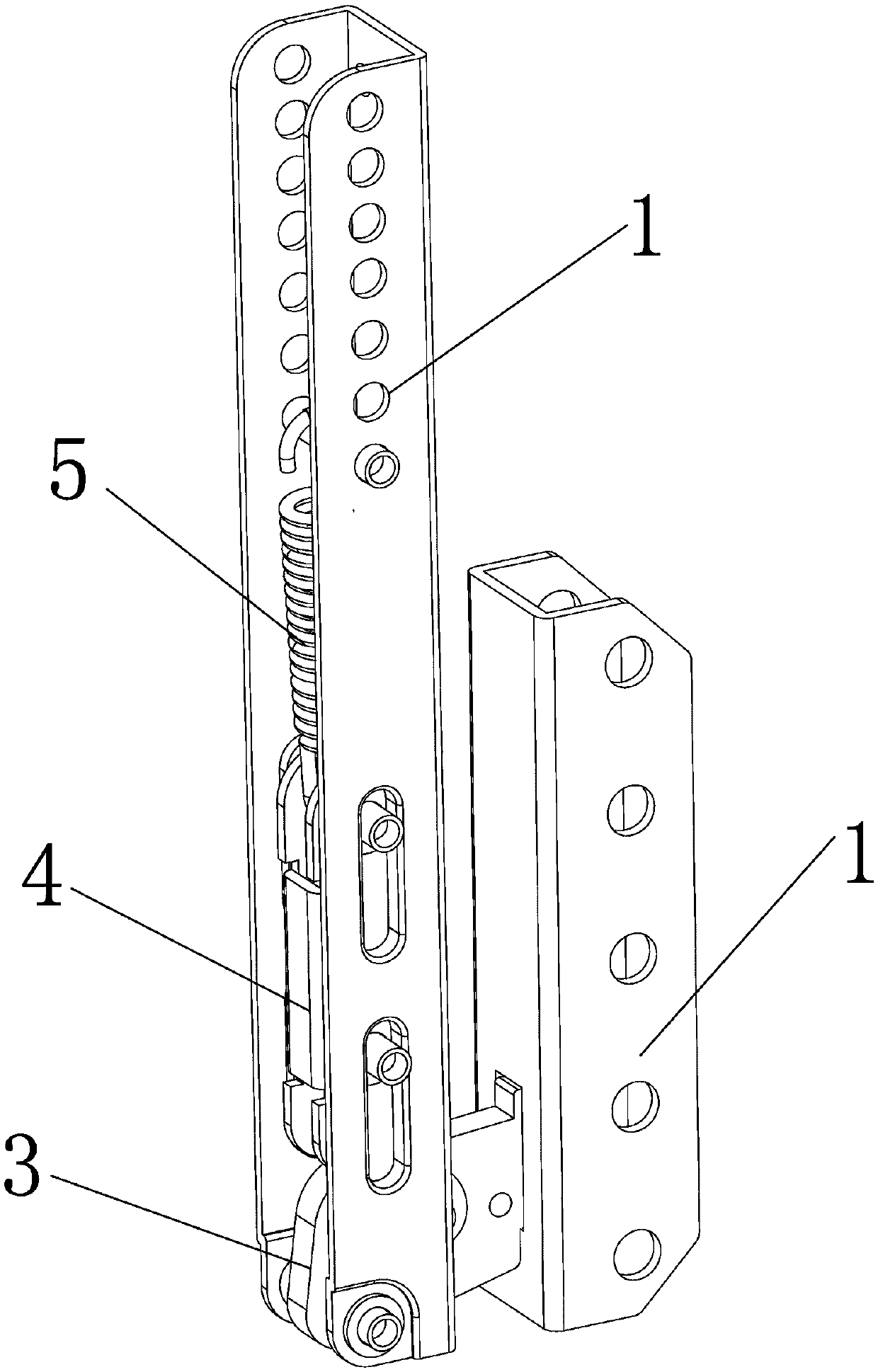

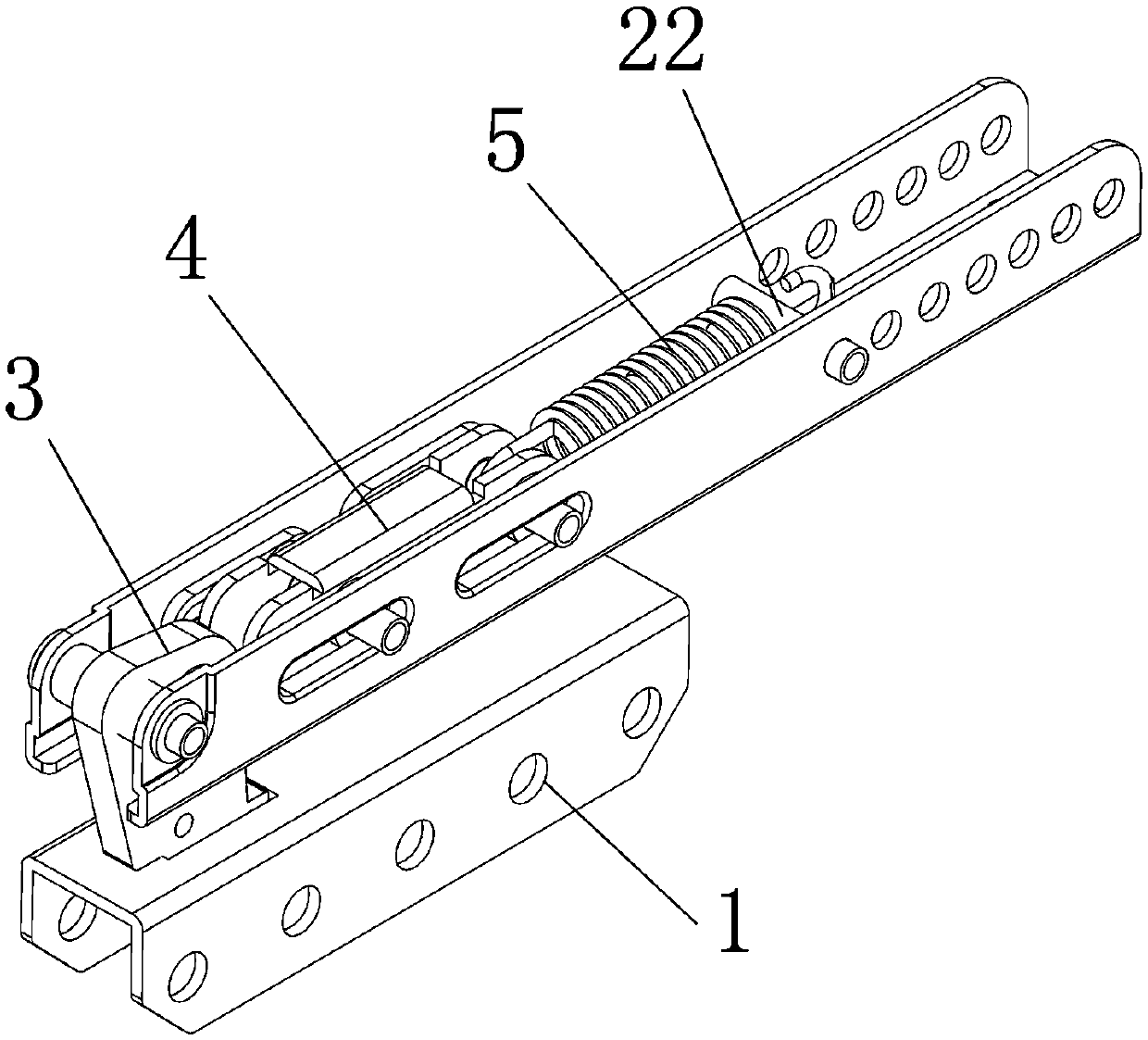

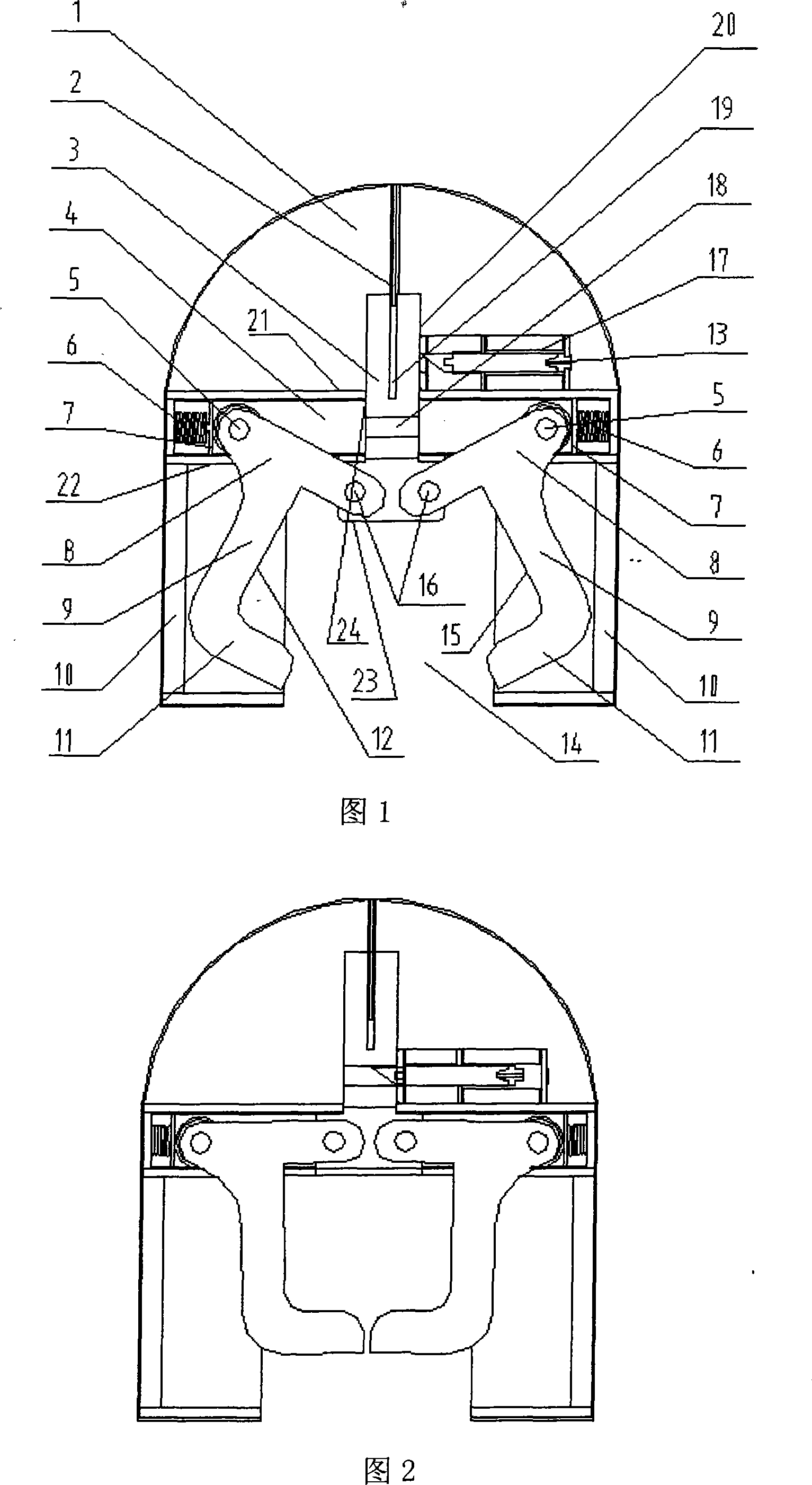

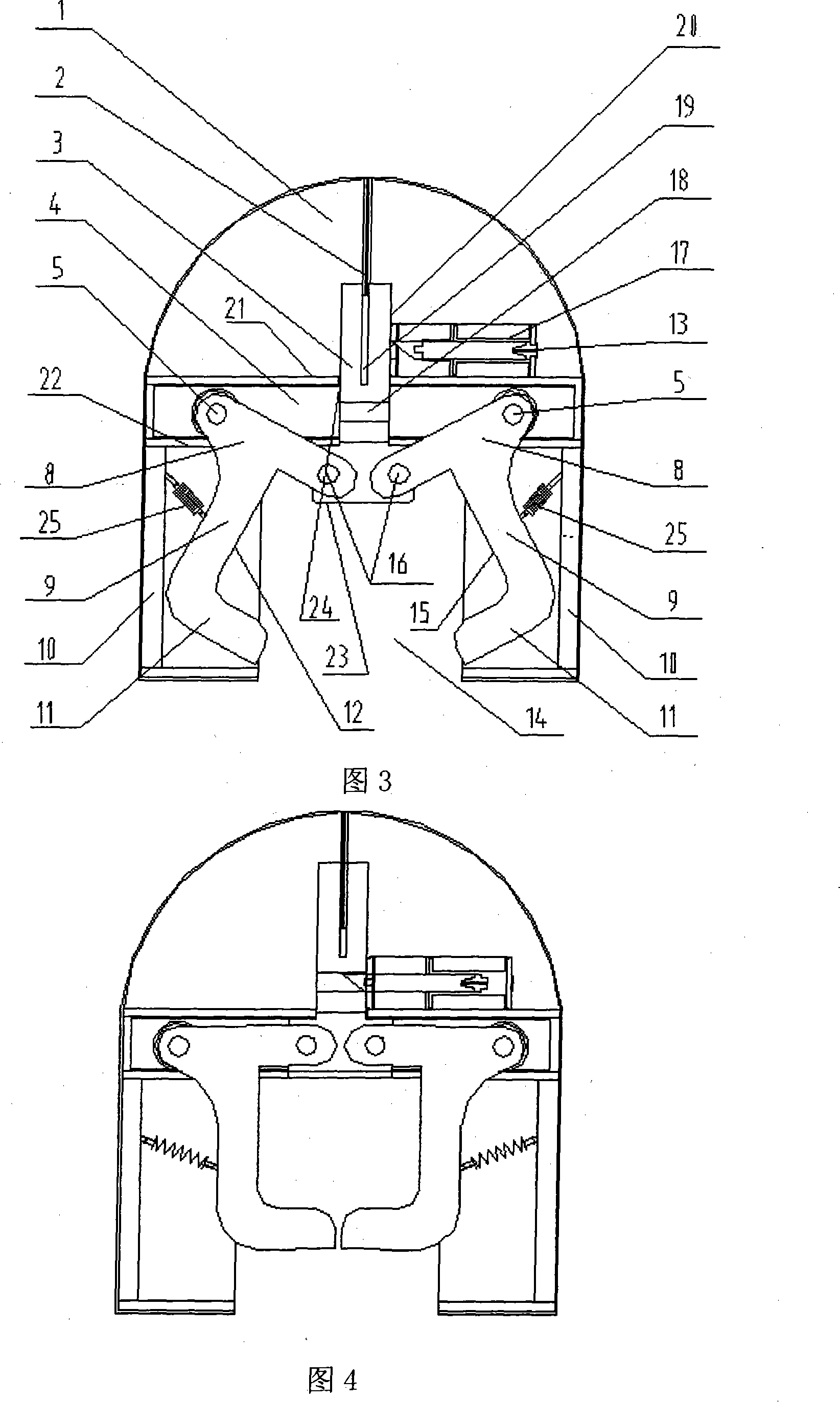

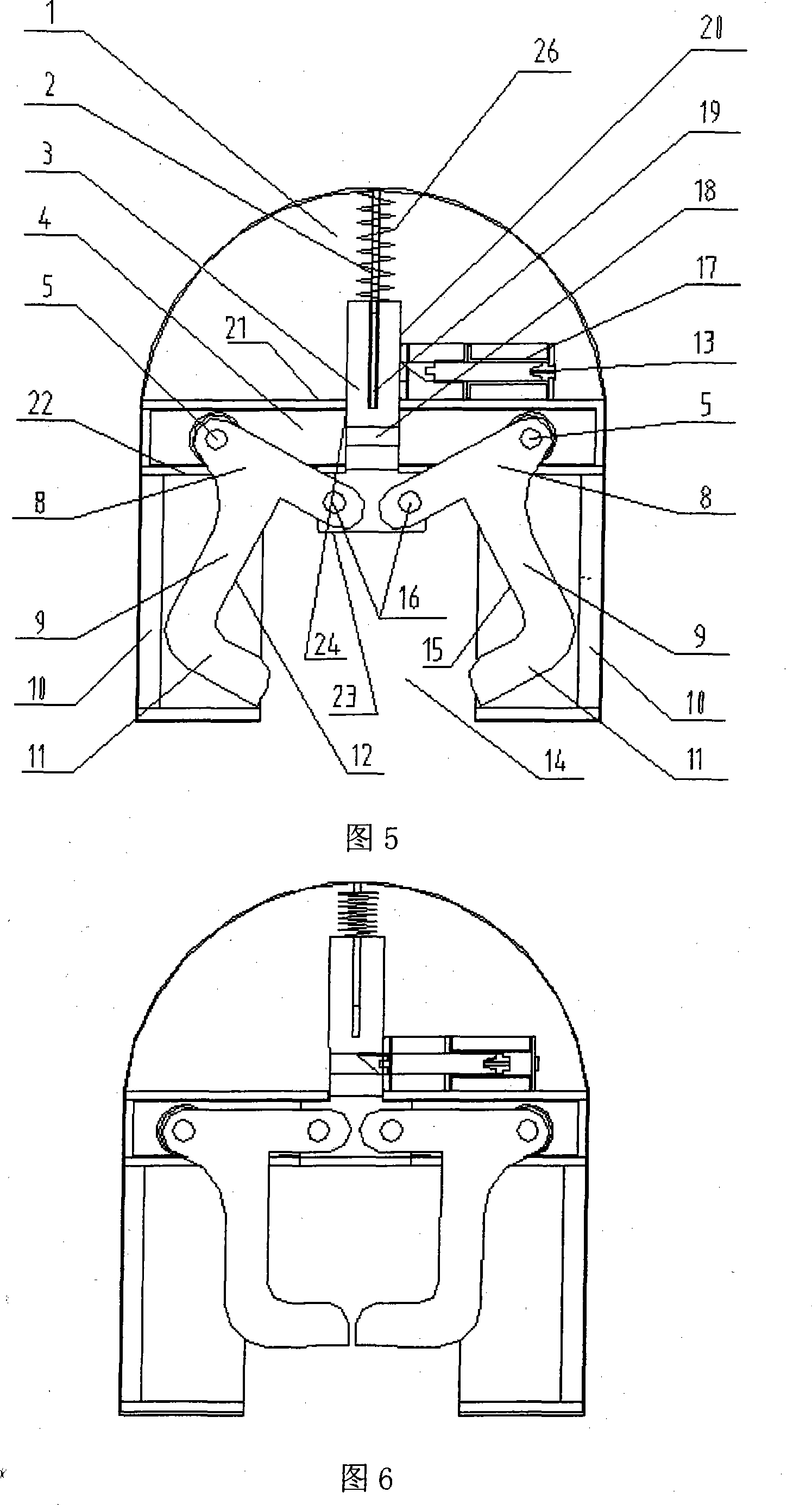

Oven hinge

InactiveCN105507706APlay a locking roleSimple structureWing accessoriesPin hingesShape changeEngineering

An oven hinge comprises a base fixed to a box body, and a support fixed to a door plate. A hinge arm is movably hinged to and installed on the head of the support. A buckle is arranged on the hinge arm and fixedly connected with the base. The oven hinge is characterized in that a containing groove is formed in the support, a pull arm is installed in the containing groove, a tension spring is arranged on the tail section of the pull arm and connected with a limiting nail on the tail section of the support, a limiting pin is arranged on the head of the pull arm and penetrates through and is inserted in a guide groove in the hinge arm, and a guide device is arranged between the pull arm and the support and conducts limiting so that the pull arm can only slide relative to the support in parallel in the containing groove. The oven hinge has the advantages that an oven door can stop at any angle when opened or closed, and the stop angle can be changed through the shape change of the unique kidney-shaped guide groove; when the oven door is completely closed or opened, the limiting pin or a wheel slides into a door closing groove part or a door opening groove part so that the oven door can be blocked.

Owner:FOSHAN SHUNDE NUOWEI ELECTRIC CO LTD

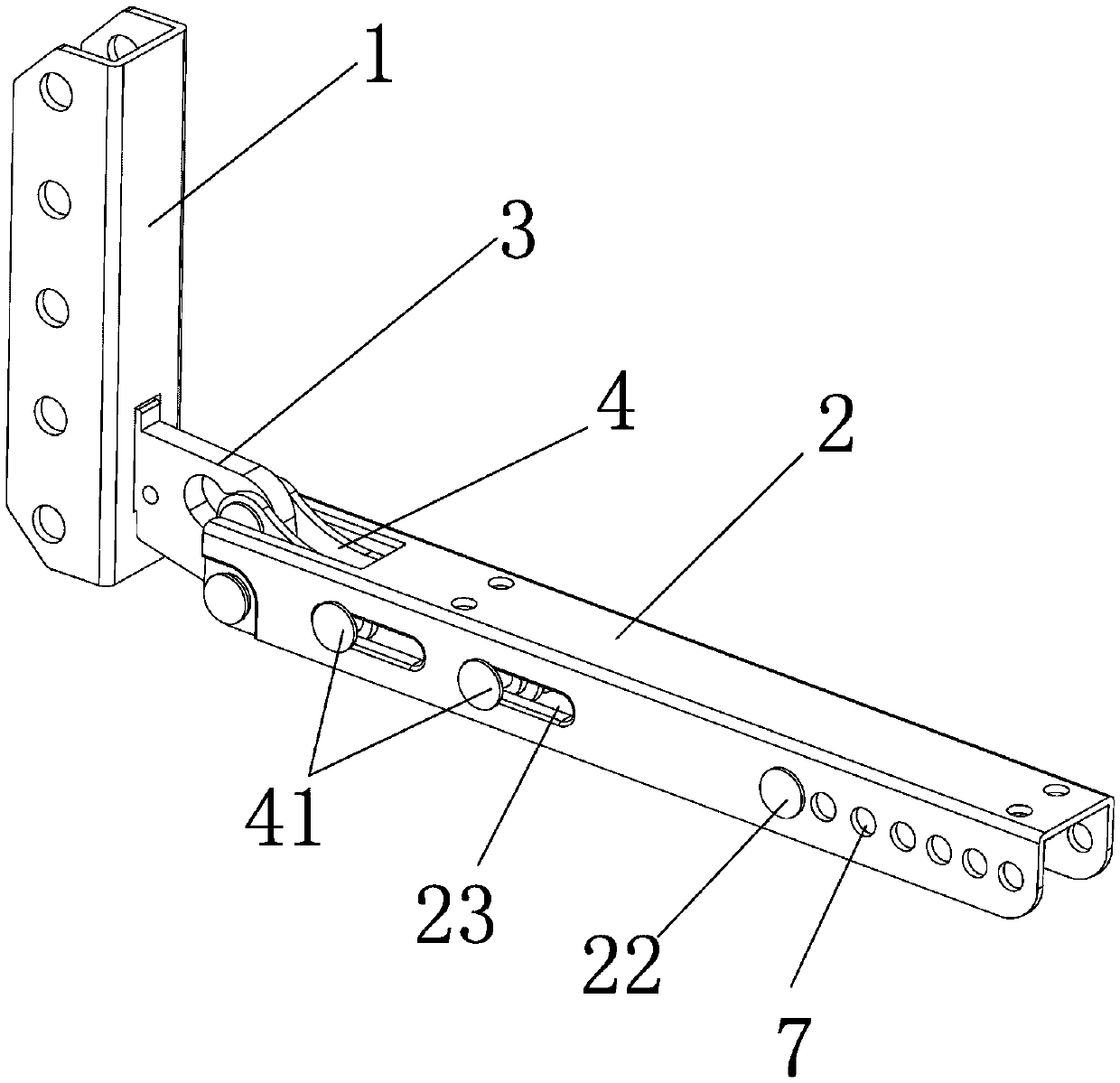

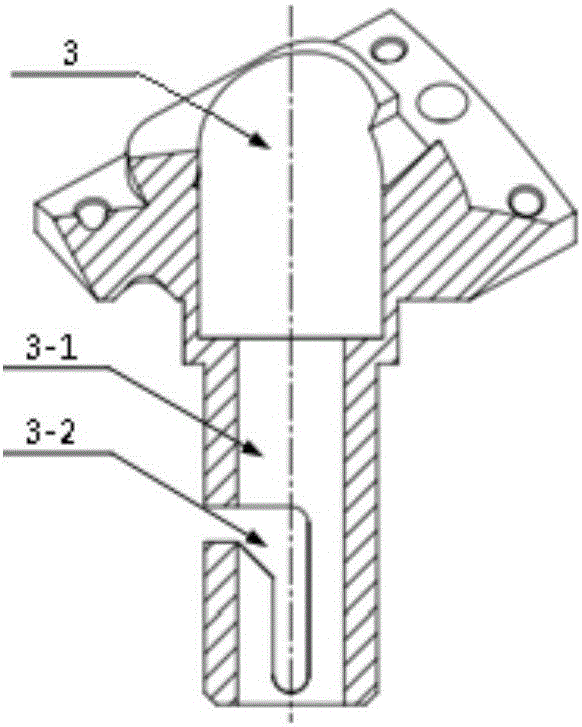

Unfolding and locking mechanism

ActiveCN106347632ASimple structureExpand and lock reliablyWing adjustmentsTorsion springAerospace engineering

The invention discloses an unfolding and locking mechanism, relating to the field of folding wing mechanisms and solving the problems that the existing folding wing mechanism cannot realize horizontal folding, lacks a small-size folding wing unfolding and locking mechanism and is complicated in structure and large in mass. The unfolding and locking mechanism comprises a folding wing unfolding motion mechanism and a locking device, the folding wing mechanism adopts horizontal folding and does rotation and translation motions during an unfolding process, the unfolding relies on a torsion spring as a power source, the torsion spring can provide both torque and elastic force, and the rotation and linear motion of the wing can be realized within a small space range to complete the unfolding process of the wing. A locking device adopts a spring to drive a locking pin to lock, and the locking pin limits the motion of the wing in one direction so as to realize the locking of the wing without the influence on the unfolding of the wing. The unfolding and locking mechanism is simple in structure, reliable to unfold and lock, low in cost and compact in occupation space. When an aircraft is launched after leaving away a canister, the rapid unfolding and locking of the folding wing can be realized under the interference of pneumatic resistance.

