Patents

Literature

183results about How to "Meet flame retardant requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency flame retardant wood plastics composite and preparation method thereof

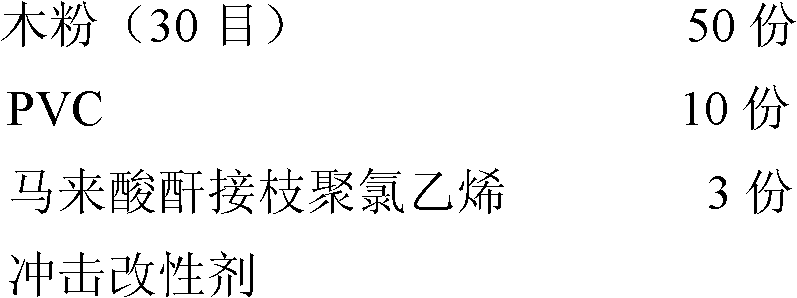

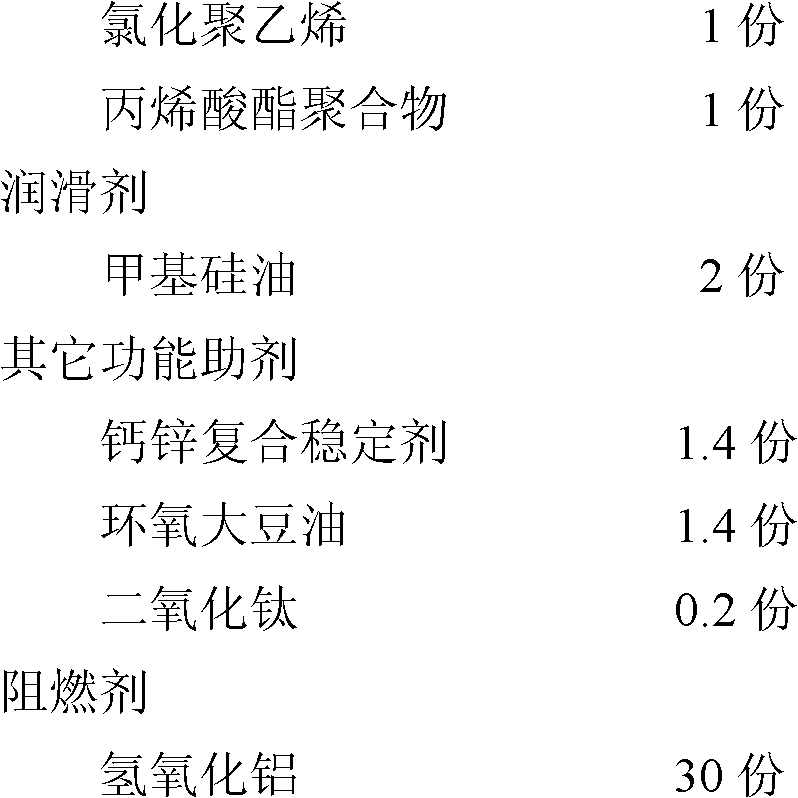

The invention discloses a high-efficiency flame retardant wood plastics composite. The high-efficiency flame retardant wood plastics composite is prepared from 50 to 75 weight parts of wood powder, 10 to 30 weight parts of plastic resin, 1 to 5 weight parts of interfacial compatibilizer, 0.5 to 2 parts of impact modifier, 1 to 3 weight parts of lubricant, 1 to 5 weight parts of other functional aid, and 10 to 30 weight parts of flame retardant. The preparation method comprises the following steps of: degreasing and drying wood powder, organically modifying bentonite and zinc borate and mechanically grinding, mixing in a high-speed mixing machine to obtain premix, and mixing and plasticizing in a double-roll plasticator and performing compression molding. The bentonite and the zinc borate which are treated organically and aluminum hydroxide are compounded to form a novel fire retardant, the mechanical property of the material is kept, the flame retardant effect of the wood plastics composite is improved and the using amount of the aluminum hydroxide is greatly reduced; and the bentonite and the zinc borate are organically ultrafined, the problem that an inorganic additive is not easily compatible with other components so as to influence the mechanical property of the composite is solved and the flame retardant requirement of the wood plastics composite is met.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Flame-retarding polymer foam material and preparation method thereof

ActiveCN102127269AIncrease the amount addedAddition changeLaminationLamination apparatusPolymer sciencePolystyrene

The invention discloses a flame-retarding polymer foam material which is characterized by comprising polymer foam plastic, wherein the surface of the polymer foam plastic is provided with an organic flame retardant layer; and the organic flame retardant layer is formed by attaching a molten organic flame retardant to the surface of the polymer foam plastic through a spraying, coating or soaking way. The invention also discloses a preparation method of the flame-retarding polymer foam material. In the invention, a flame-retarding variety which is effective to the polymer foam plastic, in particular to extrusion foamed polystyrene foam plastic, is selected from numerous flame retardants, and the polymer foam product with excellent flame-retarding property is prepared by adopting a simple and feasible method. Through the invention, an effective method for increasing the addition amount of the flame retardant is obtained on the premise of not influencing the foaming property of the foam products and not reducing the strength and the insulation and thermal preservation property of foams, and different flame-retarding requirements can be met by flexibly changing the attaching amount of the flame retardant.

Owner:连云港传奇阻燃科技有限公司

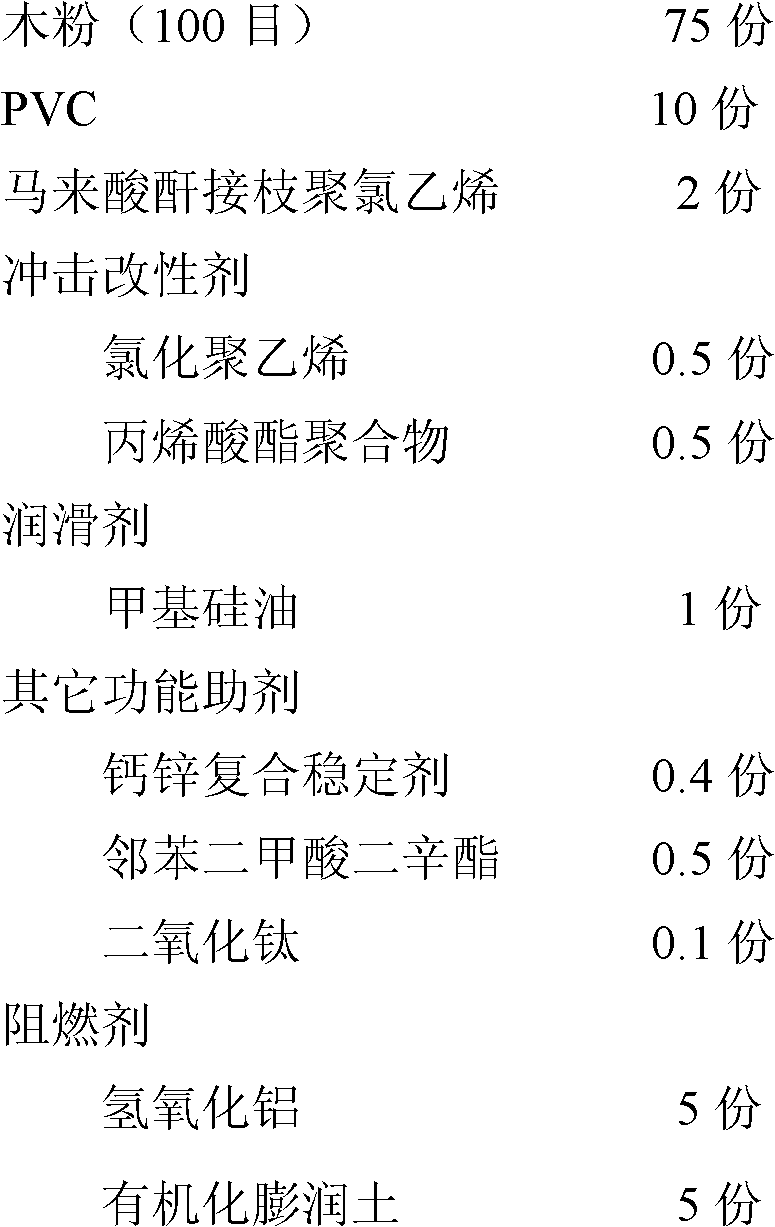

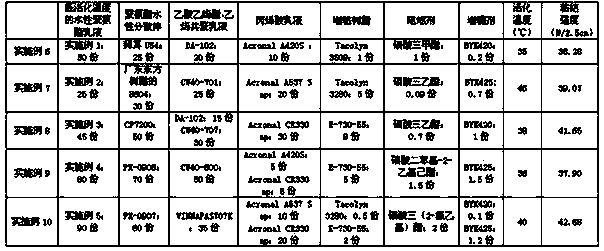

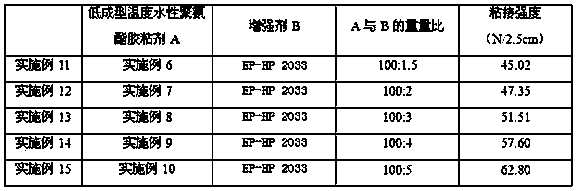

Low-molding-temperature waterborne polyurethane adhesive and preparation method thereof

ActiveCN104031596AImproved sag performanceReduce lossNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a low-molding-temperature waterborne polyurethane adhesive and a preparation method thereof. The low-molding-temperature waterborne polyurethane adhesive is prepared by matching a waterborne polyurethane dispersion, ethylene-vinyl acetate (EVA) emulsion, acrylic emulsion and the like based on low-activation-temperature waterborne polyurethane emulsion, wherein the low-activation-temperature waterborne polyurethane emulsion mainly consists of polyhydric alcohols, diisocyanate, a small molecule alcohol chain extender, a catalyst and a hydrophilic chain extender and has the activation temperature of less than 25 DEG C; the low-molding-temperature waterborne polyurethane adhesive prepared based on the low-activation-temperature waterborne polyurethane emulsion has the activation temperature of 30-60 DEG C, is high in bonding strength, is water-based emulsion, does not contain organic solvents or volatile organic compounds, is green and environment-friendly and can well meet the service requirements of adhesives for automobile roofs. The low-molding-temperature waterborne polyurethane adhesive also can be matched with a certain amount of enhancers, the bonding strength of colloid at the later stage is effectively improved, and the heat resistance of the roof at the later molding stage is guaranteed.

Owner:重庆中科力泰高分子材料有限公司

Blow molding type halogen-free flame-retardant polypropylene material

InactiveCN102286171AOvercome strengthOvercoming problems such as brittleness at low temperaturesBlow moldingHalogen

The invention provides a blow molding type halogen-free flame-retardant polypropylene material, which comprises the following components in part by weight: 100 parts of polypropylene, 40 to 85 parts of phosphorus-nitrogen series expanded halogen-free composite flame retardant, 3 to 20 parts of resin modifier, 0.05 to 0.5 part of pigment, 0.4 to 2.0 parts of antioxidant, 0.3 to 2.0 parts of ultraviolet absorbent, 0.3 to 2.0 parts of light stabilizer, and 1.0 to 3.0 parts of other processing aids. The material has good tensile strength, high impact strength, good low-temperature performance and excellent flame-retardant performance, and is particularly suitable for hollow blow molding type small and large components of automobiles, furniture and the like.

Owner:应急管理部四川消防研究所

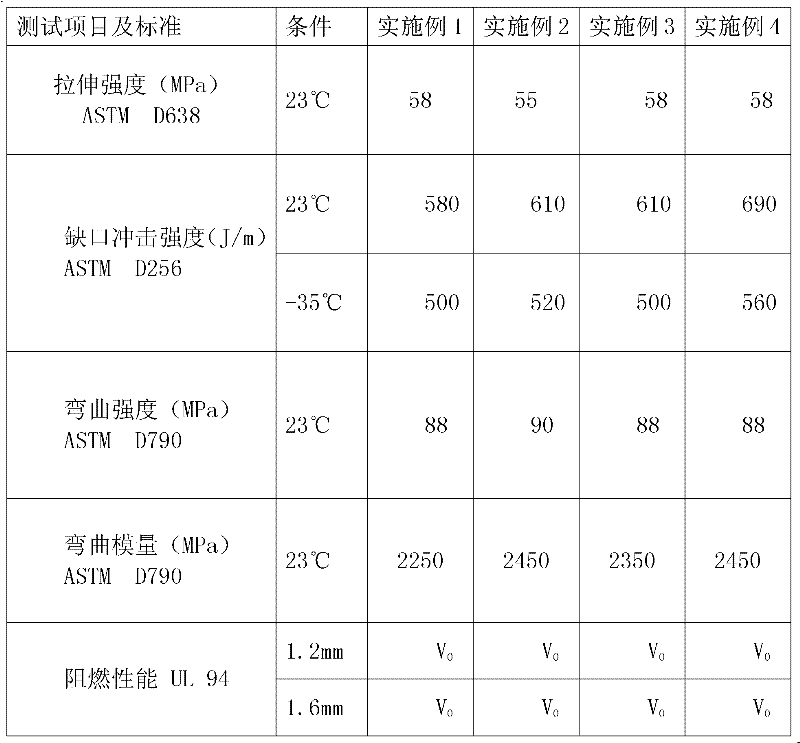

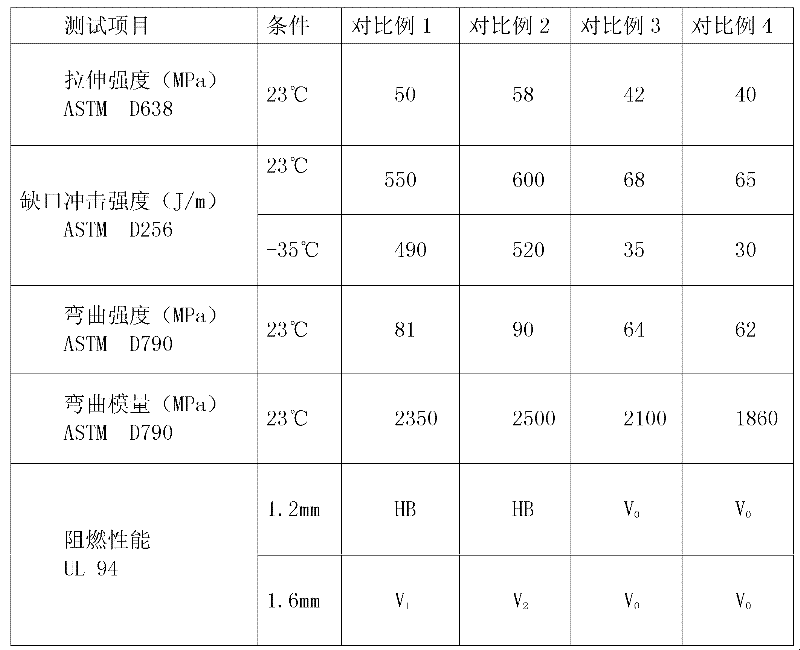

Halogen-free flame-retardant and cold-resistant PC/ABS (Poly Carbonate/Acrylonitrile Butadiene Styrene) material and preparation method thereof

The invention discloses a halogen-free flame-retardant and cold-resistant PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) material and a preparation method thereof. The halogen-free flame-retardant and cold-resistant PC / ABS material mainly comprises components of PC and ABS and further comprises a silicon fire retardant, a phosphorus fire retardant, an anti-dripping agent, a compatilizer, a flexibilizer, a lubricant, an antioxidant, and an anti-ultraviolet agent. A preparation process is a twin-screw melting extrusion pelletizing process. According to the preparation method disclosed by the invention, the silicon fire retardant and the phosphorus fire retardant are composited so that the fire resistance 1.2 mm of the obtained PC-ABS alloy material can meet the UL94V-0 class requirement in the United States. The compatilizer MBS (Methyl methacrylate-Butadiene-Styrene) not only enables the PC and the ABS to be better dissolved but also can be used for increasing the compatibility between the silicon fire retardant and a substrate. Therefore, not only can the impact property of the alloy be improved but also the flame retardant efficiency can be effectively improved. The alloy material has the good low-temperature impact property due to the flexibilizer. The silicon fire retardant has a fire retardant synergy effect and further has a smoke suppression effect, so that the fire resistance 1.2 mm of the obtained PC-ABS alloy material can meet the UL94V-0 class requirement in the United States.

