Permanent magnet motor for door motor

A technology of permanent magnet motors and door operators, applied in the direction of electromechanical devices, synchronous machines, electrical components, etc., can solve the problems of increasing civil construction area and construction costs, no invention of permanent magnet motors, and complicated overall layout of frequency conversion door operators, etc., to achieve Avoid the effects of unstable connections, light weight, and thinner thickness dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

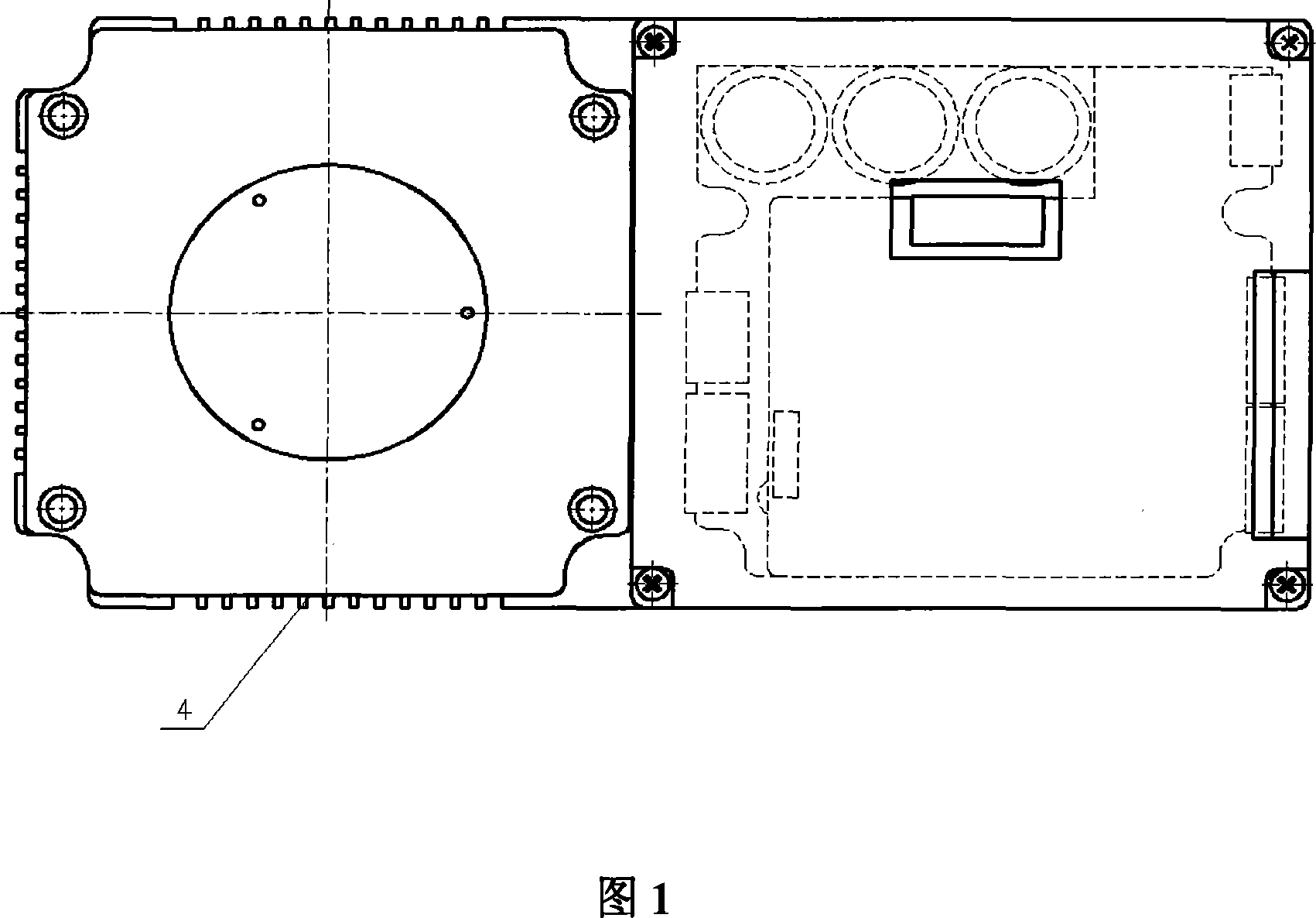

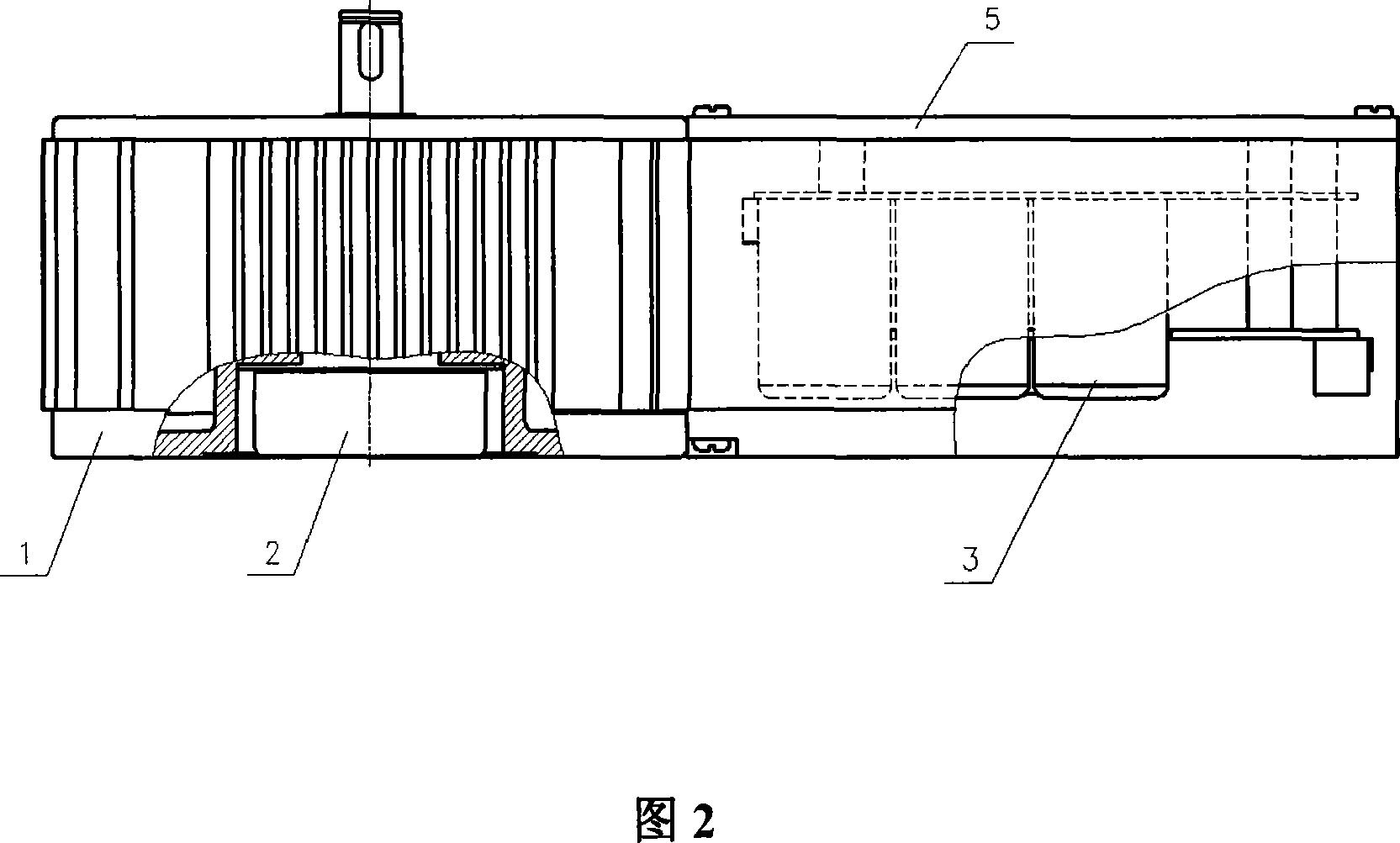

[0011] Shown in the figure: 1. Motor end cover, 2. Encoder, 3. Frequency converter, 4. Motor (body), 5. Rear seat of frequency converter.

[0012] The detailed technical contents and implementation methods of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] What above-mentioned accompanying drawing shows is the best implementation mode of the present invention, but the appearance of this device is not limited to cuboid, and it also can be cylinder shape or other geometric shapes. The permanent magnet motor for the door machine of the present invention comprises a permanent magnet synchronous motor 4, an encoder 2 and a frequency converter 3, wherein: the permanent magnet synchronous motor 4, the encoder 2 and the frequency converter 3 are in an integral casing and are installed in the elevator On the door operator: Encoder 2 is integrally or partially fixed / hidden in the inner cavity of motor end cover 1, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com