Owner:中天长光(青岛)装备科技有限公司

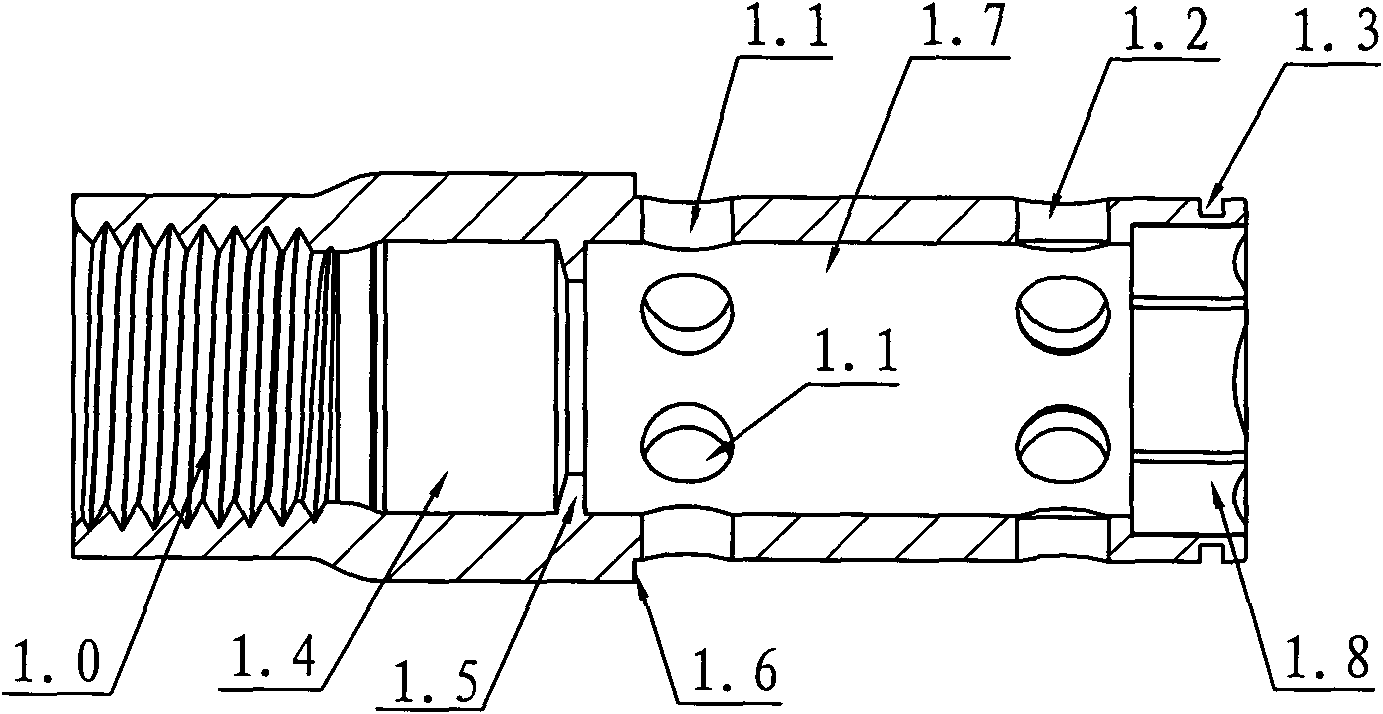

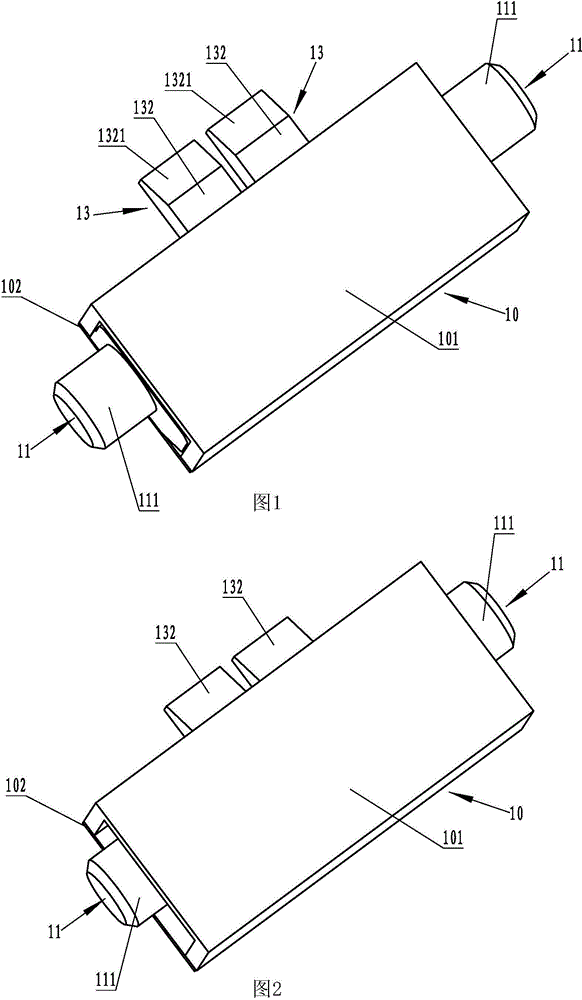

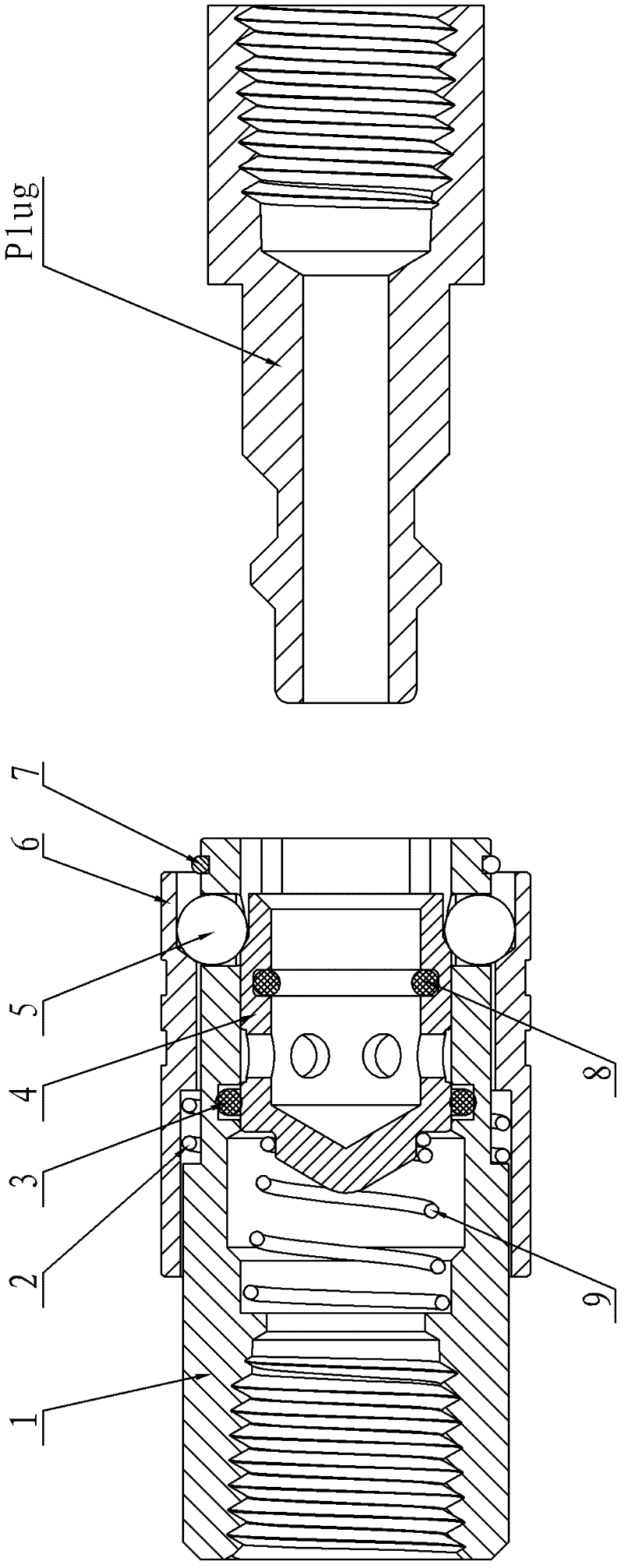

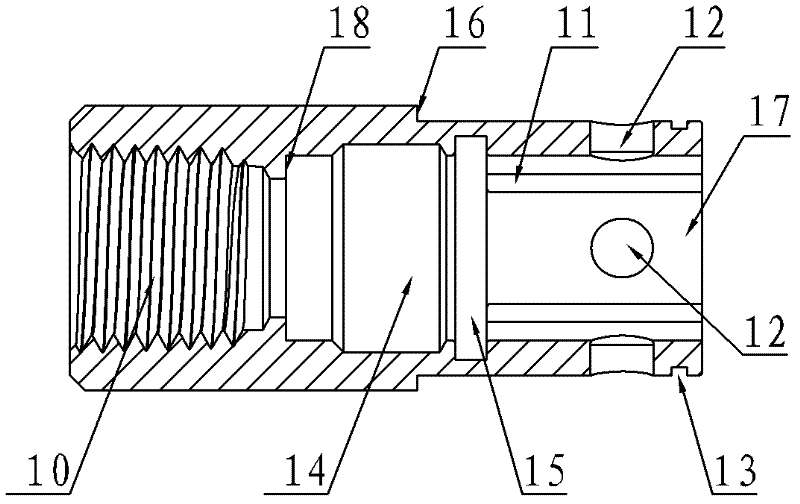

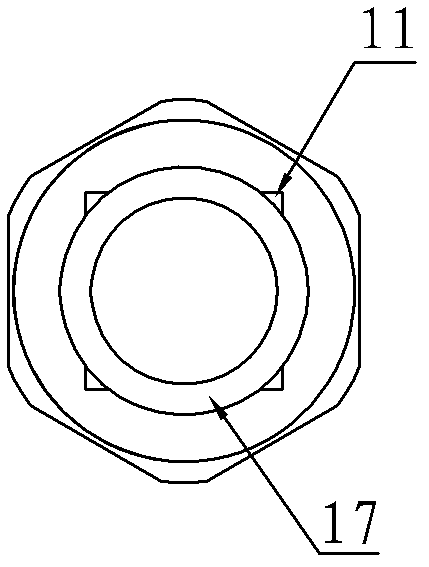

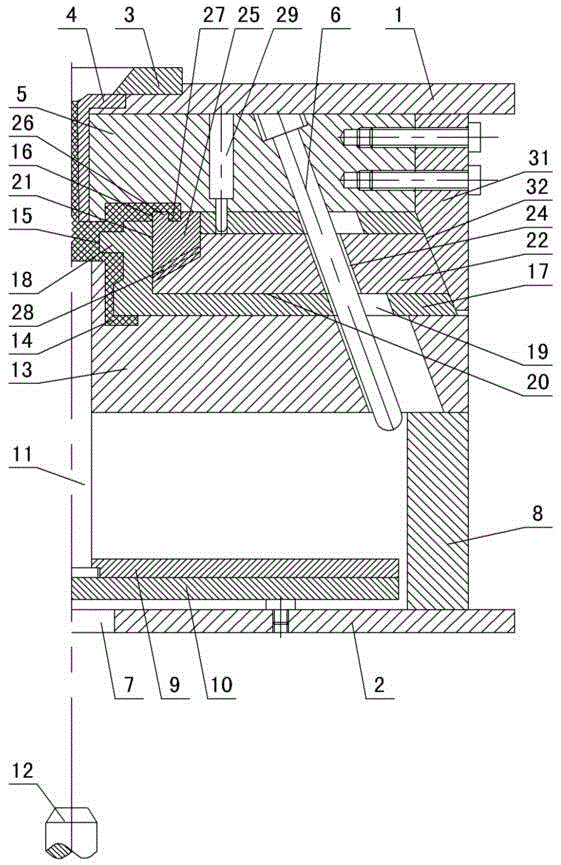

Plunger type pneumatic quick change coupler

InactiveCN102128329AEasy insertion and positioningInsert positioning solutionCouplingsSteel ballMechanical engineering

The invention discloses a plunger type pneumatic quick change coupler. The plunger type pneumatic quick change coupler comprises an air inlet connecting sleeve, an air inlet seal ring, a sealing check ring, a valve core, locking steel balls, a movable sliding sleeve, an axial check ring, an air outlet seal ring, a valve core spring and a sliding sleeve spring, wherein the air inlet connecting sleeve has a sleeve structure; the valve core has a stepped axial sleeve structure and is sleeved in an inner hole of the air inlet connecting sleeve; both the air inlet seal ring and the sealing check ring are sleeved in a valve core sliding hole of the air inlet connecting sleeve; the air outlet seal ring is arranged in an air outlet seal groove; the valve core spring is sleeved on axle diameter of a left section of the valve core; the locking steel balls are arranged in locking steel ball holes of the air inlet connecting sleeve; the sliding sleeve spring is sleeved on a matching outer circle of a right section of the air inlet connecting sleeve; and the axial check ring is clamped in an axial check ring groove. In the plunger type pneumatic quick change coupler, only three main body parts, namely the air inlet connecting sleeve, the valve core and the movable sliding sleeve, and two sealing processes are adopted; and compared with the conventional similar products, the plunger type pneumatic quick change coupler has the advantages of simple structure, small size, convenience for disassembly and assembly and long service life.

Owner:庄志军 +1

Lock for vehicle parking position

The invention discloses a frame lock for the parking spaces of bicycles, electric bicycles and motorcycles, which includes a lock case and a control device; one end of the lock case has an opening, and a transversal grooved rail is arranged on the upper part of the opening on the lock case; a hole is arranged at the back of the transversal grooved rail, the rail mouth of which faces to the opening on the lock case; the control device includes a lock bar, a pair of locking plates that can put together to form a letter 'T' in shape, a pin shaft and a control lock, wherein the lock bar passes through the hole on the grooved rail and has a locking groove that fits the plug of the control lock; the opposing end of the crossbars of the two locking plates are movably connected with the lock bar while the other end of the crossbar of the locking plate is articulated with a pin shaft that can slide in the transversal grooved rail of the lock case and restrained in the grooved rail; the vertical post and the hook of the two locking plates are at the opening of the lock case; the actuation transfer and the locking operation is reliable, and an automatic locking operation can be realized; the vehicle can be locked simply and easily, and the anti-theft performance is good, thus being convenient for the management of orderly parking.