Owner:SHENZHEN KEJU NEW MATERIAL

Halogen-free flame retardant plastic geotechnical grille master batch for mine

InactiveCN102372869ADelay thermo-oxidative agingExtended service lifePhosphoric Acid EstersMasterbatch

The invention discloses a halogen-free flame retardant plastic geotechnical grille master batch for a mine, which consists of polyolefine, special carbon black, composite flame retardants, compatilizer, modified nanometer reinforcing materials, processing auxiliary agents and antioxidizer according to a certain proportioning ratio, wherein the composite flame retardants are compounds of nanometer inorganic flame retardants, micro-capsulated red phosphorus and phosphoric acid ester flame retardants. When the master batch prepared by the method is added in grilles, the performance is stable, the flame retardant performance is good, and the environment protection effect is good.

Owner:TAIAN MODERN PLASTIC

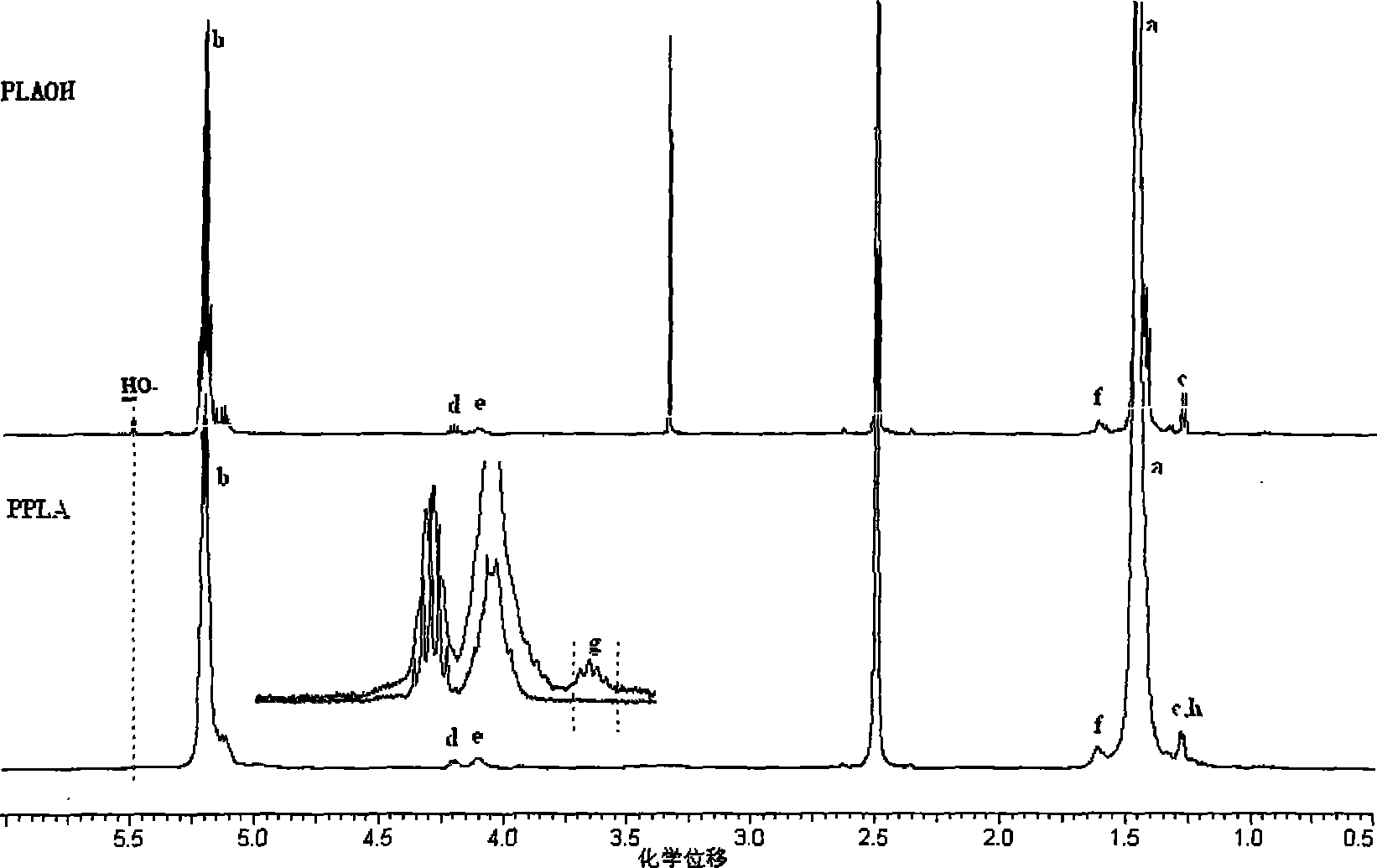

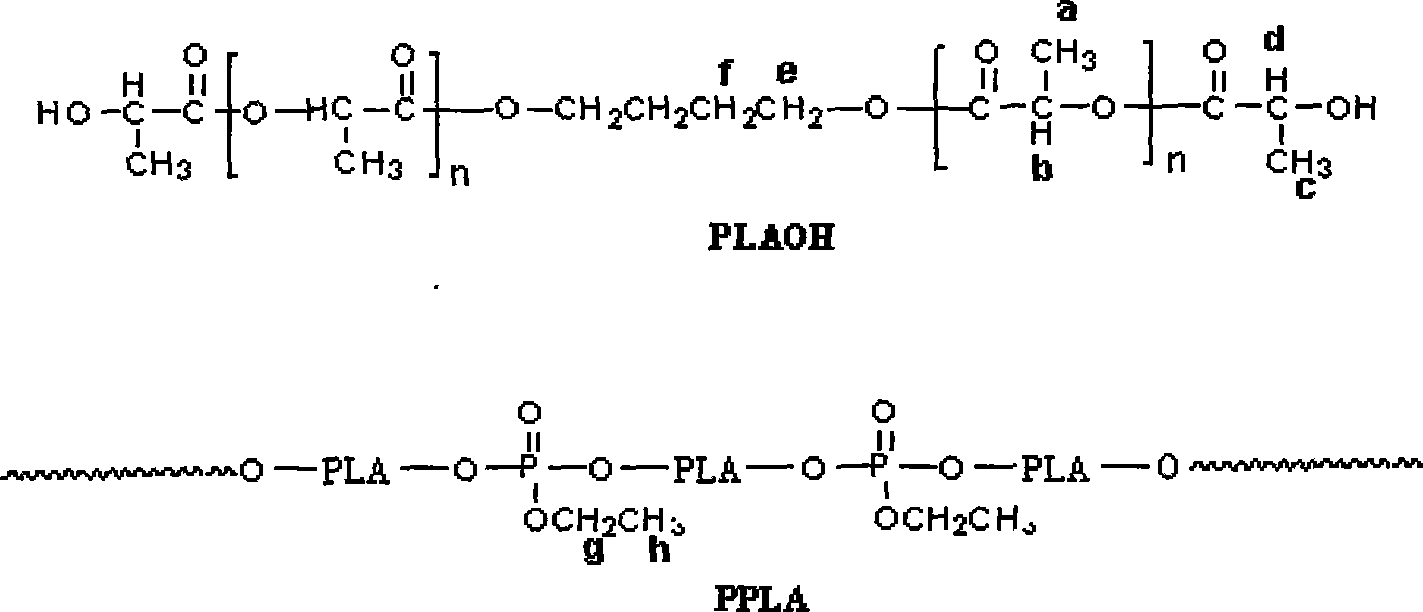

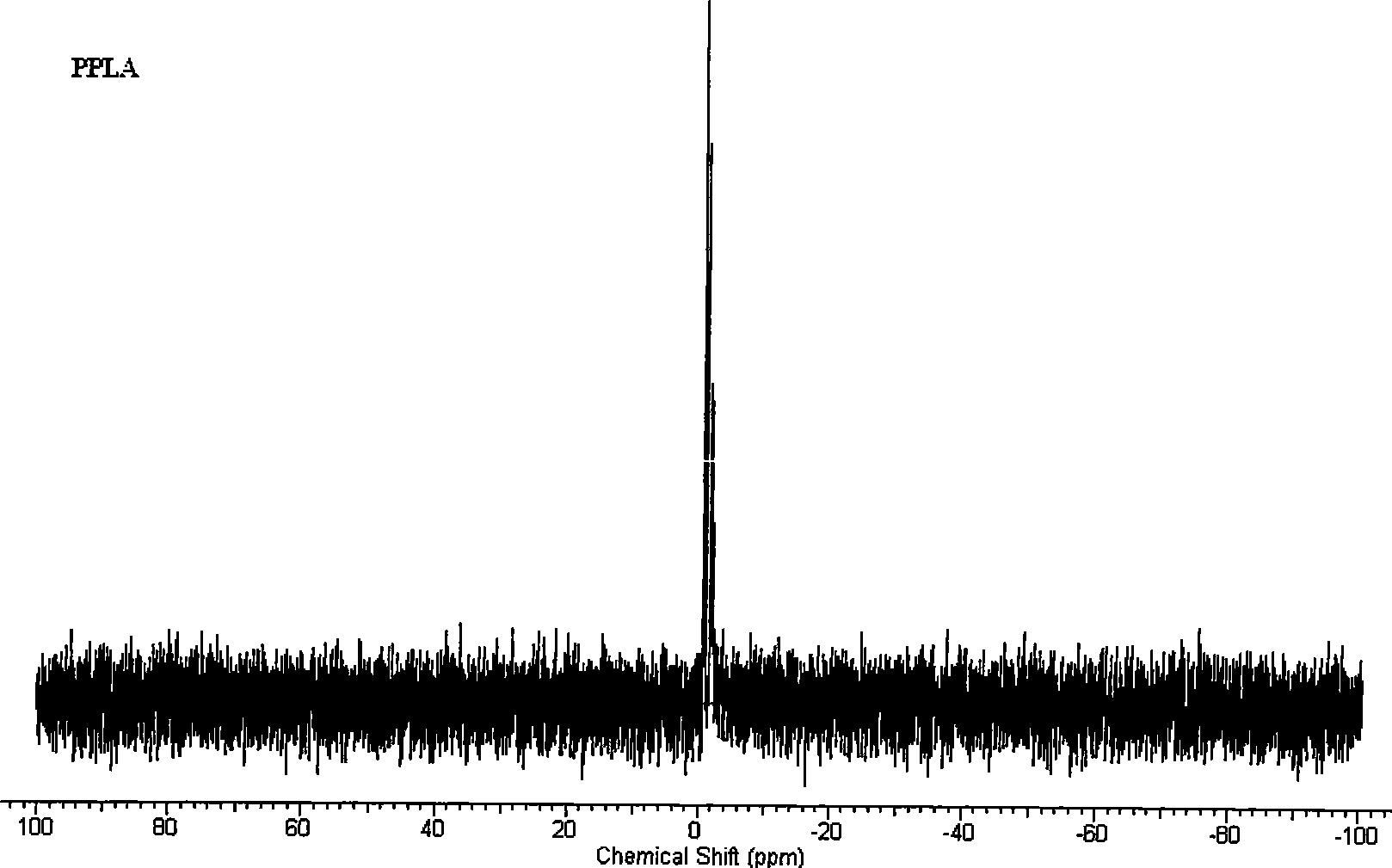

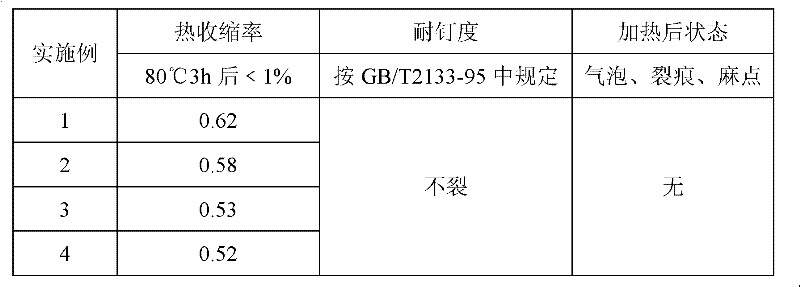

Phosphor-containing halogen-free flame-retardant polylactic acid, preparation thereof and flame-retardant material blended therewith

The invention discloses a phosphorus-containing halogen-free flame-retardant polylactic acid, which is obtained by leading phosphorus element with flame retardant function into a molecular backbone through a chain extending method or a coupling method. The phosphorus content of the polylactic acid is between 0.1 and 5 weight percent, and the vertical combustion level of the polylactic acid is V-0. The invention also discloses a method for preparing the halogen-free flame-retardant polylactic acid, and a flame retardant material formed by blending the phosphorus-containing halogen-free flame-retardant polylactic acid with common industrial polylactic acid. The phosphorus-containing flame-retardant polylactic acid provided by the invention leads flame-retardant element into the molecular backbone of the polylactic acid through chain extending or coupling reaction, thereby improving the molecular weight of the polylactic acid, endowing a polylactic acid body and the blended flame retardant material with good flame retardant property and overcoming the disadvantages of poor compatibility, precipitation easiness and the like caused by the application of additive flame retardant. In addition, as no halogen component is contained, no halogen-containing gas can be released during application, thereby particularly preventing the release of harmful gas from polluting environment and harming human bodies during combustion.

