Low-molding-temperature waterborne polyurethane adhesive and preparation method thereof

A technology of water-based polyurethane and molding temperature, applied in polyurea/polyurethane adhesives, adhesives, polymer adhesive additives, etc., can solve the problems of low use temperature, high energy consumption, high use temperature, etc., and achieve improved initial tack , Guarantee the initial bonding strength and improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

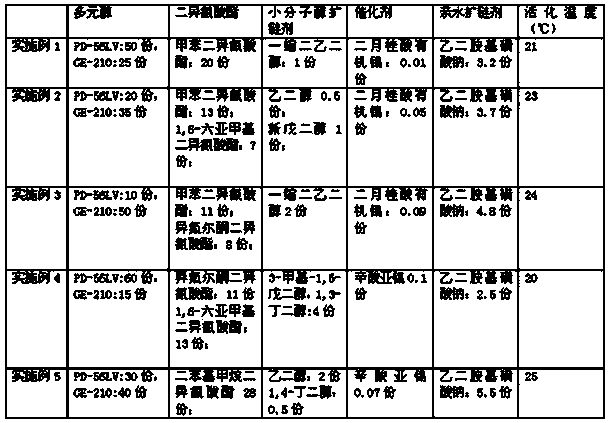

[0046] The aqueous polyurethane emulsion of low activation temperature mainly consists of the following components in parts by weight:

[0047] Polyol: phthalic anhydride polyester polyol (PD-56LV): 50 parts, polyoxypropylene glycol (GE-210): 25 parts;

[0048] Diisocyanate: toluene diisocyanate: 20 parts;

[0049] Small molecule alcohol chain extender: diethylene glycol: 1 part;

[0050] Catalyst: organotin dilaurate: 0.01 part;

[0051] Hydrophilic chain extender: sodium ethylenediamine sulfonate: 3.2 parts;

[0052] The preparation method is specifically:

[0053] Dehydrate the polyol in vacuum at 95°C-110°C, under the protection of dry inert gas, cool the dehydrated polyol to 60-70°C, add diisocyanate, react for 0.5-1 hour, add 0.5- Acetone 1.0 times the weight of the prepolymer, reduce the viscosity of the prepolymer, add a small molecule alcohol chain extender and catalyst, keep the temperature at 60-65°C for 2-4 hours, cool down to 45-55°C, add a hydrophilic chain e...

Embodiment 2-5

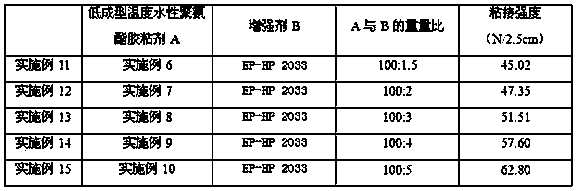

[0055] In Examples 2-5, the components and parts by weight of the water-based polyurethane emulsion with low activation temperature were added according to the data shown in Table 1, and the preparation method was the same as in Example 1.

[0056] The activation temperatures of the products prepared in Examples 1-5 were detected respectively, and the results are shown in Table 1.

[0057] Activation temperature test method: brush the glue on the medium density board, put it in a constant temperature oven at 60 ℃ and dry it for 2 minutes, take it out and let it air for 2 minutes at room temperature, then stick it with polyvinyl chloride film (PVC), press and stick it on a hot press Molding pressure setting: 0.2 MPa, molding time 30 seconds, molding temperature adjustable, polyvinyl chloride film (PVC) and MDF completely bonded to cause cohesive damage or material damage is regarded as activation, the molding temperature at this time is is the activation temperature.

[0058] ...

Embodiment 6

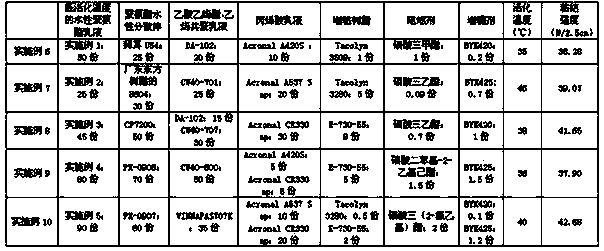

[0062] The low molding temperature water-based polyurethane adhesive mainly consists of the following components in parts by weight:

[0063] 50 parts of aqueous polyurethane emulsions of the low activation temperature prepared in embodiment 1;

[0064] Aqueous polyurethane dispersion: Bayer U54 (activation temperature at 53±5°C): 25 parts;

[0065] Vinyl acetate-ethylene copolymer emulsion: DA-102: 20 parts;

[0066] Acrylic emulsion: BASF Acronal A420S: 10 parts;

[0067] Tackifying resin: Eastman Tacolyn 3509: 1 part;

[0068] Flame retardant: trimethyl phosphate: 1 part;

[0069] Thickener: BYK420: 0.2 parts.

[0070] The preparation method is specifically:

[0071] At room temperature, stir the vinyl acetate-ethylene copolymer emulsion at a speed of 300-800 rpm, add triethanolamine pH regulator to adjust the pH of the vinyl acetate-ethylene copolymer emulsion to 7.8±1, add water-based polyurethane with low activation temperature Emulsion, polyurethane aqueous disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com