Owner:谢瑞初

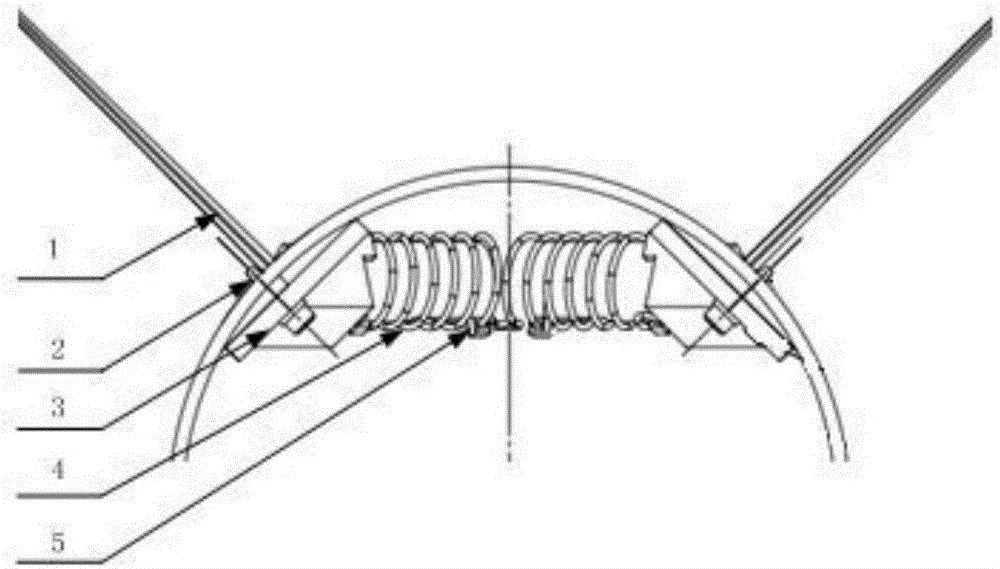

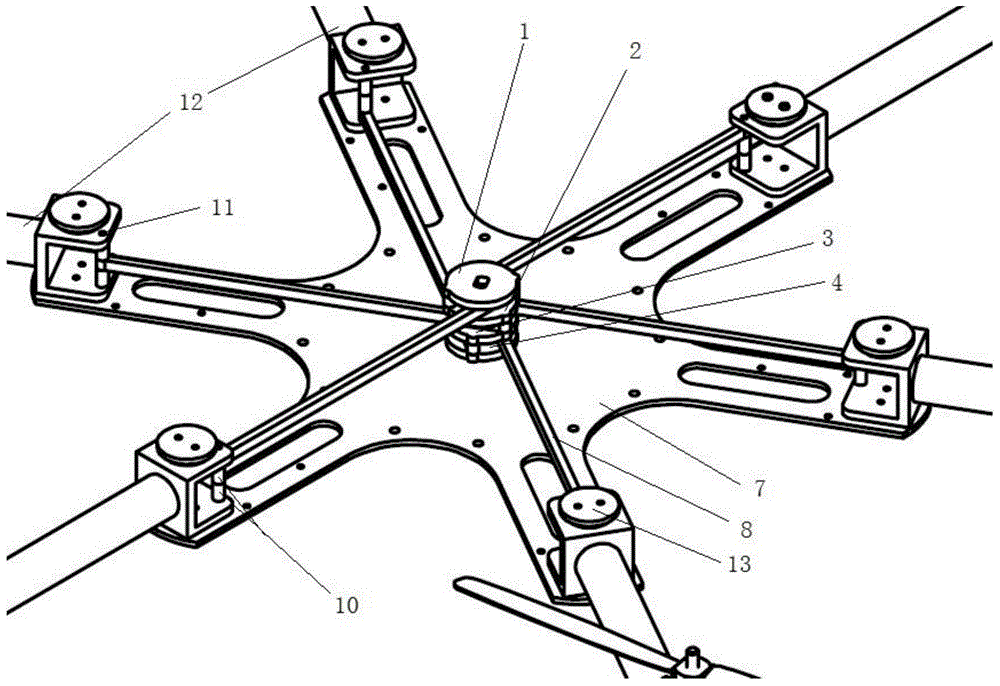

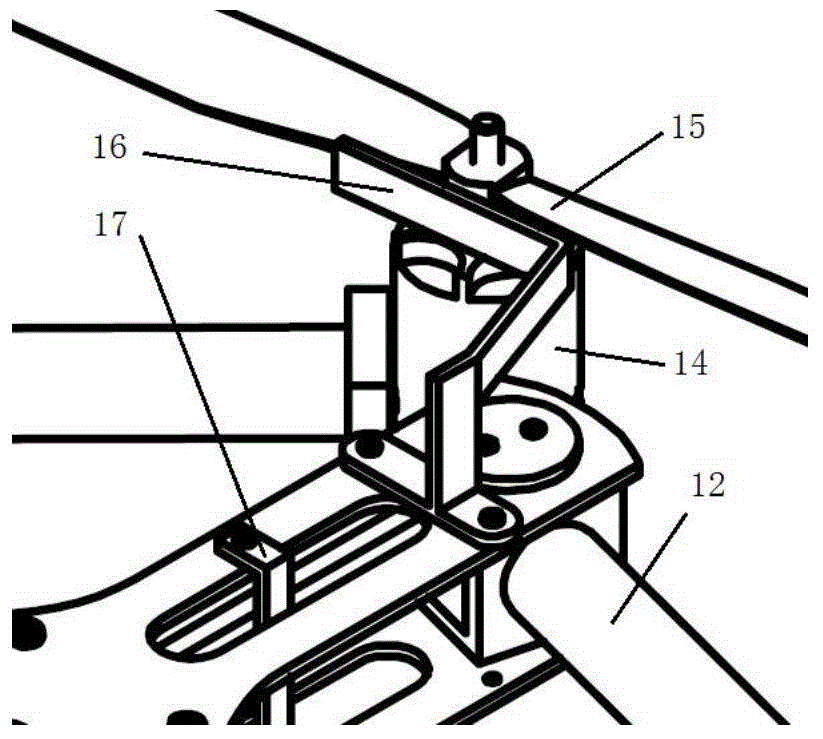

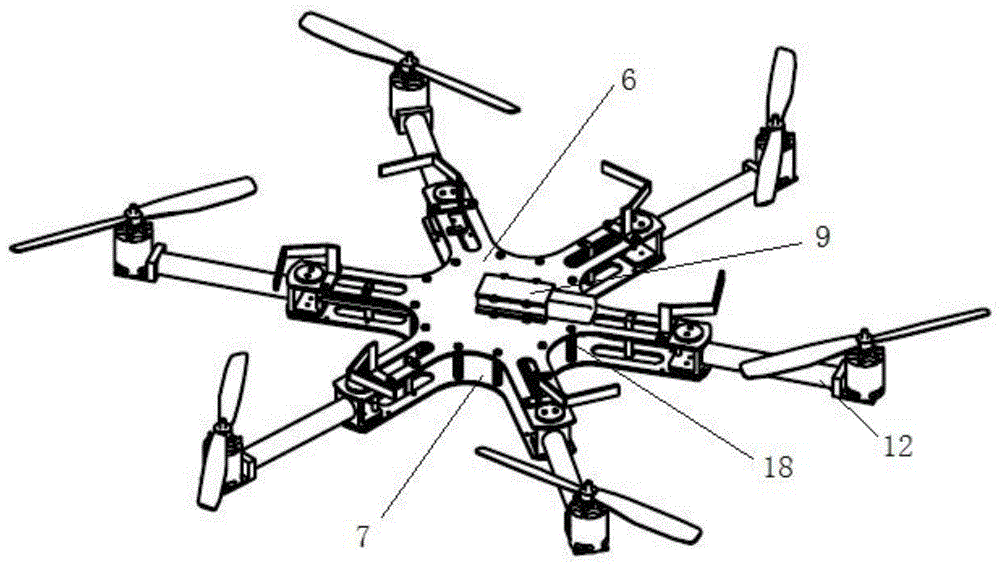

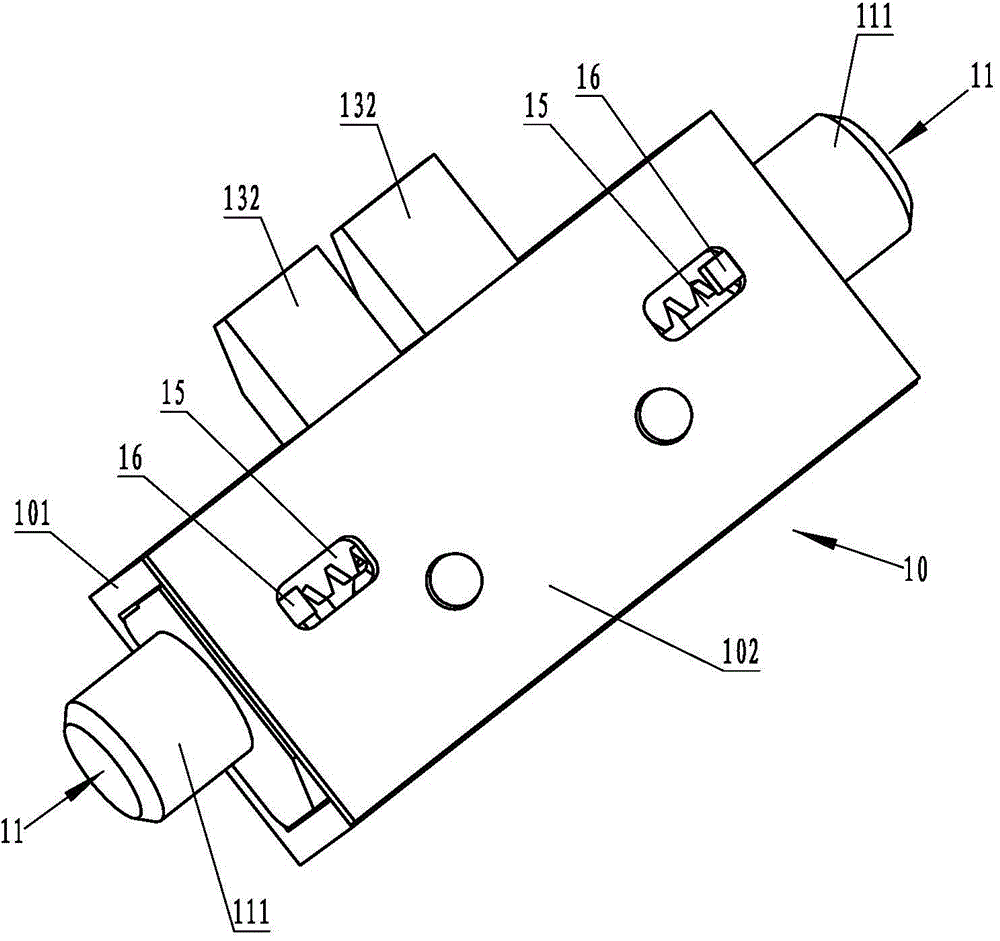

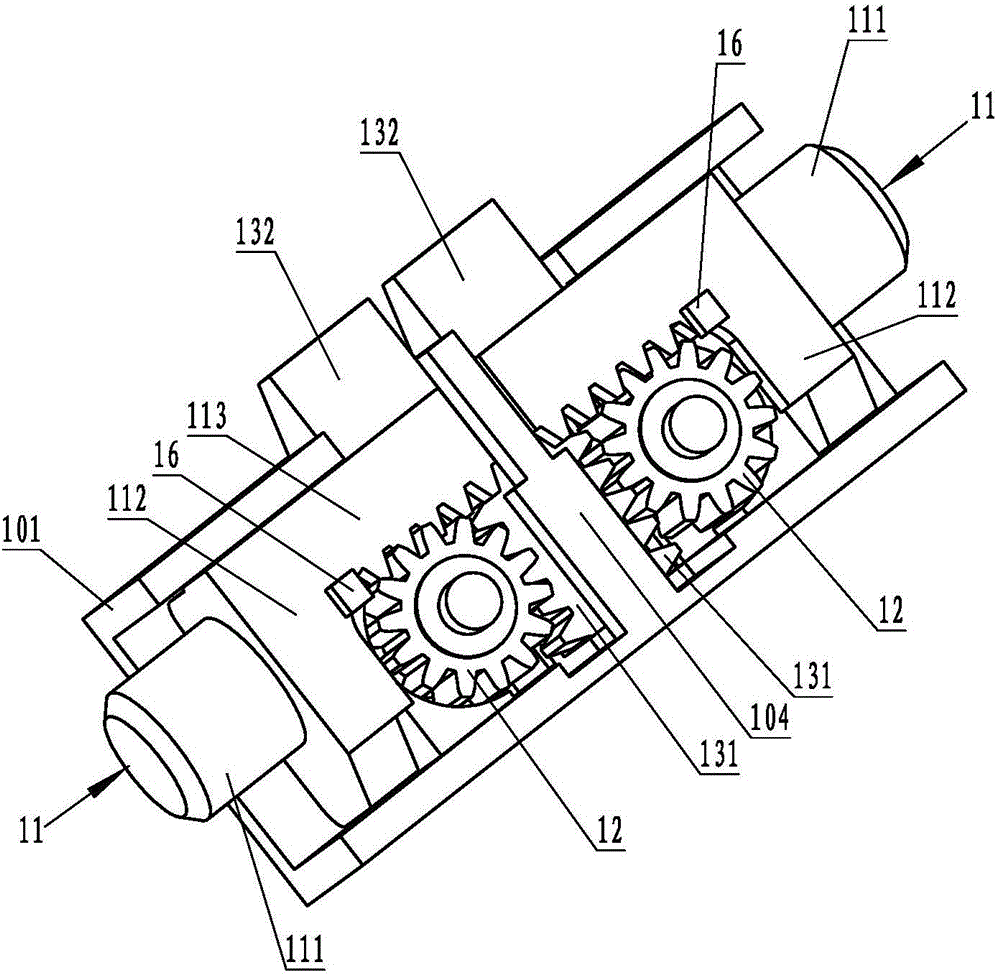

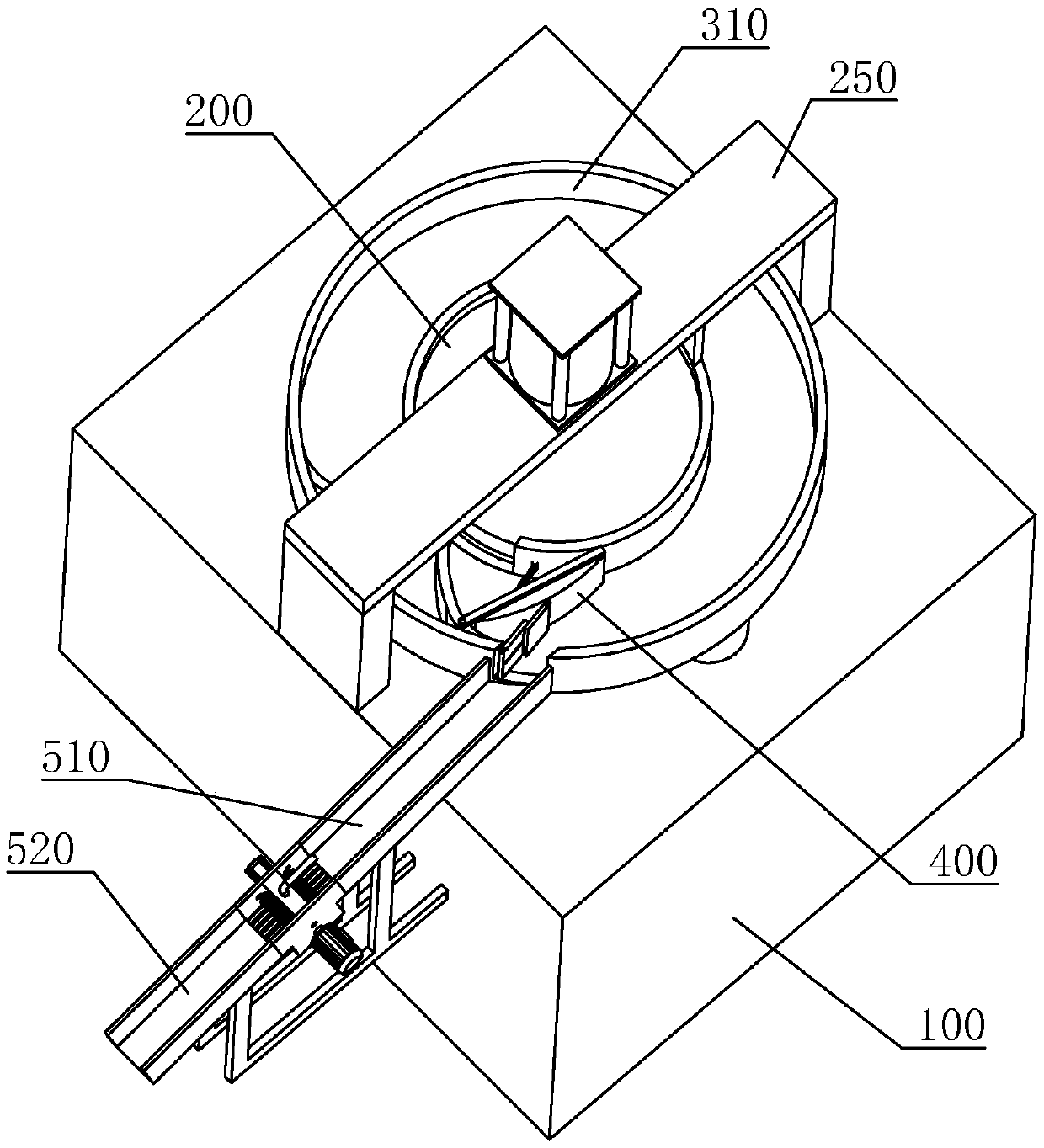

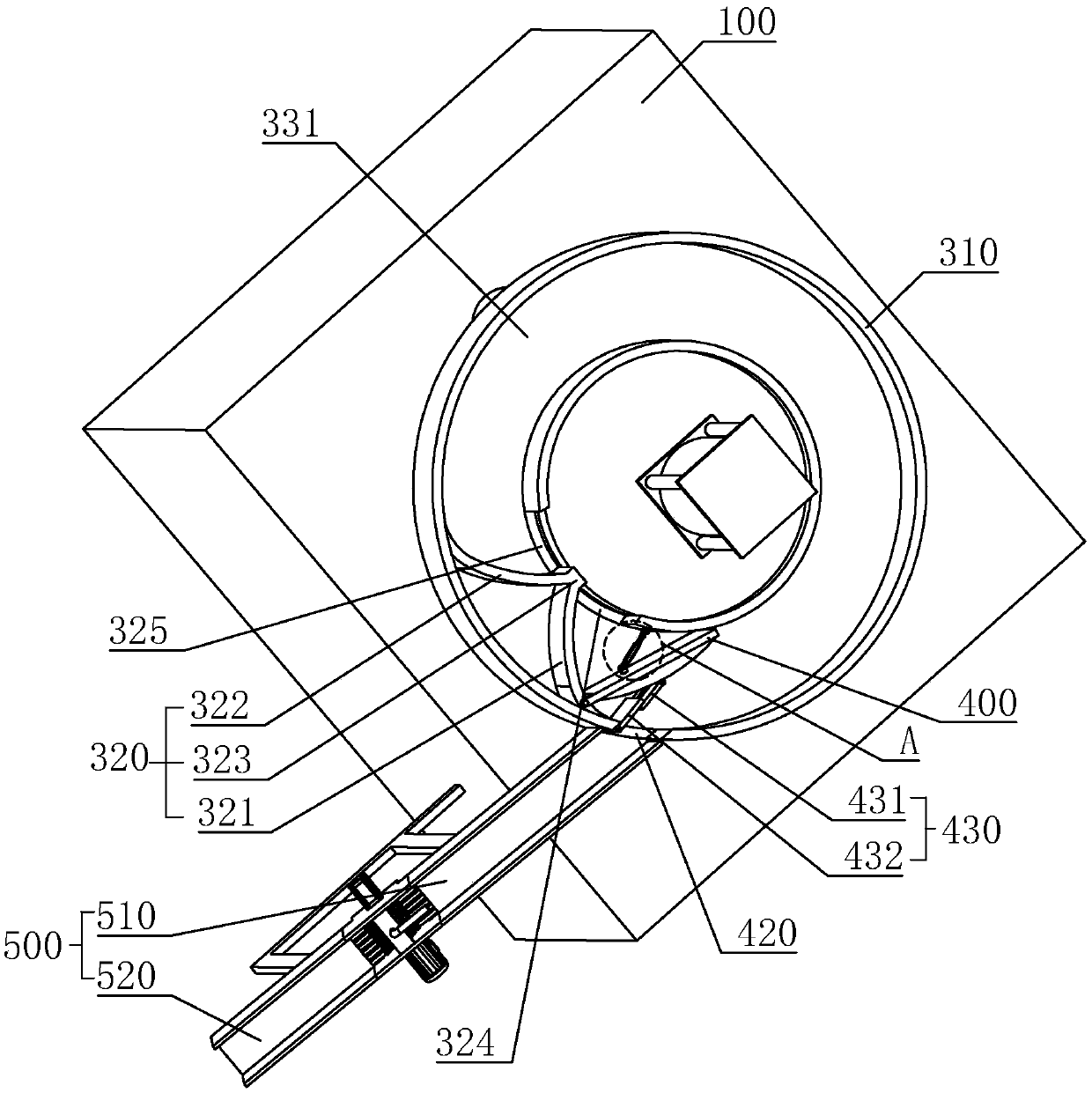

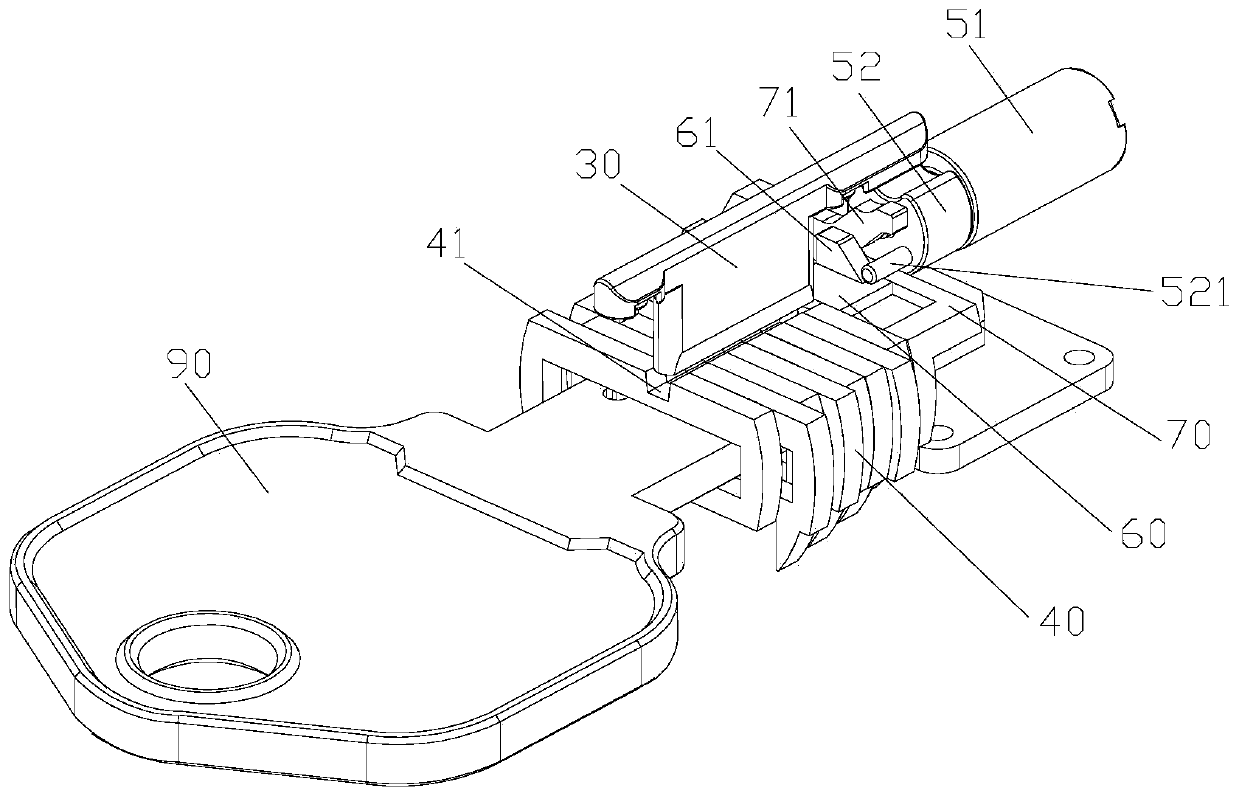

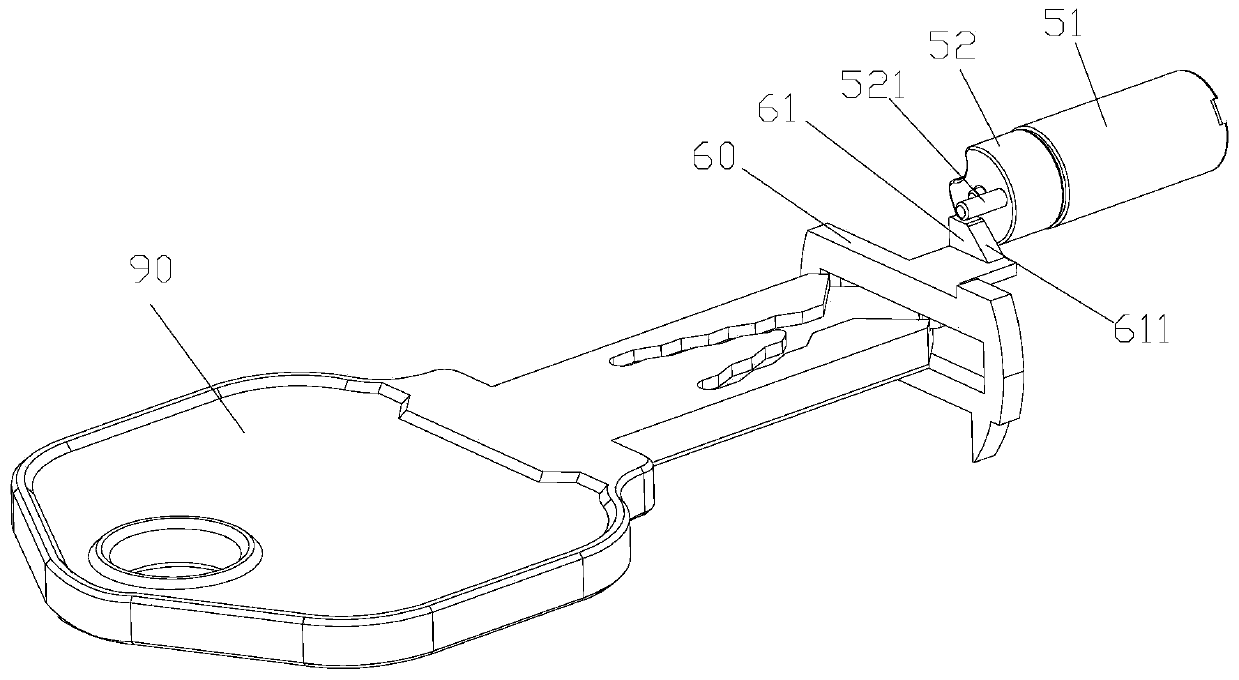

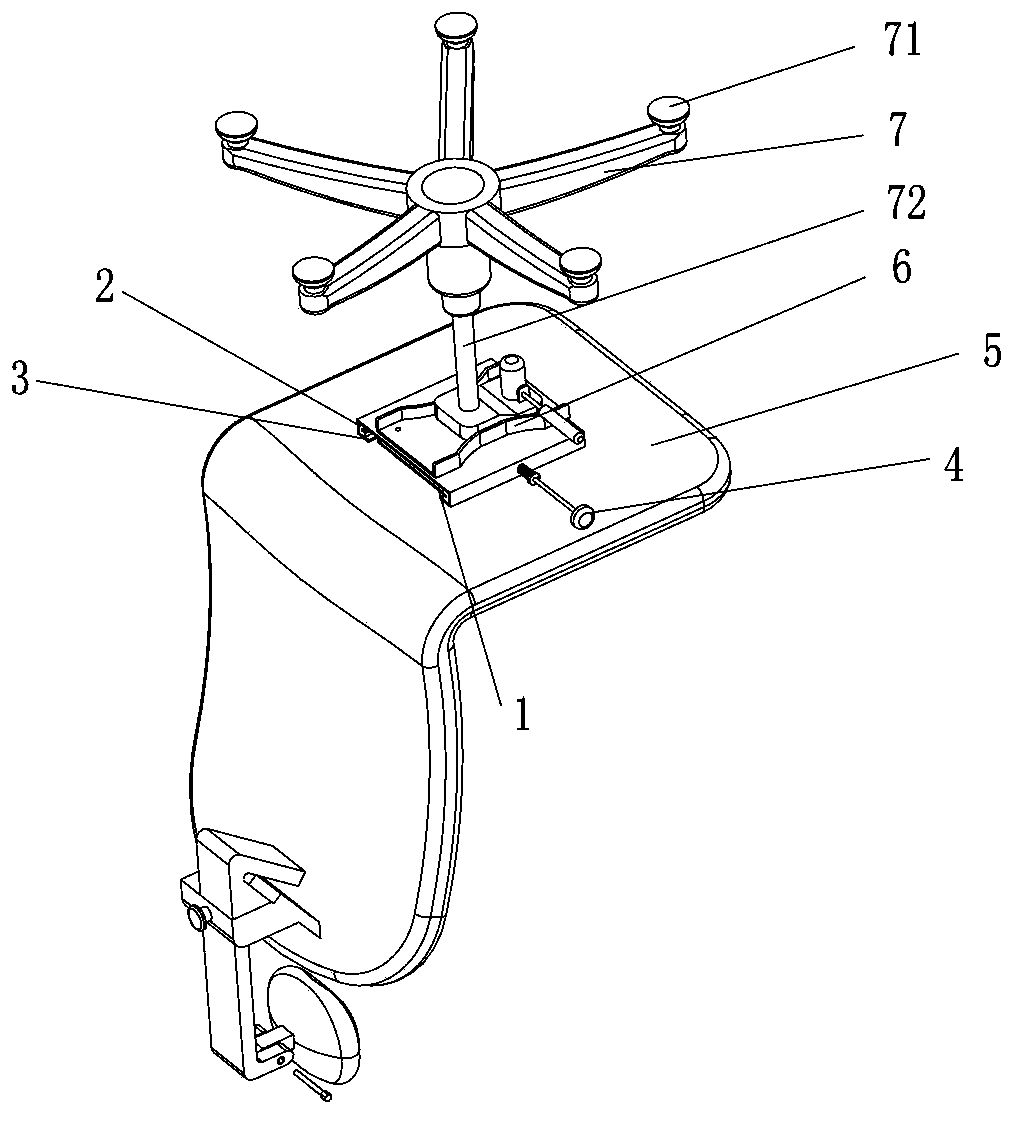

Six-rotor aircraft rack capable of being folded and expanded automatically

An aircraft rack capable of being folded and expanded automatically is designed through inspiration from a mechanical aperture tuning device of a camera lens and is composed of a central worm-and-gear gear motor, an upper central plate, a lower central plate, a crank, a connecting rod, a plurality of supporting arms and a rotor baffle so that a six-rotor aircraft can be folded to form a compact regular hexagon structure in a manner of being driven by a motor arranged at the centre of the rack. Top parts of adjacent rotors are arranged as close as possible and are regarded as vertexes of the regular hexagon structure. The positions of the rotors are relatively fixed so that a geometric size of the six-rotor aircraft can be greatly reduced. When the central motor rotates in a reverse direction, the supporting arms of the six rotors can be expanded automatically.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

