Hydraulic transmission speed change system

A technology of hydraulic transmission and transmission fluid, which is applied in transmission devices, vehicle gearboxes, fluid transmission devices, etc. It can solve the problems of no specific description of the shape and installation position, no specific description of the specific structure, etc., and achieve compact structure and strong adaptability , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

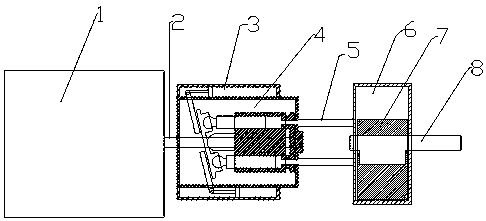

[0032] Embodiment 1: A hydraulic transmission transmission system of the present invention is used to manufacture an automatic transmission for vehicles.

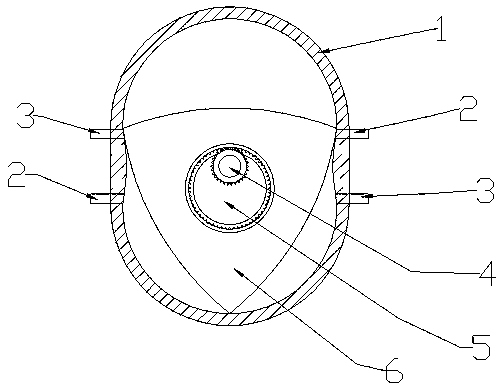

[0033] In this embodiment, a straight-axis swash plate rotary cylinder type 11-column piston pump is used as a variable displacement piston pump, with a nominal displacement of 160ml / r and a maximum torque of 800Nm. 21 degrees, the swash plate inclination adjustment mechanism is hydraulic adjustment. The cycloidal hydraulic motor adopts a triangular rotor cycloidal hydraulic motor with a nominal displacement of 200ml / r and a maximum torque of 770Nm.

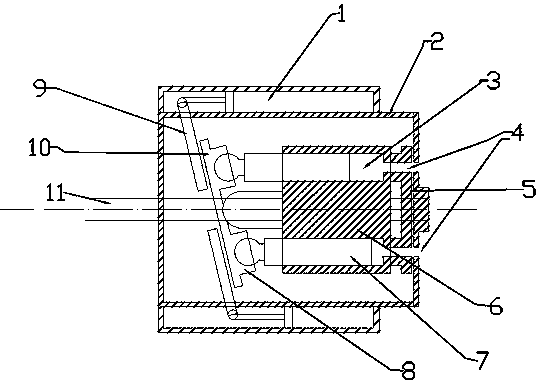

[0034] The variable displacement plunger pump includes housing, back cover, swash plate support seat, swash plate, spherical bushing, sliding shoe, return plate, cylinder block, flow plate, plunger, variable piston rod, variable piston, upper adjustment rod, lower Adjustment rod, upper return spring and lower return spring.

[0035] Among them, there is a shaft hole in the f...

Embodiment 2

[0039] Embodiment 2: Utilize a kind of hydraulic transmission speed change system of the present invention to manufacture bicycle speed change and transmission system.

[0040] In this embodiment, a straight-axis swash plate rotary cylinder type 5-column plunger pump is used as a variable displacement piston pump, with a nominal displacement of 25ml / r, a maximum torque of 130Nm, and a swash plate inclination angle perpendicular to the axial direction. 19 degrees, the swash plate inclination adjustment mechanism is adjusted by a spring cable. The cycloidal hydraulic motor adopts a triangular rotor cycloidal hydraulic motor with a nominal displacement of 20ml / r and a maximum torque of 140Nm.

[0041] The variable displacement plunger pump consists of a casing, a rear cover, a transmission shaft, a swash plate support seat, a swash plate, a spherical bush, a sliding shoe, a return plate, a cylinder block, a flow plate, a plunger, a return spring and a pull wire.

[0042] The var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com