Phosphor-containing halogen-free flame-retardant polylactic acid, preparation thereof and flame-retardant material blended therewith

A polylactic acid, flame retardant technology, applied in the field of flame retardant polylactic acid and its preparation, can solve the problems of easy precipitation, poor flame retardant compatibility, etc., to overcome easy precipitation, overcome poor compatibility, and avoid material mechanical properties. worsening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Dissolve 50ml (0.546mol) of phosphorus oxychloride in diethyl ether first, then cool in an ice bath to below 5°C, then add 51.3g (0.546mol) of phenol dropwise into the system through a constant pressure dropping funnel, and the dropwise addition is complete After reacting for 2 hours, the temperature was raised to 10°C and kept at a constant temperature for 10 minutes. Finally, diethyl ether was evaporated under normal pressure, and the phenoxyphosphoryl dichloride fraction was collected by distillation under reduced pressure for future use.

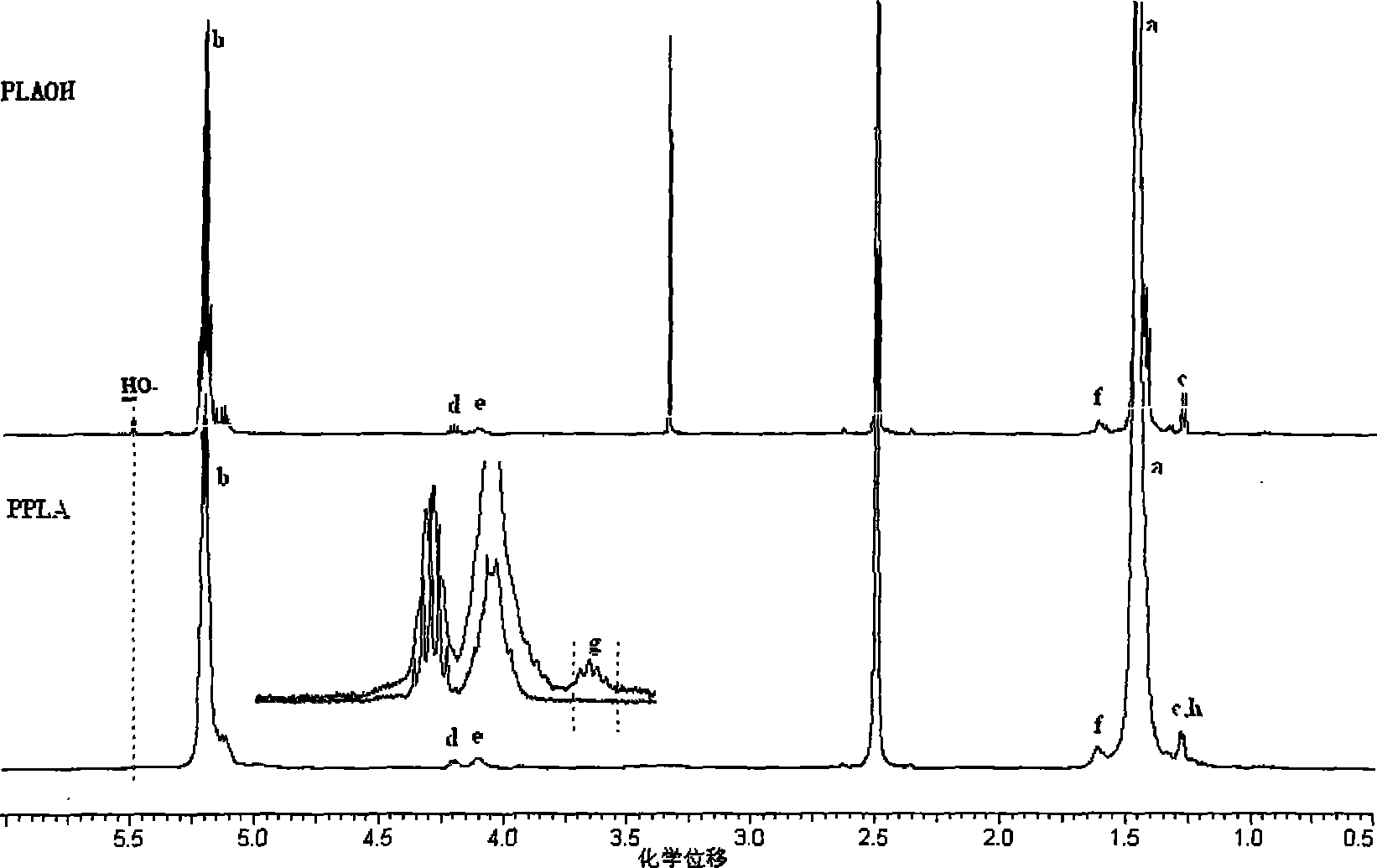

[0050] First, 30g (0.024mol) of hydroxyl-terminated polylactic acid prepolymer with a molecular weight of 1250g / mol and 0.03g of stannous chloride were protected under nitrogen, mechanically stirred and heated to 140°C, and after it melted, 2.53g (0.012 mol) phenoxyphosphoryl dichloride was added to the reaction system with a syringe, and after 10 minutes of normal pressure reaction, the pressure was reduced to 100Pa, and the react...