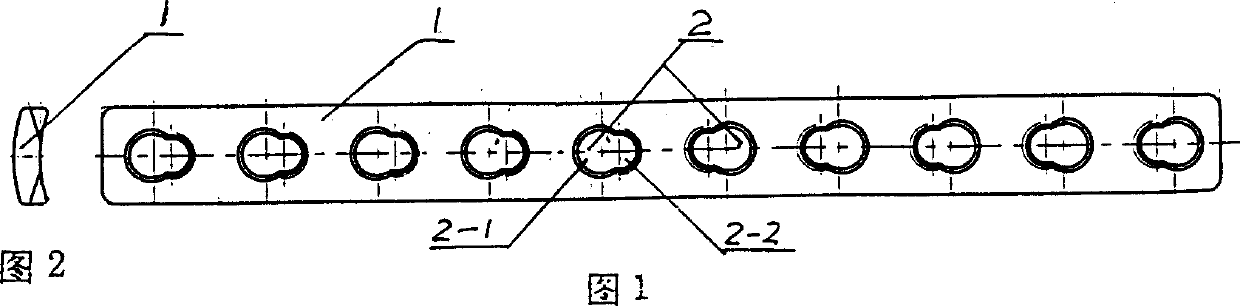

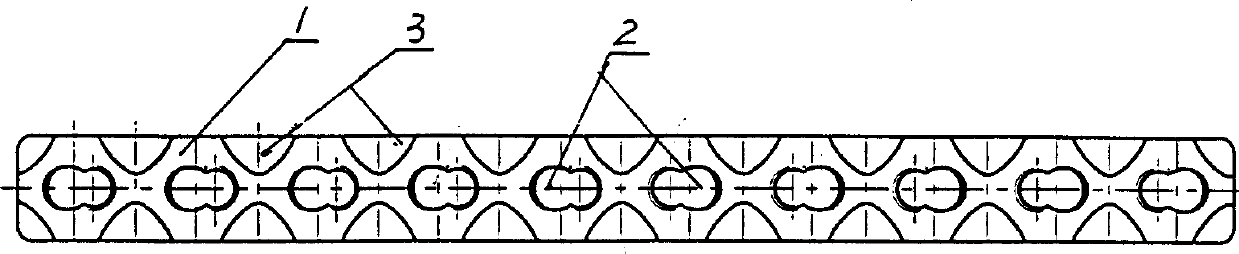

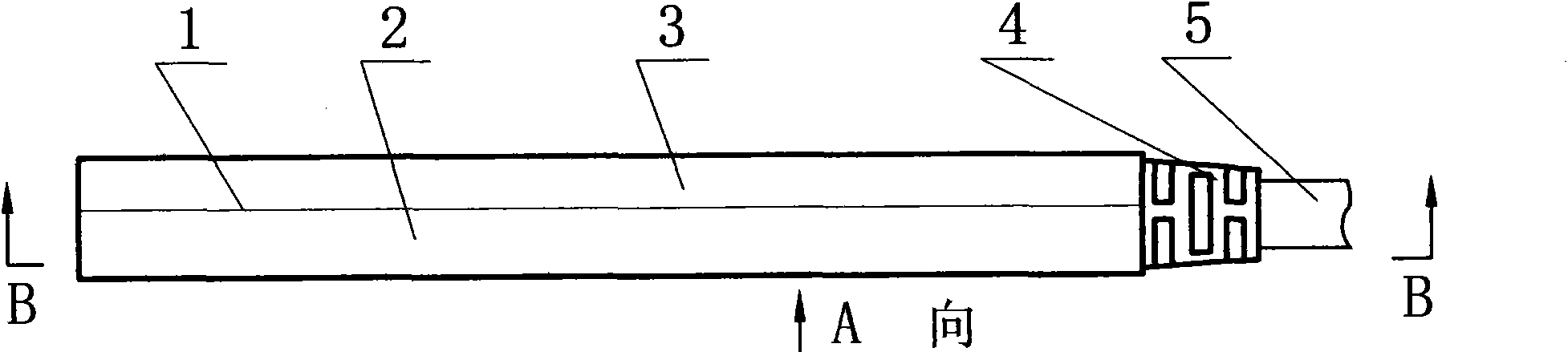

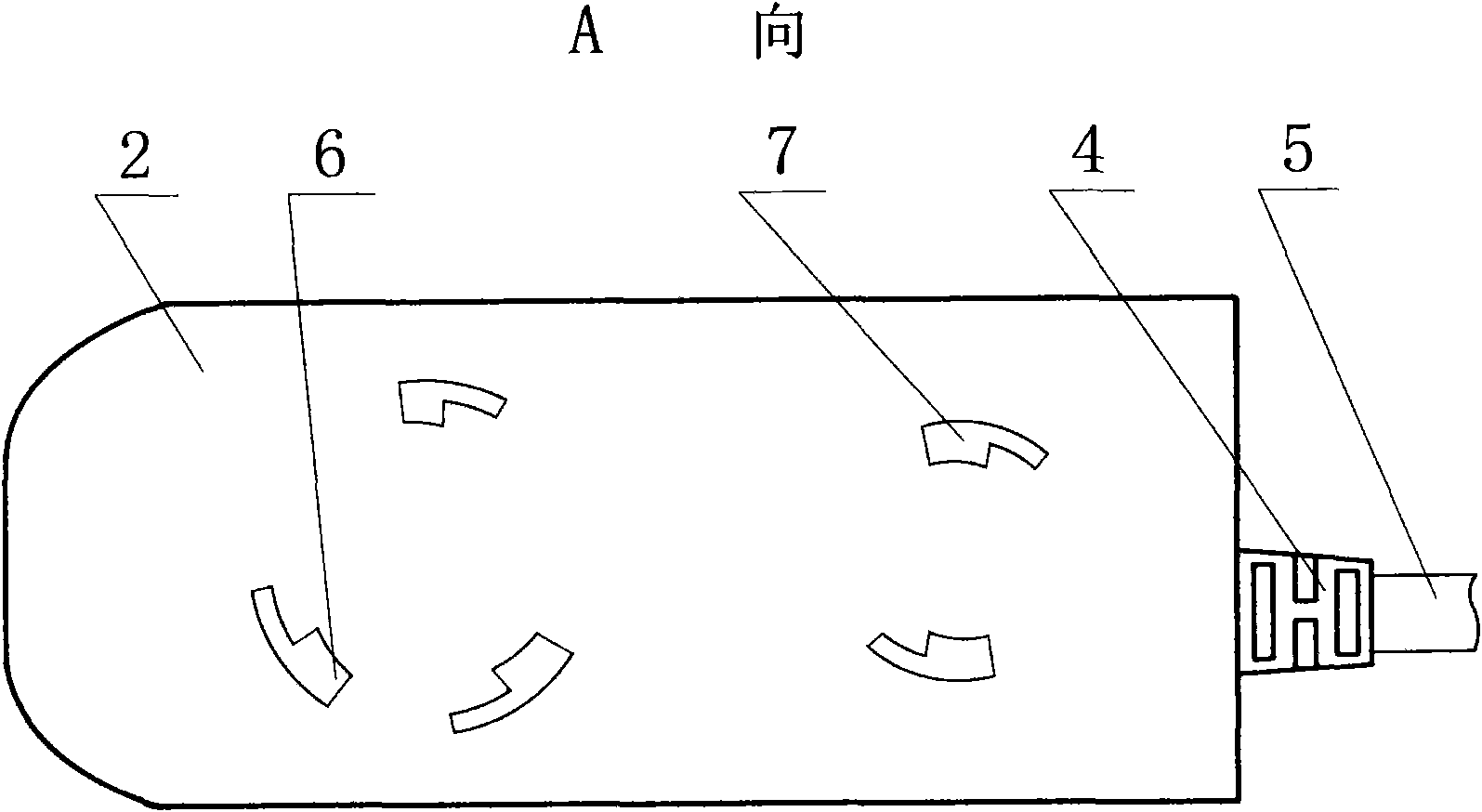

Locking and pressurizing bone fracture plate

The locking and pressurizing bone fracture plate is medical equipment suitable for fixing fracture, especially fracture of limb fracture. The locking and pressurizing bone fracture plate is one bone fracture setting steel plate with several slot openings, holes for spherical pressurizing screws and holes for locking screws, and is especially suitable for fixing cancellous bone. The arc fracture setting steel plate has pressure reducing slots, and has also elastic slots, hold-down plate slots and hold-down plates with screw.

Owner:蒋谊康

Lifting device for mounting of hydraulic power distribution cabinet

The invention discloses a lifting device for mounting of a hydraulic power distribution cabinet. The lifting device comprises a vehicle body, a lifting mechanism, a carrier and a supporting mechanism, wheels are mounted at the bottom of the vehicle body; the lifting mechanism is mounted on the vehicle body; the carrier is mounted on the lifting mechanism; and the supporting mechanism is mounted between the carrier and the vehicle body. The lifting device is simple in structure, a roller is arranged on the vehicle body, components of the power distribution cabinet can be transferred from one place to another place conveniently, and a hydraulic pump does work to lift the components located on the objective table, so that mounting of the power distribution cabinet is facilitated, manual carrying is not required, and the labor intensity of workers is greatly reduced.

Owner:石茂惠

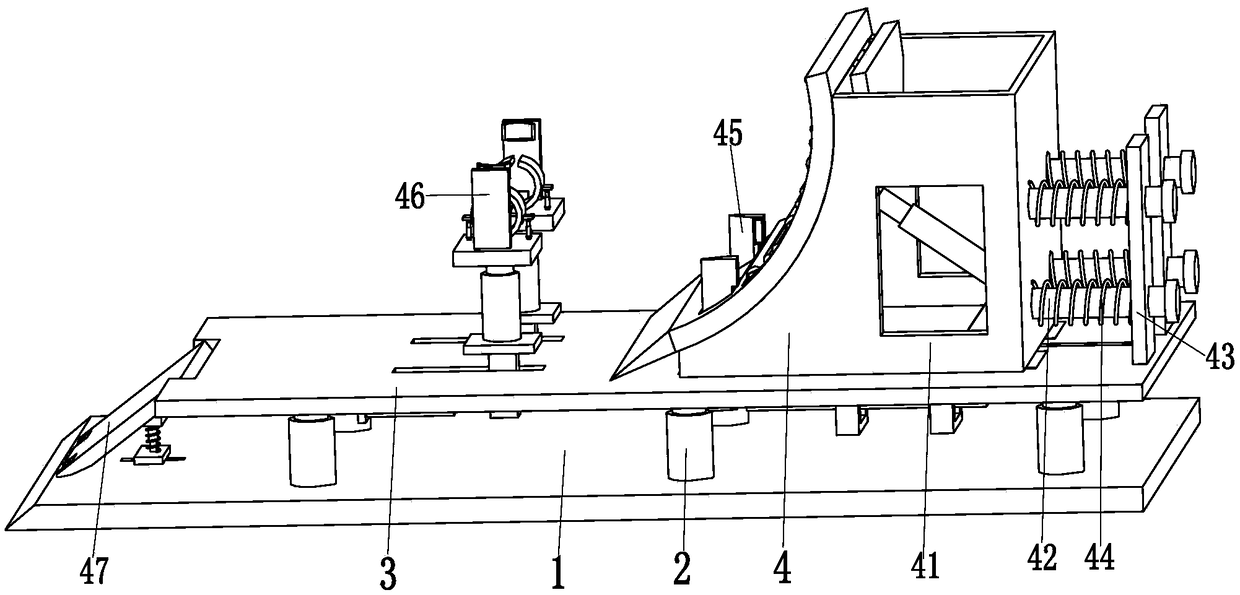

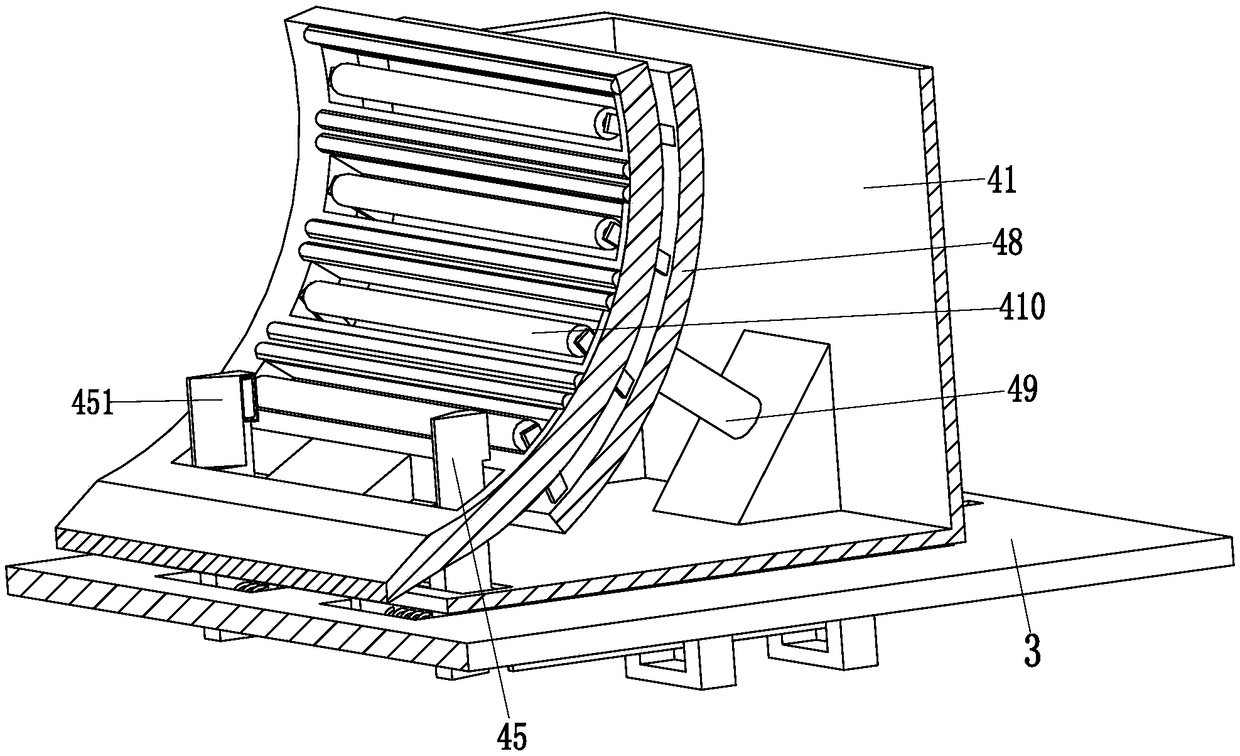

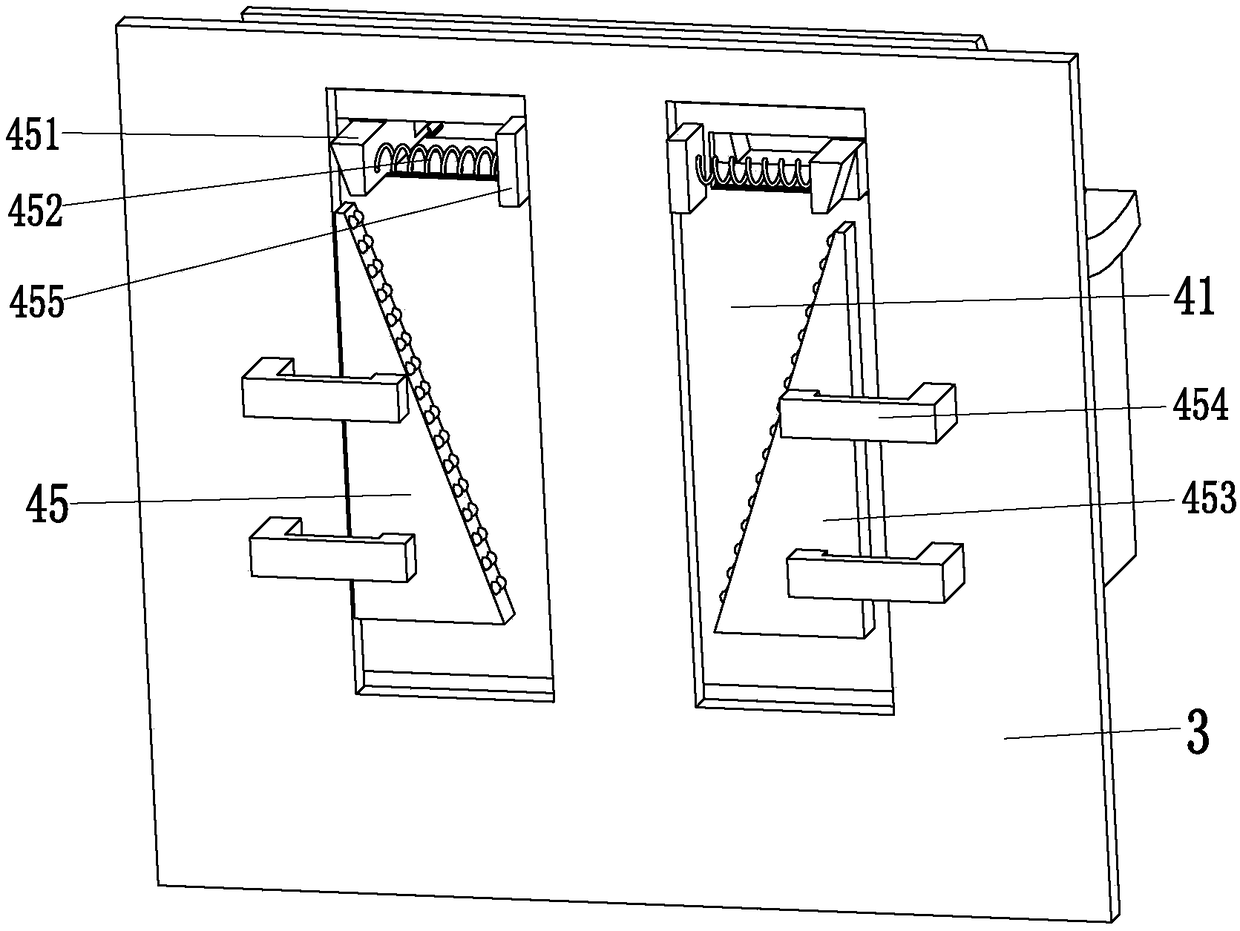

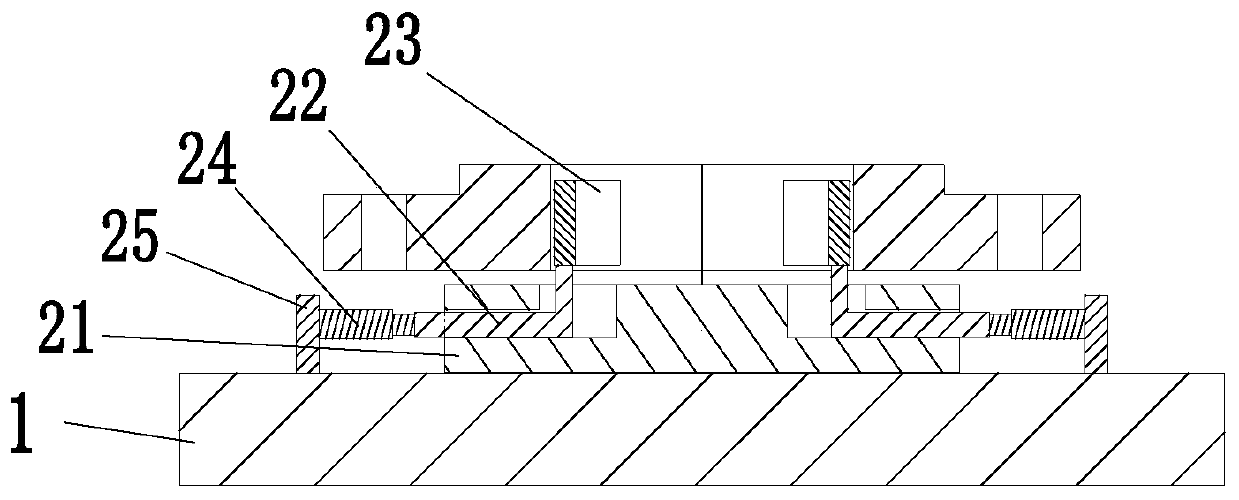

Stable support system for dismantlingmotorcycle tire

ActiveCN109263413APlay a guiding roleEasy to disassembleTyre repairingSupporting systemMotorcycle tyre

The invention relates to astable support system for dismantling a motorcycle tire comprising a support plate, a height push rod, a placing platform and a locking device; a sliding groove is arranged on the top of the left end of the support plate, the top of the support plate is connected with the bottom of the height push rod, The placing platform is installed on the top of the height push rod, the left side surface of the placing platform is provided with a guide square groove, the left end front and rear sides of the placing platform are distributed with a lifting sliding groove, the rightend middle part of the placing platform is provided with a buffer sliding groove, the right end front and rear sides of the placing platform are provided with a square groove, and a locking device isinstalled on the placing platform. The present invention can solve the problems that the whole position of the motorcycle can not be raised when the existing motorcycle is dismantled, the front wheelof the motorcycle can not be locked, the position of the motorcycle can not be corrected when the motorcycle is parked, the motorcycle can not be steadily lifted, and the motorcycle will sway forwardand backward when the tire is dismantled, and the like.

Owner:重庆劲扬摩托车工业有限公司

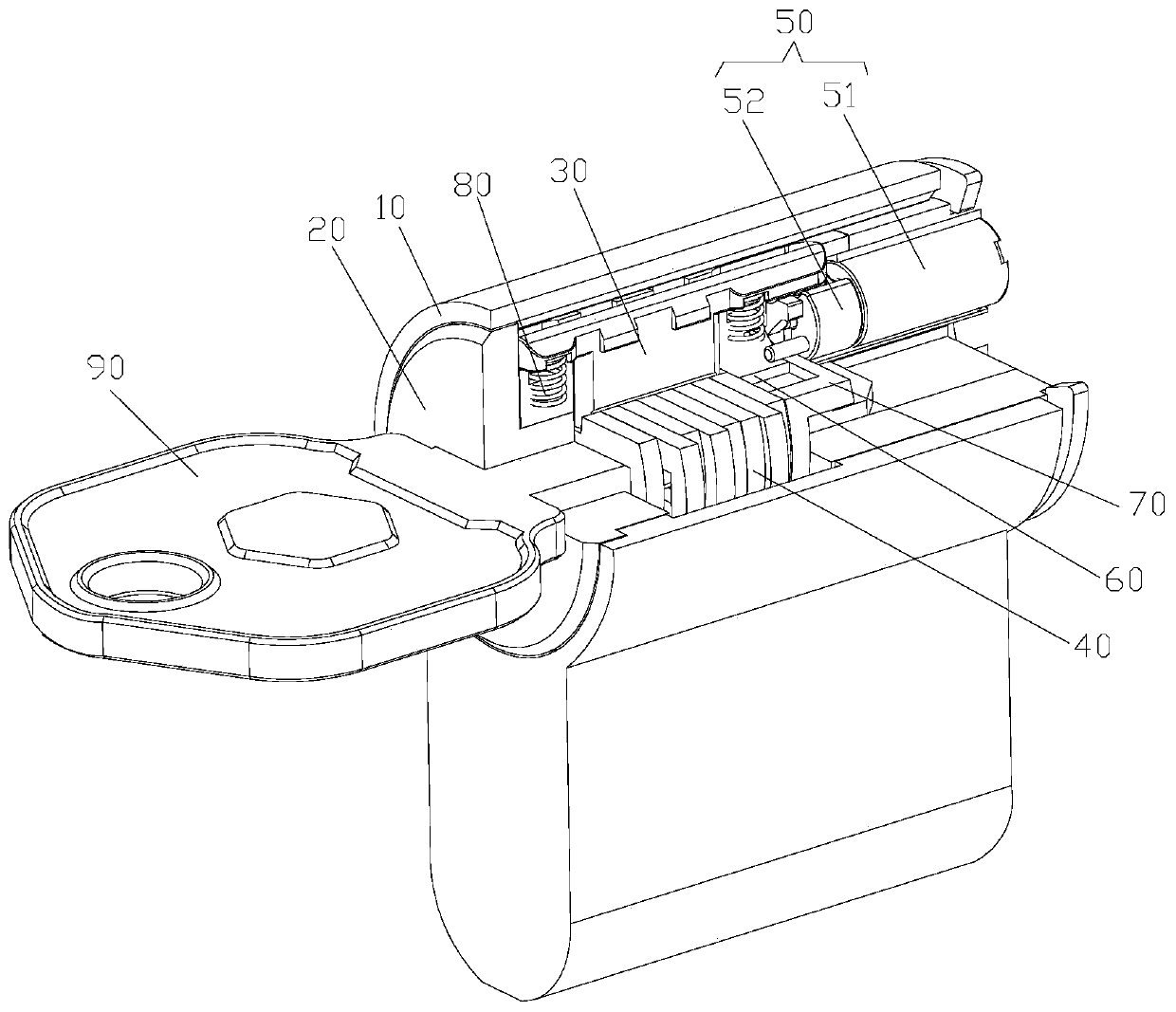

Double-buckle device and wearing product structure

ActiveCN104534235APlay a locking roleUnlocking does not causeStands/trestlesKey pressingClosed cavity

The invention belongs to the technical field of buckles and particularly relates to a double-buckle device and a wearing product structure. The double-buckle device comprises a shell, wherein a first buckle structure and a second buckle structure are arranged in a non-closed cavity defined by the shell, and the first buckle structure and the second buckle structure each comprise a gear rotationally connected with the shell, a key, a buckle and an elastic reset piece arranged in the pressing direction of the key and used for resetting the key. A limiting device used for limiting the stroke of each key is arranged between each key and the shell. Each key comprises a pressing part stretching out of the outer side of the shell, a sliding part which is fixedly connected with the pressing part and can slide along the shell, and a key transmission part which is fixedly connected with the sliding part and used for being meshed with the corresponding gear. Each buckle comprises a buckle transmission part and a buckling part, wherein the buckle transmission part is arranged on the side portion of the corresponding gear and used for being meshed with the corresponding gear, and the buckling part is fixedly connected with the buckle transmission part, stretches out of the shell and is used for buckling and fixing. The problem that the buckle structure is loosened due to error triggering in the prior art is solved.

Owner:QINGDAO GOERTEK

Rotary contact socket and plug

InactiveCN102655289AReduce space occupationIncrease contact surfaceCoupling contact membersTwo-part coupling devicesElectrical and Electronics engineeringElectrode

The invention relates to rotary contact socket and plug. A three-pole jack slide and a two-pole jack slide are arranged on a socket front housing, each jack slide comprises a jack and a narrow slide which are communicated, a horizontal electrode clamping spring is fixed in the front shell, and a rear cover is fixed on the front shell to form a housing. A three-pole cascade insert, a three-pole power lead jacket and a three-pole power lead are fixed on a three-pole plug; and a two-pole cascade insert, a two-pole power lead jacket and a two-pole power lead are fixed on the plug II. According to the rotary contact socket and plug, under the condition of reaching the rated load of the traditional socket and plug, the ultrathin structure is realized; after the pug is inserted into the socket, the plug is locked with the socket, the plug can not be vertically pulled out, no shaking exists between the socket and the plug, so that the socket and the plug can keep better contact for a long time; and the rotary contact socket and plug are safe in use and convenient for operation.