Owner:SICHUAN UNIV

Low-density wood-plastic composite shaving board and manufacture method thereof

ActiveCN102504557ALow densityHigh strengthFlat articlesDomestic articlesWood shavingsProduction line

The invention discloses a low-density wood-plastic composite shaving board and a manufacture method thereof. The shaving board comprises the following components in parts by weight: 5 to 200 parts of expandable polystyrene, 200 to 600 parts of wood shavings (50 to 100 parts of surface shavings, 150 to 500 parts of core shavings), 1.5 to 5 parts of coupling agent, and 4 to 10 parts of adhesive. The manufacture process comprises the following steps of: drying the wood shavings until the water content is between 2 and 5 percent; separating the wood shavings into surface shavings and core shavings by virtue of separation equipment, wherein the surface shavings are glued to serve as a surface material, and the core shavings are subjected to surface treatment by using the coupling agent and mixed with EPS (expandable polystyrene) to serve as a core material; and producing the low-density wood-plastic composite shaving board by virtue of assembling, pre-pressing and thermal-press molding. Compared with a common shaving board, the product has the advantages of low density, excellent physical and mechanical performances, good water repellency and environmental friendliness and simple production process, can be produced on an existing shaving board production line, and can be widely used as furniture materials, package materials and wall materials.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for preparing composite microsphere of polymer-nano magnesium hydroxide

A process for preparing the composite polymer-nano magnesium hydroxide microspheres includes sphericizing the magnesium hydroxide nanoparticles by use of polymer monomer, cross-linking agent and trigger, and the simulative emulsion polymerizing method and spray drying. Its advantages are high product performance in coated rate, quality, flame retarding, compatibility, etc.

Owner:ZHEJIANG UNIV

Flame retardant micro-foamed all plastic wood-like material and its preparation method

InactiveCN102408642ARealistic imitation wood effectFlame retardant requirements are easyPolymer chemistryColoring agents

Relating to an all plastic wood-like material and its preparation method, the invention provides a flame retardant micro-foamed all plastic wood-like material and its preparation method. The all plastic wood-like material comprises: 100 of polystyrene, 20-40 of high impact polystyrene, 10-15 of resin, 2-5 of an inorganic filling material, 15-25 of fire retardants, 5-15 of a smoke suppressant, 0.5-1.5 of foaming agents, 0.5-2 of a cell regulator, 0.5-2 of a colouring agent and 1.5-3 of auxiliary agents. The method consists of: mixing the auxiliary agents, the colouring agent, the fire retardants, the smoke suppressant, the foaming agents and the cell regulator according to the ratio so as to obtain a mixture A; drying the resin and the inorganic filling material; mixing polystyrene, high impact polystyrene, resin and the inorganic filling material, as well as the mixture A, thus obtaining a mixture B; subjecting the mixture B to granulation, and molding the obtained particles, thus obtaining the halogen-free and flame retardant micro-foamed all plastic wood-like material.

Owner:XIAMEN UNIV +1

Method for preparing halogen-free high-efficiency flame retardant aryloxy cyclotriphosphazene compound

ActiveCN102180908APromote low-carbon and high-efficiencyEase of industrial scale productionGroup 5/15 element organic compoundsPolymer scienceHalogen

The invention discloses a method for preparing a halogen-free high-efficiency flame retardant aryloxy cyclotriphosphazene compound. The flame retardant is a pure white crystal product prepared by reacting sodium phenate and hexachlorocyclotriphosphazene serving as raw materials with dioxane serving as a solvent under heating and stirring, filtering and purifying. The preparation method of the flame retardant overcomes the defects of long reaction time, a yellow product color and high production cost existing in the conventional synthesis method commonly. The prepared flame retardant has the characteristics of high efficiency, no halogen, flame retardance, no toxicity, low smoke and the like, has high compatibility with most of organic polymer materials, and has processing stability and using stability.

Owner:JINAN TAIXING FINE CHEM

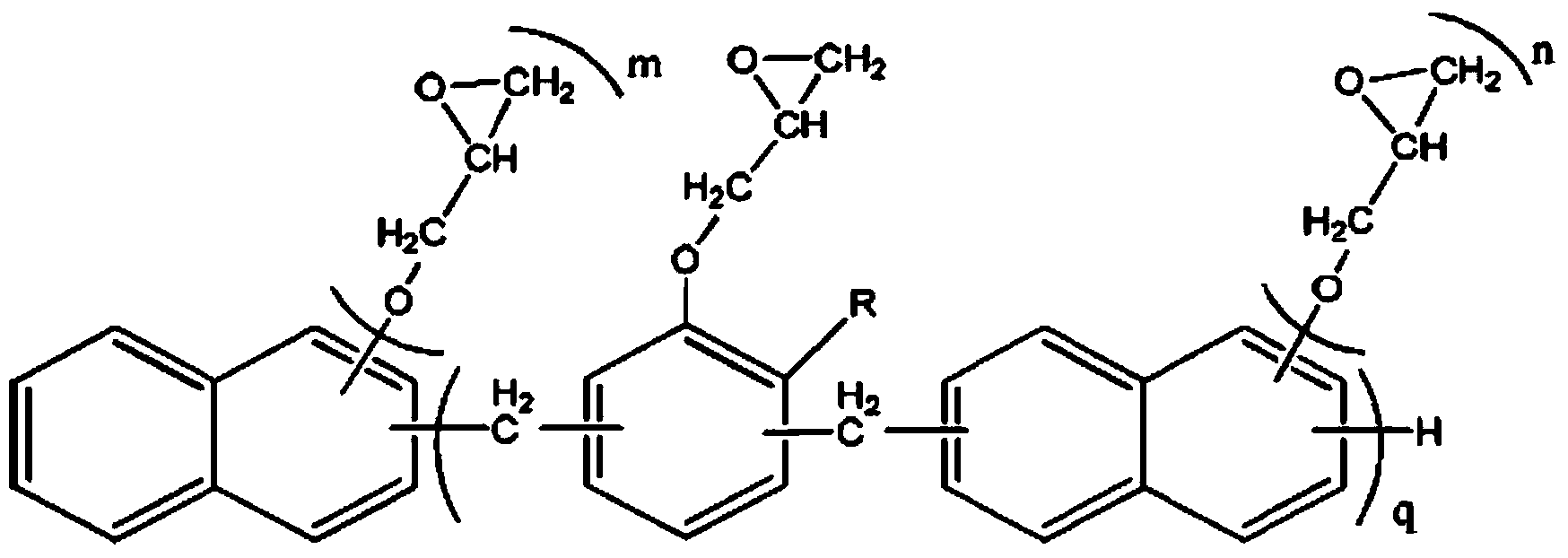

Halogen-free epoxy resin composition and application thereof

InactiveCN103724944AExcellent dielectric propertiesExcellent heat and humidity resistanceSynthetic resin layered productsPrinted circuitsCopper foilChemistry

The invention discloses a halogen-free epoxy resin composition, and a prepreg and copper foil clad laminated board prepared from the same. The epoxy resin composition comprises the following components: (A) halogen-free epoxy resin; (B) styrene-maleic anhydride copolymer (SMA) used as a first curing agent; and (C) phosphorus-containing compound used as a second curing agent. The prepreg and copper foil clad laminated board prepared from the halogen-free epoxy resin composition have the advantages of favorable dielectric properties, favorable processability, simple technological operation and favorable moisture and heat resistance.

Owner:GUANGDONG SHENGYI SCI TECH

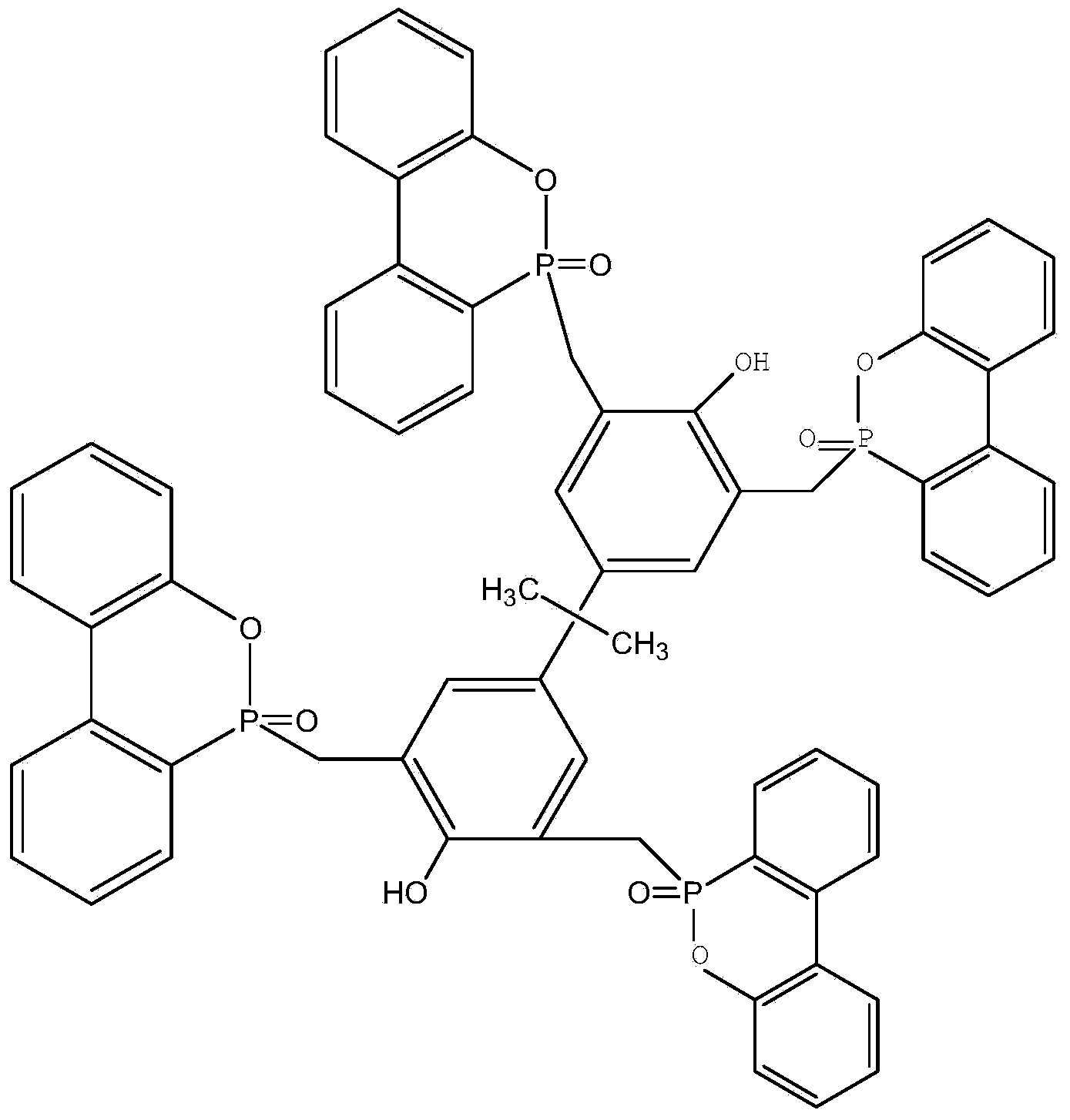

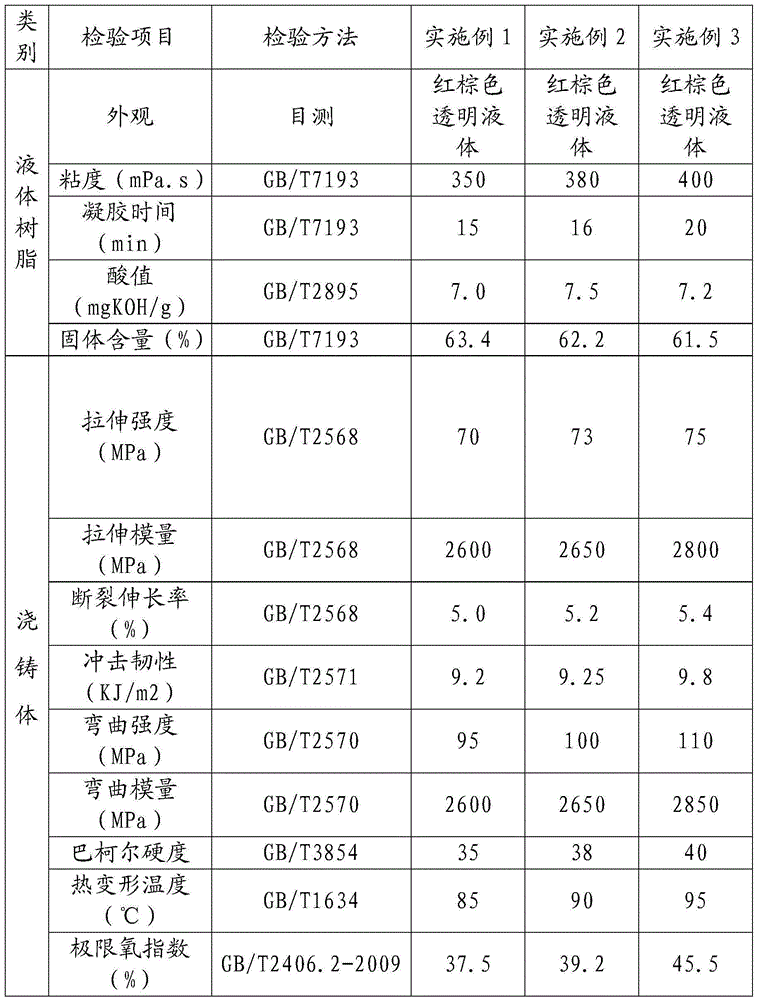

Synthetic method of efficient flame-retardant epoxy vinyl ester resin

The invention discloses a synthetic method of efficient flame-retardant epoxy vinyl ester resin. Biophenol A diglycidyl ether, brominated epoxy resin, a polymerization inhibitor, a catalyst and an antioxidant are sequentially added to a reaction kettle, the reaction temperature slowly rises to 50 DEG C, chain extension binary acids / anhydrides are added in small quantities in batches, the mixture is heated to the temperature of 75-85 DEG C, the temperature is kept for 2 h, and the reaction acid value is decreased to be lower than 2; (3) unsaturated monoacid is dropwise added to the reaction kettle at the dropping speed of 50 ml / h, the reaction temperature change condition is observed, and congelation caused by excessively fast temperature rises is avoided; after addition, the mixture is slowly heated to the temperature of 110-115 DEG C, and the temperature is kept for 4-5 h until the acid value is decreased to be lower than 15; (4) the mixture is diluted with a crosslinking agent and fully stirred, then a flame-retardant aid is added, after the material temperature is decreased to be lower than 45 DEG C, stirring is stopped, cooling water is turned off, and package is performed. By means of the method, the best flame-retardant effect can be realized and the flame-retardant requirement in certain special fields can be met.

