Automatic turning mechanism

A technology of automatic flipping and flipping components, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of corporate profits and product competitiveness, product quality cannot be guaranteed, and friction between products and institutions is large, so as to achieve novel structure, The effect of low friction and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

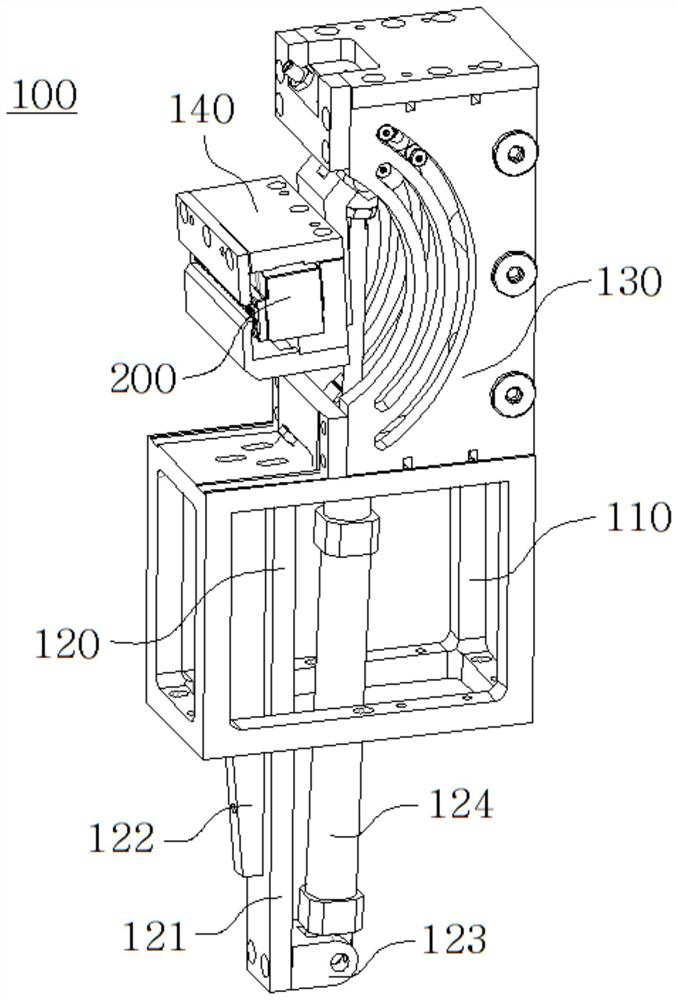

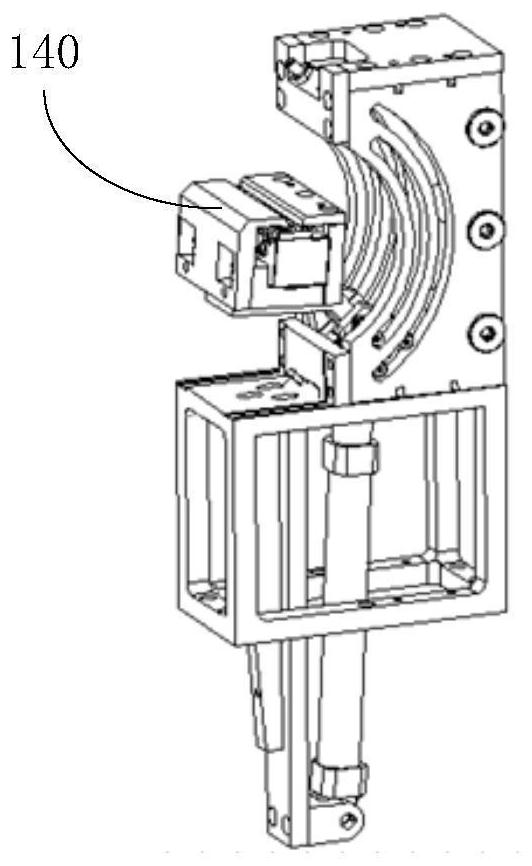

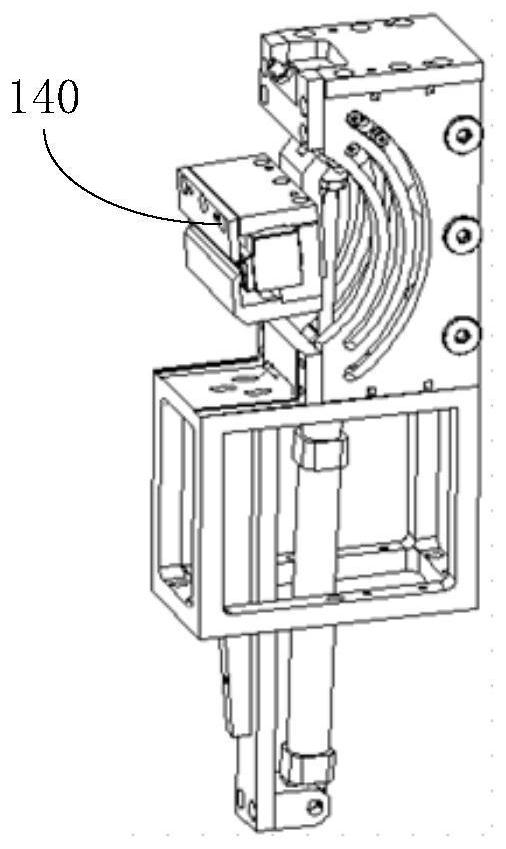

[0021] see figure 1 The present invention provides an embodiment of an automatic turning mechanism 100 comprising: a support base 110 , a driving component 120 , an arc-shaped slide rail component 130 and a turning component 140 . The automatic turning mechanism 100 is used to turn the product 200 from a forward position of 0 degrees to a reverse position of 90 degrees.

[0022] Specifically, in one embodiment, the support base 110 includes a support plate at the top and a support frame at the bottom of the support plate. Specifically, the support frame is a rectangular frame and a hollow structure. The support plate and the support frame are steel structures and integrally formed.

[0023] see figure 1 Specifically, in one embodiment, the drive assembly 120 includes a support frame composed of a support square bar 121 and a support triangular bar 122 , a connecting piece 123 , and a drive rod 124 . The connecting piece 123 is used for connecting the support frame and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com