Owner:侯永昌

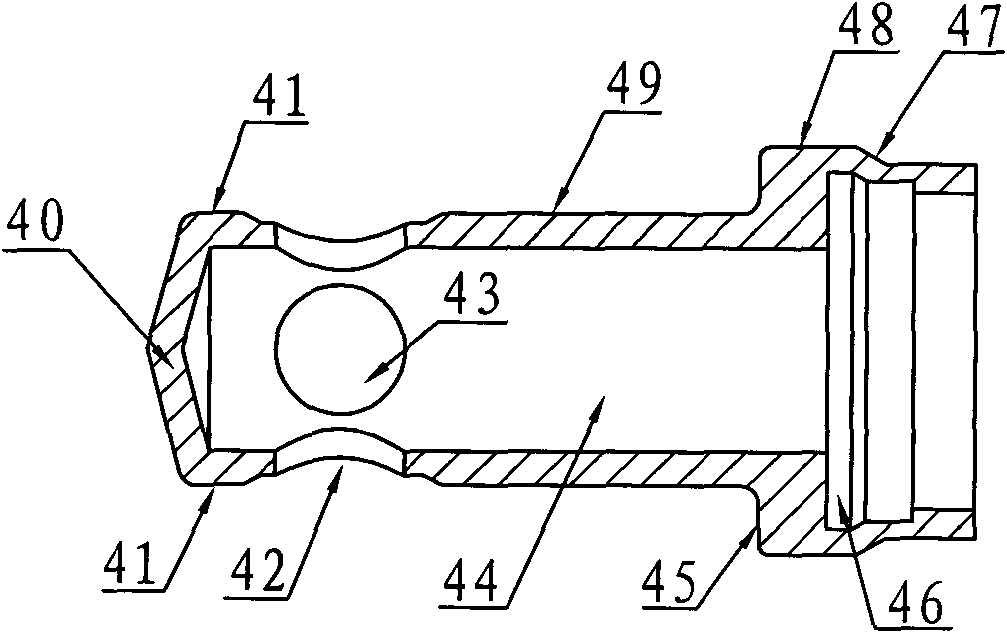

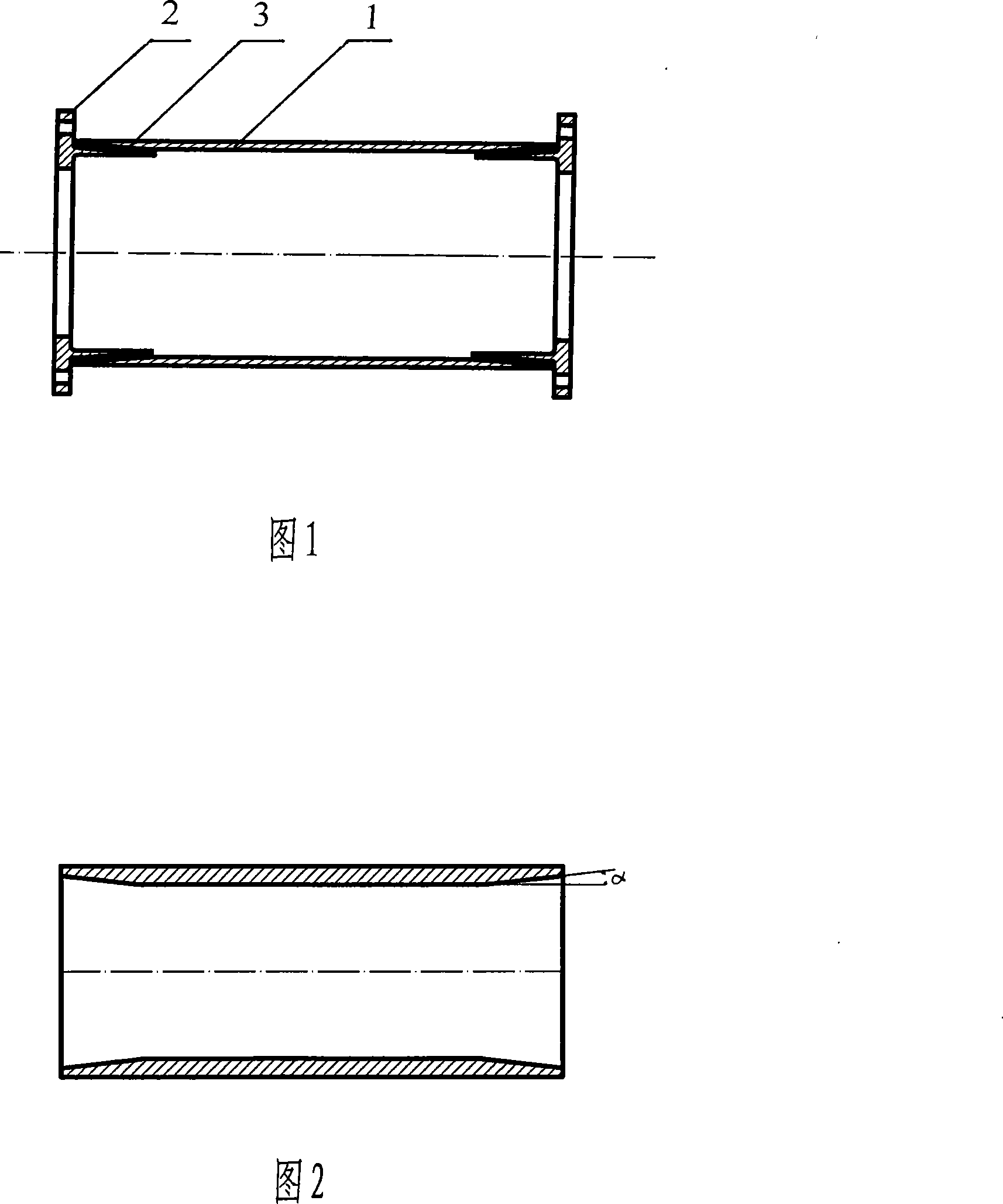

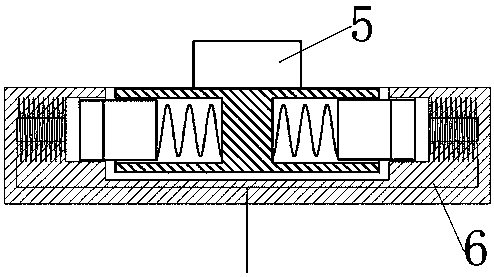

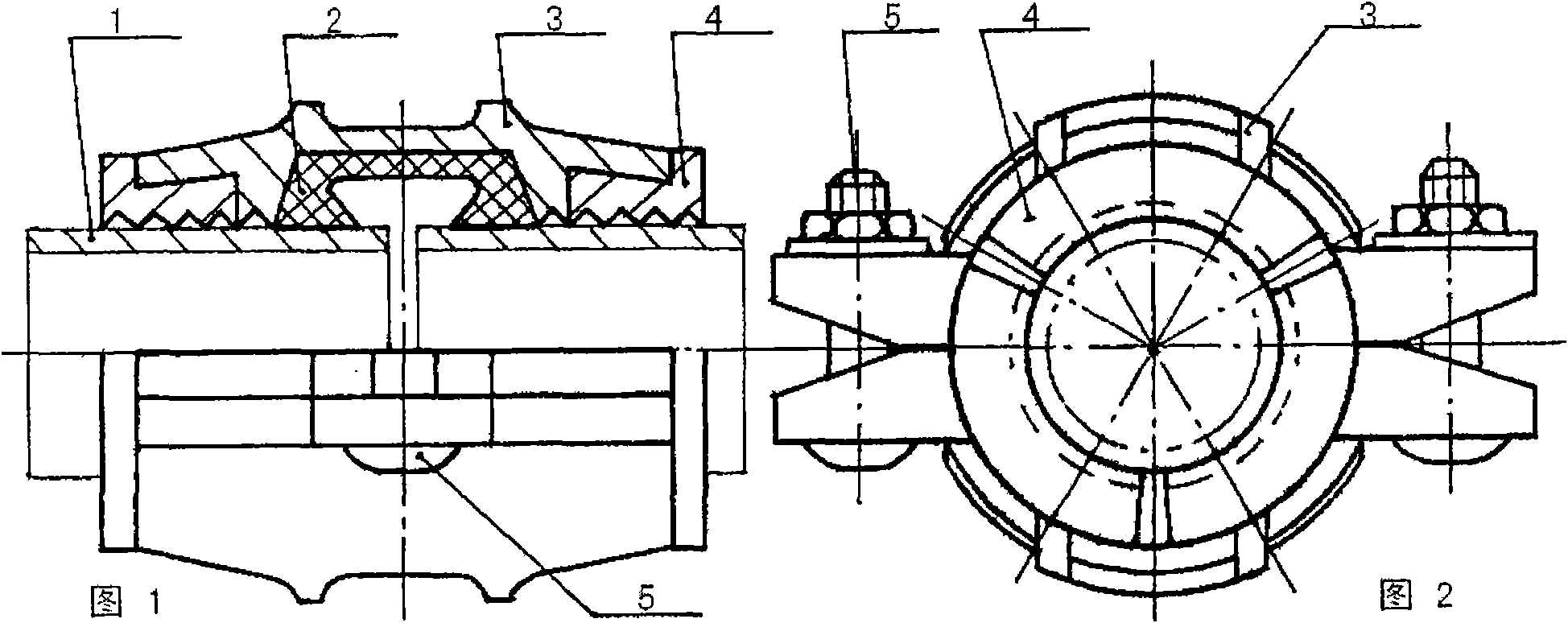

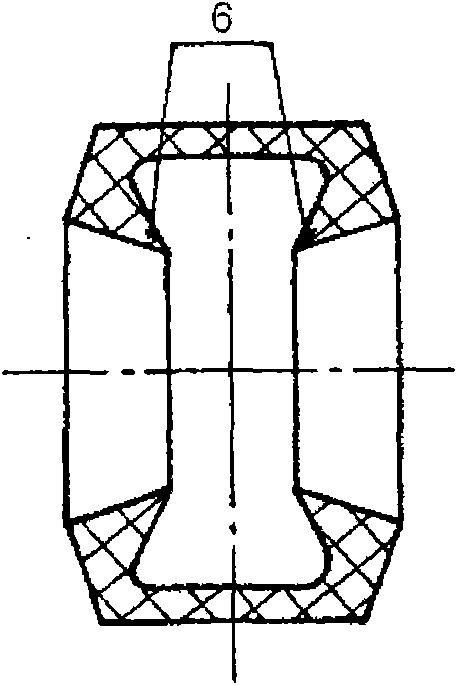

Flexible coupling

The invention provides a flexible coupling, comprising a cylinder body and flanges which are arranged at two ends of the cylinder body. The invention is characterized in that the cylinder body is an FRP cylinder body; the flanges are fixedly connected with or integrated into a whole with a taper sleeve or a cylinder sleeve; the two ends of the FRP cylinder body are sheathed with, fixedly bonded to or fixedly connected with the taper sleeve or the cylinder sleeve respectively. The invention is especially suitable for the connection of a speed increasing box in wind power generation equipment and a wind power generation set, plays a good damping and impact and vibration absorption role, has the capability of providing the displacement compensation, effectively improves the motion quality and stability of transmission machines, reduces the noise and improves the safety performance of the equipment.

Owner:黄顺国

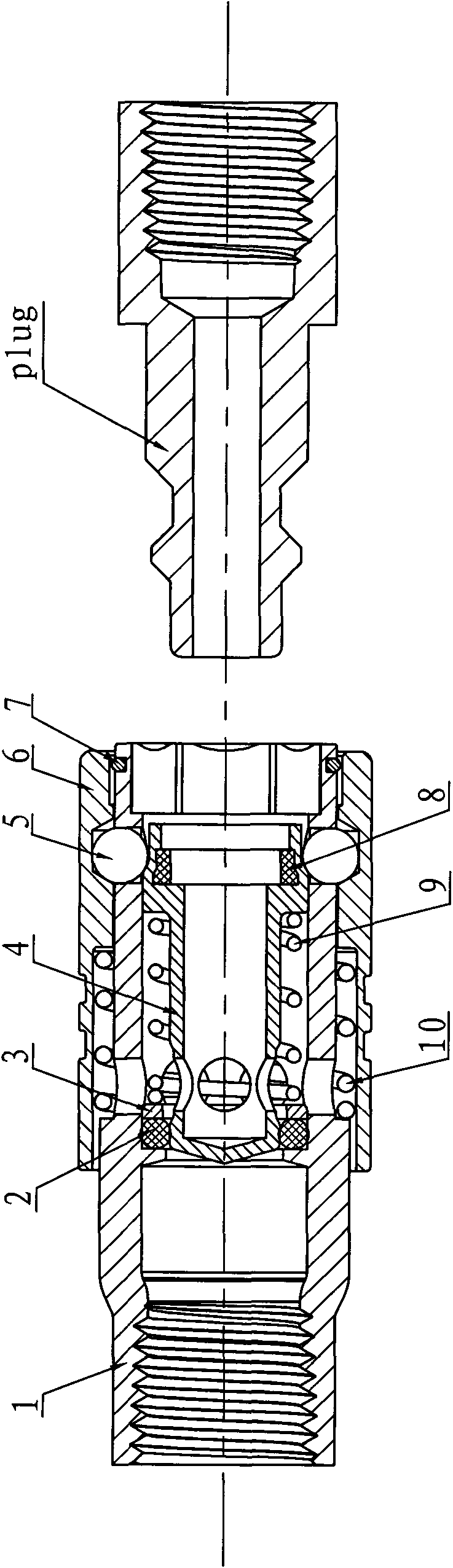

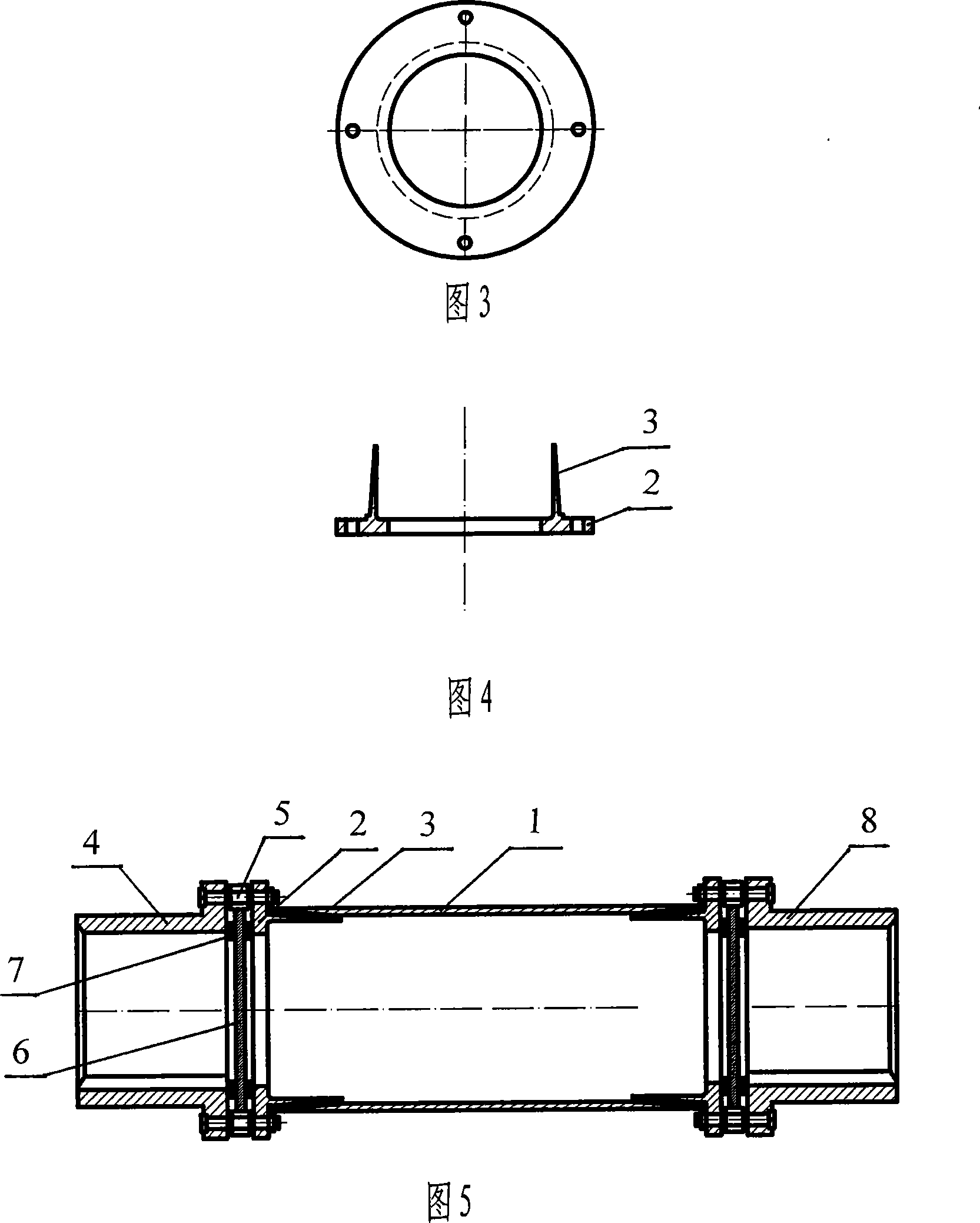

Plunger pneumatic quick-change coupler

The invention discloses a plunger pneumatic quick-change coupler. The plunger pneumatic quick-change coupler comprises an air inlet connecting sleeve, a sliding sleeve spring, an air inlet sealing ring, a valve core, a locking steel ball, a mobile sliding sleeve, a sliding sleeve limit component, an air outlet sealing ring and a valve core spring, wherein a pressure release groove is axially formed on an inner hole wall of a matching section of the air inlet connecting sleeve; a locking steel ball hole is formed on the excircle of the right end of the matching section; the locking steel ball is arranged in the locking steel ball hole; the relative axial slide limit among the air inlet connecting sleeve, the valve core and the mobile sliding sleeve is controlled by the locking steel ball; and before an air entraining plug (Plug) is inserted, the locking steel ball is positioned in a locking cavity. A smooth grinding undercut is formed on a matching excircle of the valve core, so shear-free contact between the matching excircle and the air inlet sealing ring in the opening and closing process of the valve core can be ensured, the valve core can be ensured to be closed and opened without difficulty, and the service life of the plunger pneumatic quick-change coupler is long. Compared with like products, the plunger pneumatic quick-change coupler has a simple structure and smaller radial size, and the air entraining plug (Plug) is easy to insert and cannot fall off accidentally, so the plunger pneumatic quick-change coupler is safe and reliable.

Owner:庄志军 +1

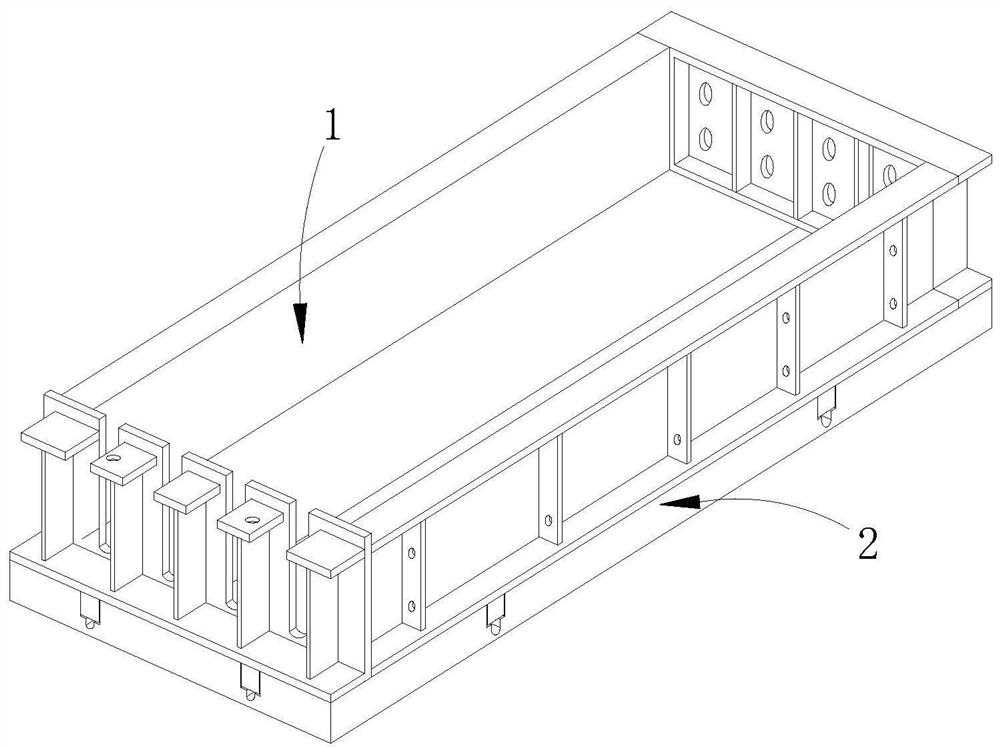

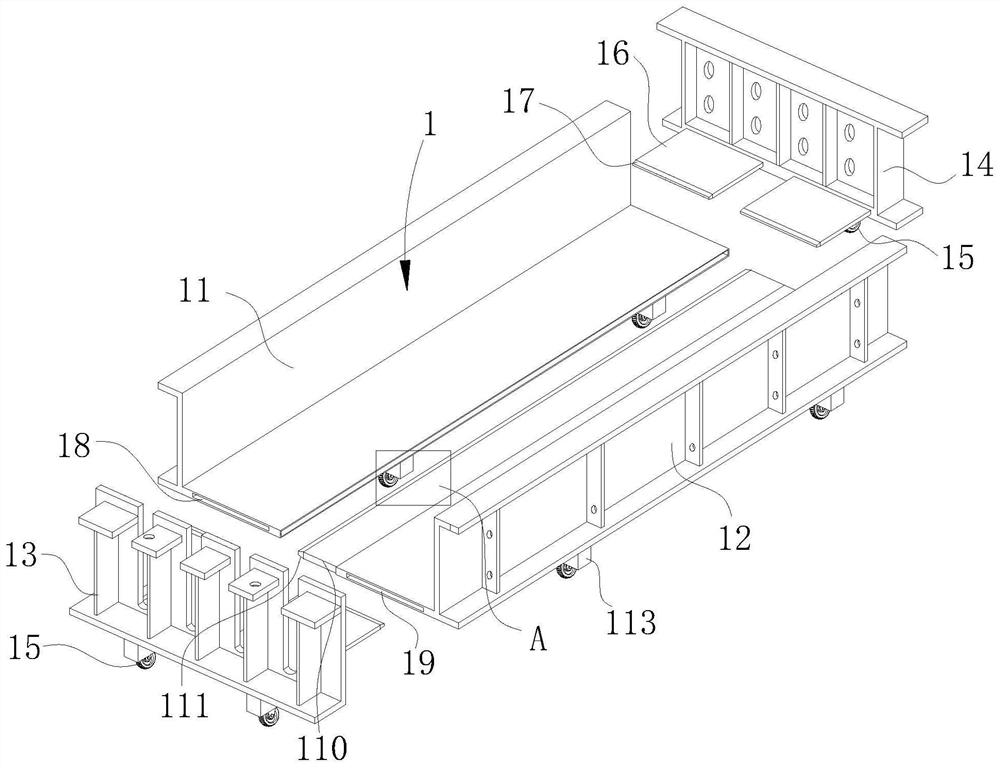

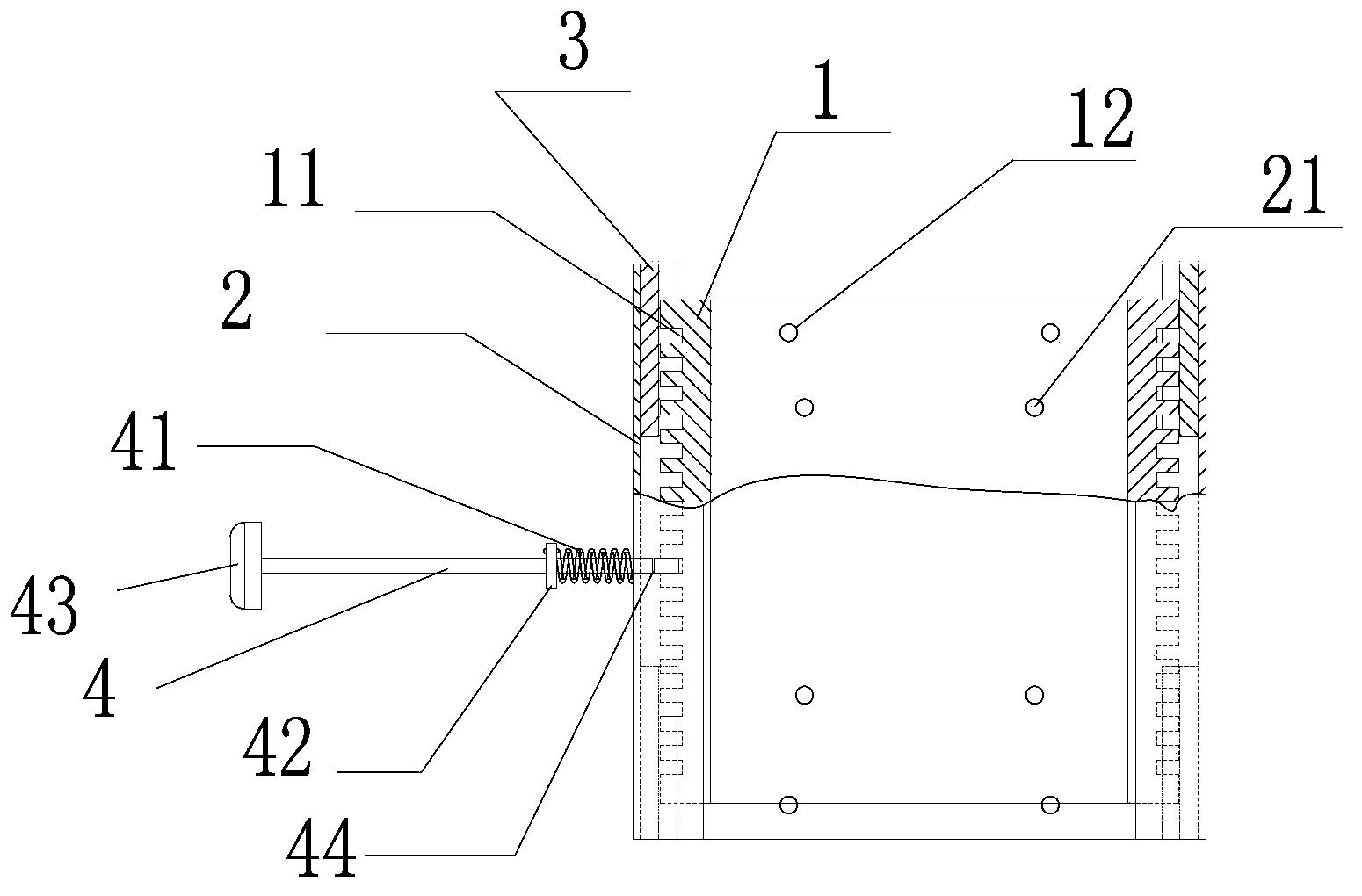

Assembly type precast concrete member die

ActiveCN111605050AEasy to assemble and disassembleAvoid damageMouldsMould fastening meansPrecast concreteArchitectural engineering

The invention relates to an assembly type precast concrete member die. The assembly type precast concrete member die comprises a die mechanism and a bearing mechanism. According to the assembly type precast concrete member die, the die adopts an assembly structure, so that when a prefabricated member is molded and demoulded, the effect of rapidly disassembling and assembling the prefabricated member is achieved through a die split mechanism; meanwhile, in the disassembly and assembly process, the prefabricated member is not required to be carried and overturned, so that the prefabricated member is prevented from being damaged; and specifically, the die is composed of a first master die, a second master die, a first slave die and a second slave die, during form removal, firstly the first slave die and the second slave die are disassembled and assembled, and then one of the first master die or the second master die is removed, so that the demoulding of the prefabricated member is realized.

