Multi-functional integrated type hydraulic cylinder

An integrated, hydraulic cylinder technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of low response frequency, complex hydraulic system, mechanical installation, etc., achieve fast cycle speed, expand the scope of application, and improve power density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

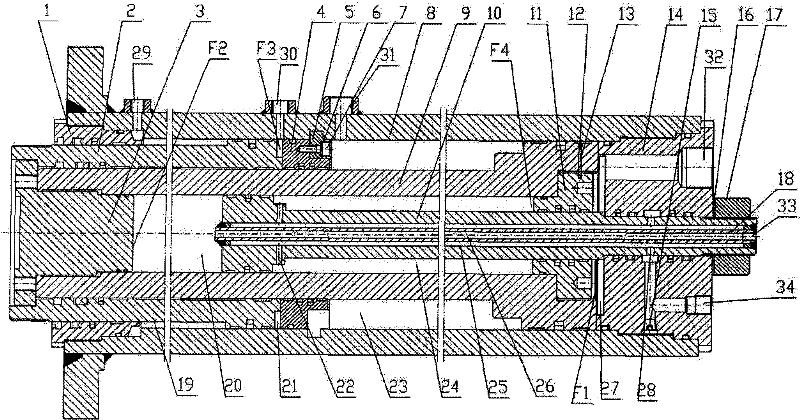

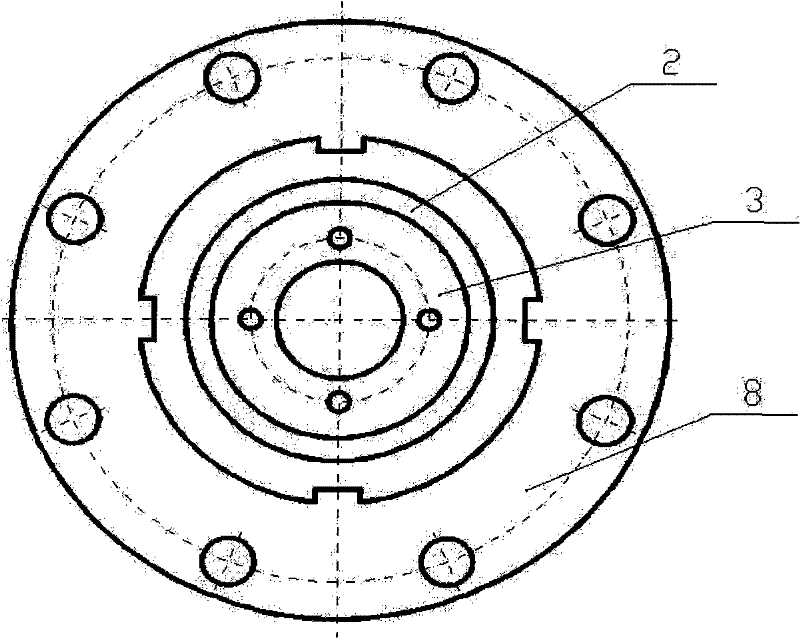

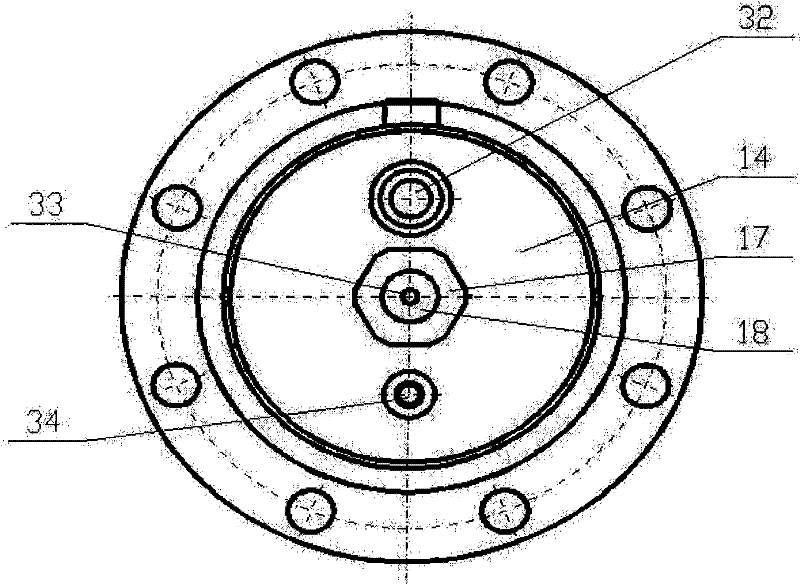

[0029] See figure 1 figure 2 with image 3 The multifunctional integrated hydraulic cylinder shown includes a master cylinder head 14 fitted and connected to the right end of the master cylinder 8, a cylindrical master cylinder piston rod 9, which is arranged in the master cylinder and whose right end is matched with the master cylinder. The quick cylinder guide sleeve 11 arranged in the right end of the cylindrical master cylinder piston rod 9 is matched with the middle of the cylindrical master cylinder piston rod and fixedly connected to the spacer ring 4 in the middle of the master cylinder. The three-petal snap key 5 connected by the isolation ring, the master cylinder guide sleeve 2 whose inner wall matches the left part of the cylindrical master cylinder piston rod and the right end matches the inner wall of the master cylinder;

[0030] The main cylinder 8 is provided with a first oil port 29, a second oil port 30 and a third oil port 31, and the main cylinder head 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com