Preparation method of halogen-free composite flame retardant polypropylene/thermoplastic polyurethane elastomer composite material

A thermoplastic polyurethane and composite flame-retardant technology, which is applied in the field of preparation of halogen-free composite flame-retardant polypropylene/thermoplastic polyurethane elastomer composite materials, can solve the problems of application limitations, small holes and cracks, and difficulties in meeting flame-retardant plastics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

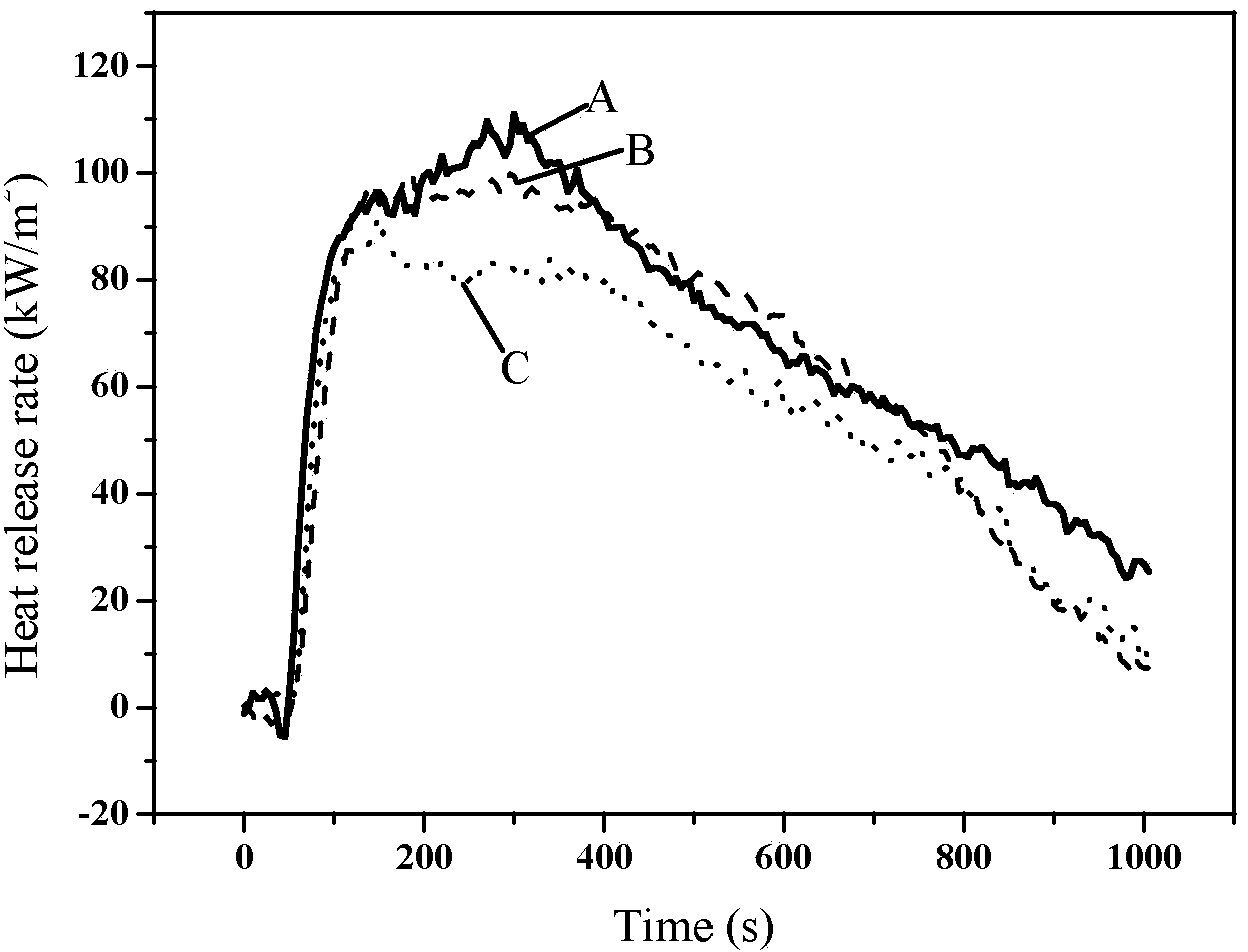

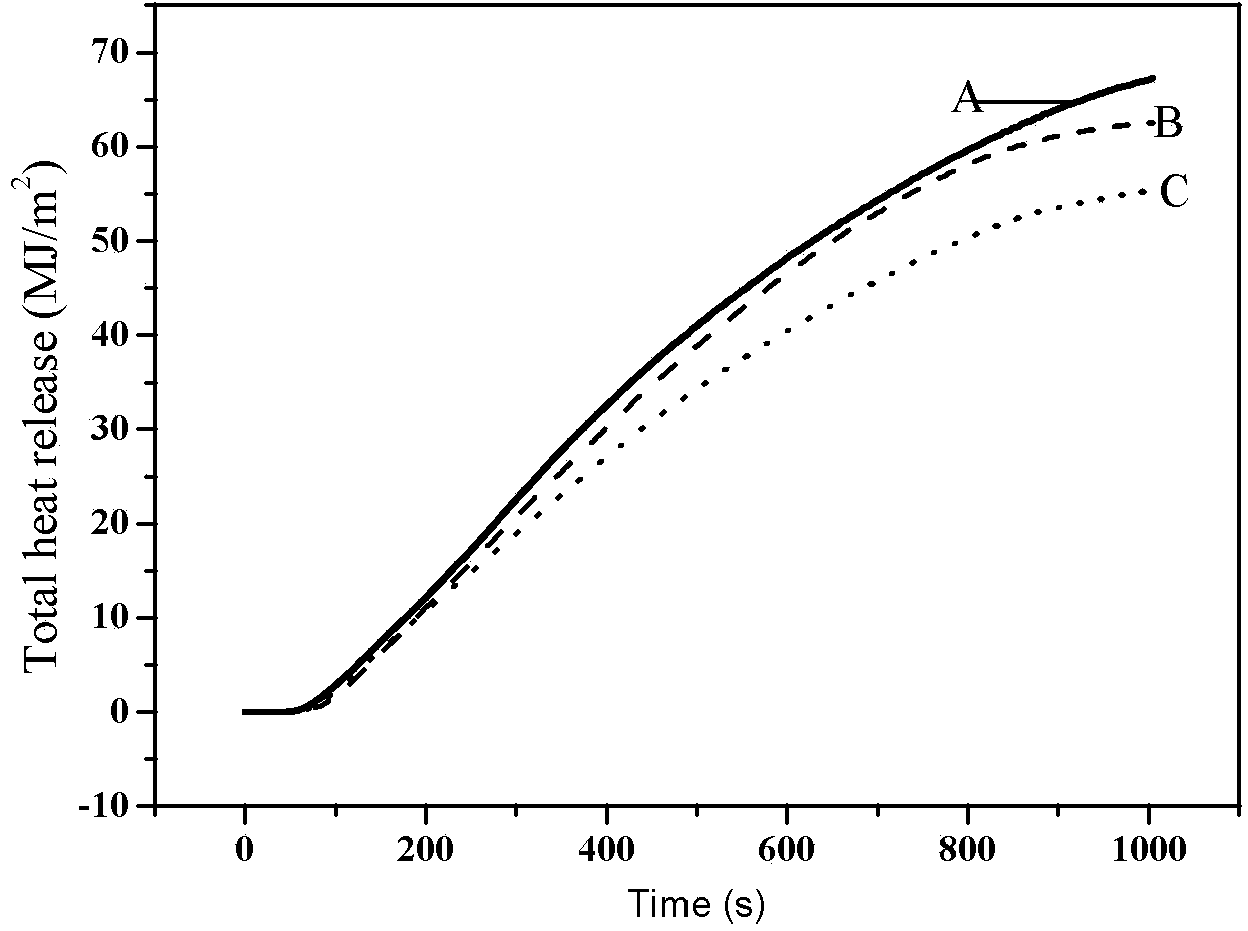

Examples

Embodiment 1

[0021] A preparation method of a halogen-free composite flame-retardant polypropylene / thermoplastic polyurethane elastomer composite material, the specific method of which is:

[0022] A. After fully mixing 80 parts of weight of dry polypropylene, 20 parts of weight of dry thermoplastic polyurethane elastomer, 3 parts of weight of dry polypropylene grafted maleic anhydride and 0.2 parts of antioxidant in a mixer, use Twin-screw extruder for mixing and granulation, the temperature range of the extruder barrel is 180-230°C (the temperature of the feeding section of the extruder barrel is 180°C, the temperature of the outlet section of the die is 230°C), and the screw speed is 150rpm , to obtain modified polypropylene masterbatch after drying;

[0023] B, then fully mix 100 parts by weight of modified polypropylene masterbatch, 15 parts by weight of modified expandable graphite, and 5 parts by weight of red phosphorus flame-retardant masterbatch to obtain a mixture; wherein the m...

Embodiment 2

[0025] A preparation method of a halogen-free composite flame-retardant polypropylene / thermoplastic polyurethane elastomer composite material, the specific method of which is:

[0026] A. After fully mixing 80 parts of weight of dry polypropylene, 20 parts of weight of dry thermoplastic polyurethane elastomer, 3 parts of weight of dry polypropylene grafted maleic anhydride and 0.2 parts of antioxidant in a mixer, use Twin-screw extruder for mixing and granulation, the temperature range of the extruder is 180-230°C, the screw speed is 160rpm, and the modified polypropylene masterbatch is obtained after drying;

[0027] B, then fully mix 100 parts by weight of modified polypropylene masterbatch, 13.3 parts by weight of modified expandable graphite, and 6.7 parts by weight of red phosphorus flame-retardant masterbatch to obtain a mixture; wherein the modified expandable graphite is The expandable graphite is obtained by surface modification with a silane coupling agent, and its a...

Embodiment 3

[0029] A preparation method of a halogen-free composite flame-retardant polypropylene / thermoplastic polyurethane elastomer composite material, the specific method of which is:

[0030] A, after fully mixing the dry polypropylene of 80 parts by weight, the dry thermoplastic polyurethane elastomer of 20 parts by weight, the dry polypropylene grafted maleic anhydride of 3 parts by weight and the antioxidant of 0.2 parts by weight in the mixer, use Twin-screw extruder for mixing and granulation, the extruder barrel temperature range is 180-230°C, the screw speed is 170rpm, and the modified polypropylene masterbatch is obtained after drying;

[0031] B, then fully mix 100 parts by weight of modified polypropylene masterbatch, 10 parts by weight of modified expandable graphite, and 10 parts by weight of red phosphorus flame-retardant masterbatch to obtain a mixture; wherein the modified expandable graphite is The expandable graphite is obtained by surface modification with a silane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com