Owner:界首市宝业瑞祥建筑工业化有限公司

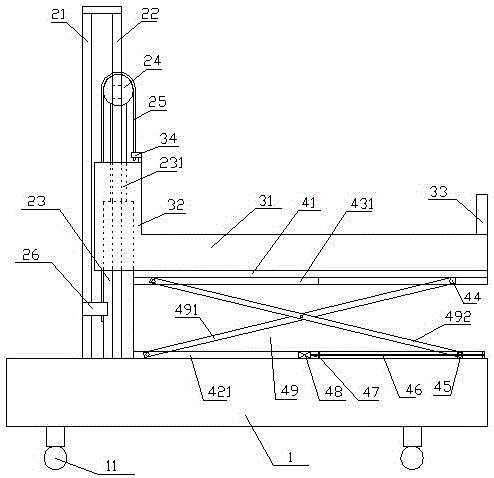

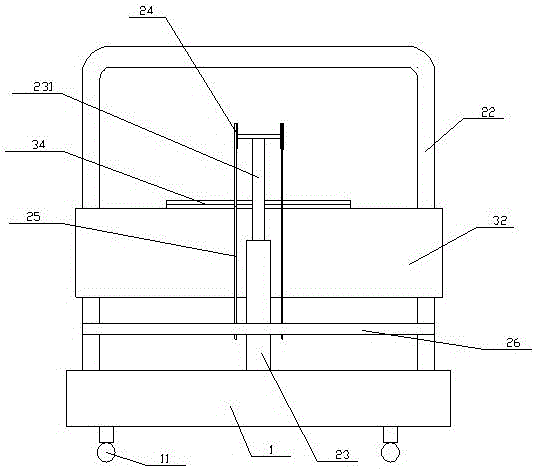

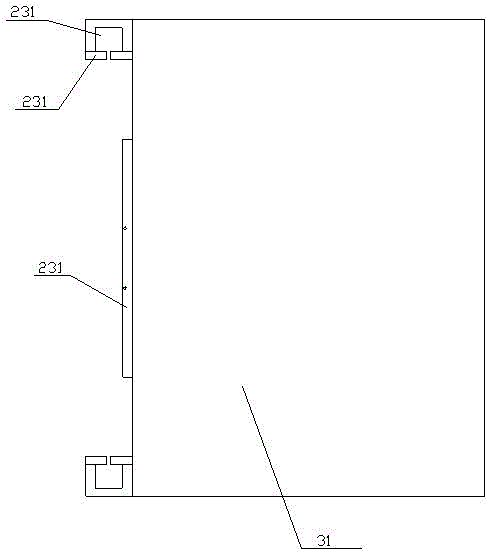

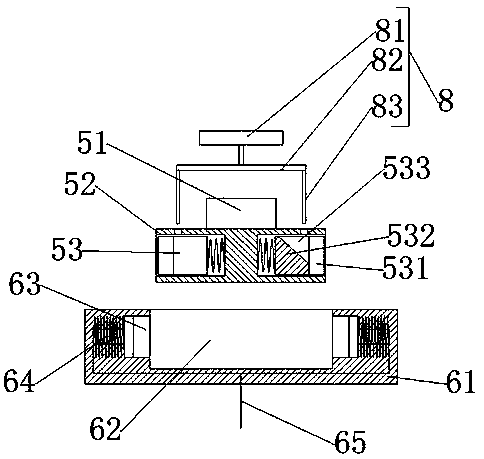

Automatic positioning and lifting device for maintaining electric vehicles

InactiveCN108216140AFunction increaseImprove stabilityLifting framesCleaning apparatus for vehicle exteriorsEngineeringElectric vehicle

The invention relates to an automatic positioning and lifting device for maintaining electric vehicles. The automatic positioning and lifting device comprises a support device, lifting devices and twolimit devices. The lifting devices are mounted on the top of the support device, and the two limit devices are mounted at the left end and the right end of the support device and are symmetric with each other; each lifting device comprises two lifting mechanisms, two auxiliary push rods, rubber pads, a cleaning electric slider, a cleaning upright column, a cleaning transverse column, a cleaning frame and a cleaning branch chain. The automatic positioning and lifting device has the advantages that the difficulty problems of high risks when tires of existing electric vehicles are detached, requirements on manually lifting the existing electric vehicles, low lifting stability, incapability of automatically cleaning protrusions of chassis of the existing electric vehicles, incapability of clearing sundries in the tires and the like can be solved by the aid of the automatic positioning and lifting device; the automatic positioning and lifting device can have functions of clearing sundriesin grooves of front wheels of different models of electric vehicles and automatically stably lifting the electric vehicles.

Owner:刘秀娟

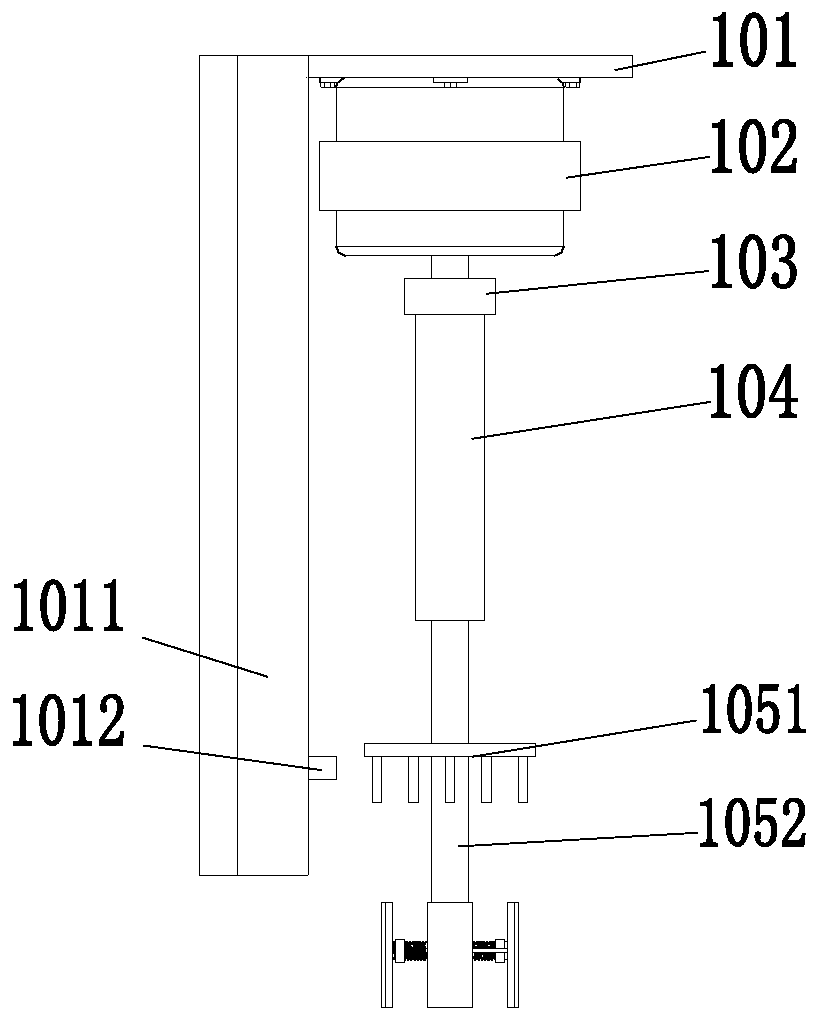

Manufacture machine for stainless steel alloy flange

ActiveCN111469013AFast and stable lockPlay a locking roleGrinding drivesGrinding machinesStructural engineeringAlloy

The invention relates to a manufacture machine for a stainless steel alloy flange. The manufacture machine comprises a base, a limit mechanism, L-shaped rods, a circular base, a bolt, an annular block, adjustment arms, connection arms, driven arms and polishing mechanisms. The upper end surface of the base is provided with the limit mechanism, the front right and rear left portions of the upper end surface of the base are provided with the L-shaped rods, the circular base is installed between the inner sides of the upper ends of the L-shaped rods, and the circular base is connected with the lower end of the bolt through a bearing. The annular block is connected to the middle of the bolt in a thread cooperation mode, four adjustment arms are symmetrically installed on the outer side surfaceof the annular block, the lower end of each adjustment arm is connected with the middle of the upper surface of the corresponding driven arm through the corresponding connection arm, and the lower end of each driven arm is provided with the polishing mechanism through a hinge. The manufacture machine can solve the problems that when burrs of a bolt hole in a flange are removed in the prior art, the effect of locking the flange by a clamp of processing equipment is poor, the processing equipment can only process one bolt hole, and burrs of the upper surface of the bolt hole need to be subjected to secondary processing through other equipment.

Owner:盐城斯天康精密制造有限公司

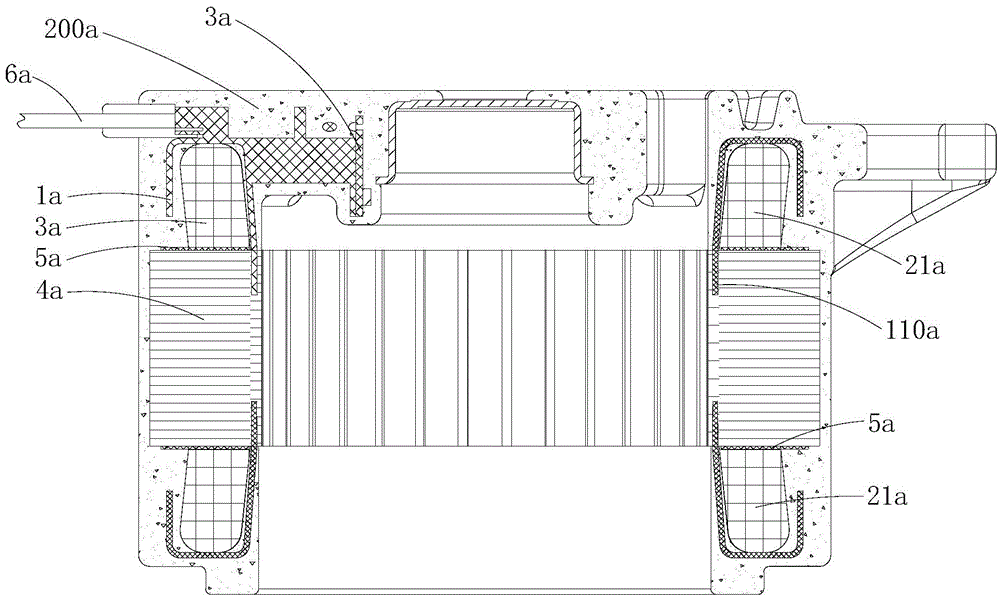

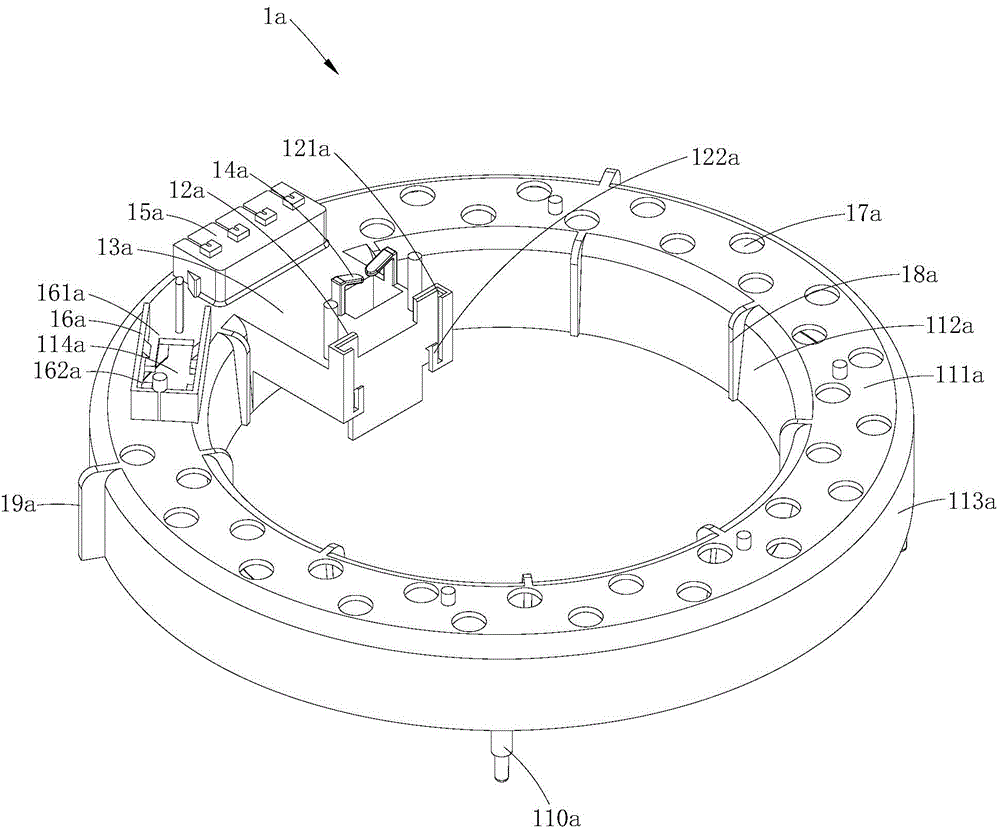

Stator winding end insulation frame, plastic-packaging stator assembly, and plastic-packaging motor

ActiveCN104836358AAutomate installationGuaranteed reliabilityWindings insulation shape/form/constructionPlastic packagingEngineering

The invention is suitable for the field of motors, and discloses a stator winding end insulation frame, a plastic-packaging stator assembly, and a plastic-packaging motor. The insulation frame comprises an insulation frame body which is disposed at an axial end part of a stator winding along the axial direction of a motor in a sleeve manner. The insulation frame body is provided with a PG plate installation frame which is used for the installation and positioning of a PG plate member, wherein the PG plate installation frame is provided with a clamping groove which is used for the storage and positioning of the PG plate member. According to the invention, the insulation frame body is additionally provided with the PG plate installation frame, thereby achieving the installation and positioning of the PG plate member only if the PG plate member is slidingly clamped and inserted in the clamping groove of the PG plate installation frame during installation. The installation is very convenient, thereby facilitating the implementation of the automatic installation of the PG plate installation frame. Moreover, the PG plate member cannot be damaged by pressing in an installation process, thereby guaranteeing the reliability of motor performances. Meanwhile, the reduction design of the PG plate member is also facilitated, thereby avoiding the material waste, and reducing the cost of a motor.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

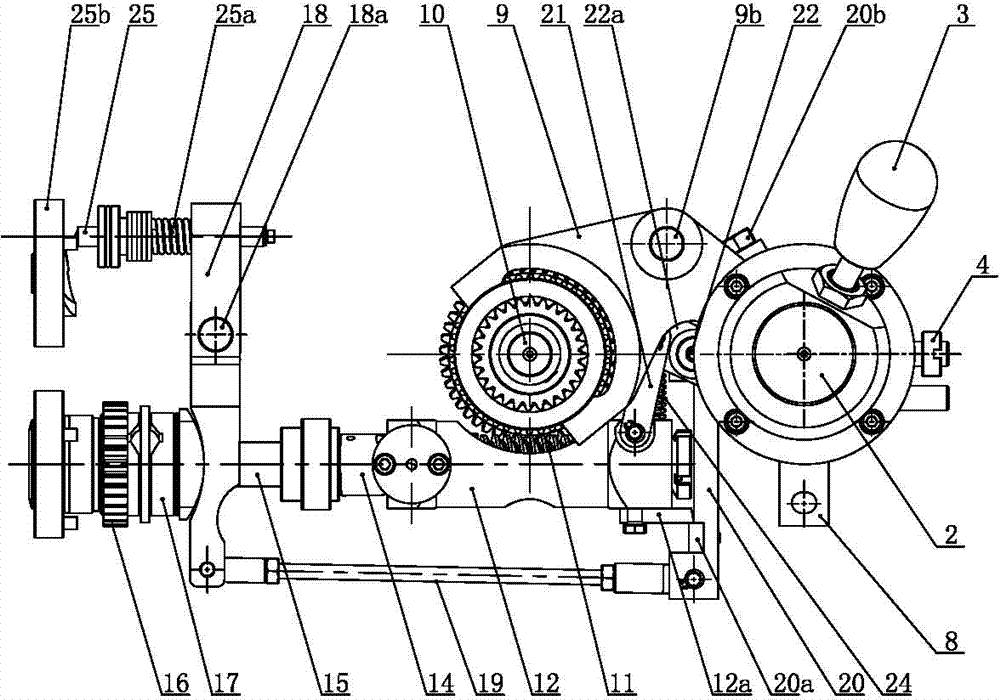

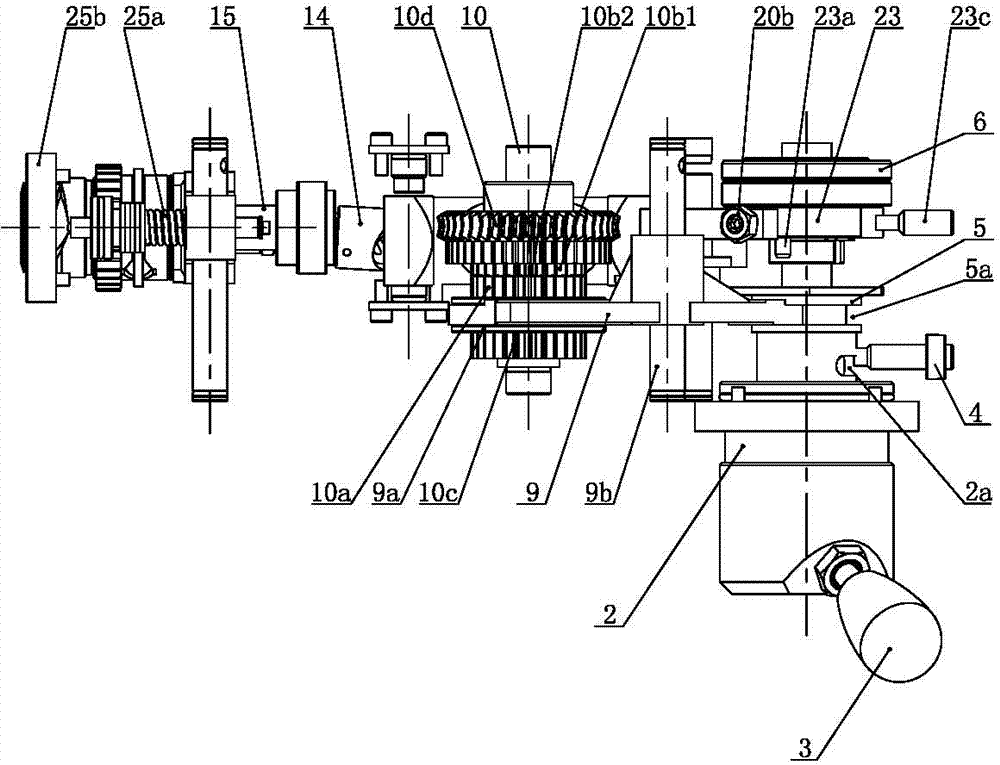

Lathe sliding box

ActiveCN104259492AAchieve interlockAvoid displacementFeeding apparatusLarge fixed membersGear wheelEngineering

The invention relates to a lathe sliding box; a transverse knife feeding gear and a longitudinal knife feeding gear are installed on front and rear sides of a middle gear on a wheel shaft; the middle gear, the transverse knife feeding gear and the longitudinal knife feeding gear are respectively engaged with an annular gear; a control handle shaft is parallel to the wheel shaft; a handle capable of driving the control handle shaft to rotate or slide forwards and backwards is installed on the control handle shaft; the annular gear is rotationally connected to one end of a sliding link rod, and the middle part of the sliding link rod is installed on a sliding link rod shaft that is parallel to the control handle shaft; a sliding link rod driving plate is fixedly installed on the control handle shaft and provided with a sliding link rod slot extending along the circumference, and the other end of the sliding link rod is inserted into the sliding link rod slot. A concave arc cam is installed on the control handle shaft, the rear end face of the concave arc cam is provided with a concave arc groove in which a link rod pin is inserted, and the outer end of the link rod pin is hinged to the upper end of a half nuts control link rod. According to the sliding box, interlocking of the transverse knife feeding gear, the longitudinal knife feeding gear and the half nuts is achieved by the control handle.

Owner:YANGZHOU SUPER MASCH TOOL CO LTD

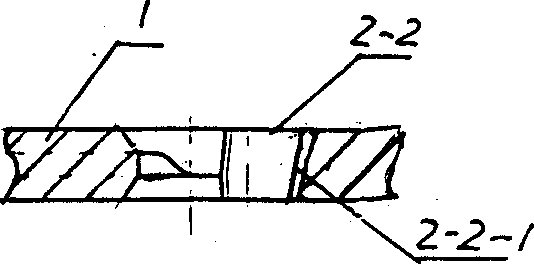

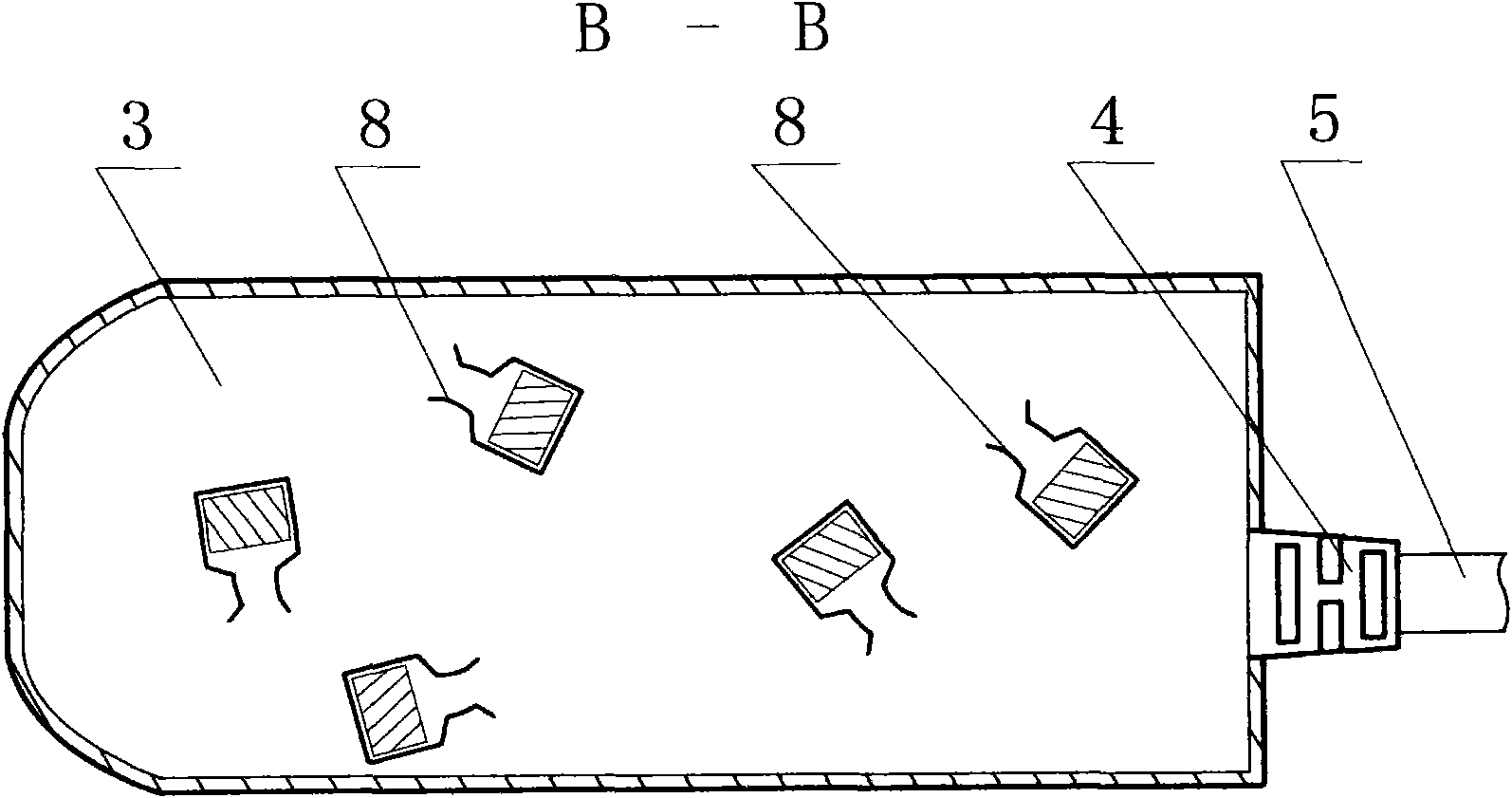

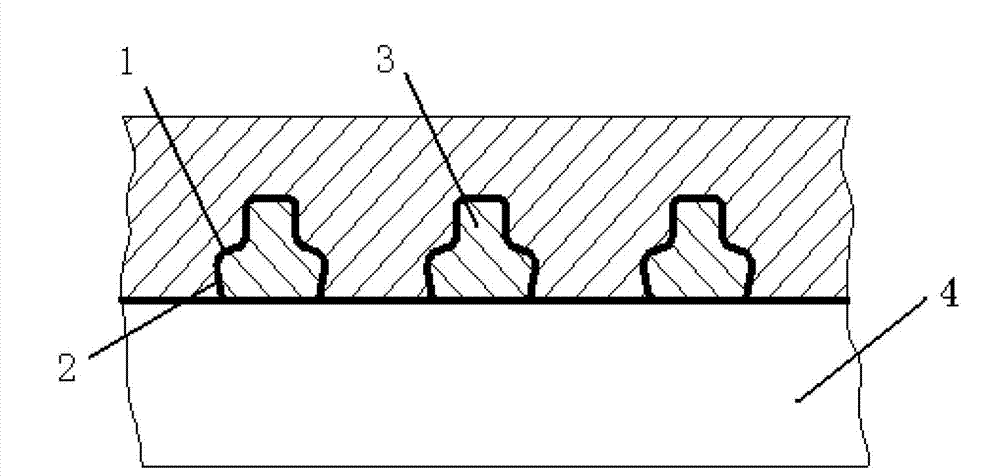

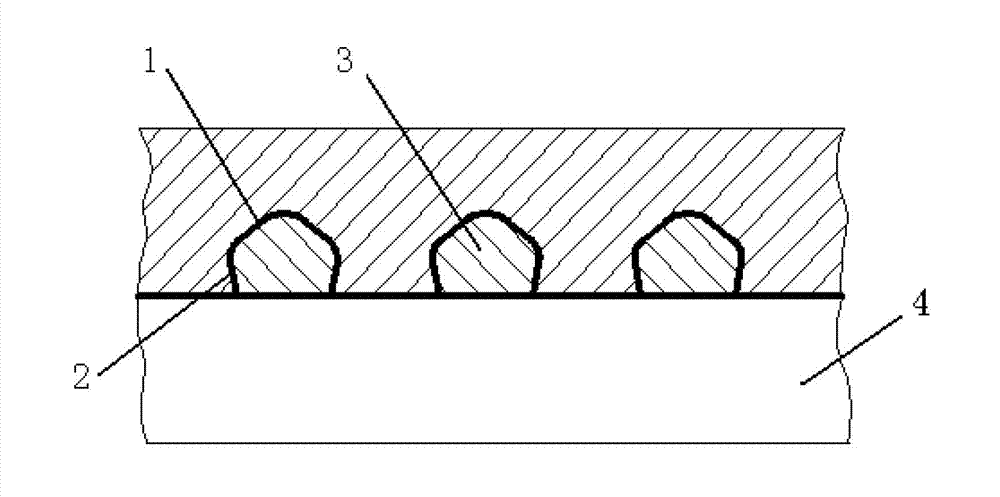

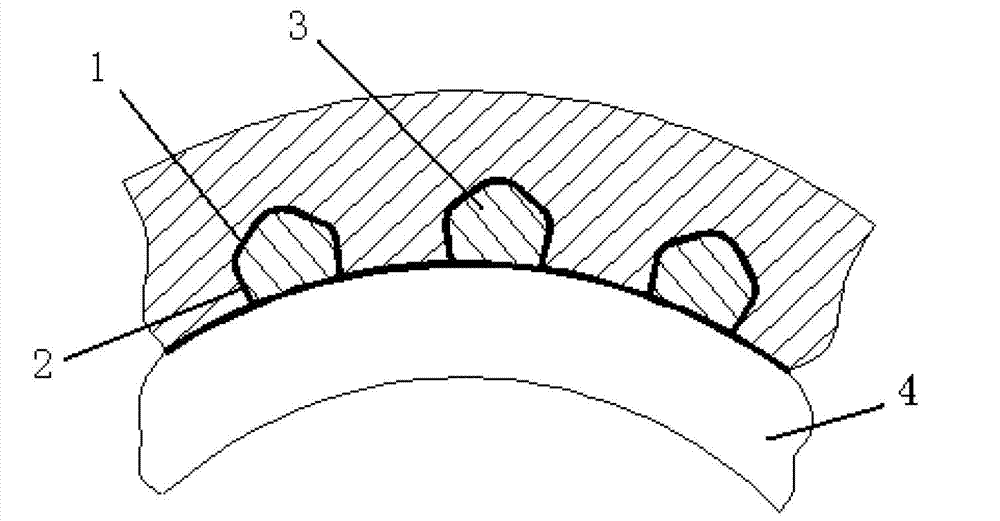

Method for brazing SiO2f/SiO2 composite ceramic and metal material

ActiveCN102924110AAchieving a soldered connectionAvoid residual thermal stressSurface layerComposite ceramic