Owner:YONGYUE SCI & TECH

Preparation method of halogen-free composite flame retardant polypropylene/thermoplastic polyurethane elastomer composite material

The invention discloses a preparation method of a halogen-free composite flame retardant polypropylene / thermoplastic polyurethane elastomer composite material. The method mainly consists of: A. mixing 80 parts by weight of polypropylene, 20 parts by weight of a thermoplastic polyurethane elastomer, 3 parts by weight of dry polypropylene grafted maleic anhydride and 0.2 part by weight of an antioxidant fully, then employing a double-screw extruder to perform mixing and granulating, and conducting drying to obtain a modified polypropylene masterbatch; B. then fully mixing 100 parts by weight of modified polypropylene masterbatches, 6.7-15 parts by weight of modified expandable graphite, and 4-13.3 parts by weight of red phosphorus flame retardant masterbatches to obtain a mixture; and then subjecting the mixture to mixing and granulating by the double-screw extruder, drying the extruded granules, and then carrying out injection molding by an injection molding machine, thus obtaining the halogen-free composite flame retardant polypropylene / thermoplastic polyurethane elastomer composite material. The flame retardant polypropylene / thermoplastic polyurethane elastomer composite material prepared by the method has good flame retardance, and the flame retardant level can reach vertical burning UL-94V-0.

Owner:SOUTHWEST JIAOTONG UNIV

Polyethane conveyer belt for coal mine and its making process

ActiveCN1974661AImprove delivery efficiencyIncrease elasticityBeltsWear resistantToluene diisocyanate

The present invention relates to polyurethane conveyer belt for coal mine and its making process. The polyurethane conveyer belt is covered with polyurethane elastomer, which is one polyol oligomer / toluene diisocyanate system or one polyol oligomer / diphenyl alkyl diisocyanate system. The polyurethane has optimized recipe, phosphate fire retardant and / or halogen fire retardant added while synthesis and in the amount accounting for 5-20 wt% of the pre-polymer, and antistatic agent of quaternary ammonium salt type surfactant one conducting carbon black added while casting the covering elastomer.The modified polyurethane elastomer is fire retardant, antistatic, wear resistant and suitable for use in coal mine, and has long service life and capacity of resulting in high conveying efficiency.

Owner:东莞华工佛塑新材料有限公司

A kind of silicone potting glue and its preparation method and application

ActiveCN102295911AImprove applicabilityNo metal corrosionOther chemical processesAdhesivesRoom temperatureElectronic component

The invention relates to an organic silicon pouring sealant, a preparation method and application thereof. The organic silicon pouring sealant comprises a component A and a component B. The preparation method comprises the steps of: respectively preparing the component A and the component B according to the requirement of a formula, cooling to room temperature, during the application, and statically mixing the component A and the component B according to the weight ratio of 1: (1-1.2) for 20-30min to ensure that the component A is uniformly mixed with the component B to obtain the organic silicon pouring sealant. Compared with the prior art, the organic silicon pouring sealant has excellent applicability to various materials without metal corrosion, can achieve insulation, heat conductionand inflaming retarding requirements according to the requirements without damaging electronic components, has better operating performance, is easy to blend, and is suitable for encapsulation production application of a manual or general sealant injection device.

Owner:马鞍山海鹰新材料有限公司

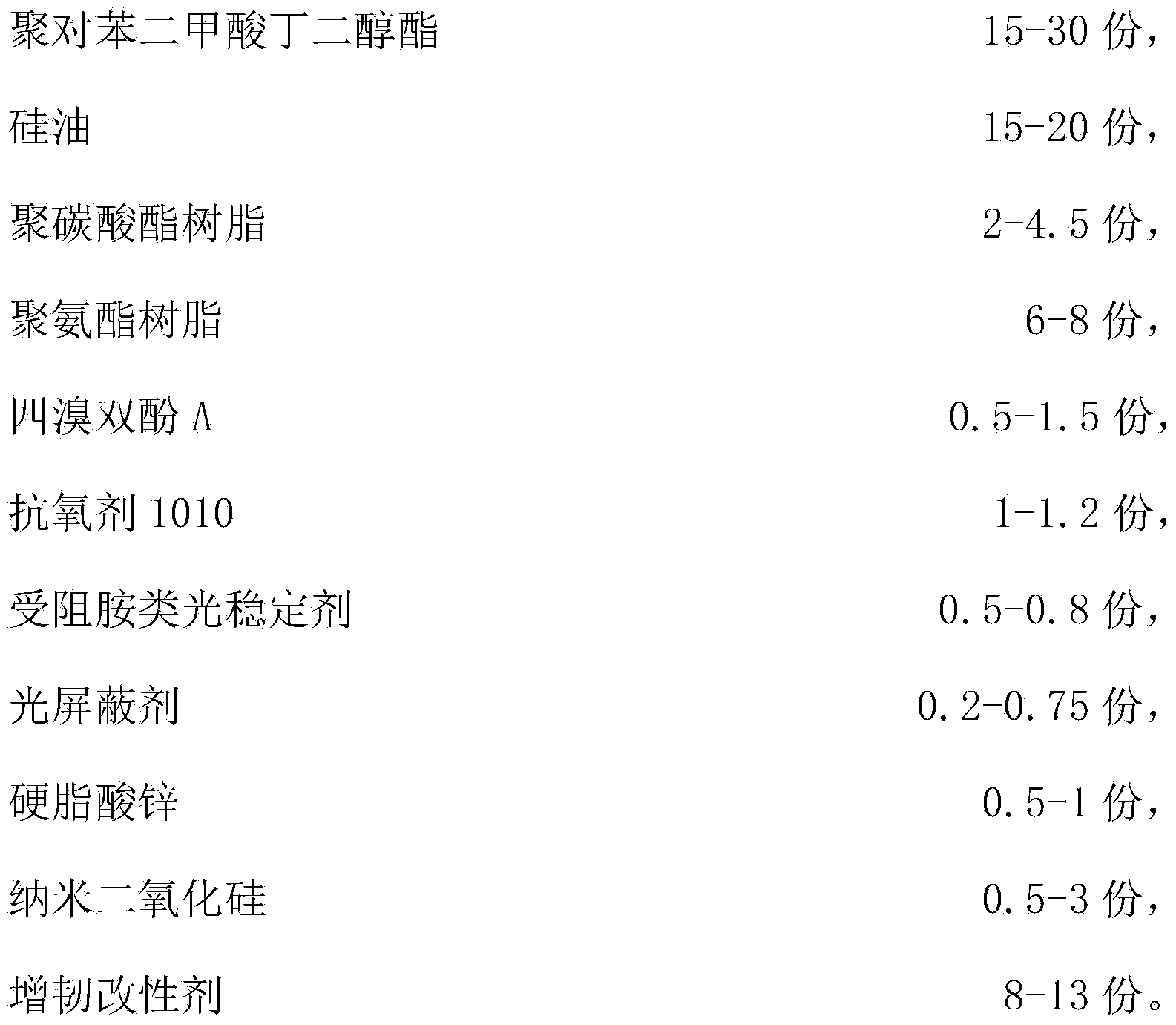

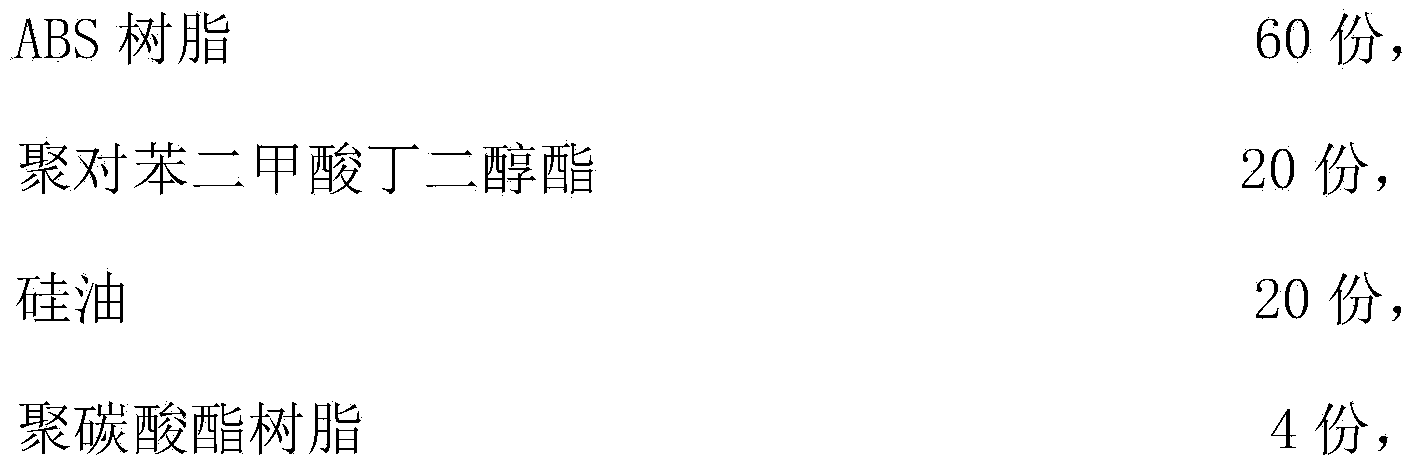

Heat-resistant and ageing-resistant acrylonitrile-butadiene-styrene (ABS) resin with high tensile strength and preparation technology of resin

InactiveCN104072932AGood dispersionImprove heat resistanceTetrabromobisphenol APolyethylene terephtalate

The invention discloses heat-resistant and ageing-resistant acrylonitrile-butadiene-styrene (ABS) resin with high tensile strength. The ABS resin comprises the following raw materials in parts by weight: 50-60 parts of ABS resin, 15-30 parts of polybutylene terephthalate, 15-20 parts of silicone oil, 2-4.5 parts of polycarbonate resin, 6-8 parts of polyurethane resin, 0.5-1.5 parts of tetrabromobisphenol A, 1-1.2 parts of an antioxidant 1010, 0.5-0.8 part of a hindered amine light stabilizer, 0.2-0.75 part of a light screener, 0.5-1 part of zinc stearate, 0.5-3 parts of nanosilicon dioxide and 8-13 parts of a toughened modifier. The invention also discloses a preparation technology of the heat-resistant and ageing-resistant ABS resin with high tensile strength. The heat-resistant and ageing-resistant ABS resin with high tensile strength has excellent fire resistance, heat resistance, ageing resistance and weatherability, high tensile strength and good tenacity.

Owner:ANHUI WANDONG CHEM

Packaging adhesive tape

ActiveCN104946154AAvoid harmMeet blow molding requirementsFilm/foil adhesivesStearic acidAnti oxidant

The invention discloses a packaging adhesive tape which is prepared by taking a polyurethane modified chlorinated polypropylene composite as a base material, wherein the polyurethane modified chlorinated polypropylene composite comprises the following raw materials in parts by weight: 100 parts of chlorinated polypropylene, 60-85 parts of a chlorinated polypropylene graft polymer, 12-24 parts of a toughened master batch, 5-20 parts of a halogen-free flame retardant, 0.5-4 parts of a coupling agent, 1-3 parts of an anti-oxidant, 2-4 parts of stearic acid, 1-3 parts of dioctyl phthalate, 0.5-2 parts of ethylene bis stearamide and 0.2-4 parts of polyethylene wax; the composite is formed by conducting graft modification on chlorinated polypropylene through polyurethane and maleic anhydride, and is used for preparing a high-performance high-molecular composite, and the finally obtained composite has relatively high abrasion resistance, weather resistance, impact resistance, corrosion resistance and high-low temperature resistance.

