Flexible coupling

A coupling and flexible technology, applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve the problem that the axial, radial and angular displacement cannot play any compensation role, affect the transmission effect, and the coupling Short service life of the coupling shaft and other problems, to avoid the motor from being burned, improve safety performance, and maintain the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: refer to each accompanying drawing.

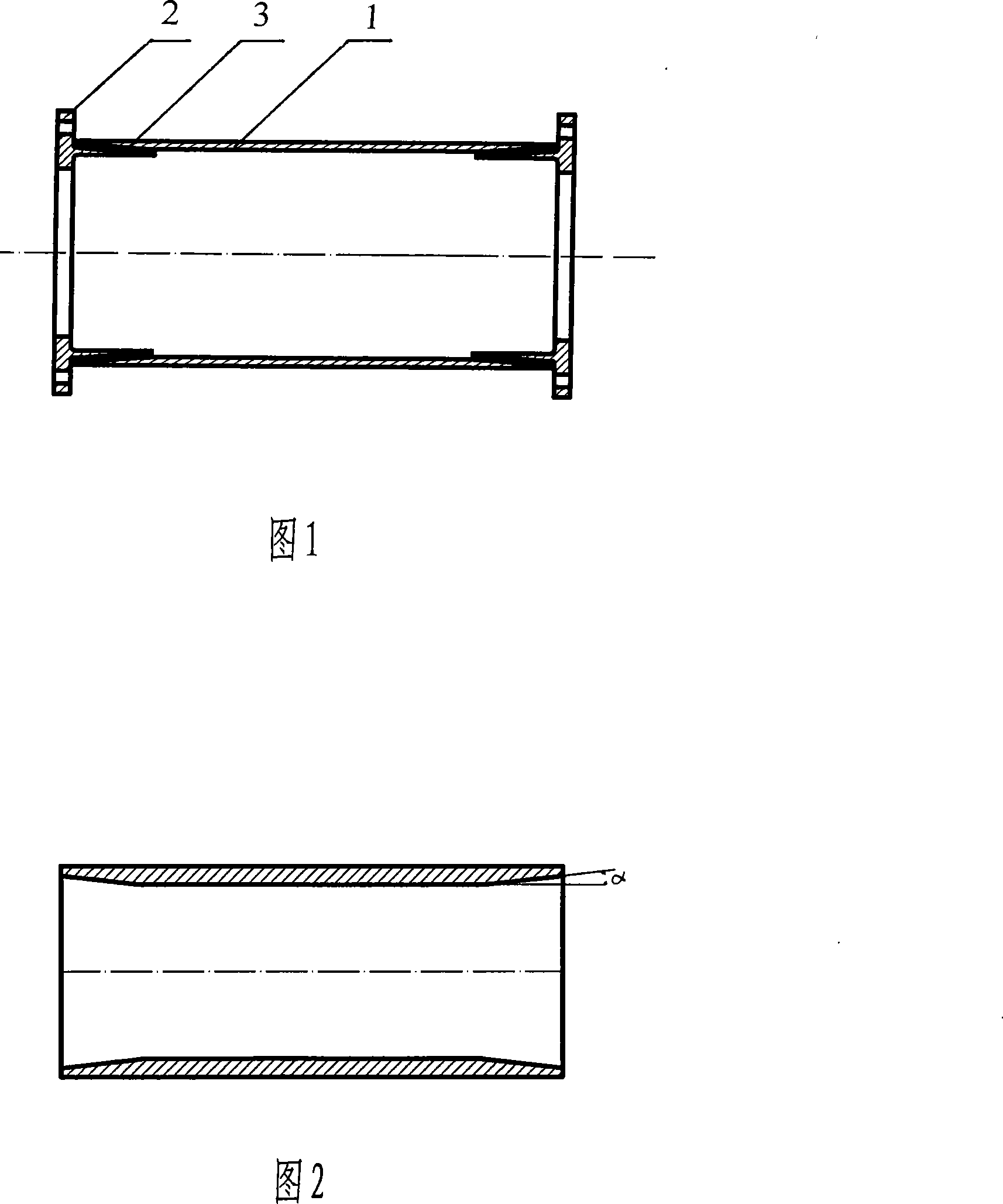

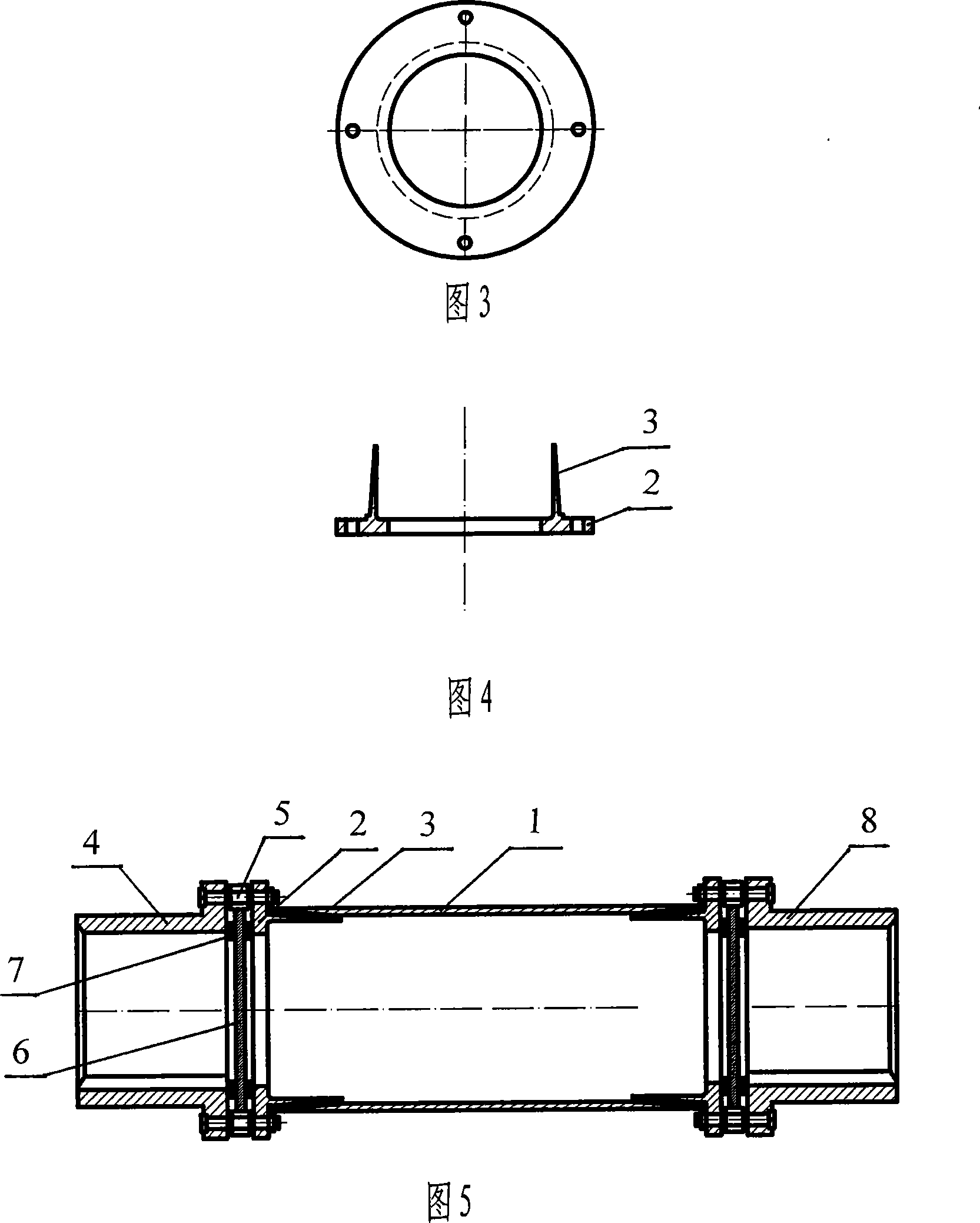

[0033] A flexible coupling, mainly composed of: a glass fiber reinforced plastic cylinder 1 (or FRP cylinder), flanges 2 arranged at both ends of the cylinder, and connected with each flange 2 as a whole (that is, integrally formed) Taper sleeve 3 (flange 2 and taper sleeve 3 can be cast iron or other metal materials);

[0034] The two ends of the FRP cylinder 1 are respectively socketed and fixedly bonded to a taper sleeve 3. The adhesive can be a two-component methacrylic structural adhesive (for example: Plexus MA310, etc.), or an existing Other adhesives in technology;