Embodiment 2

[0052] First, 30g (0.0097mol) of hydroxyl-terminated polylactic acid prepolymer with a molecular weight of 3100g / mol and 0.09g of stannous chloride were protected under nitrogen, mechanically stirred and heated to 150°C, and after it was melted, 2.05g (0.0097 mol) phenoxyphosphoryl dichloride (because its preparation is the same as in Example 1, so it is omitted.) was added to the reaction system with a syringe, after 30 minutes of normal pressure reaction, the pressure was reduced to 10Pa, and the product was obtained after 1 hour of reaction. Its intrinsic viscosity is 0.44dl / g.

Embodiment 3

[0054] Dissolve 50ml (0.546mol) of phosphorus oxychloride in ether first, then cool in an ice bath to below 5°C, then add 32.0ml (0.546mol) of ethanol dropwise into the system through a constant pressure dropping funnel, and the dropwise addition is complete After reacting for 1 hour, the temperature was raised to 10°C, and the temperature was kept constant for 20 minutes. Finally, diethyl ether was evaporated under normal pressure, and the ethoxyphosphoryl dichloride fraction was collected by distillation under reduced pressure for future use.

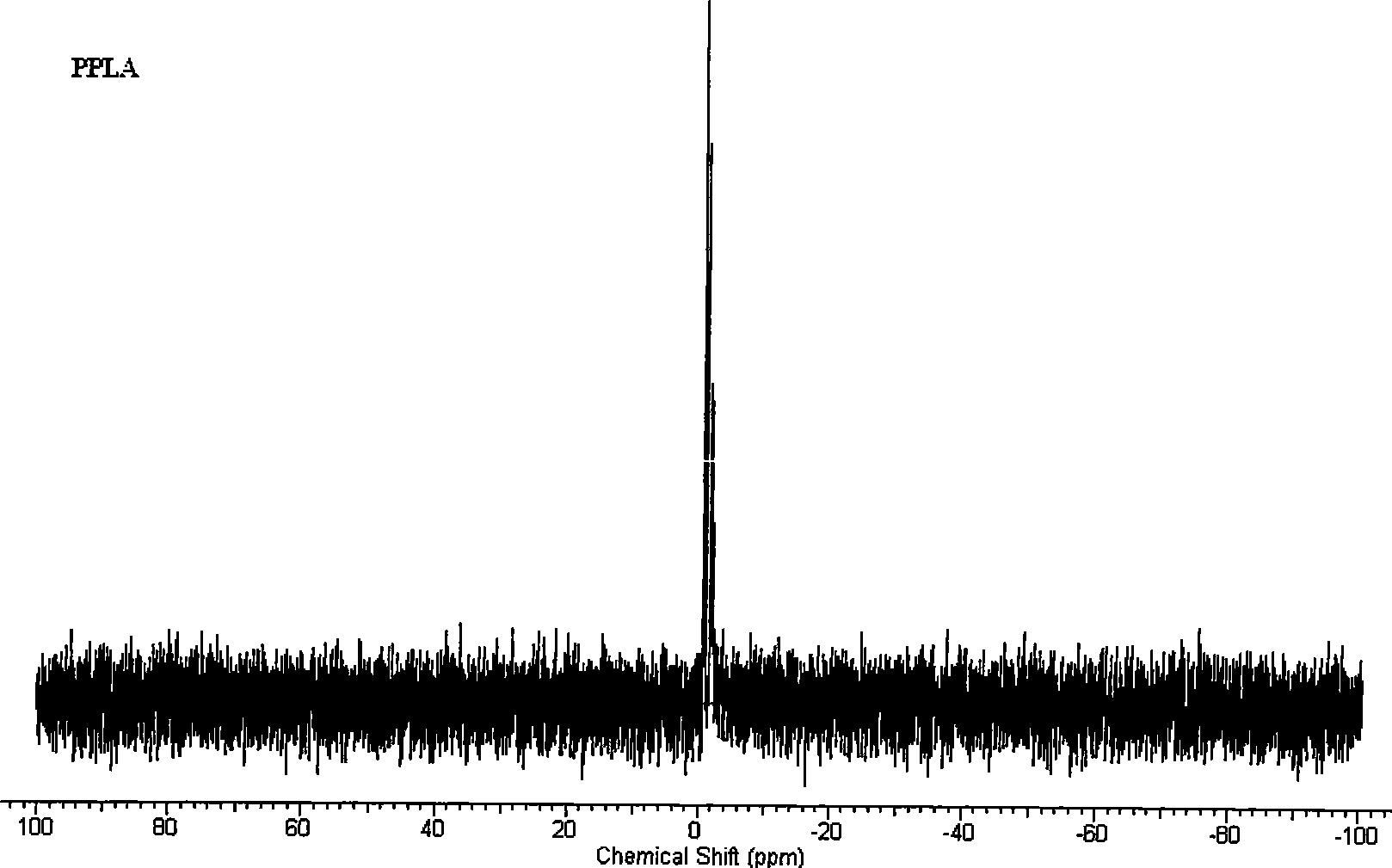

[0055] First, 30g (0.0066mol) of hydroxyl-terminated polylactic acid prepolymer with a molecular weight of 4520g / mol and 0.15g of stannous chloride were protected under nitrogen, mechanically stirred and heated to 160°C, and after melting, 0.94ml (0.0080 mol) ethoxyphosphoryl dichloride was added into the reaction system with a syringe, and after 90 minutes of normal pressure reaction, the pressure was reduced to 20Pa, and the product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com