The invention discloses a method for brazing a SiO2f / SiO2 composite ceramic and a metal material. The method comprises the following steps of: uniformly processing a plurality of open grooves in a surface to be brazed of the SiO2f / SiO2 composite ceramic; correspondingly singly processing mosaic blocks of which the sizes are matched with those of the open grooves and the quantity is the same as that of the open grooves; assembling the mosaic blocks into the open grooves in the surface layer of the brazed SiO2f / SiO2 composite ceramic one by one; filling AgCu-based active solders on an interface between each metal mosaic block and each open groove and on the interface to be brazed between the brazed SiO2f / SiO2 composite ceramic and the brazed metal material; and effectively binding the SiO2f / SiO2 composite ceramic of a large size with the metal material in a vacuum brazing heating mode. The method is also suitable for binding between C / C composite materials, Cf / SiC composite materials, SiCf / SiC composite materials, Al2O3 ceramics, SiC ceramics as well as Sialon ceramics of the larger size and the metal material.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

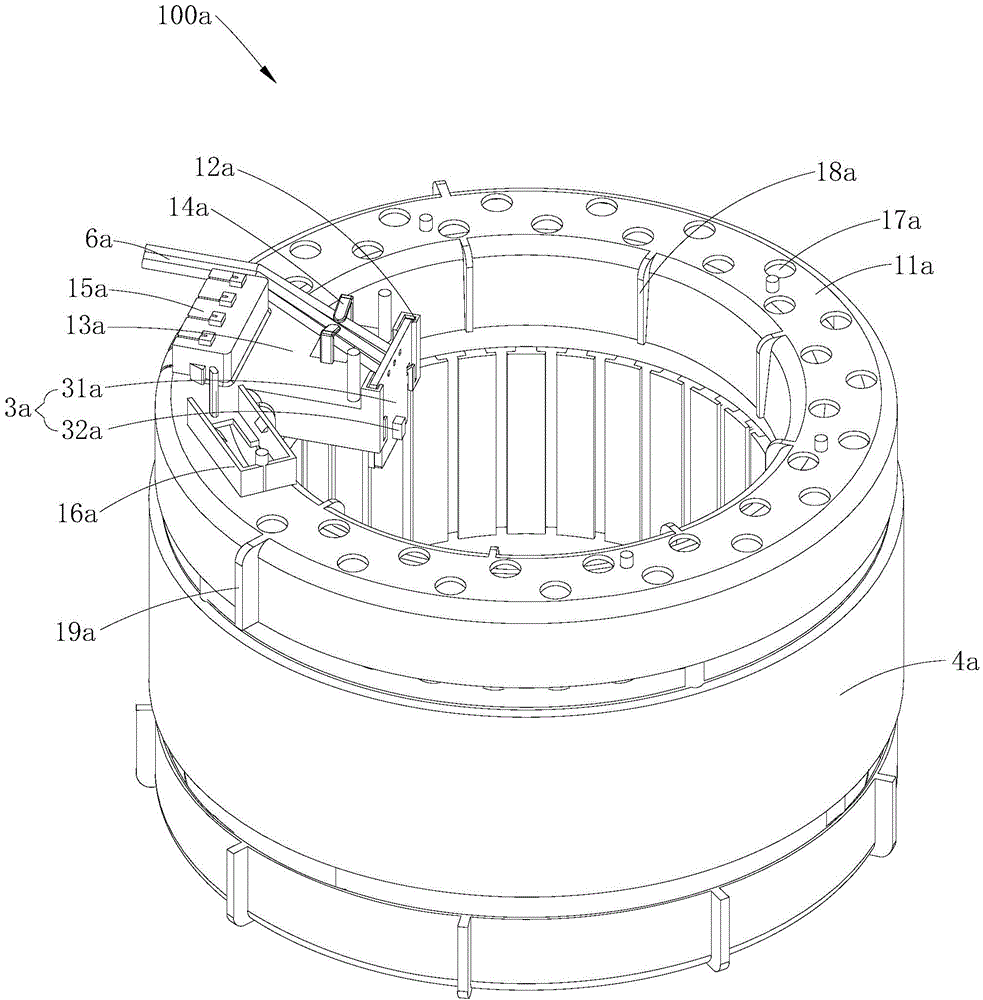

Lapping machine

ActiveCN109551334AEasy to take outEasy to operateSpherical surface grinding machinesGrinding feedersSteel ballMachining

The invention relates to the technical field of steel ball machining equipment, in particular to a lapping machine. The lapping machine includes a rack, a ring feeding channel and a driving assembly,wherein the ring feeding channel is provided with a guiding block in a T shape, a feeding plate and a discharging plate are arranged at the two ends of the guiding block respectively, a splitter plateis arranged in the middle of the guiding block, and the splitter plate is positioned in an opening and divides the opening into a feeding opening and a discharging opening; and the end, away from thedischarging plate, of the feeding plate is connected with a direction changing plate in a hinged mode, the ring feeding channel is provided with an adjusting structure, position, on the side, away from the discharging plate, of the feeing plate, on the outer side wall of the ring feeding channel is provided with a falling opening, and the direction changing plate can cover the falling opening after rotating. The lapping machine has the following effects that when a steel ball is made to move towards the feeding opening by the driving assembly, the steel ball abuts against the direction changing plate, the steel ball moves away from the ring feeding channel through the falling opening, an operation worker only needs to collect the steel ball from the falling opening and can take out the lapped steel ball conveniently, the operation process is simplified, and the machining efficiency is improved.

Owner:绍兴市上虞叶华实业有限公司

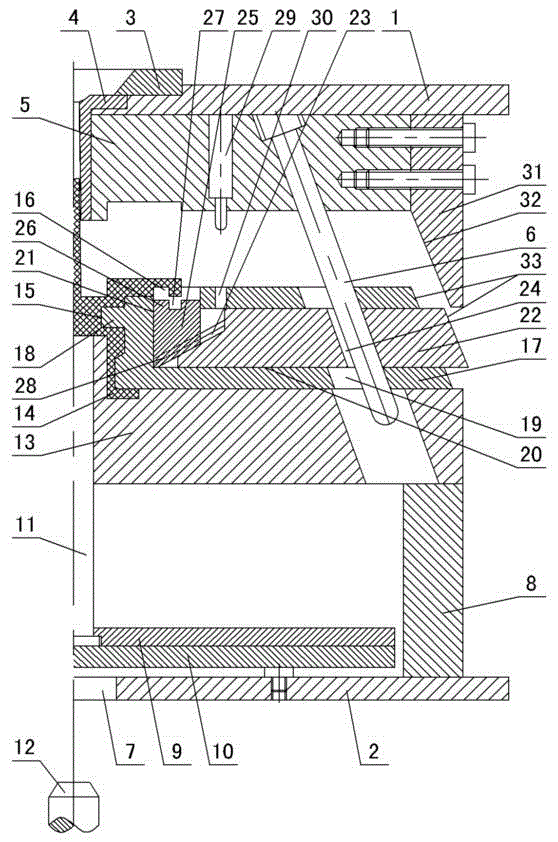

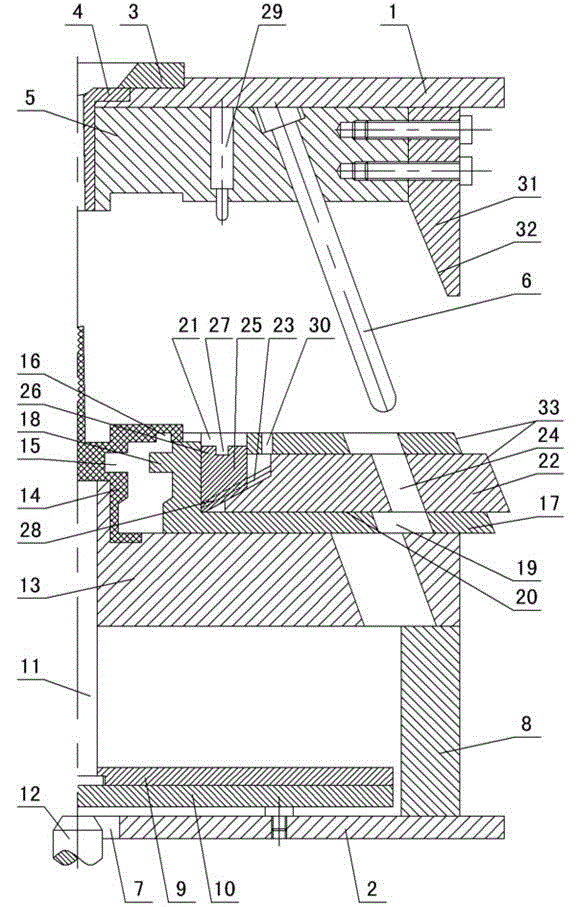

Injection die horizontal and vertical direction combination loose core mechanism

An injection die horizontal and vertical direction combination loose core mechanism comprises an upper compound plate and a lower compound plate, a cavity is arranged below the upper compound plate, an inclined guide column is arranged in the cavity, the lower compound plate is provided with a through hole, the lower compound plate is provided with a die foot, the lower compound plate is provided with an upper thimble plate and a lower thimble plate, a thimble is arranged between the upper thimble plate and the lower thimble plate, an injection machine push rod traverses through the through hole and contacts with the lower thimble plate, the die foot is provided a core, a plastic member is arranged between the core and the cavity, one side of the plastic member is provided with a horizontal direction side undercut and a vertical direction side undercut, the core is provided with an outer slide block, one side of the outer slide block is provided with a side loose core, the side loose core cooperates with the plastic member horizontal direction undercut, a large inclined guide hole, a transverse loose core hole and a straight loose core hole are arranged in the outer slide block, an inner slide block is arranged in the transverse loose core hole, one side of the inner slide block is provided with an inclined slide slot, a small inclined guide hole is arranged in the inner slide block, the large and small inclined guide hole cooperate with the inclined guide column, a vertical loose core slide block is arranged in the straight loose core hole, the vertical loose core slide block is provided with an upper loose core and an upper groove, the upper loose core cooperates with the vertical direction side undercut, an inclined guide rail is arranged below the vertical loose core slide block, and the inclined guide rail cooperates with the inclined slide slot.

Owner:ZHEJIANG KAIHUA MOLDS

Special locking device for high-low voltage cabinets

InactiveCN107747434APlay a locking roleEasy to operateNon-mechanical controlsSubstation/switching arrangement casingsLow voltageEngineering

A special locking device for high-low voltage cabinets comprises a spring locking structure and an electromagnetic locking structure. The spring locking structure comprises a connecting portion and acylindrical portion vertical to the connecting portion, two ends of the cylindrical portion are provided with first dead circular holes, and movable pins are respectively disposed in the first circular holes at the two ends. The electromagnetic locking structure comprises a fixed block, one side of the fixed block is provided with a U-shaped notch cooperated with the cylindrical portion, two endsof the U-shaped notch are provided with second circular holes cooperated with the movable pins, and the bottoms of the second circular holes at the two ends are respectively provided with electromagnet structures. Deficiency of the prior art is overcome, the special locking device comprises the spring locking structure and the electromagnetic locking structure, the movable pins in the spring locking structure are pulled by springs and contracted in the cylindrical portion under a normal condition, when a door is closed, the movable pins are cooperated with the electromagnetic locking structure, attracted by the electromagnets in the electromagnetic locking structure and inserted into the electromagnetic locking structure so as to lock the door, and when the door is required to be opened, electromagnet current is cut off by a control switch. The special locking device is simple in operation and wide in application range.

Owner:合肥智鼎电控自动化科技有限公司

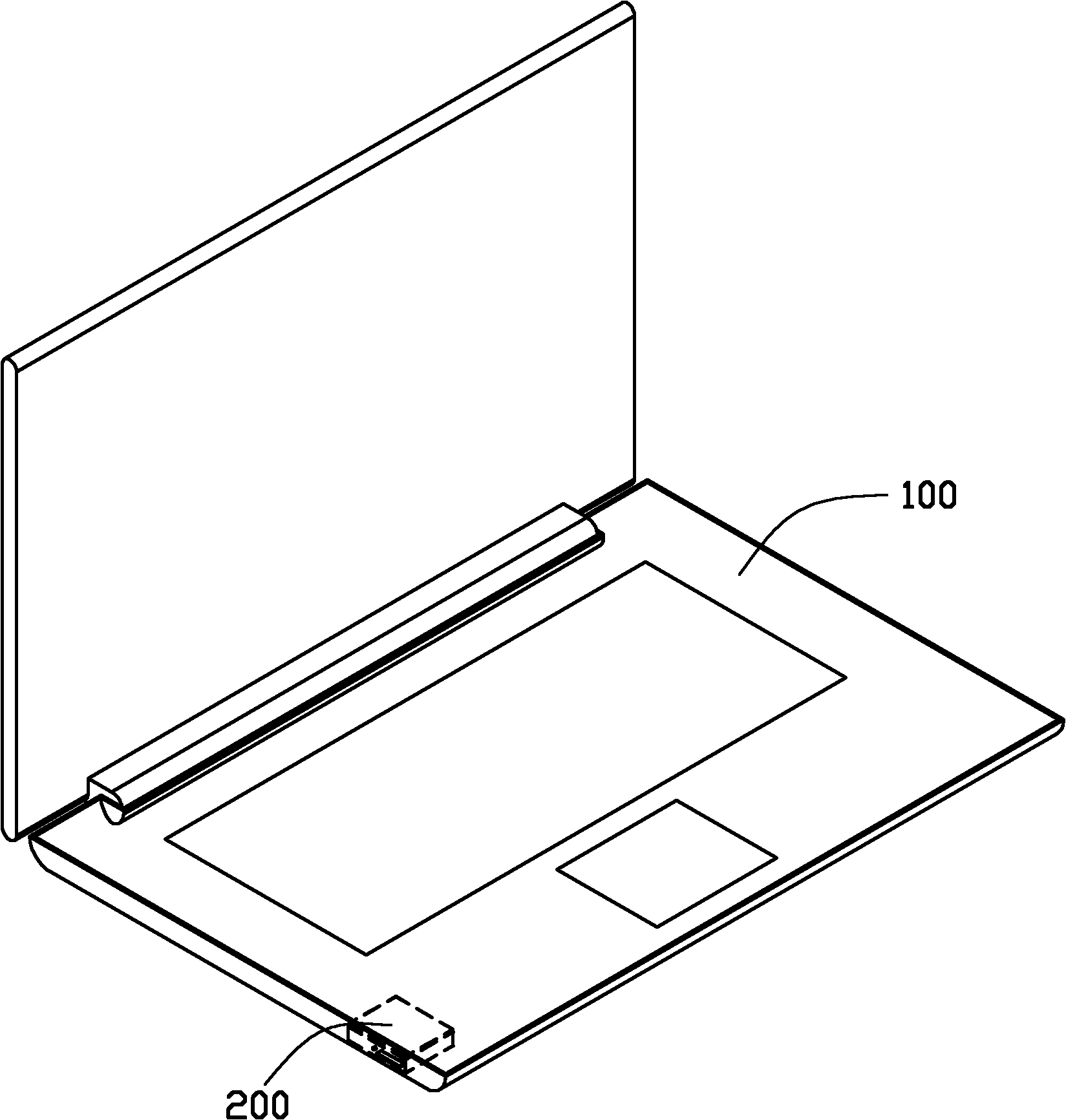

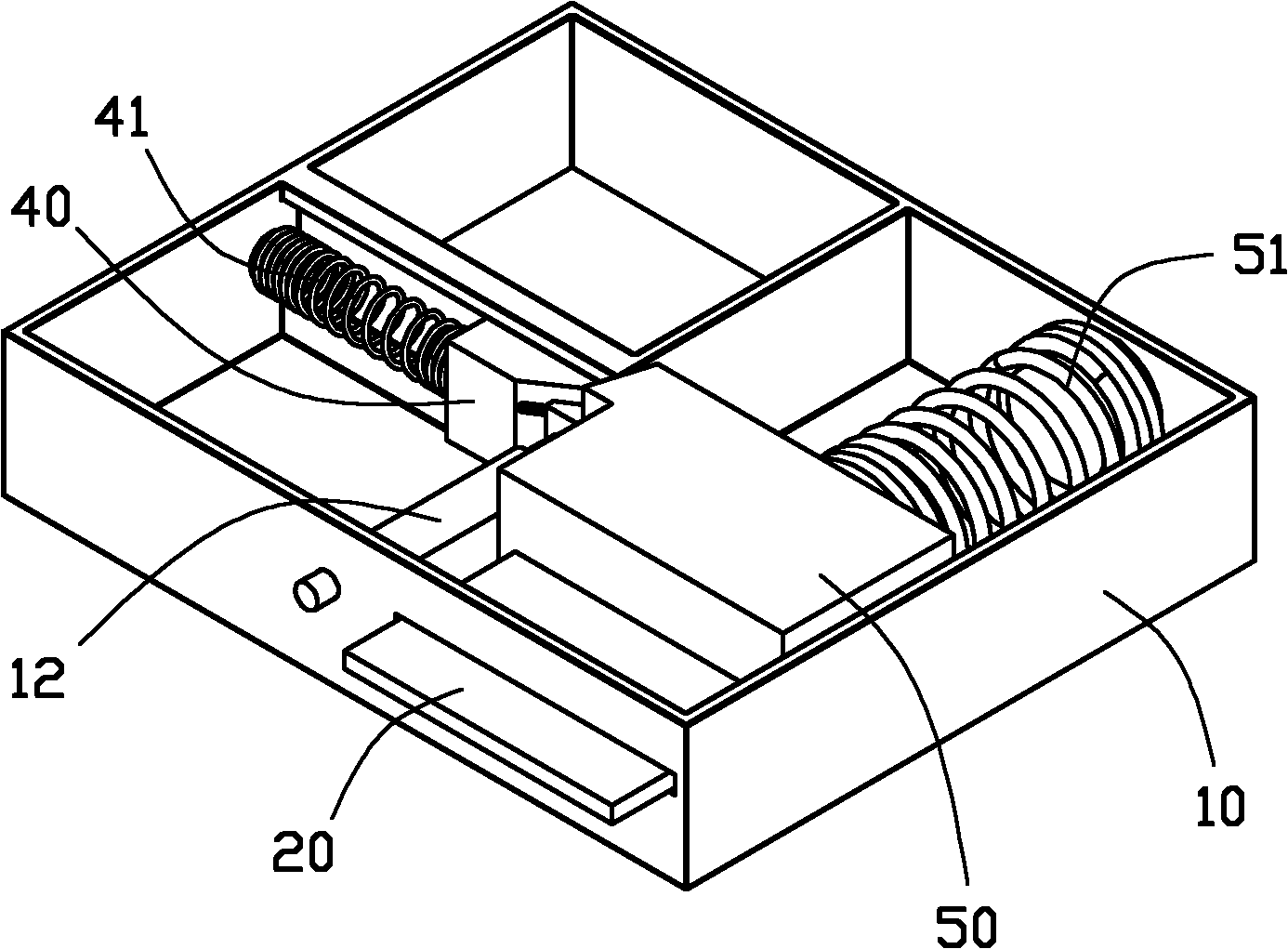

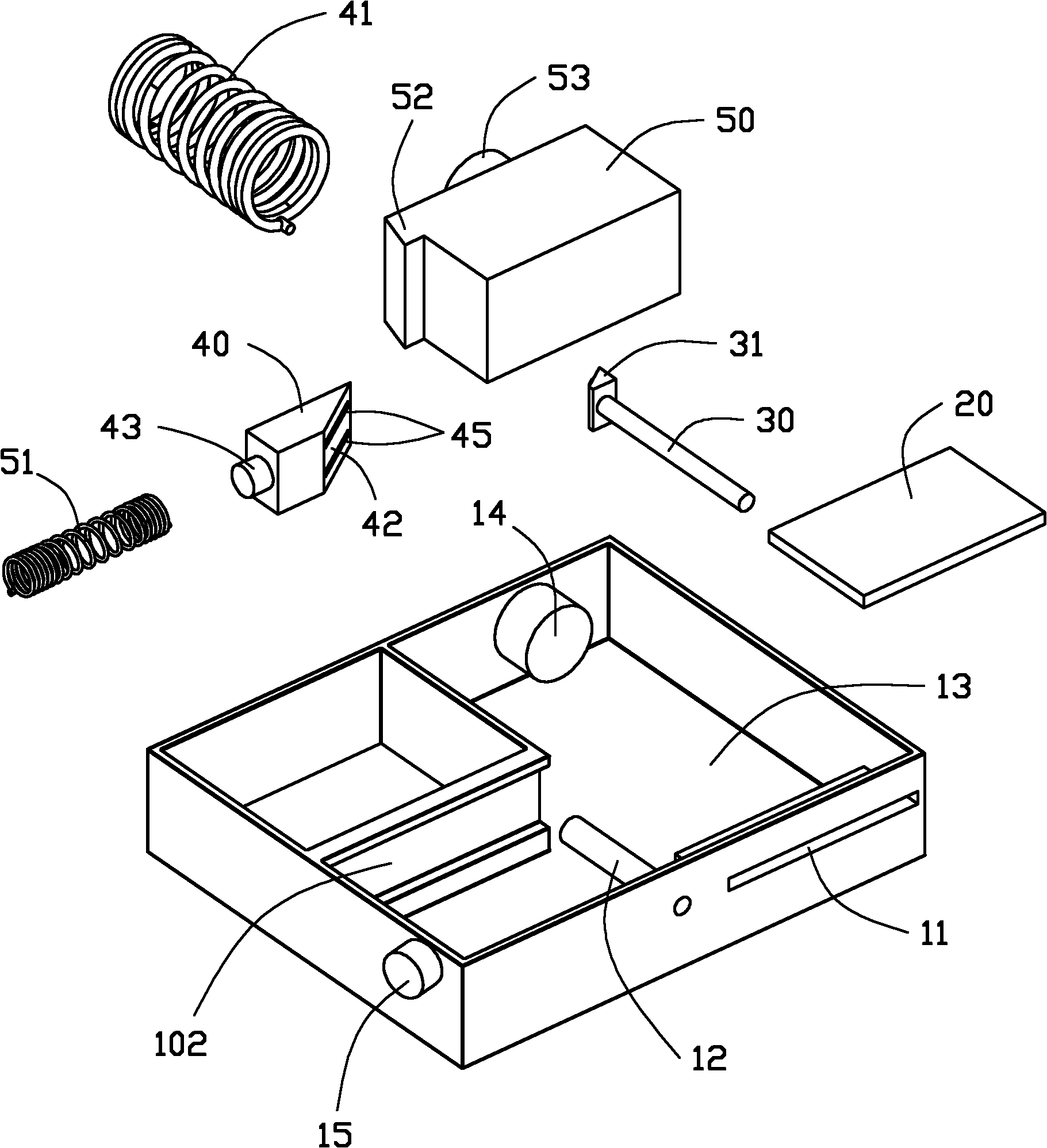

Electronic equipment and ejecting device thereof

InactiveCN101841989APlay a locking roleEasy to take outCasings/cabinets/drawers detailsSupport structure mountingMechanical engineeringElectronic equipment

The invention relates to electronic equipment which comprises an ejecting device of a plug-in element, wherein the ejecting device comprises a shell, a connector, a sliding block and a button; the shell is provided with an opening; the connector is arranged in the shell in a sliding way, and one side of the connector is provided with a locking hook; a first spring for connecting the connector and the shell is used for driving the connector to move towards the opening; the sliding block is arranged in the shell in a sliding way, and one end of the sliding block is provided with a slope; a second spring for connecting the sliding block and the shell is used for driving the sliding block to hook the locking hook; one end of the button goes out of the shell, and the other end is provided with an inclined wedge; and the inclined wedge butts against the slope of the sliding block. When the button is pressed, the inclined wedge moves along the slope, thereby driving the sliding block to be separated from the locking hook and ejecting the plug-in element.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Lock cylinder and unlocking key

ActiveCN110359775APlay a locking roleAchieve mechanical lockingNon-mechanical controlsKeysMechanical engineeringEngineering

The invention provides a lock cylinder and an unlocking key. The lock cylinder comprises a lock case, a lock core, a locking part, locking blades, a driving assembly and a driving control blade; the lock core is rotatably arranged in the lock case; the locking part is movably arranged between the lock core and the lock shell and has a locking position and an unlocking position; the locking bladesare movably connected with the lock core and can stop or avoid movement of the locking part so as to lock or unlock the locking part; at least one part of the driving assembly is movably arranged relative to the locking part and can stop or avoid movement of the locking part so as to lock or unlock the locking part; and the driving control blade is movably connected with the lock core and has a stopping position and an avoiding position, when the driving control blade is located at the stopping position, the driving control blade stops movement of the driving assembly, and when the driving control blade is located at the avoiding position, the driving control blade avoids movement of the driving assembly. According to the lock cylinder and the unlocking key, the problem that in the prior art, the safety of a lock cylinder is low is solved.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

Improved chair structure with sliding device

The invention mainly discloses an improved chair structure with a sliding device. The improved chair structure comprises a chair plate, the bottom of which is provided with the sliding device. The lower end of the sliding device is connected with an adjusting pallet. The adjusting pallet is connected with a gas pole and a foot rest. The sliding device is composed of an upper slide plate and a lower slide plate. The lower slide plate is provided with a chute. The upper end of the upper slide plate is fixed with the chair plate, and two sides of the upper slide plate are installed inside the chute of the lower slide plate. Thus, relative back and forth displacement between the chair plate and the foot rest is realized, and the problem that a swivel chair without pulleys is not convenient to adjust the distance between a seat board and an office table is solved. In addition, a headrest support is connected above a backrest connected with the chair plate, and the rotatably adjusting function of the headrest body is realized through a hinge joint mode between the headrest support and the headrest body.

