High-gloss high-heat-resistance high-fluidity halogen-free flame-retardant glass-fiber-reinforced PC material and preparation method thereof

A high fluidity, high heat resistance technology, applied in the field of materials, can solve the problems of resistance to environmental stress cracking, difficult production and processing, notch damage, etc., achieve high gloss, reduce material cost, and increase hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

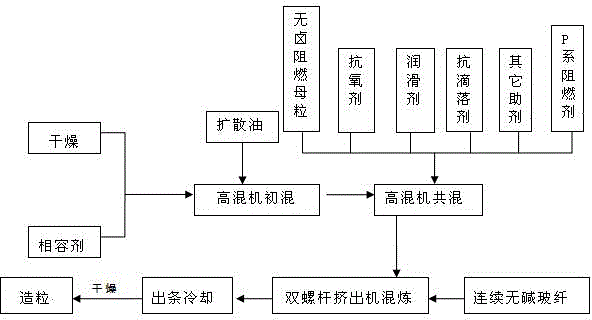

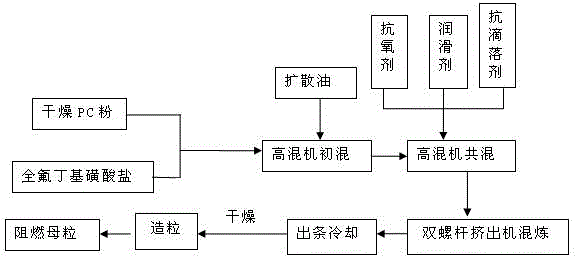

Method used

Image

Examples

Embodiment 1-5

[0038] Prepare the halogen-free flame retardant masterbatch of the present invention according to the formula shown in Table 1, and prepare the halogen-free flame-retardant glass fiber reinforcement with high gloss, high heat resistance and high fluidity of the present invention according to the formula shown in Table 2. PC material, and the performance test of the prepared material is shown in Table 3.

[0039] Table 1 Preparation of the component formula of the halogen-free flame retardant masterbatch of the present invention

[0040] type Example PC powder 3025P 100 PFBS 5 antioxidant 0.1 lubricant 0.2 PTFE 0.1

[0041] Table 2 Component formula for preparing the high gloss, high heat resistance and high fluidity halogen-free flame retardant glass fiber reinforced PC material of the present invention

[0042] type Example 1 Example 2 Example 3 Example 4 Example 5 PC 76 71 66 60 62 Glass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com