Oven hinge

A hinge and oven technology, applied in the field of oven hinges, can solve the problems of high production cost, cumbersome installation, easy damage, etc., and achieve the effect of low production cost, simple structure and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

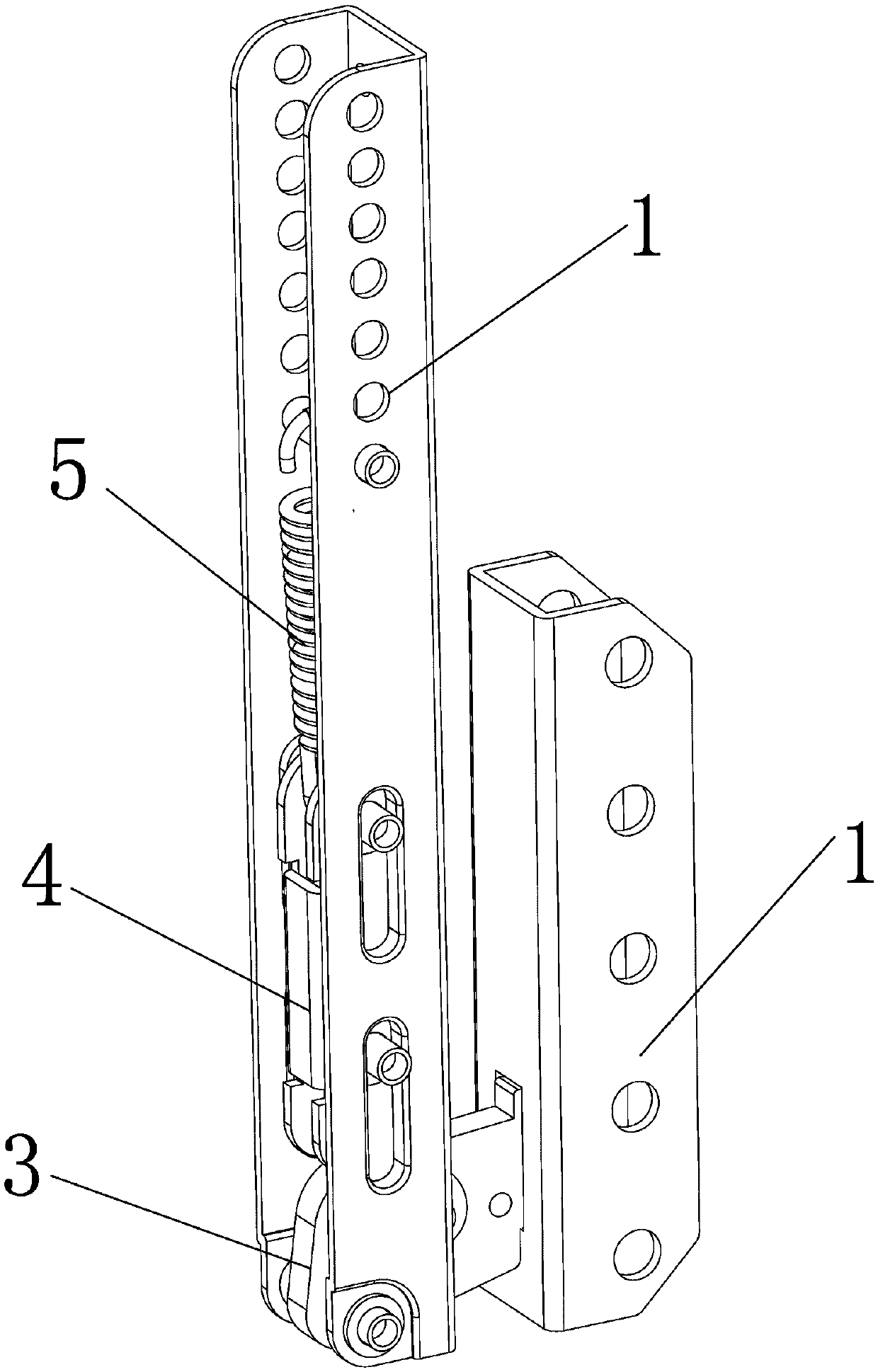

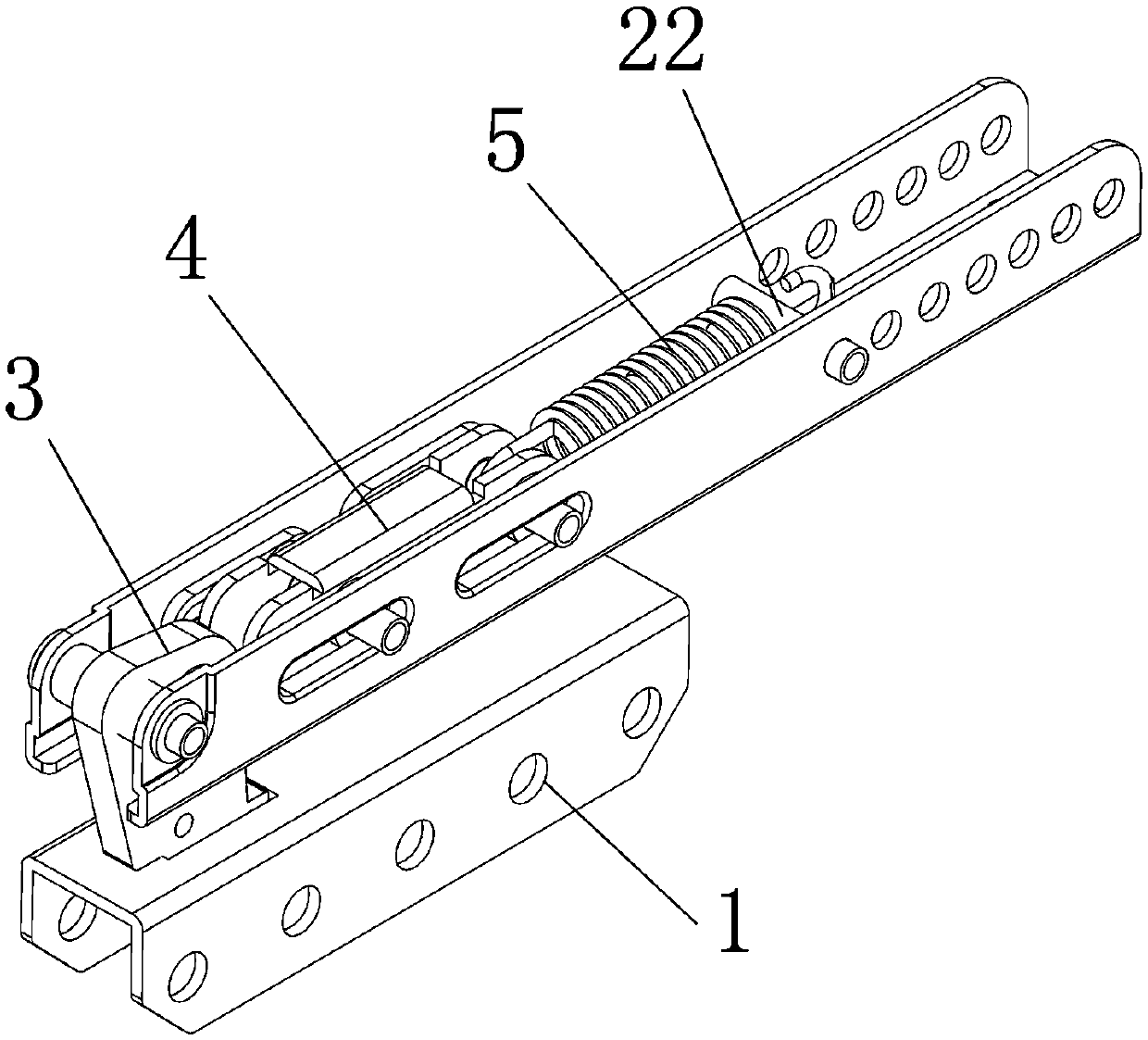

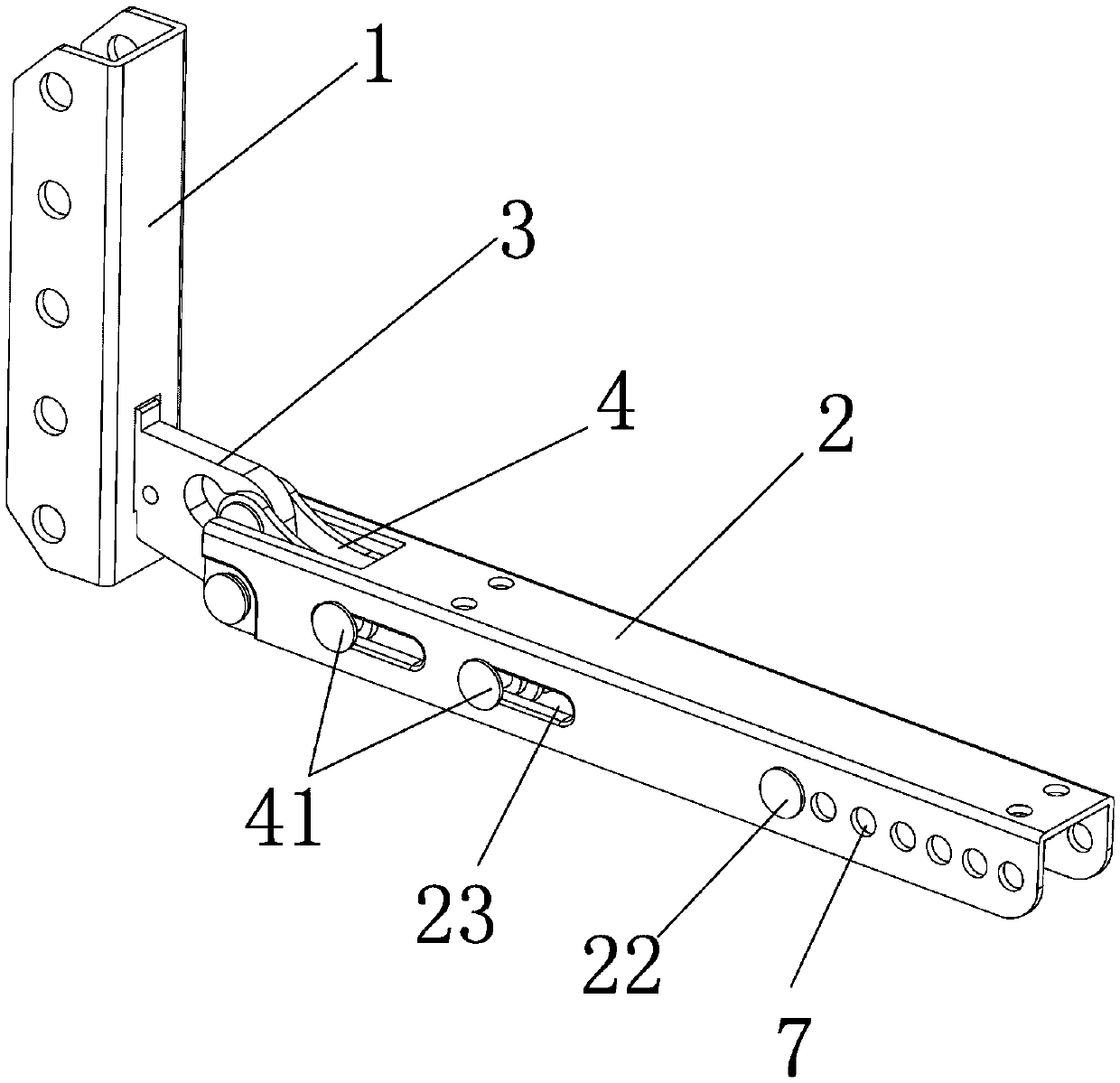

[0021] The present invention will be specifically and further described below in conjunction with the accompanying drawings.

[0022] An oven hinge, which includes a base 1 fixed on the box body, a bracket 2 fixed on the door panel, the head of the bracket 2 is articulated and installed with a hinge arm 3, and the hinge arm 3 is provided with a buckle and fixedly connected with the base 1 , it is characterized in that: the inside of the bracket 2 is provided with an accommodating groove 21, the accommodating groove 21 is equipped with a pull arm 4, and the tail section of the pull arm 4 is equipped with a tension spring 5 and a limit nail 22 at the tail section of the bracket 2 Link, the head of the pull arm 4 is provided with a limit pin 6 inserted in the guide groove 31 on the hinge arm 3, and the pull arm 4 and the bracket 2 are provided with a guide device to limit the pull arm 4 to only fit in the accommodating groove. The inner relative bracket 2 slides in parallel.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com