Owner:芜湖通发机械科技有限公司

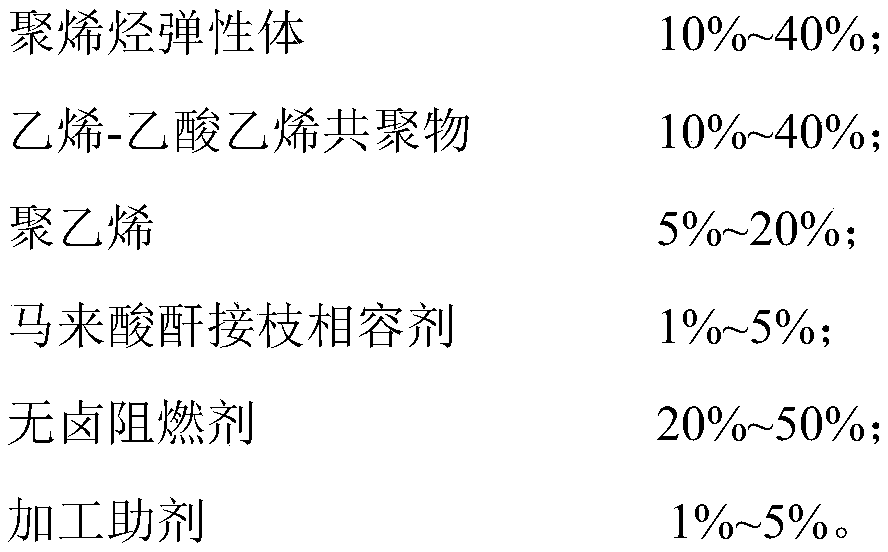

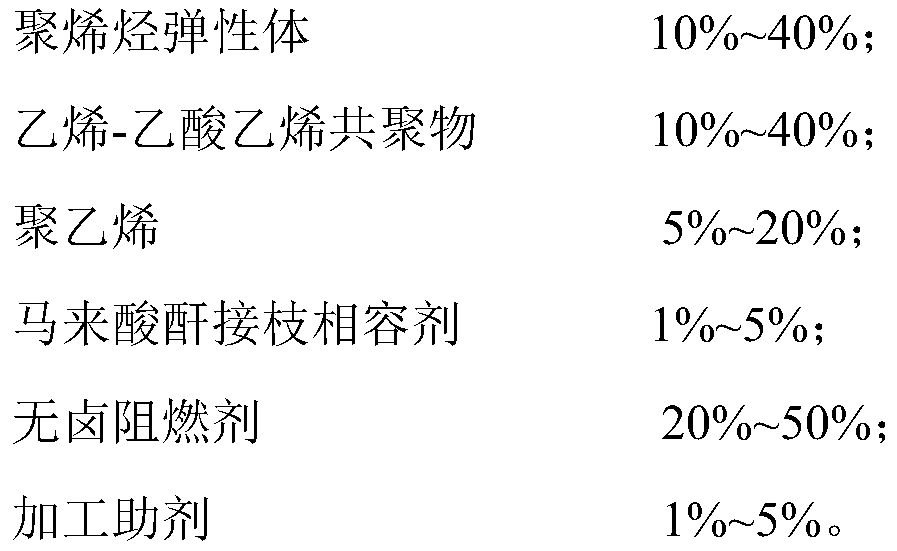

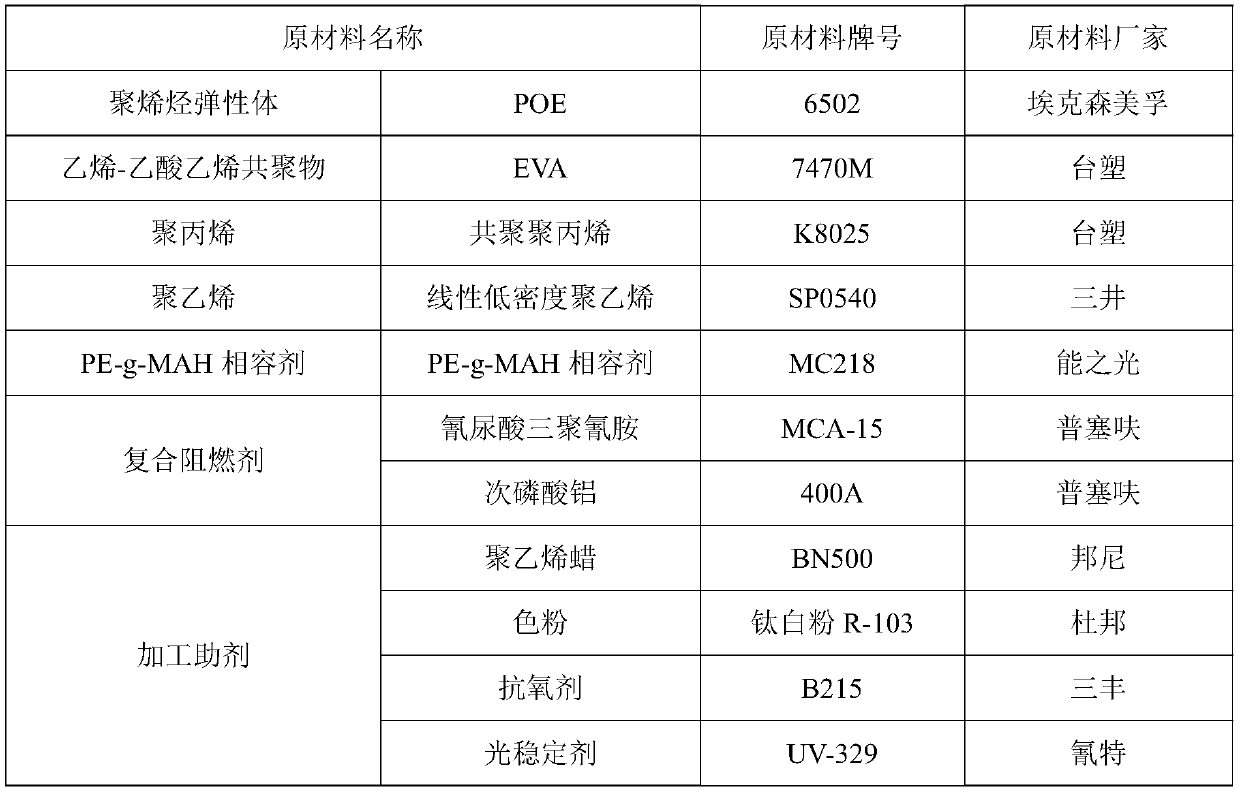

Halogen-free flame-retardant soft material used for automobile interior decoration, and preparation method thereof

The invention discloses a halogen-free flame-retardant soft material used for automobile interior decoration, a preparation method thereof, and applications of the halogen-free flame-retardant soft material in preparation of automobile interior decoration parts. The halogen-free flame-retardant soft material used for automobile interior decoration is composed of polyolefin elastomer, ethane-ethenyl ethanoate copolymer, polyethylene, a maleic anhydride grafted compatilizer, a halogen free fire retardant, and a processing auxiliary agent. The halogen-free flame-retardant soft material is soft, possesses high and low temperature resistance, UV resistance, and weatherability, is low in smell, and is capable of satisfying UL94 V0 flame resistance requirements. The material comprehensive performance is excellent; the preparation method is simple; the halogen-free flame-retardant soft material is worthy of popularization and applications, is suitable to be used for preparation of automobile interior decoration parts such as seat guard board coating rubber, glove box storage box rubber pad, and leather pattern decoration coating rubber.

Owner:GUANGDONG JUSHI CHEM CO LTD

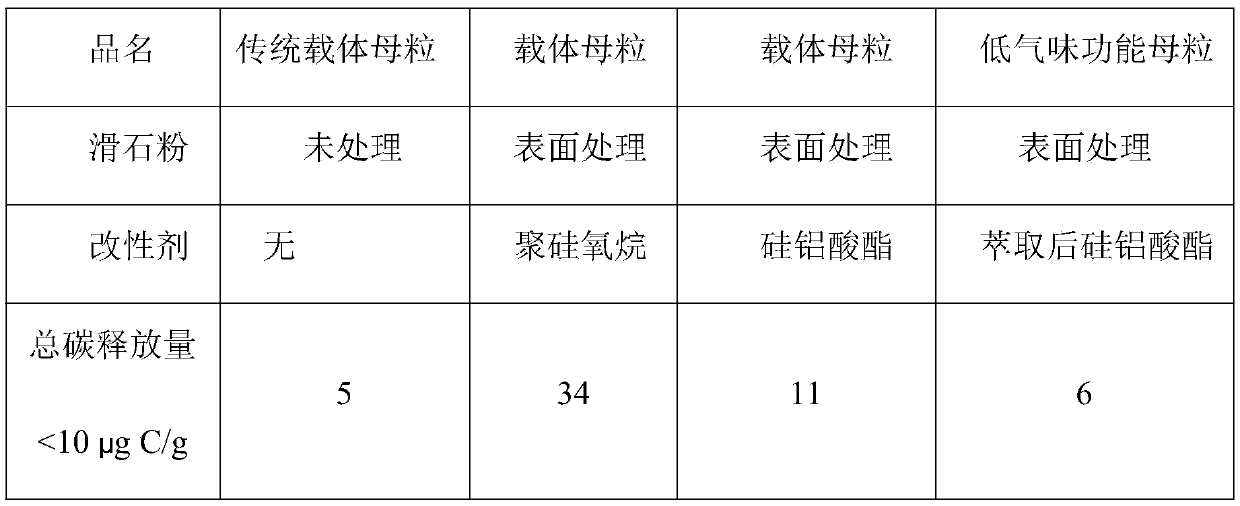

Polypropylene composite flame-retardant material for vehicle interior decoration as well as preparation method and application thereof

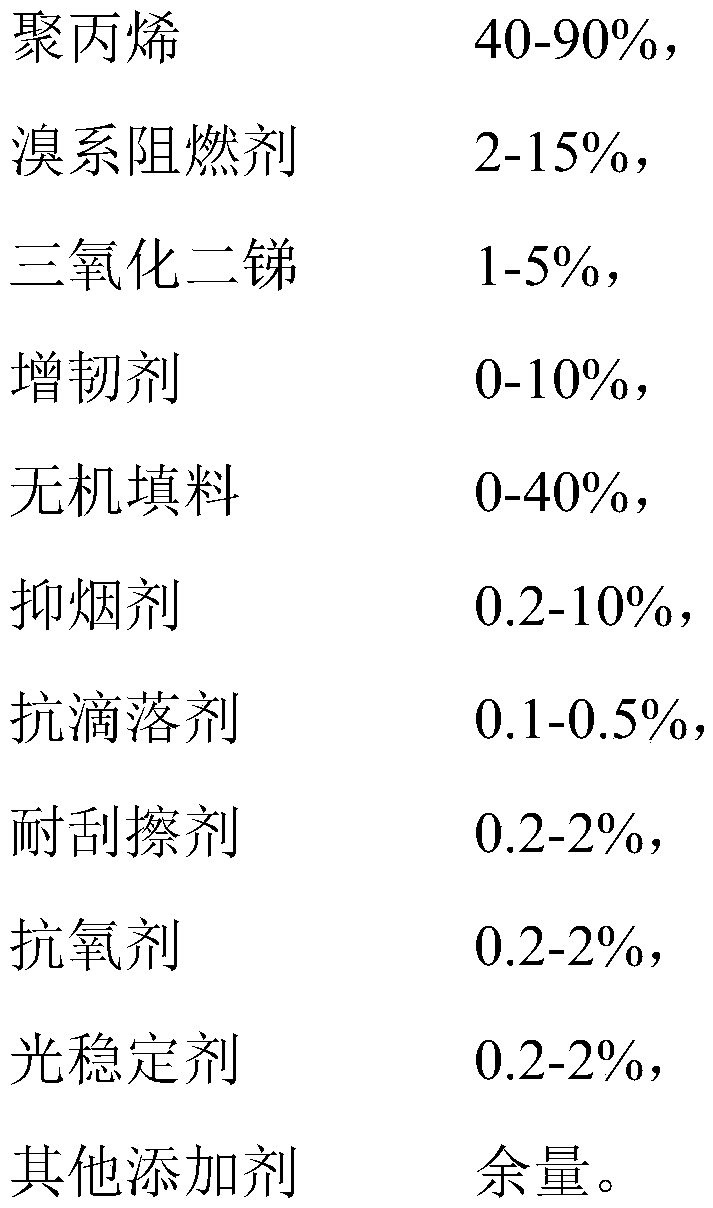

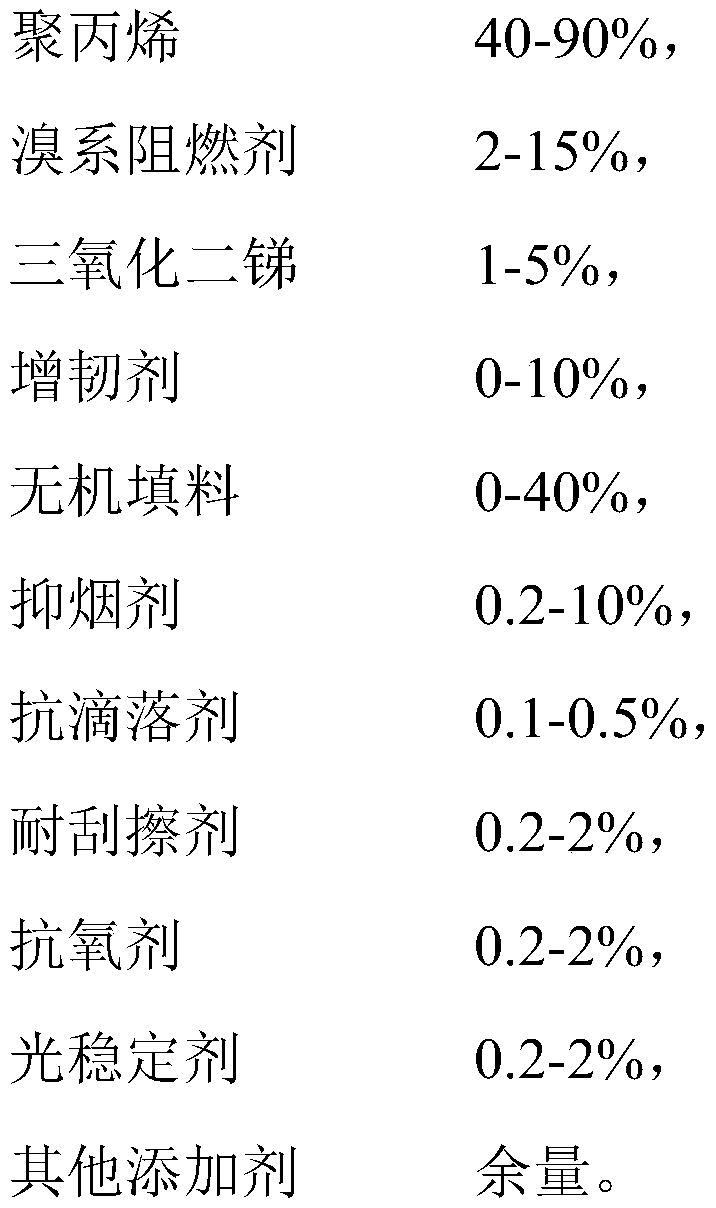

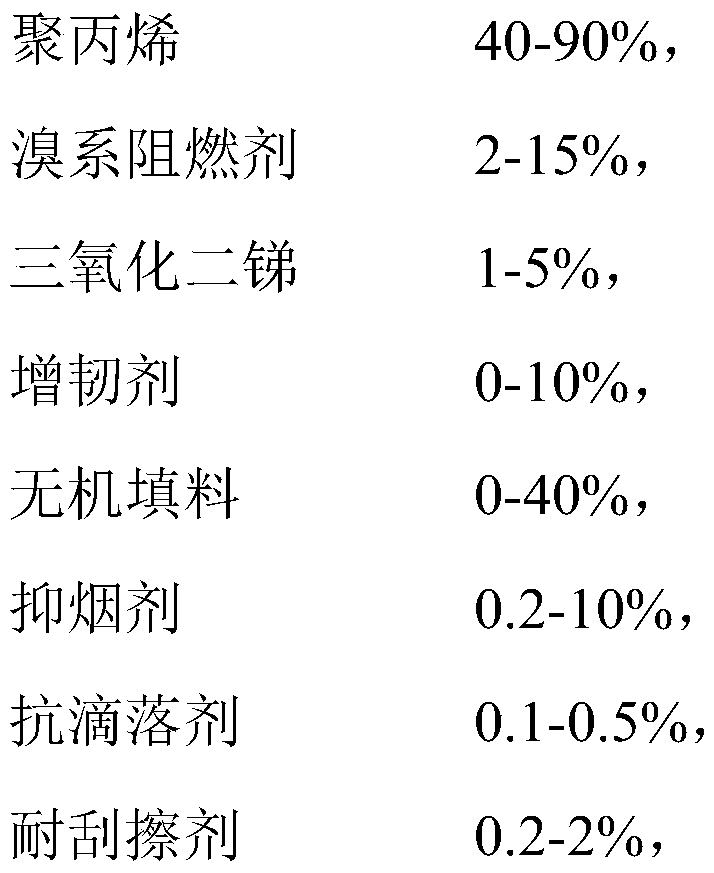

ActiveCN110713657AHigh retention rate of mechanical propertiesImprove mechanical propertiesPolypropylene compositesLimiting oxygen index

