Multi-shift speed change gear box for sectional warping machine

A slit warping machine and variable speed gearbox technology, which is applied in other manufacturing equipment/tools, textiles and papermaking, manufacturing tools, etc., can solve problems such as high transmission accuracy, yarn forming cannot meet process requirements, etc., and achieve precise adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

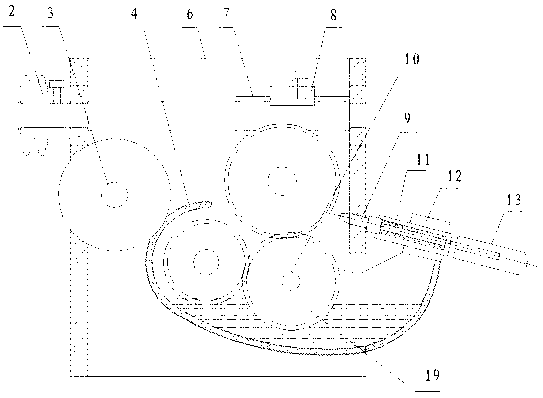

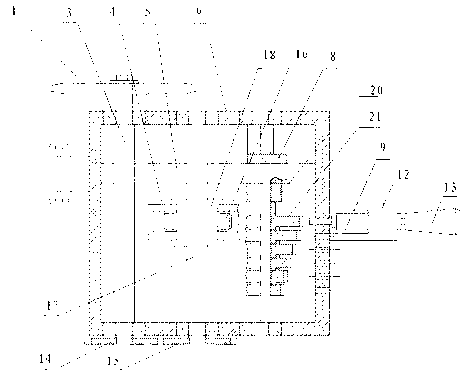

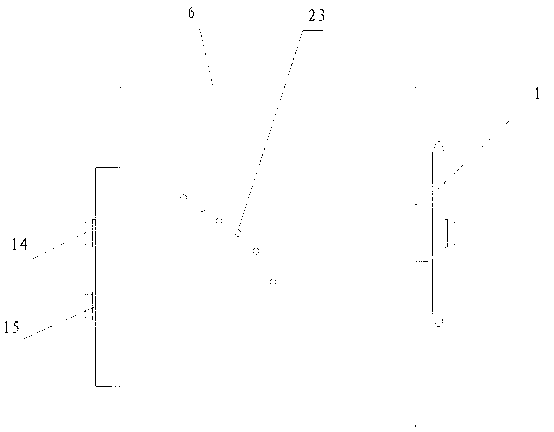

[0016] Such as Figure 1 to Figure 3 As shown, the preferred embodiments of the present invention are further described in detail.

[0017] The six-speed transmission gearbox of the section warping machine, the main components involved include input sprocket 1, output sprocket 2, input shaft 3, bracket 4, output shaft 5, box body 6, tight ring 7, steering gear upper 8, Positioning pin 9, gear pin 10, compression spring 11, positioning seat 12, positioning handle 13, changing gears 14 and 15, moving gear 16, intermediate shaft 17, bushing 18, intermediate wheel 19, steering gear lower 20, tower Speed change gear 21, speed change gear shaft 22.

[0018] The casing 6 is a casing part of the present invention, and the input shaft 3 , the output shaft 5 , the intermediate shaft 17 , and the transmission gear shaft 22 are all supported on the casing 6 . One end of the input shaft 3 is equipped with an input sprocket 1, and the other end is equipped with a distributing gear 14. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com