Juicer

A technology for a juicer and a juicer, which is applied in the field of juicers, can solve the problems of inconvenient disassembly and assembly of the slag cup, difficulty in disassembly of the slag cup, and congestion of the inner space of the juice squeezing cover and the slag cup, and achieves convenient separation and installation. Slag cup and juice cup, easy to carry, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

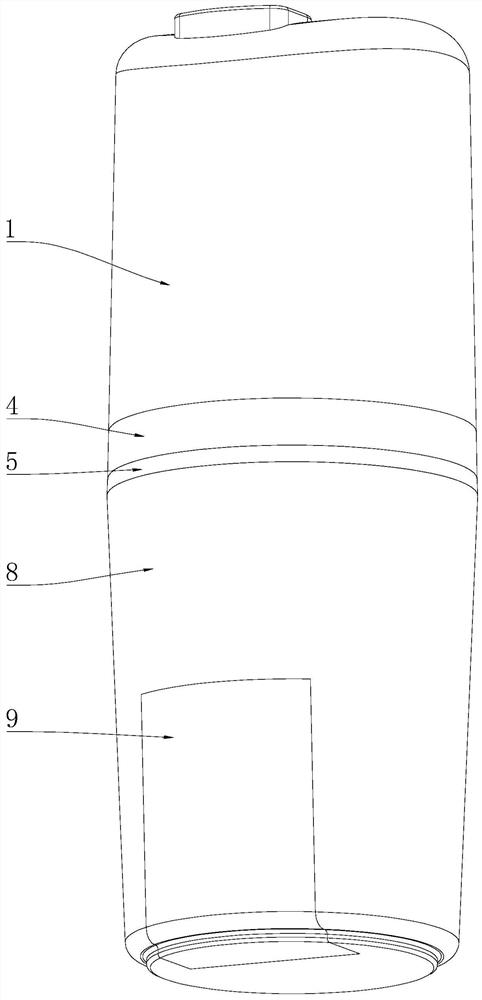

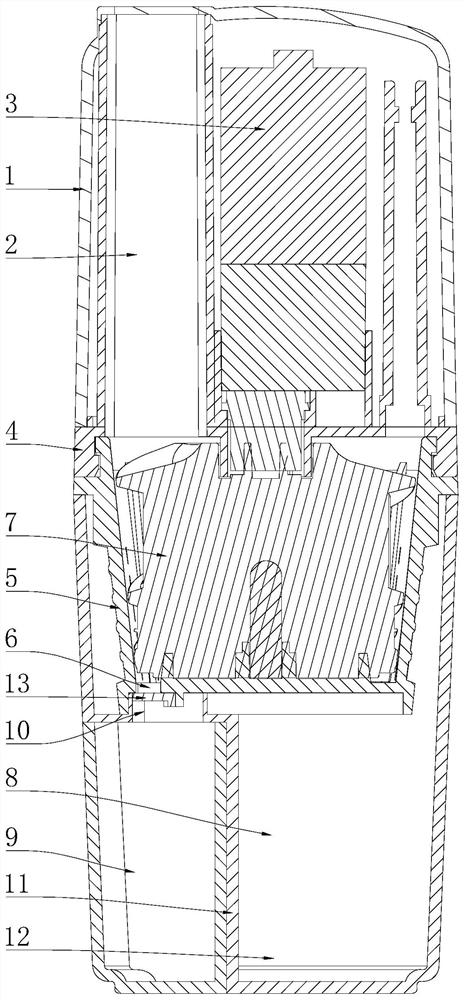

[0039] see figure 1 -shown: a juicer comprising:

[0040] Housing 1, the top is provided with a feed channel 2 through the bottom;

[0041] The motor 3 is arranged in the housing 1;

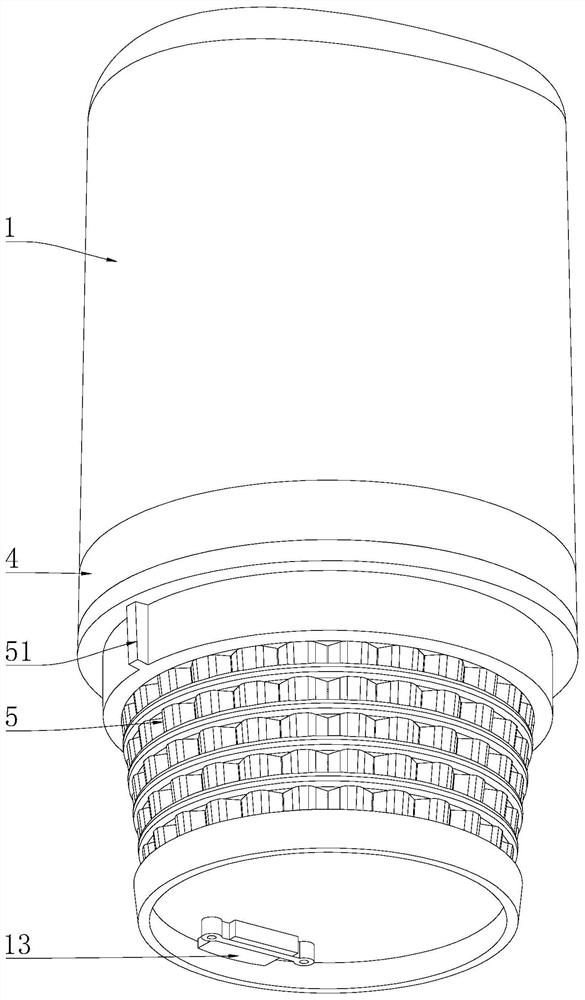

[0042] The frame 4 is installed on the bottom of the housing 1;

[0043] The juice squeeze cover 5 is arranged at the bottom of the machine base 4, and the bottom of the juice squeeze cover 5 is provided with at least one slag outlet 6; the juice squeeze cover 5 is provided with a juice discharge gap; the juice squeeze cover 5 is preferably in the shape of a grid in the present invention And it is a single-layer structure, the through holes between the grids are set to form a juice outlet gap, and the single-layer structure can be integrally injection molded, so that the structure is simpler, the economy is better, and it is convenient to dismantle and clean; of cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com