The invention belongs to the technical field of flame retardance, in particular to a polypropylene composite flame-retardant material for vehicle interiors. Based on a condition that the total mass ofthe polypropylene composite flame-retardant material is 100%, the composite flame-retardant material comprises the following raw material components in percentage by mass: 40-90% of polypropylene, 2-15 of a brominated flame retardant, 1-5% of antimonous oxide, 0-10% of a flexibilizer, 0-40% of an inorganic filler, 0.2-10% of a smoke suppressant, 0.1-0.5% of an anti-dripping agent, 0.2-2% of a scratch-resistant agent, 0.2-2% of an antioxidant, 0.2-2% of a light stabilizer and other additives. The polypropylene composite flame-retardant material for vehicle interior decoration has good tensilestrength, bending property, impact strength and other mechanical properties, and also has the properties of high limit oxygen index, low smoke density grade, low odor, low total carbon, light resistance and the like.

Owner:江苏沃特新材料科技有限公司

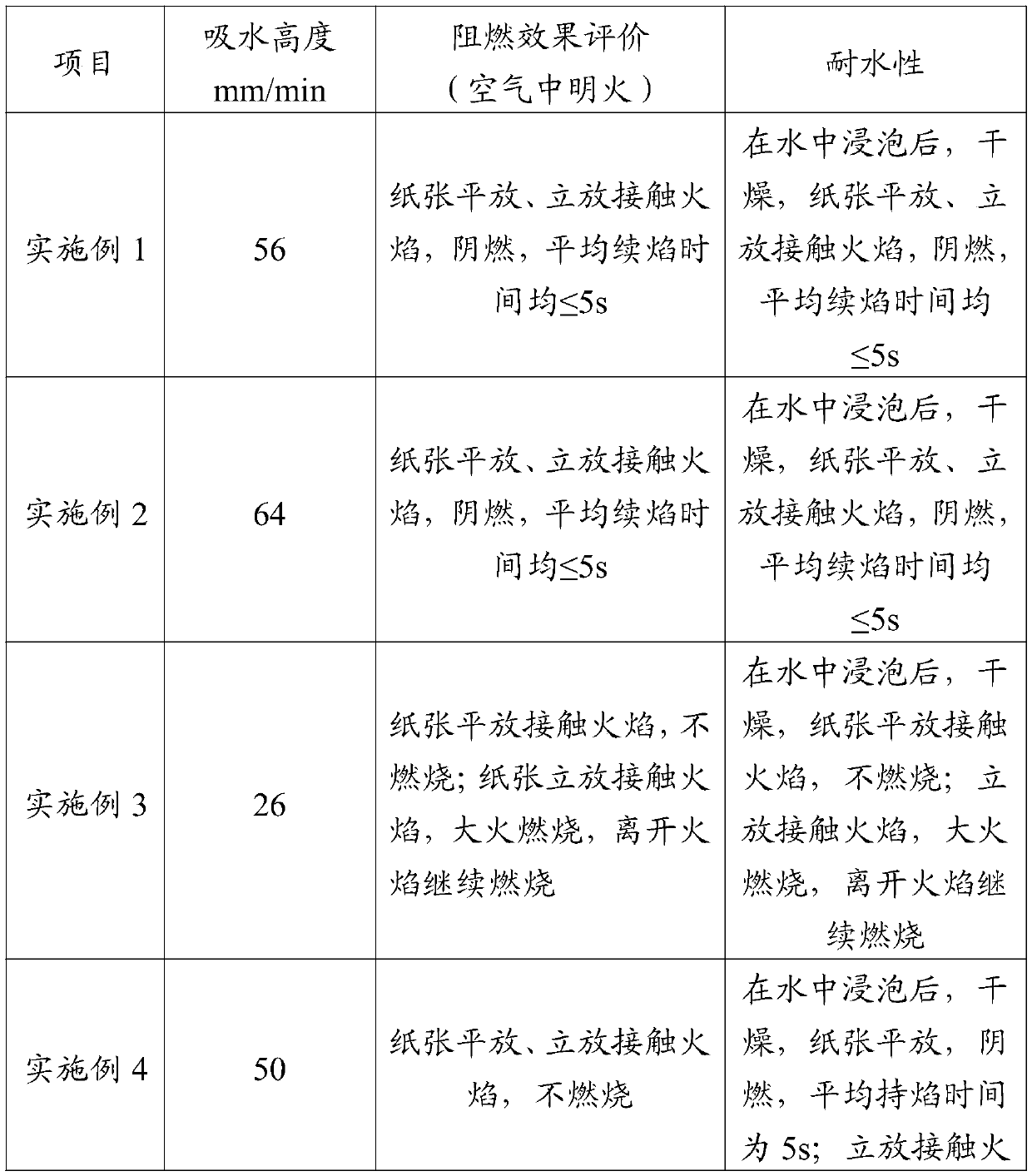

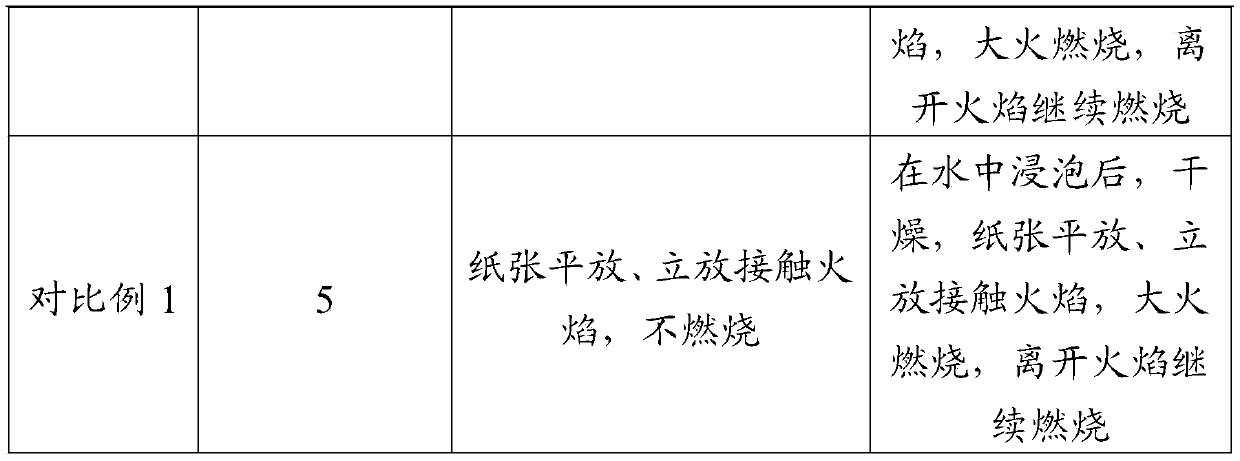

Waterproof and flame-retardant paper, and preparation method and application thereof

InactiveCN110644288AImprove water absorptionImprove water resistanceDefoamers additionSpecial paperPolymer sciencePlant fibre

The invention provides a waterproof and flame-retardant paper, and a preparation method and an application thereof, and belongs to the technical field of materials. The waterproof and flame-retardantpaper comprises fibers and assistants; the fibers comprise 70-90 wt% of flame-retardant fibers and 10-30 wt% of plant fibers; and the assistants comprise a wet strength agent and a defoaming agent, the using amount of the wet strength agent is 0.5-1.0% of the mass of the fibers, and the using amount of the defoaming agent is 0.01-0.1% of the mass of the fibers. The waterproof and flame-retardant paper has excellent water absorption, water resistance and flame retardancy, still has excellent flame retardancy after being soaked in water, has the advantage of low cost, and is suitable for being industrially applied.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

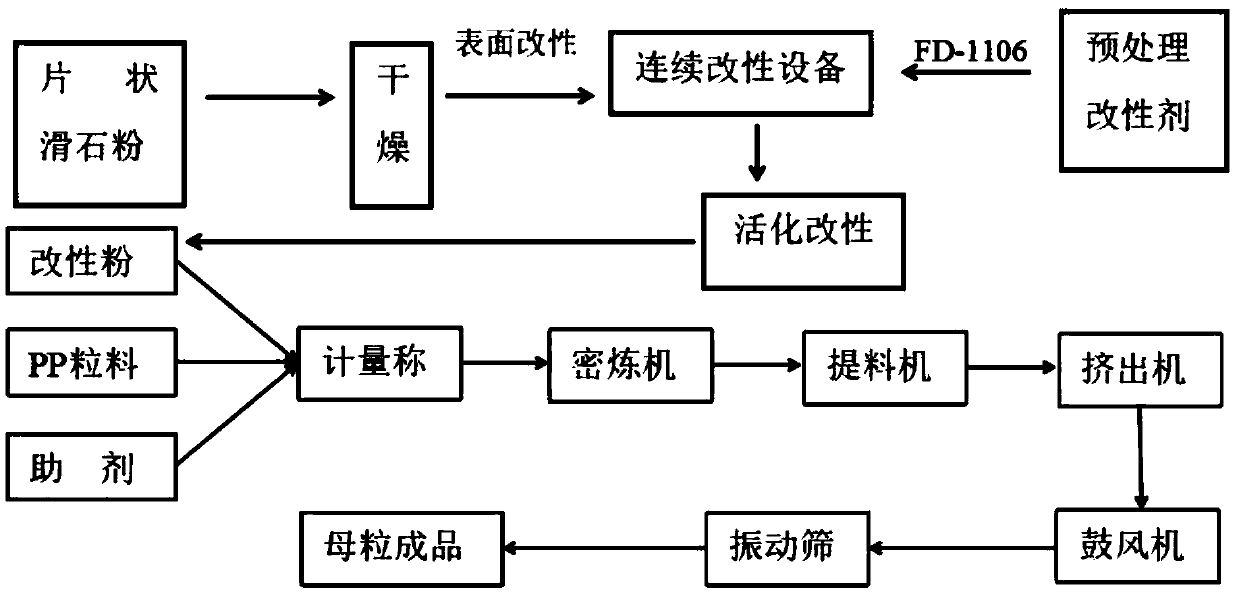

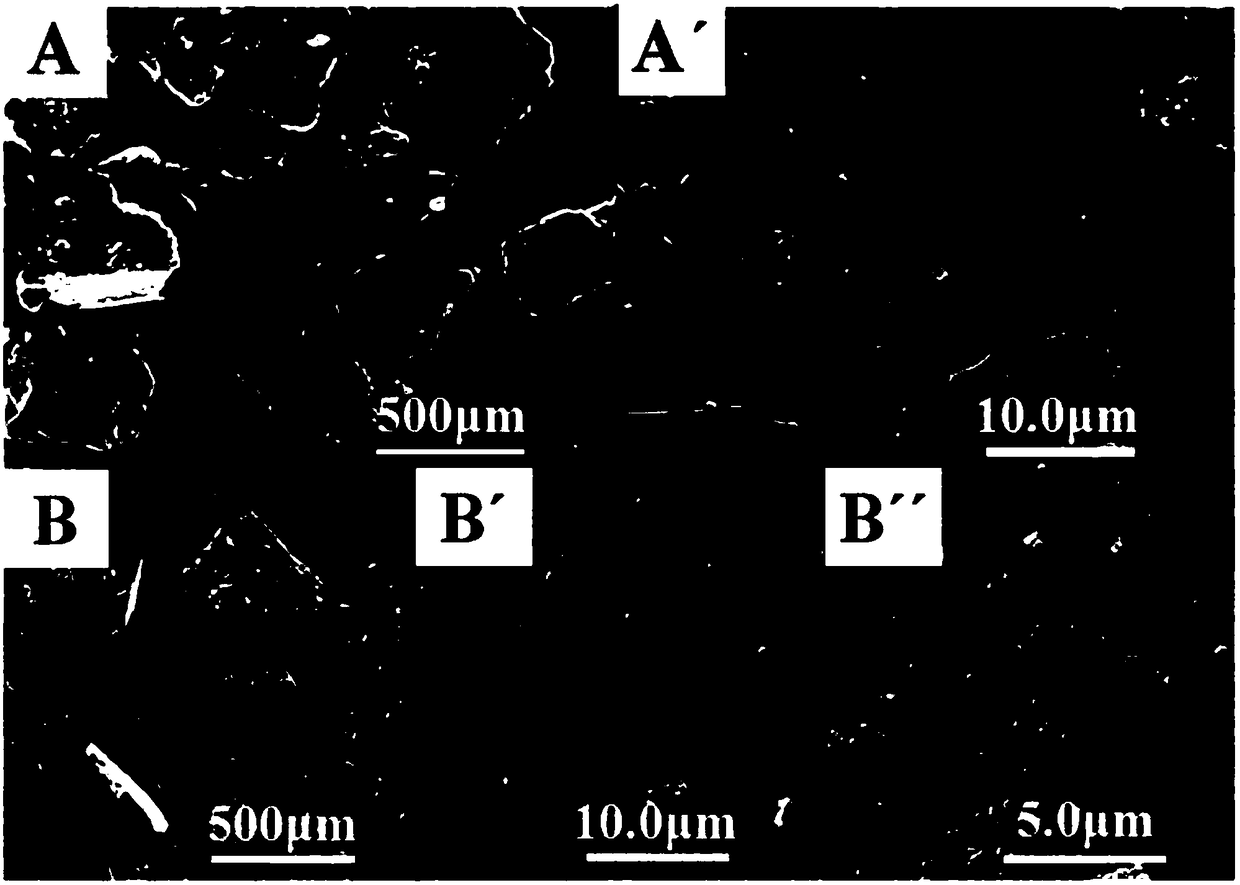

Low-odor functional talc master batch and preparation method thereof

The invention discloses a low-odor functional talc master batch and a preparation method thereof. The low-odor functional talc master batch comprises the following raw materials (by weight): 78-80 parts of talc powder, 0.8-1 part of a coupling agent, 20-22 parts of a polypropylene monomer, 0.5-0.8 part of a lubricant and 0.2-0.5 part of an antioxidant. The raw materials are wide in source, the preparation process is simple, the prepared finished product is a rigid-tough balance type product after being filled, and the material shrinkage rate and the smell of the whole material can be reduced;the finished product is easy to process, the fluidity and demolding property of plastic processing are promoted to be improved, emission is reduced, and the volatilization amount of VOC is reduced without increasing the cost; the finished product has low atomization performance, the volatile matter content can be effectively reduced, the finished product has a synergistic effect with various flameretardants, the addition amount of the flame retardants can be properly reduced, the flame retardant requirement is met, and the application prospect is wide.

