Automatic water feeding device of barreled water

A technology for automatic water filling and bottled water, which is applied in hoisting devices, hoisting devices, etc., can solve problems such as flow fluctuations, inflow, and water filling failures, and achieve safe and reliable energy consumption, simple control system, and small motor power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

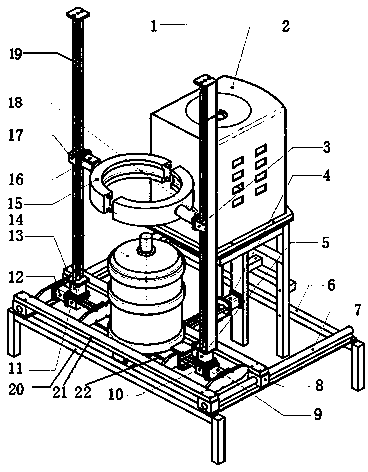

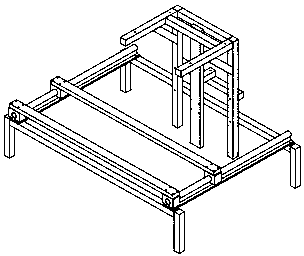

[0014] Such as figure 1 As shown, the bottled water automatic filling device of the present invention is made up of three major parts of mechanical system, power system and control system.

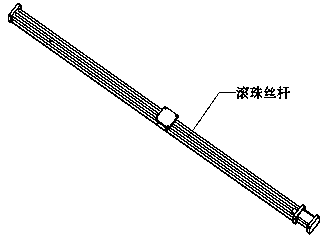

[0015] Mechanical system and power system include lifting column a1, water dispenser 2, lifting slider a3, longitudinal drive motor 4, lift drive motor a5, bracket 6, longitudinal guide rail 7, longitudinal guide rail slider 8, transverse drive motor a9, transverse guide rail slide Block a10, horizontal guide rail slider b11, horizontal driving motor b12, lifting driving motor b13, bottled water 14, grasping mechanism 15, rotating driving motor 16, lifting slider b17, limit stopper 18, lifting column b19, bracket base 20, support cross bar 21, barreled water seat 22.

[0016] The lifting slider, the horizontal guide rail slider and the barreled water seat are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com