Polypropylene composite flame-retardant material for vehicle interior decoration as well as preparation method and application thereof

A composite flame retardant and polypropylene technology, which is applied in the field of flame retardant, can solve the problems of high limiting oxygen index, low level, vertical burning speed, and excellent comprehensive mechanical properties at the same time, and achieve the maintenance of mechanical properties, low smoke density level, The effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

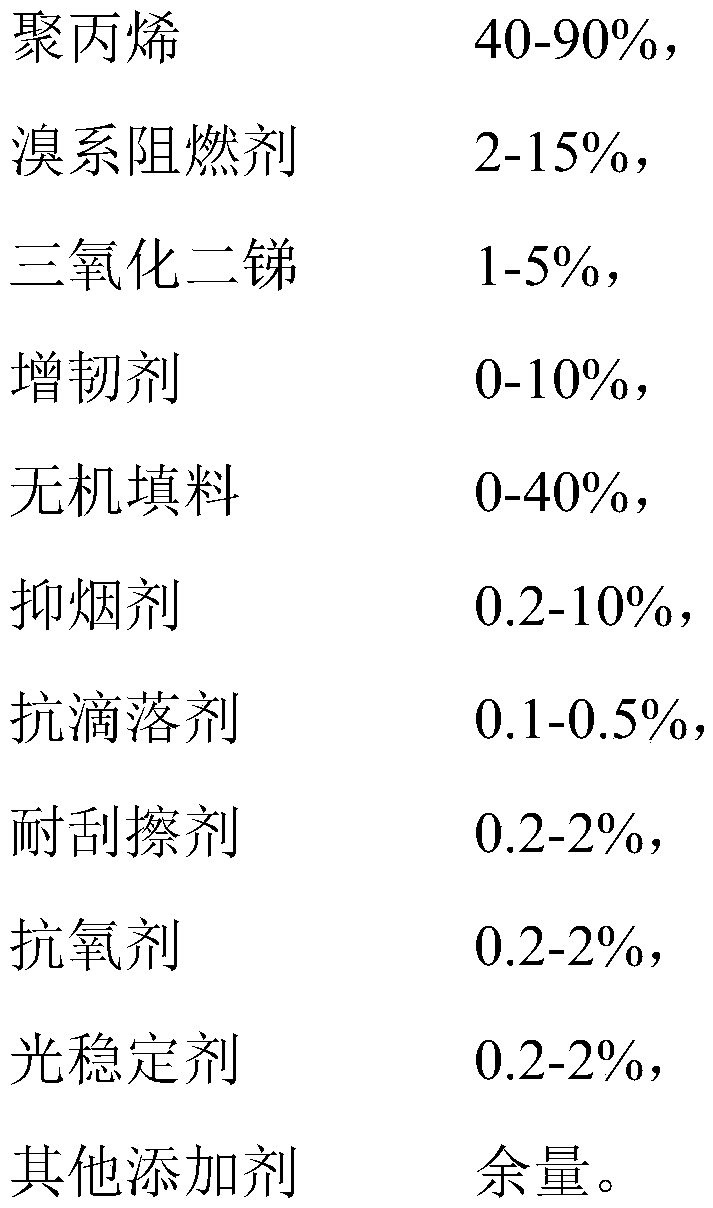

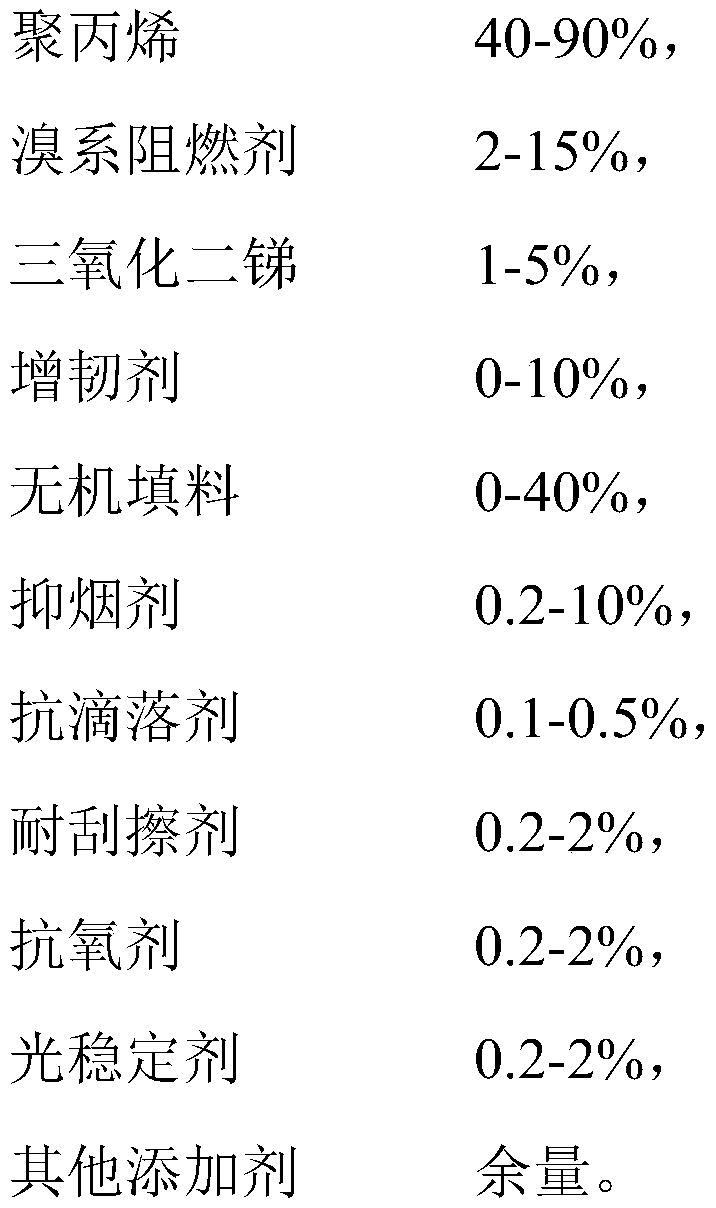

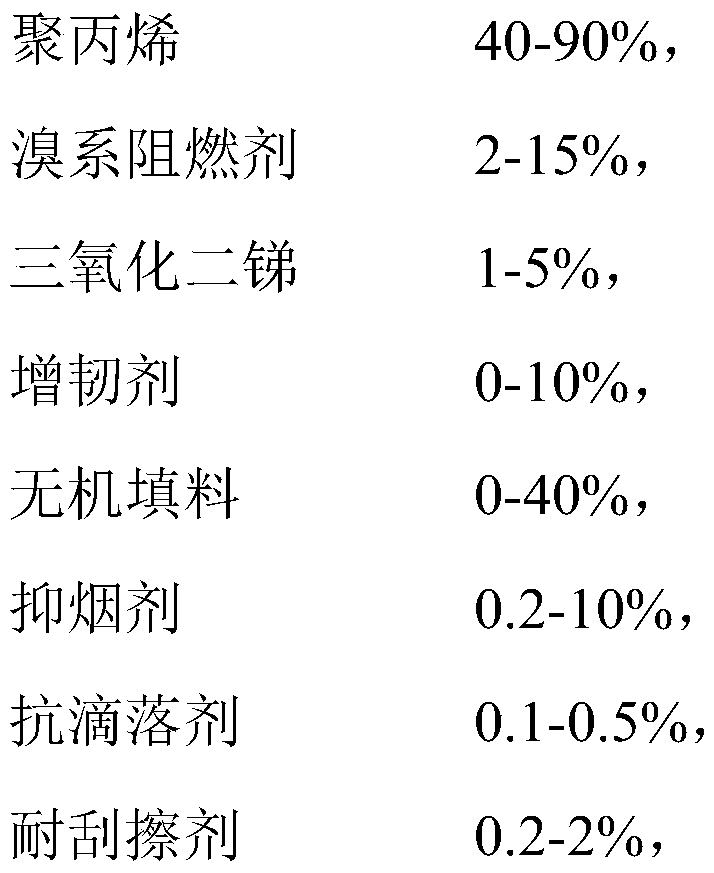

[0051] The embodiment of the present invention also provides a method for preparing a polypropylene composite flame-retardant material for vehicle interiors, which includes the steps of combining polypropylene, brominated flame retardant, antimony trioxide, toughening agent, After mixing inorganic fillers, smoke suppressants, anti-dripping agents, scratch-resistant agents, antioxidants, light stabilizers and other additives, the working temperature is 200℃~250℃, and the twin screw speed is 250~350rpm It is extruded and pelletized by a twin-screw extruder under the conditions of, to obtain a polypropylene composite flame-retardant material.

[0052] The preparation method of polypropylene composite flame-retardant material for vehicle interiors provided by the embodiment of the present invention, after mixing each raw material component of the formula amount, the working temperature is 200 ℃ ~ 250 ℃, the twin screw speed is 250 ~ 350 The polypropylene composite flame-retardant mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com