Owner:ONSUN FURNITURE

Self-compensating, locking and quick-connecting high-pressure pipe connector

InactiveCN101776192AShorten the installation periodImprove economic efficiencyPipeline expansion-compensationFastenerFusion welding

The invention relates to a self-compensating, locking and quick-connecting high-pressure pipe connector, which consists of a rubber sealing sleeve 2, a clamp hoop 3, a clamp claw 4 and a fastening component 5 and overcomes the defects of the existing pipe connection technology such as high cost and poor practicality. The self-compensating, locking and quick-connecting high-pressure pipe connector is characterized in that the rubber sealing sleeve 2 surrounds the excircle of a pipe, the angular ring of the open cavity of the rubber sealing sleeve 2 is arranged on two pipes. The clamp hoop 3 is symmetrically buckled with the pipe and is pressed on the outer surface of the rubber sealing sleeve 2, the upper annular pointed teeth of the clamp hoop 3 are adhered to the pipe, the inner arc-shaped surface of the clamp claw 4 is provided with a plurality of annular pointed teeth and is arranged in the inner conical groove of the clamp hoop 3, and the clamp claw 4 is adhered to the outer wall of the pipe and can slide along the axial direction of the pipe to concentrically contract, buckle and lock the pipe. The high-pressure pipe connector can resist high, medium and low pressure, and adopts no welding, no flange, no groove, no electric thermal fusion welding or no external compensator, and has the functions of self compensation, locking, all-round safe sealing due to integration of rigid and flexible features, and labor and time conservation. Particularly under harsh environmental conditions, the high-pressure pipe connector has the advantages of convenient and rapid connection, low cost, high efficiency, energy conservation, emission reduction and environmental protection. The invention can be used for connecting two pipes for fluid transmission.

Owner:王甲南

Equipment wire clamp anti-breaking device

ActiveCN111509480APrevent disengagementPlay a locking roleRelieving strain on wire connectionBolt connectionElectrical and Electronics engineering

Owner:GUIZHOU POWER GRID CO LTD

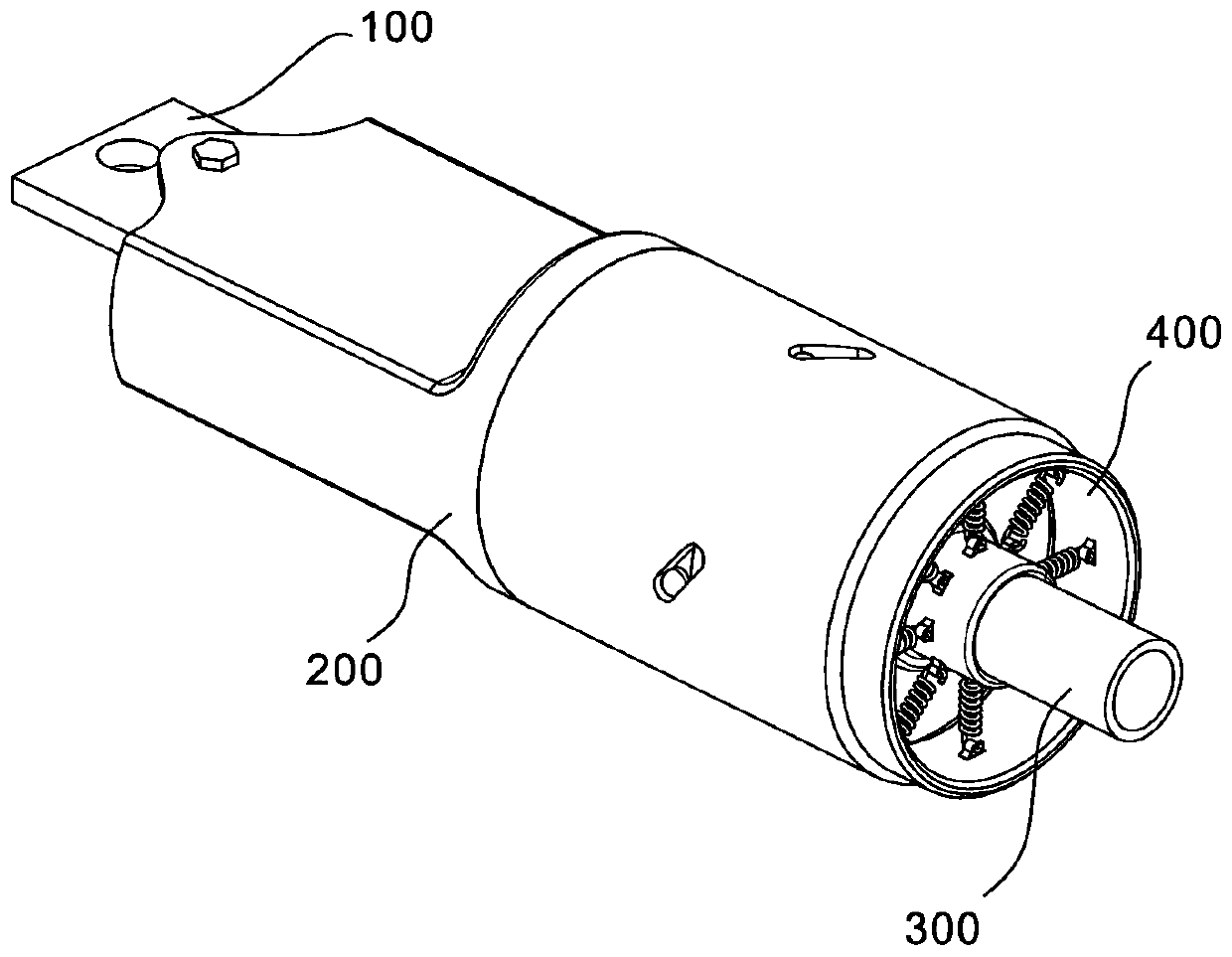

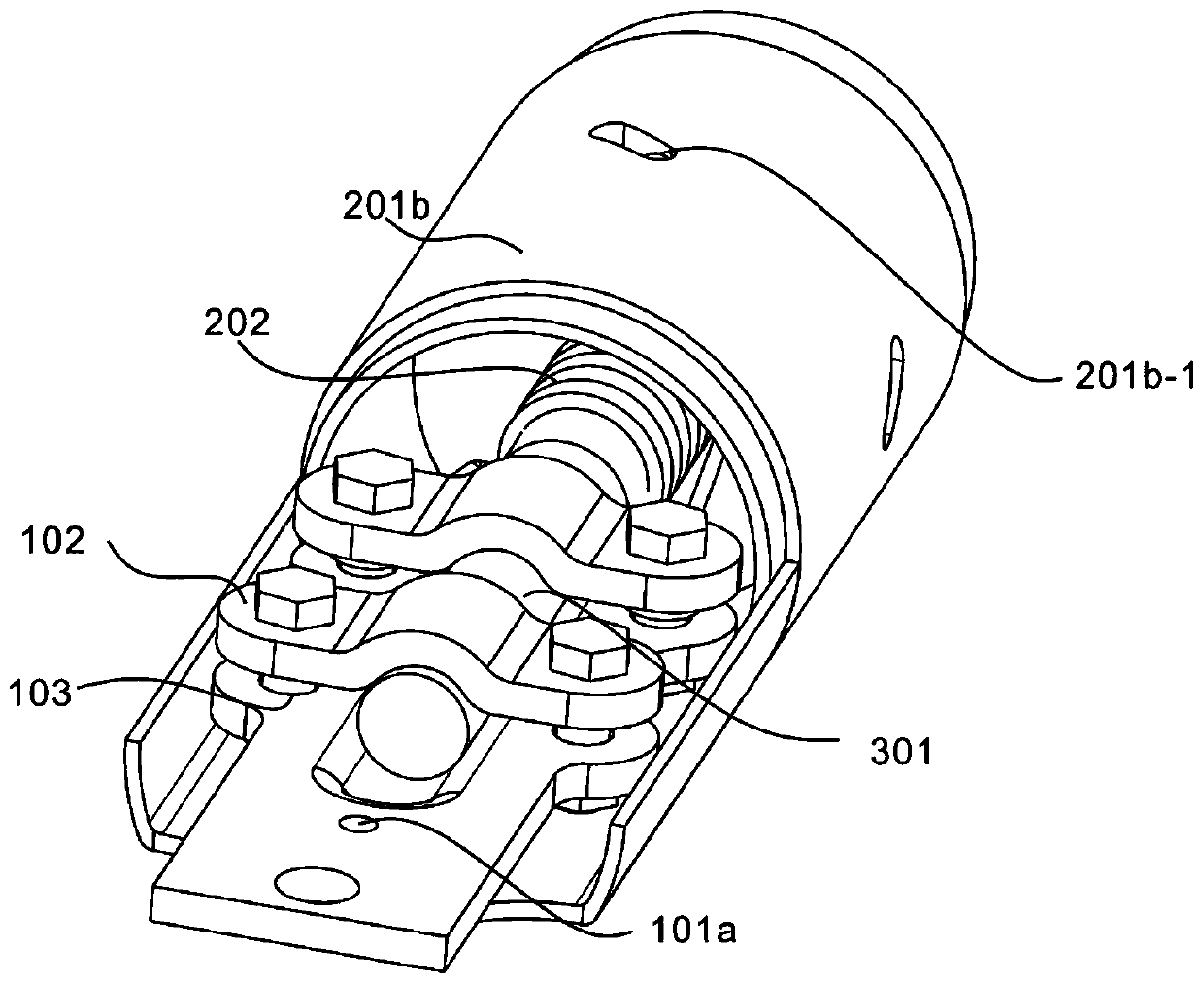

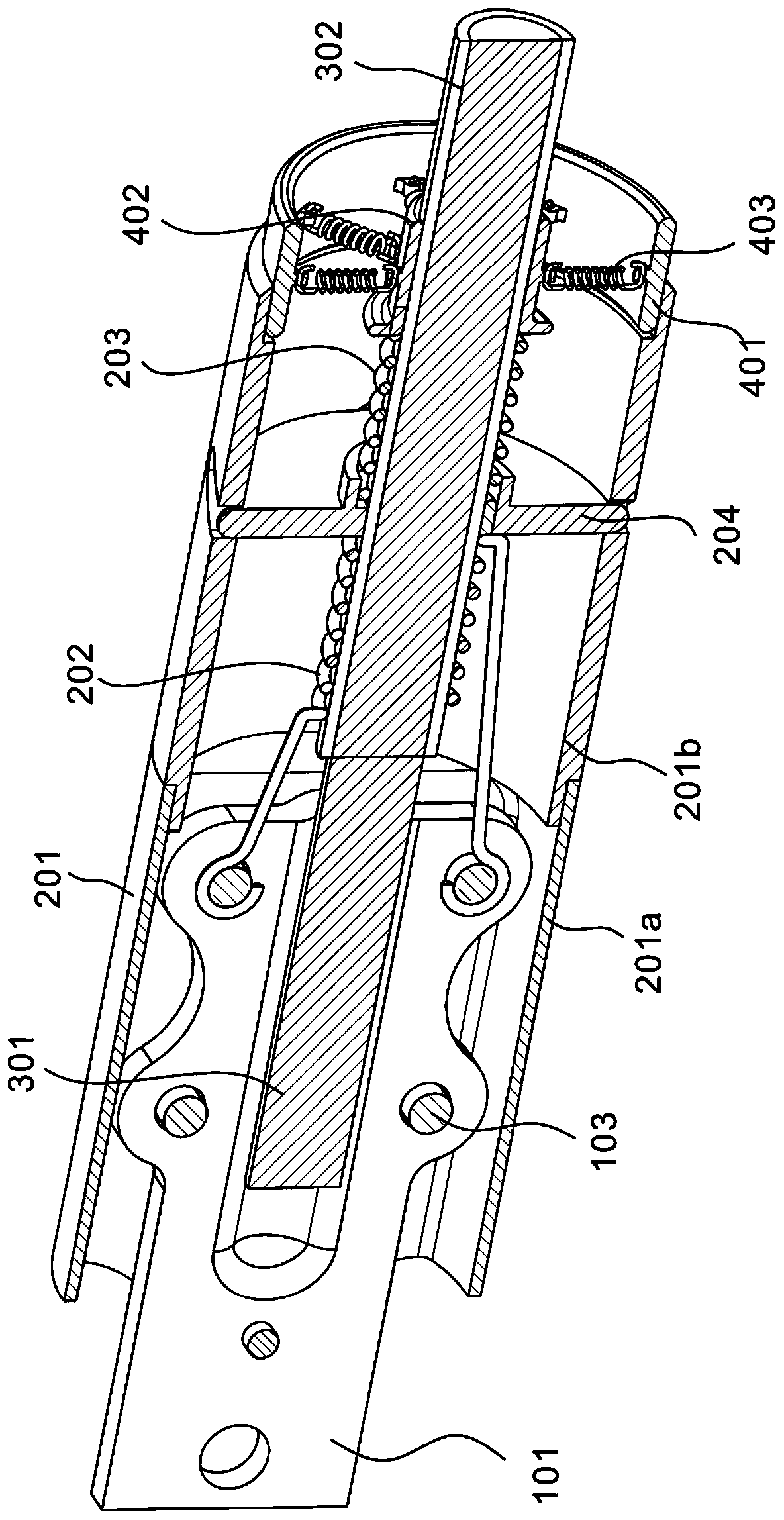

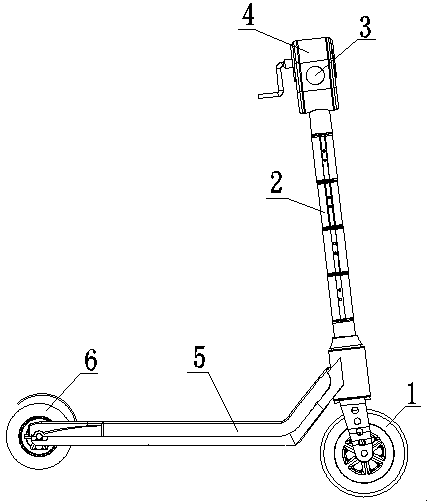

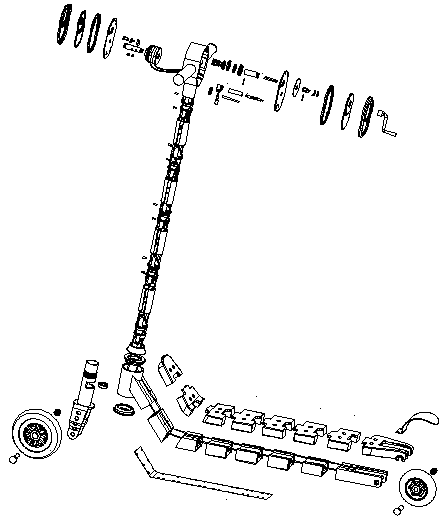

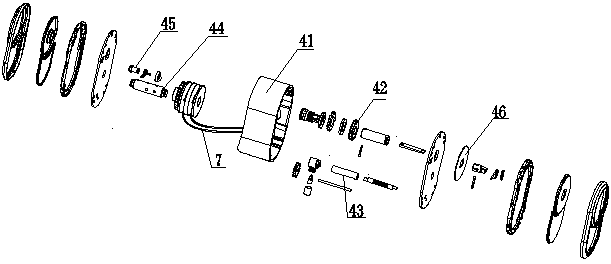

Foldable scooter and using method thereof

The invention provides a foldable scooter. The scooter comprises a rolling wheel winding device, handrails, a multi-joint vertical rod assembly, a front wheel assembly, a multi-joint pedal assembly, a rear wheel assembly and connecting ropes. According to the foldable scooter, a rolling wheel assembly rotates through manually rotating a rocking handle or a knob, and the connecting ropes are used for loosening or tensioning so that the whole scooter can be stored in a foldable mode or used in an unfolding mode. Moreover, in the tight winding process, the gear ratio is beneficial to making a person with small strength easily perform tensioning, and furthermore, a set torsion requirement can be determined through a torsion meter; in this way, the playing interests are increased, besides, the scooter can be bent to be round or square, the scooter storage is facilitated better, and the scooter can be placed in various cages and is convenient to store and move; the same structure can be used for an electric scooter driven by a front wheel hub motor or a rear wheel hub motor or an electric scooter, wherein belt or chain drive is adopted between a rear wheel and a motor.

Owner:宁波雷格士光电科技有限公司

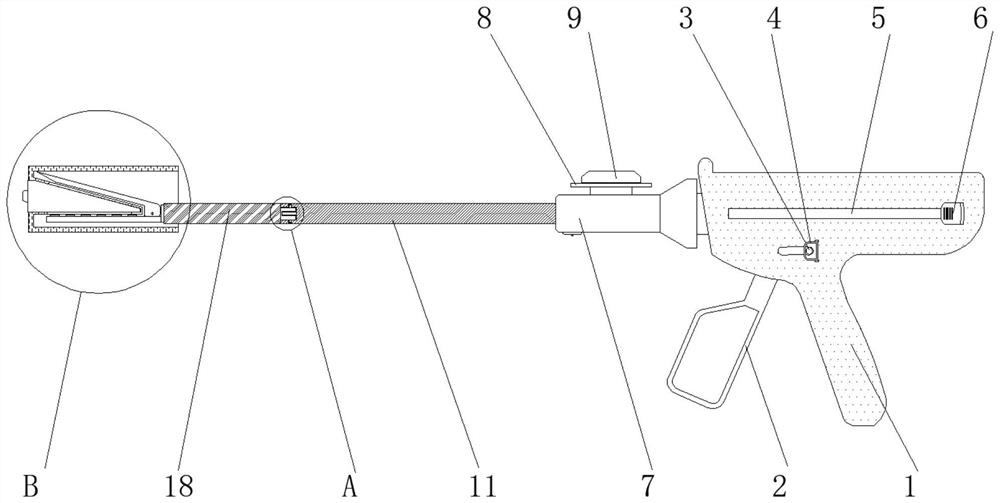

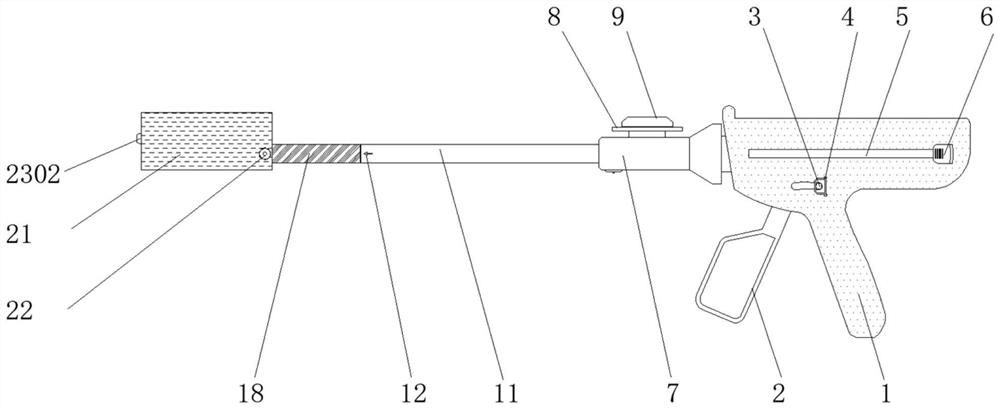

Detachable endoscope anastomat

PendingCN112603411AEasy to achieve locking effectTo achieve the effect of lockingDrying solid materials without heatSurgical staplesAnastomosis couplerEndoscope

The invention discloses a detachable endoscope anastomat, and the endoscope anastomat comprises a fixed handle, an adjusting shifting piece and a drying mechanism; a movable handle is rotatably connected to the left side of the bottom of the fixed handle, the adjusting shifting piece penetrates through a dial to be rotatably connected to a connecting sleeve, and a first gun barrel is fixed to the left end of the connecting sleeve; the left end of the first gun barrel is connected with a second gun barrel in a clamped mode, the left end of the second gun barrel is rotationally connected with a nail bin base, and the drying mechanism is clamped on the protective cover. According to the detachable endoscope anastomat, when the second gun barrel and the first gun barrel are connected together in a left-right clamped mode through the connecting rod and the connecting block, the second arrow indication mark corresponds to the first arrow indication mark, and then the second gun barrel is manually rotated till the second arrow indication mark corresponds to the rotation in-place indication mark; at the moment, the sliding block slides in place in the second sliding groove, the locking effect is conveniently achieved, and after the device is used and the operation is reversely repeated, the second gun barrel and the first gun barrel can be detached.

Owner:CHANGZHOU ANKANG MEDICAL EQUIP

Vertical double-end-face grinding wheel dresser

ActiveCN102814739AFlat surfaceImprove grinding qualityAbrasive surface conditioning devicesPlane surface grinding machinesIn planeAgricultural engineering

The invention discloses a vertical double-end-face grinding wheel dresser. The vertical double-end-face grinding wheel dresser comprises a support and a handle, an upper bearing seat and a lower bearing seat are arranged at the upper end and the lower end of the support respectively, a bearing is arranged in each of the upper bearing seat and the lower bearing seat, a rotating shaft is arranged between the bearings, a thread is arranged in the middle of the rotating shaft, a linkage sleeve, an upper adjusting nut, a lower adjusting nut and a cushion sleeve are sequentially arranged between the upper end and the lower end of the support, the upper adjusting nut and the lower adjusting nut match with the thread arranged in the middle of the rotating shaft, the linkage sleeve and the cushion sleeve are circumferentially fixed with the rotating shaft, the linkage sleeve is fixed with the handle, a dressing arm is arranged at the lower end of the rotating shaft, a dressing block clamp is arranged at the other end of the dressing arm, and a dressing block is arranged on the dressing block clamp. The vertical double-end-face grinding wheel dresser has the advantages that fine adjustment and locking are combined by performing vertical fine adjustment by the two adjusting nuts, movement is stable, the dressed grinding wheel is smooth in plane, and grinding quality of parts is improved.

Owner:沈阳海默数控机床有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com