Stepless speed change carrier vehicle

A technology of infinitely variable speed and transport vehicles, which is applied in the direction of motor vehicles, vehicle parts, transportation and packaging, etc. It can solve the problems of uncontrollable forward speed, inability to adapt flexibly, inconvenient operation, etc., and achieve stable transmission and reasonable functional structure design , to avoid the effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

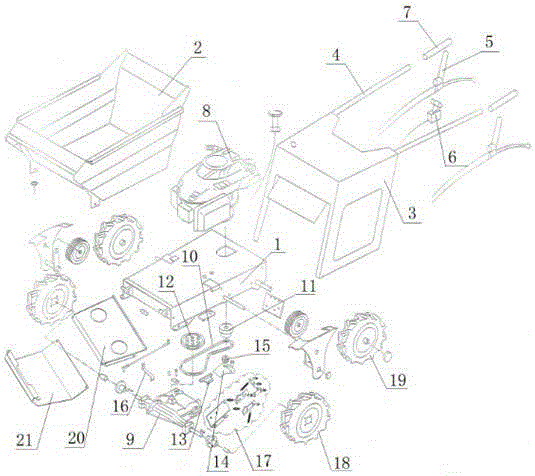

[0017] Such as figure 1 As shown, the invention discloses a continuously variable speed transfer vehicle, which includes a bottom plate 1, a hopper 2, a drive system and a panel 3.

[0018] The base plate 1 is arranged horizontally and has a through hole in the middle of the rear end of the base plate 1. A panel 3 and a hopper 2 are sequentially arranged on the upper end of the base plate 1 along the advancing direction of the transport vehicle.

[0019] The hopper 2 is horizontally arranged on the upper end of the bottom plate 1, and the two sides of the front end of the hopper 2 are respectively hinged to the two sides of the front end of the bottom plate 1, and the hopper 2 can rotate around the hinge point to unload; the panel 3 is a hollow structure, fixedly installed on the bottom plate 1 on the The rear end of the hopper 2, and two operating rods 4 are respectively extended backward on both sides of the upper part of the panel 3, and a handle 5 is respectively arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com