Owner:泉州市旭丰粉体原料有限公司

Preparation methods of SiO2 nano particle modified expandable graphite and flame retardant polypropylene

The invention discloses preparation methods of SiO2 nano particle modified expandable graphite and flame retardant polypropylene. The preparation method of the SiO2 nano particle modified expandable graphite comprises the following steps of step 1, adding expandable graphite into an ethanol aqueous solution, performing dispersion to form a suspension, regulating the pH value of the suspension to be 7-9 to obtain an expandable graphite suspension; step 2, slowly dropwise adding tetraethyl orthosilicate into the expandable graphite suspension obtained in the step 1 for reaction; and step 3, performing pumping filtration after reaction is complete, performing washing until a filtrate is neutral, and performing drying to obtain the SiO2 nano particle modified expandable graphite. The preparation method of the flame retardant polypropylene comprises the following steps of adopting polypropylene particles and an SiO2 nano particle modified expandable graphite flame retardant with the mass ratio of 8 to 2, performing melt blending, extruding pelletizing and injection moulding to obtain a halogen-free flame retardant polypropylene composite. The prepared flame retardant polypropylene composite is remarkably improved in flame retardant property, heat stability, carbon formation ability, impact property, tensile strength and the like and has the advantages of no halogen, low smoke, nontoxicity, corrosion resistance and the like.

Owner:SOUTHWEST JIAOTONG UNIV +1

Synthesis method of improved efficient flame-retardant epoxy ethyl ester resin

The invention discloses a synthesis method of improved efficient flame-retardant epoxy ethyl ester resin. Disphenol A epoxy resin is used as a synthesis material, and other synthesis materials includechain extender binary acid containing halogen element, unsaturated monoacid, flame-retardant aid, catalyst, polymerization inhibitor, antioxidant and crosslinking agent. By introducing the reactive chain extender containing flame-retardant element and adding the solvent-type organic phosphate flame-retardant aid for compounding, flame-retardant synergism between the chain extender and the flame-retardant aid is brought into full play to prepare the efficient flame-retardant epoxy ethyl ester resin.

Owner:泉州永悦新材料有限公司

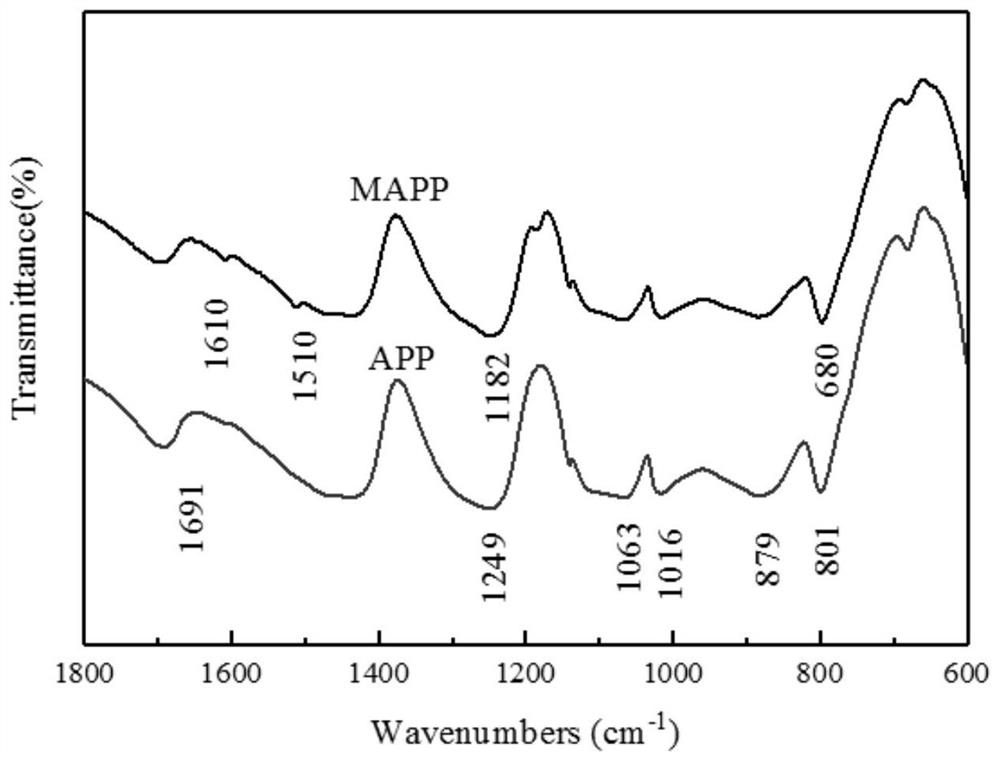

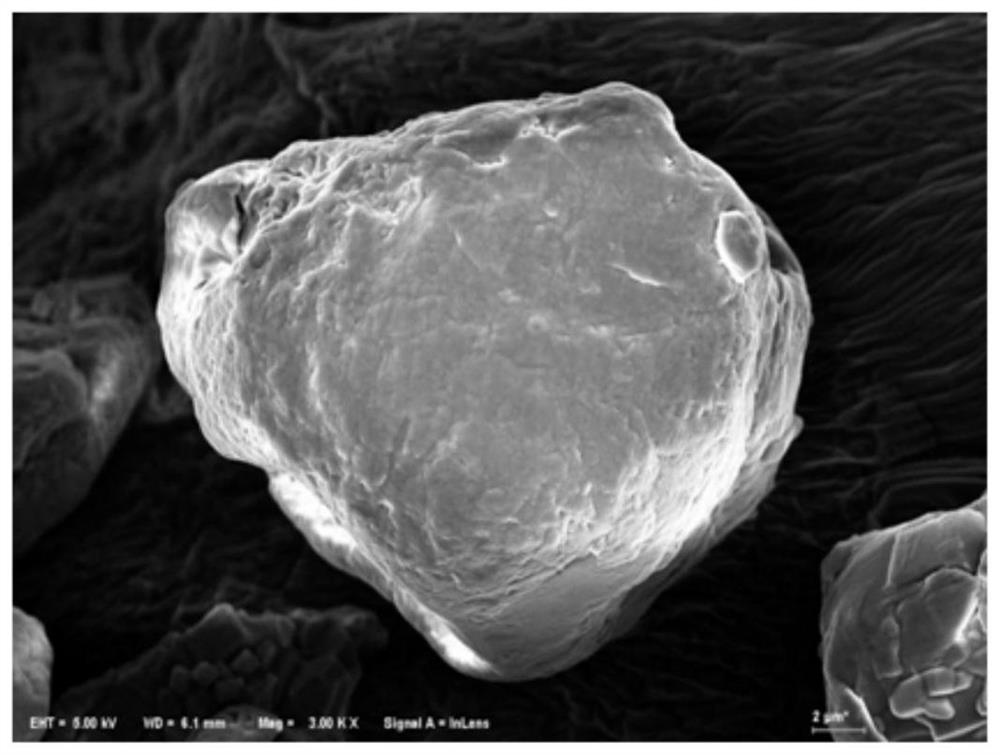

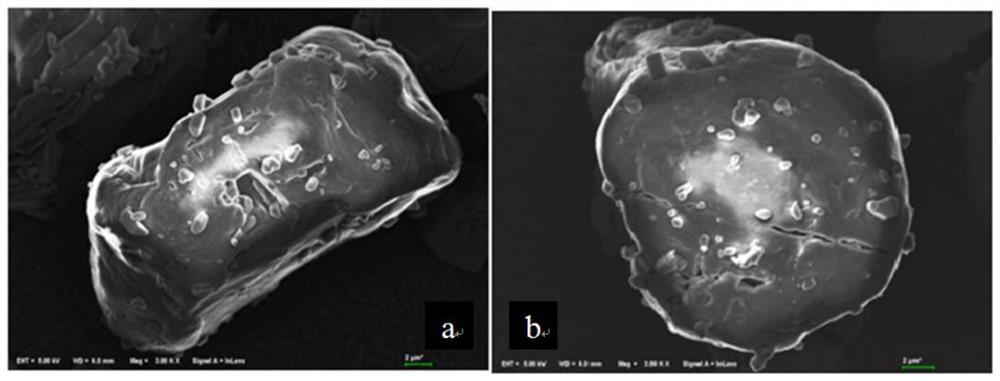

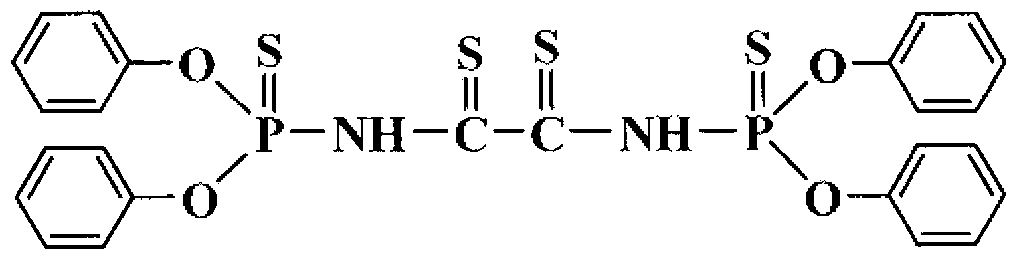

Method for preparing flame-retardant polypropylene by in-situ coating of modified ammonium polyphosphate

PendingCN111704769AFully curedEnsure uniformity of dispersionMicroballoon preparationMicrocapsule preparationEpoxyPolymer science

The invention relates to a method for preparing flame-retardant polypropylene by in-situ coating of modified ammonium polyphosphate. The method comprises the following steps: taking epoxy resin as a wall material and ammonium polyphosphate as a core material; carrying out in-situ polymerization in a step heating mode to obtain epoxy resin coated ammonium polyphosphate microcapsules, compounding the epoxy resin coated ammonium polyphosphate microcapsules with pentaerythritol and other carbon sources to obtain an intumescent flame retardant, and finally mixing and molding polypropylene and the flame retardant to obtain the flame-retardant polypropylene product with excellent properties. Experiments show that the prepared ammonium polyphosphate microcapsules are more completely cured, the flame retardant property and charring performance of the final polypropylene product are greatly improved, and the dripping phenomenon is prevented.

Owner:WUHAN UNIV OF TECH

Blended fabric of polysulfonamide and viscose fiber

InactiveCN103306030AMeet flame retardant requirementsWeft knittingArtificial filaments from viscoseViscoseEngineering

The invention discloses a blended fabric of polysulfonamide and viscose fiber. The blended fabric of polysulfonamide and viscose fiber is formed by blending and weaving 40wt% to 80wt% of polysulfonamide and 20wt% to 60wt% of viscose fiber. The blended fabric of polysulfonamide and viscose fiber has the advantages that the afterflame time, the smoldering time and the damaged length meet the state standards, and the specified flame retardant requirement is met.

Owner:SHANGHAI TANLON FIBER CO LTD

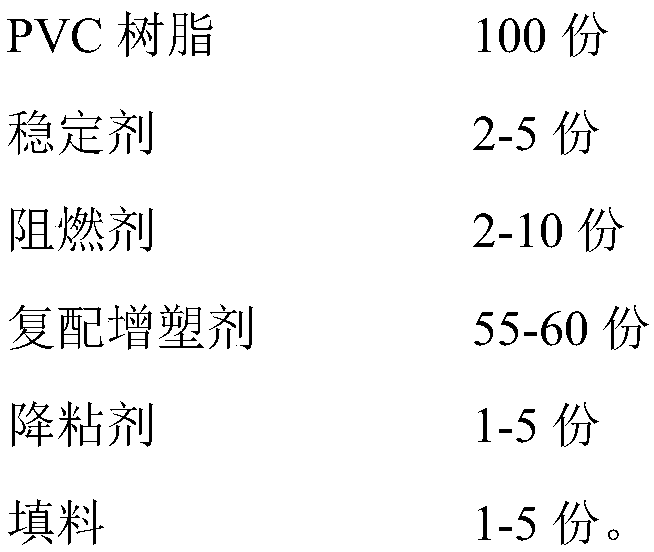

Polyvinyl chloride (PVC) impregnating solution for copper bar insulation sheaths, and impregnation processing technology of PVC impregnating solution

The invention discloses a polyvinyl chloride (PVC) impregnating solution for copper bar insulation sheaths, and an impregnation processing technology of the PVC impregnating solution. The PVC impregnating solution is prepared by mixing PVC resin, a stabilizing agent, a flame retardant, a compound plasticizer, a viscosity reducer and filler; after copper bars are impregnated and cured by using thePVC impregnating solution, the PVC copper bar insulation sheaths can be obtained. The PVC copper bar insulation sheaths are excellent in insulating property, high-temperature-resistant, good in flame-retardant property and long in service life.

