Tooth-forming method having tooth finishing, and combination tool therefor

A technology of combining cutting tools and cutting tools, applied in the direction of gear tooth manufacturing tools, manufacturing tools, components with teeth, etc., can solve problems such as increasing machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

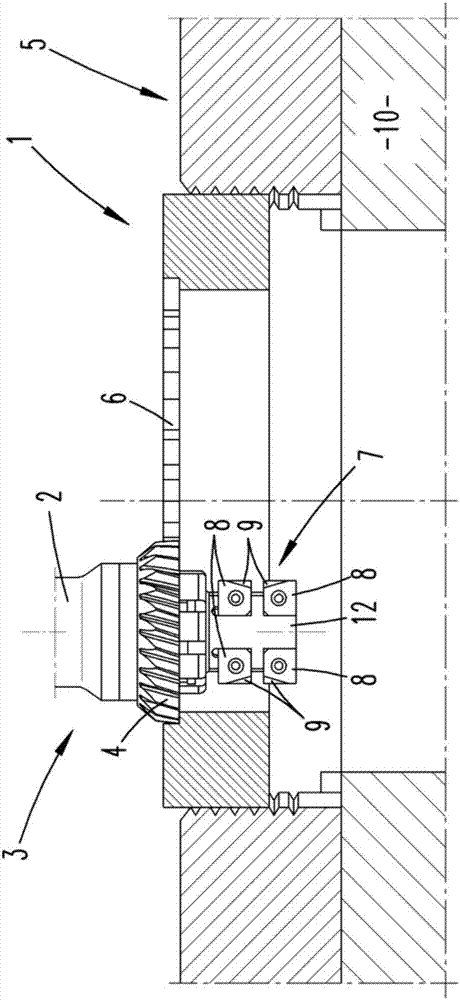

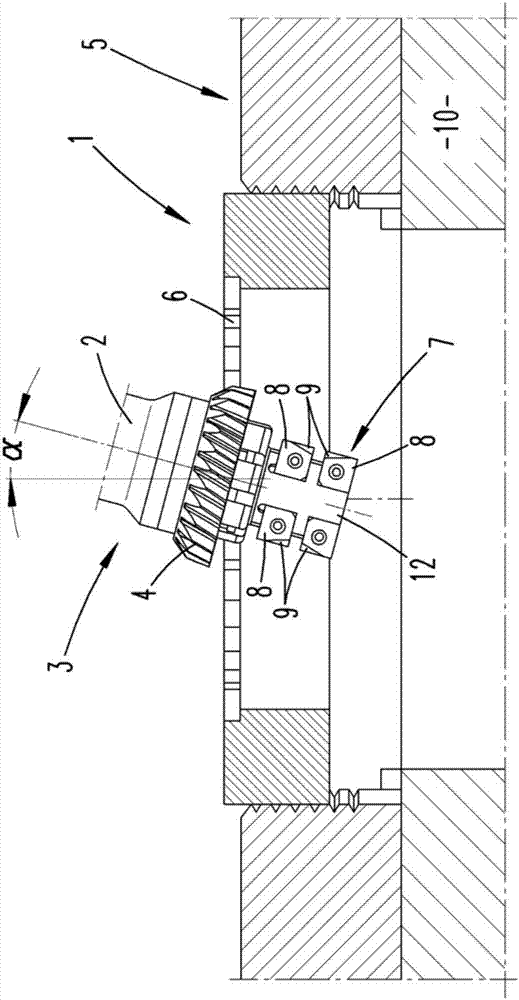

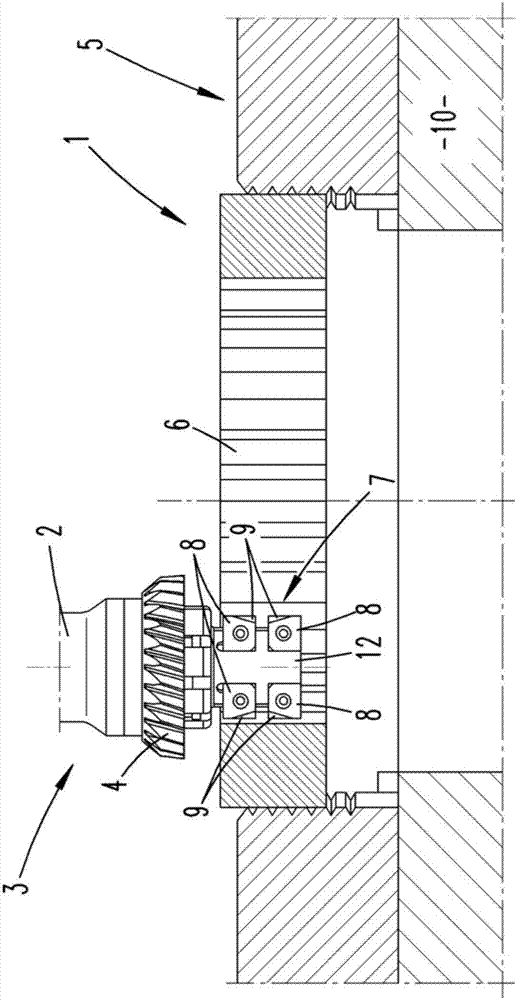

[0019] exist Figures 4 to 6 The combination tool 3 shown in has a clamping end 11, by means of which the combination tool 3 can be clamped in the chuck of the tool shaft 2, which can be driven in rotation by an electric motor. The motor is controlled by the controller. The controller also controls another motor for driving the workpiece axis 5 . The workpiece shaft 5 has a chuck 10, and the wheel blank 1 to be processed is clamped in the chuck 10. The controller is designed to drive the tool shaft 2 and the workpiece shaft 5 in synchronous rotation relative to each other.

[0020] The combination tool 3 has a skiving gear 4 with which an internal toothing 6 can be produced by hobbing a wheel blank as a blank, as described in DE 10 2008 037 514 A1. For this purpose, the tool shaft 2 and the workpiece shaft 5 are driven to rotate synchronously with one another in such a way that the cutting teeth of the scraper gear 4 scrape into the tooth spaces formed by the gear teeth 6 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com