[0035] The inner surfaces of both ends of the FRP cylinder 1 are socketed with the taper sleeve 3, and the angle α between the FRP cylinder 1 and the central axis is 4 degrees, and the taper of the taper sleeve 3 corresponds to the angle α. , is 4 degrees;

[0036] The FRP cylinder 1 is composed of multiple glass fiber layers bonded by resin;

...

Embodiment 2

[0043] Embodiment 2: refer to each accompanying drawing.

[0044] A flexible coupling, the inner surface of both ends of the glass fiber reinforced plastic cylinder 1 is socketed with the taper sleeve 3, the angle α between the glass fiber reinforced plastic cylinder 1 and the central axis is 1 degree, and the taper of the tapered sleeve 3 is in line with the The included angle α corresponds to the same, being 1 degree; others are the same as in Embodiment 1, omitted.

Embodiment 3

[0045] Embodiment 3: refer to each accompanying drawing.

[0046] A flexible coupling, the inner surface of both ends of the glass fiber reinforced plastic cylinder 1 is socketed with the taper sleeve 3, the angle α between the glass fiber reinforced plastic cylinder 1 and the central axis is 5 degrees, and the taper of the tapered sleeve 3 is in line with the The included angle α corresponds to the same, being 5 degrees; others are the same as in Embodiment 1, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com