Owner:佛山市方普防护技术有限公司 +1

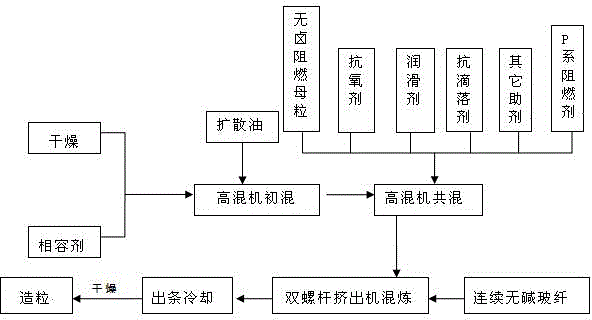

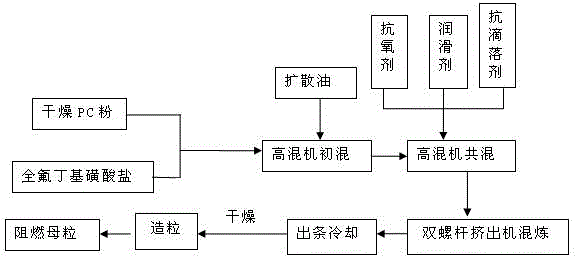

High-gloss high-heat-resistance high-fluidity halogen-free flame-retardant glass-fiber-reinforced PC material and preparation method thereof

The invention provides a high-gloss high-heat-resistance high-fluidity halogen-free flame-retardant glass-fiber-reinforced PC material and a preparation method thereof. The material is composed of the components of, by weight, 50-80 parts of polycarbonate, 0-15 parts of an inorganic flame retardant, 1-6 parts of halogen-free flame retardant masterbatch, 3-10 parts of a compatibilizing agent, 0.2-3 parts of a lubricant, 0.1-0.4 parts of an antioxidant, 0.1-0.3 parts of an anti-dripping agent, 5-30 parts of glass fiber, and 0.2-1 parts of other auxiliary agents. According to the preparation method, dried PC, the compatibilizing agent and the auxiliary agents are mixed in a high-speed mixer according to a certain ratio; when the materials are uniformly mixed, the mixture is added into a twin-screw extruder, and is subjected to kneading and extrusion with continuously inputted glass fiber. According to the invention, the requirements on high-efficiency halogen-free flame retarding property and environment friendliness are realized. Under a specific process environment, the product has relatively high gloss, and can be widely applied in home appliances, LCD televisions and tablet computers.

Owner:广东国恩塑业发展有限公司

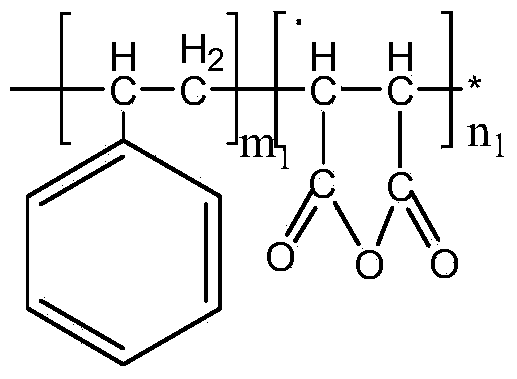

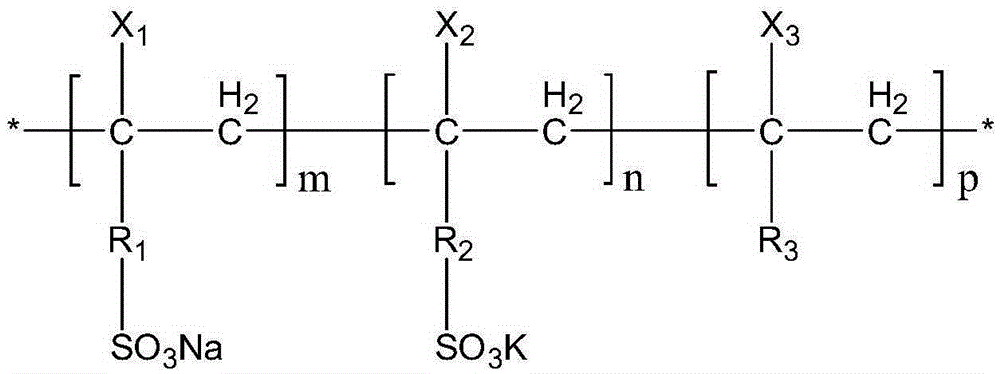

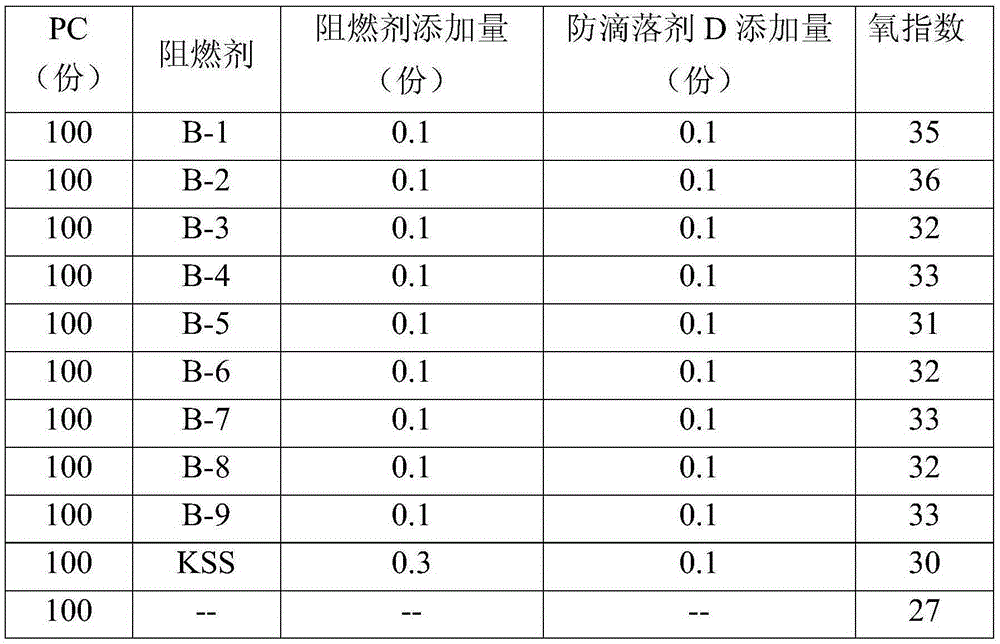

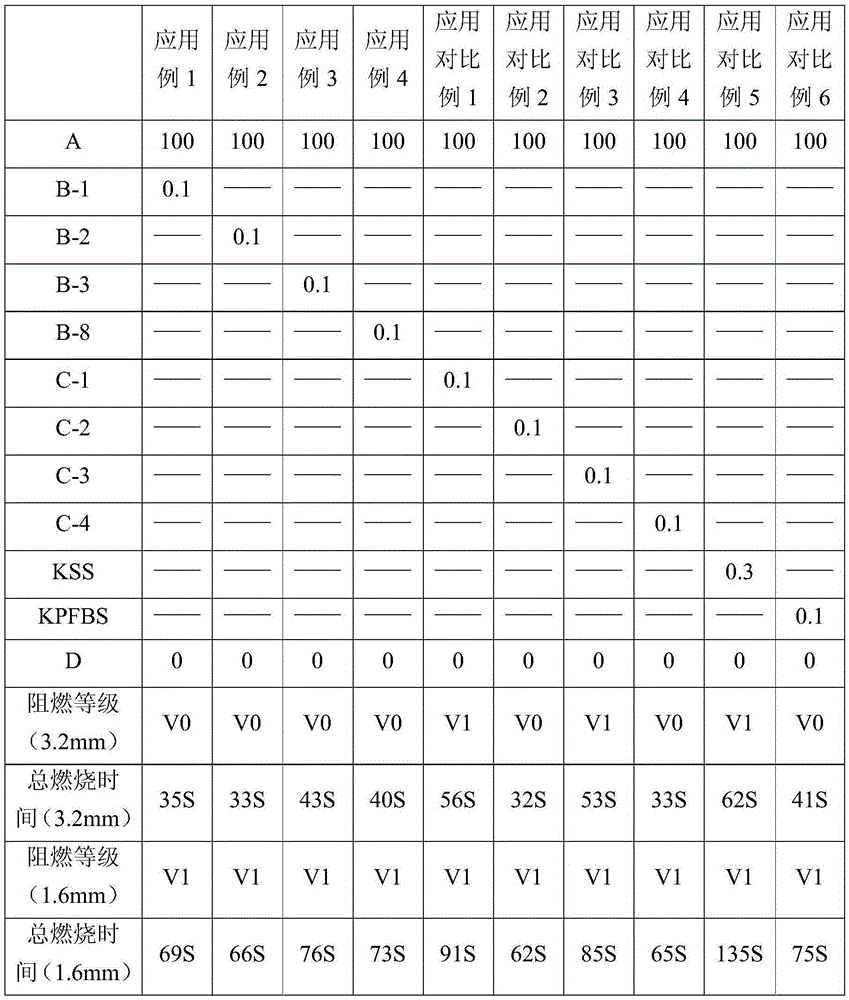

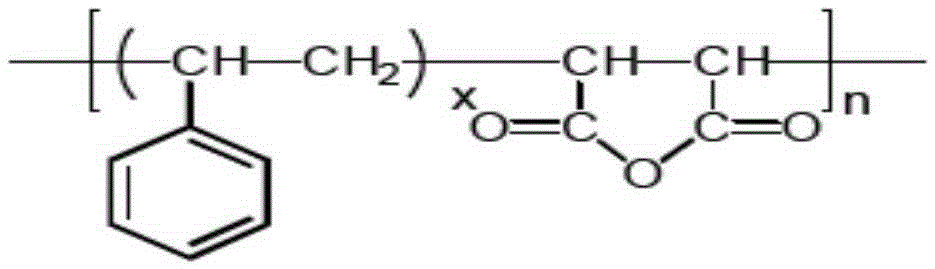

Polymer sulfonate fire retardant, and preparation method as well as application thereof

The invention relates to a polymer sulfonate fire retardant, containing a copolymer obtained by polymerization reaction from an unsaturated sodium sulfonate monomer, an unsaturated potassium sulfonate monomer and a vinyl monomer; the vinyl monomer is selected from any one or more of C6-C12 aromatic vinyl compounds, a (methyl) acrylate compound, a vinyl amide compound, a vinyl ether compound or a cyanation vinyl ether compound; the mole ratio of the total of the unsaturated sodium sulfonate monomer and the unsaturated potassium sulfonate monomer to the vinyl monomer in polymer sulfonate is (0.025 to 0.5):1; the mole ratio of the unsaturated sodium sulfonate monomer to the unsaturated potassium sulfonate monomer in the polymer sulfonate is (30:70) to (90:10); a number-average molar mass of the polymer sulfonate is 1000-200000. The invention also relates to a preparation method and application of the polymer sulfonate fire retardant.

Owner:GUANGZHOU SHINE POLYMER TECH

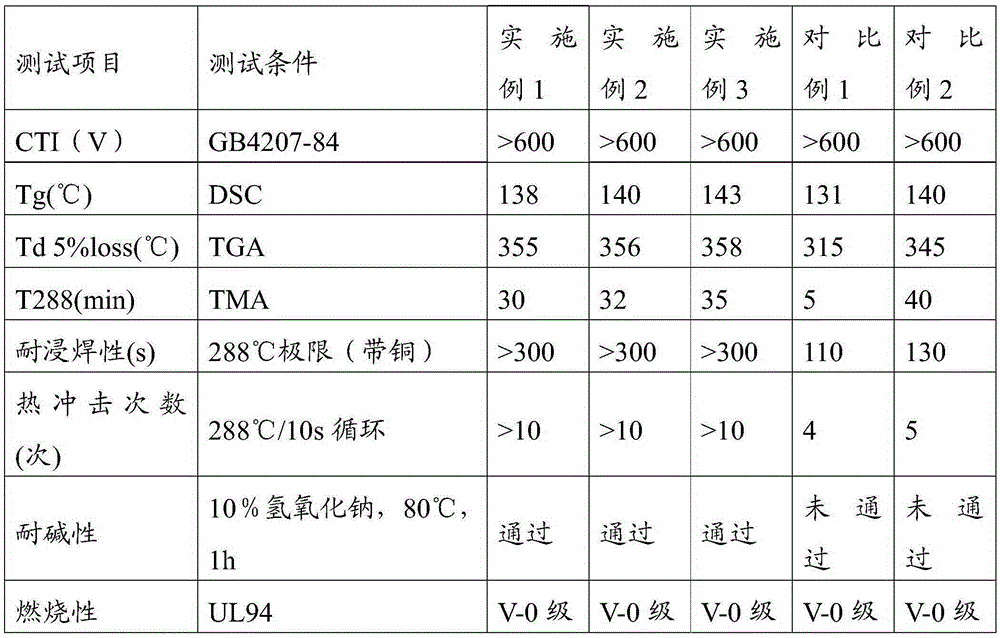

Resin composition and copper-clad plate and PCB made of same

ActiveCN105419231AImprove electrical performanceImprove performanceSynthetic resin layered productsCircuit susbtrate materialsAluminium hydroxideHeat resistance

The invention relates to the technical field of printed circuit boards and particularly relates to a resin composition. The resin composition is prepared from, by weight, 20-25 parts of phosphoric epoxy resin, 10-15 parts of brominated epoxy resin, 10-20 parts of cycloaliphatic epoxy resin, 25-30 parts of anhydride, 10-15 parts of phosphorus-containing phenolic aldehyde and 5-15 parts of phenolic aldehyde, wherein the epoxide equivalent range of the cycloaliphatic epoxy resin is 100-200 g / eq. According to the resin composition, the cycloaliphatic epoxy resin is introduced to an ordinary epoxy resin system and solidified with anhydride, and excellent electric leakage and tracking resistance and heat-resisting performance can be obtained; meanwhile, the system reaches the inflaming retarding requirement through a bromine and phosphorus cooperative mode, a small amount of boehmite filler which is better in heat resistance is introduced, aluminium hydroxide filler is not needed, and the defect of adding a great amount of filler is avoided; the invention further relates to a copper-clad plate and a PCB made of the resin composition, the CTI is larger than or equal to 600 V, heat resistance is good, alkali resistance is excellent, and the inflaming retarding requirement is reached.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com