Stator winding end insulation frame, plastic-packaging stator assembly, and plastic-packaging motor

A stator winding and end insulation technology, applied to the shape/style/structure of the winding insulation, can solve the problems of unfavorable automatic production and assembly of motors, high installation costs, and inconvenient installation, and improve the degree of automated production and installation process. Convenience and the effect of avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

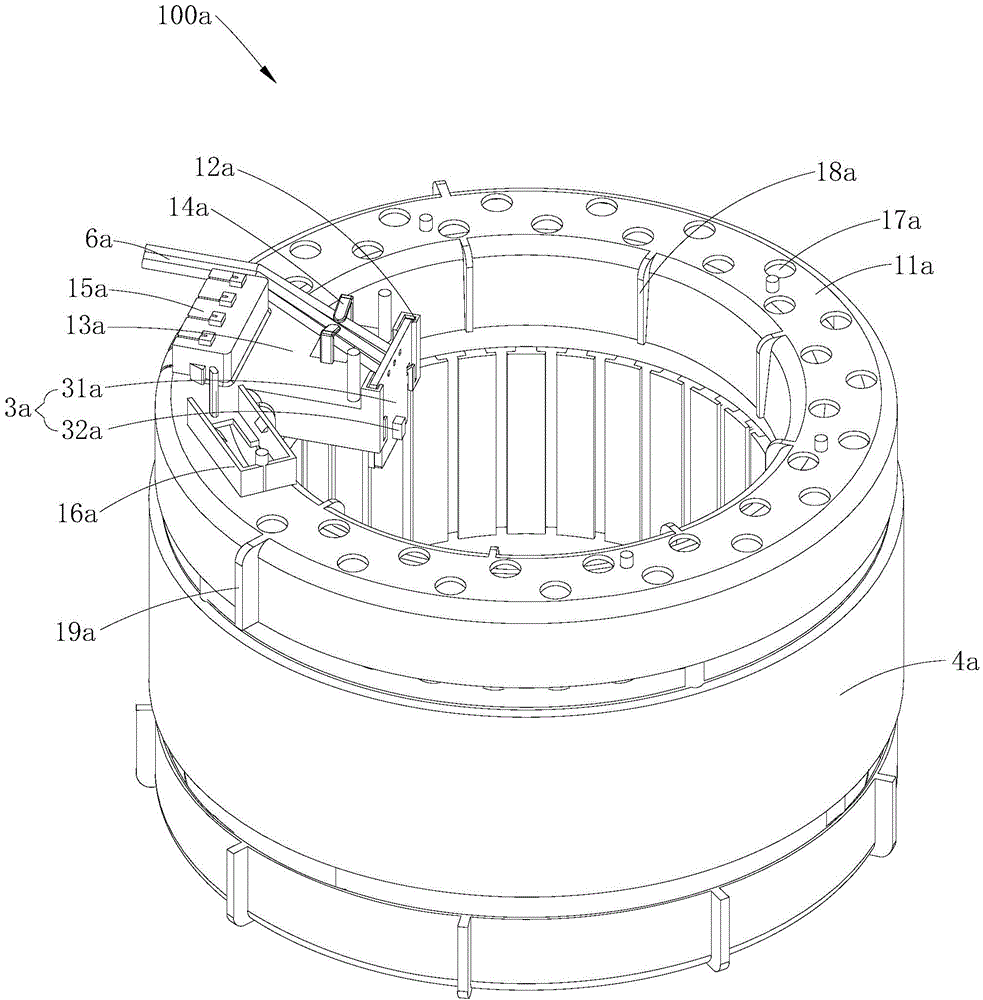

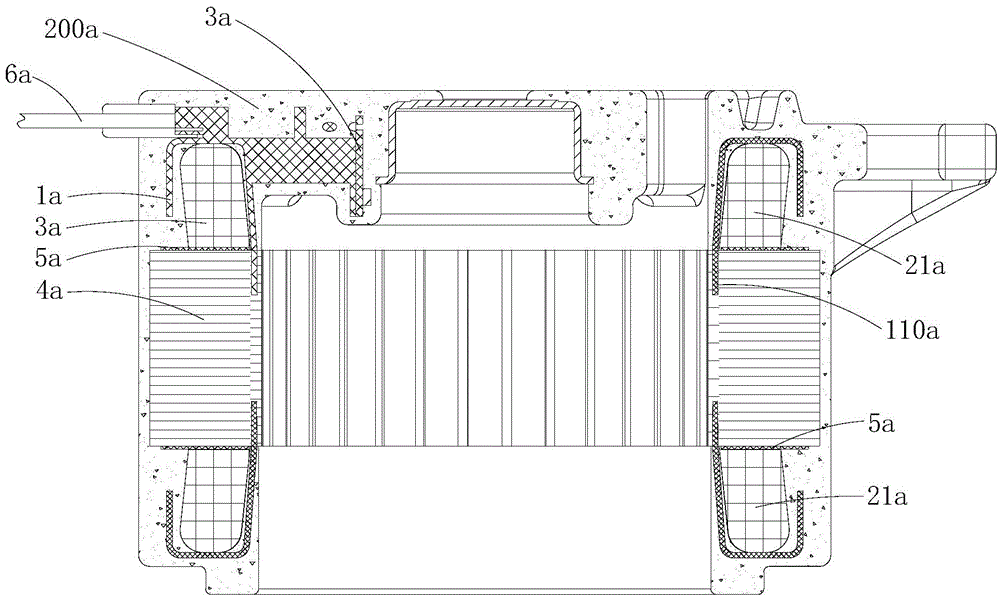

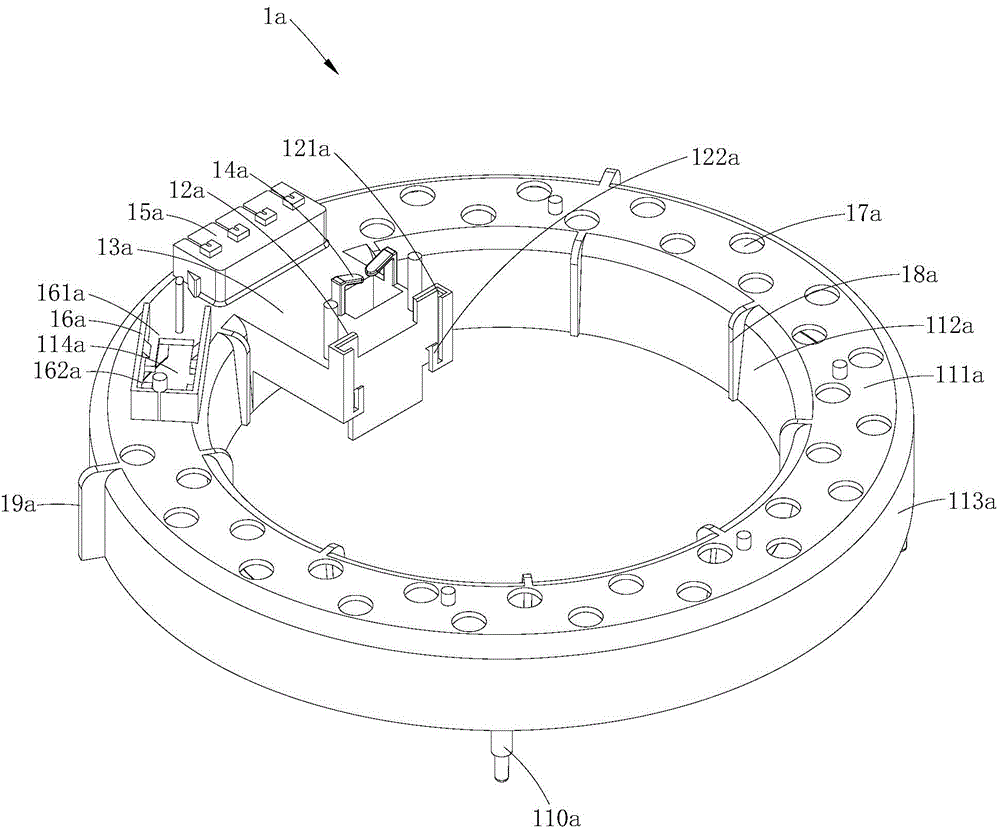

Embodiment 1

[0030] combined reference Figure 1~3 As shown, the stator winding end insulating frame 1a provided by Embodiment 1 of the present invention includes an insulating frame body 11a sleeved on the axial end 21a of the stator winding 2a along the motor axial direction. The PG plate member 3a is mounted on the PG plate mounting frame 12a, and the PG plate mounting frame 12a is provided with a slot 121a for receiving and positioning the PG plate component 3a. The PG board member 3a includes a circuit board 31a and a Hall element 32a provided on the circuit board 31a. In the stator winding end insulating frame 1a provided in this embodiment, the PG plate member 3a can be directly installed on the stator winding end insulating frame 1a by adding a PG plate mounting frame 12a on the insulating frame body 11a. In the specific installation process, the installation and positioning of the PG board member 3a can be realized by simply inserting the sliding card of the PG board member 3a in...

Embodiment 2

[0057] The main difference between the stator winding end insulation frame, the plastic-encapsulated stator assembly and the plastic-enclosed motor provided in this embodiment and the first embodiment lies in the different structural settings of the PG plate mounting frame. Specifically, in Embodiment 1, the insertion direction of the slot 121a is parallel to the axial direction of the motor; Image 6 with Figure 7 As shown, in this embodiment, the insertion direction of the slot 121b is perpendicular to the axial direction of the motor, and the PG plate component 3b is equivalent to being installed on the PG plate mounting frame 12b in a horizontal insertion manner. In this way, the PG plate component can also be realized The installation of 3b on the PG plate installation frame 12b is very convenient, and it is also conducive to the automatic installation of the PG plate component 3b.

[0058] Specifically, in this embodiment, the PG plate member 3b is inserted into the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com