Waterproof and flame-retardant paper, and preparation method and application thereof

A flame-retardant paper and flame-retardant fiber technology, applied in the field of materials, can solve the problems of non-absorbent, poor environmental protection, water pollution, etc., achieve excellent water absorption and water resistance, will not cause environmental pollution, and have excellent flame-retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

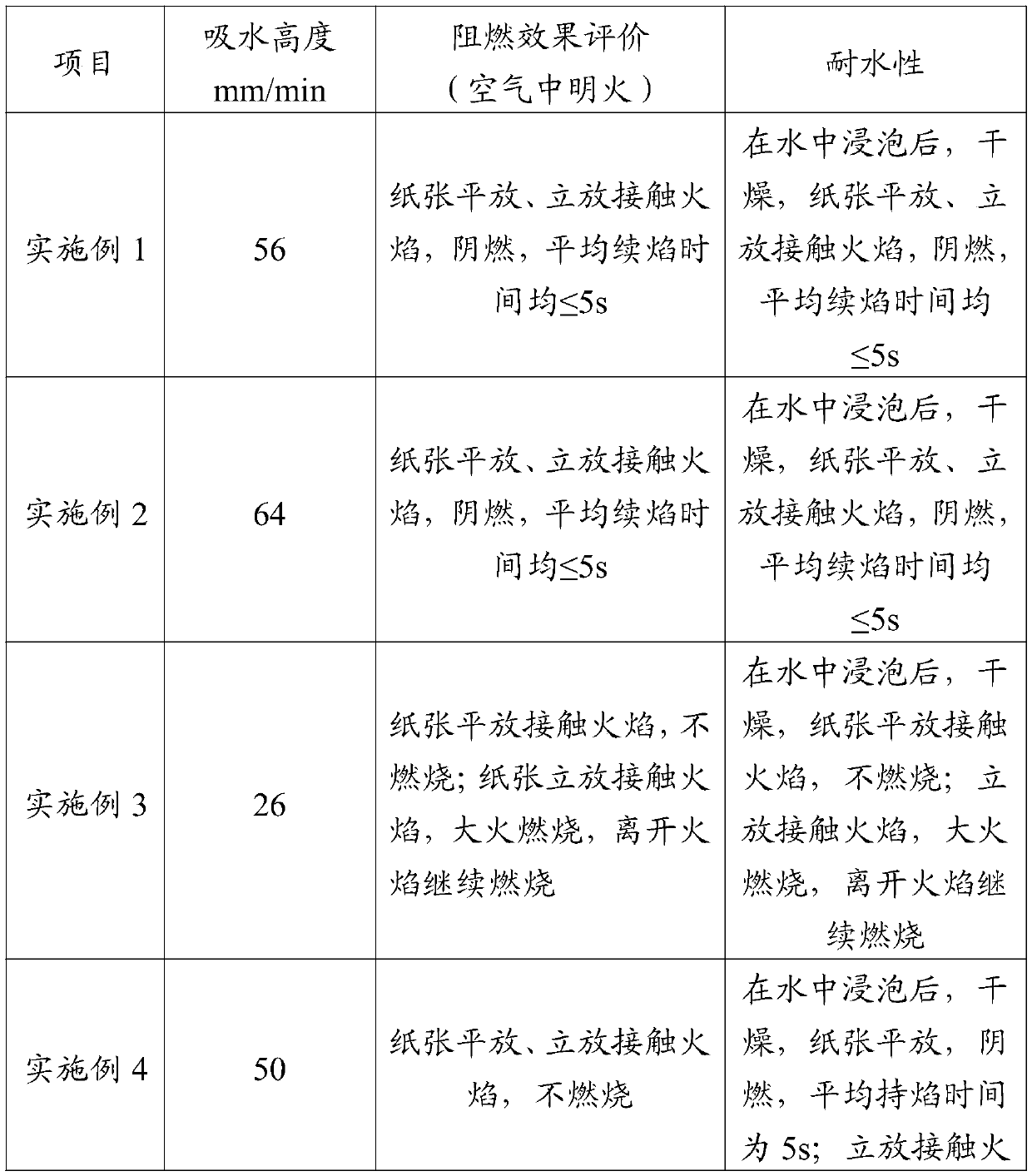

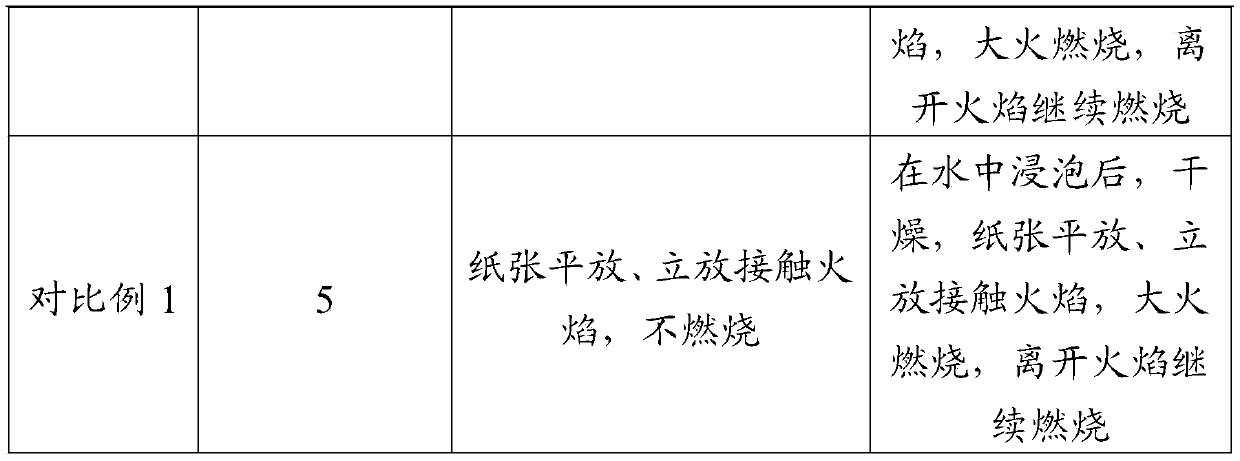

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing water-resistant and flame-resistant paper described in the above technical solution, comprising the following steps:

[0028] Mix the flame retardant fiber with water to decompose to obtain the flame retardant fiber slurry;

[0029] mixing the plant fiber with water for beating to obtain a plant fiber slurry;

[0030] After mixing the flame retardant fiber slurry, plant fiber slurry, wet strength agent and defoamer, dehydration forming is carried out at the wire part to obtain water-resistant and flame-retardant paper.

[0031] In the invention, the melamine fiber is mixed with water to decompose to obtain the melamine fiber slurry.

[0032] In the present invention, there is no special limitation on the method of disentangling, as long as the flame-retardant fibers can be completely dispersed, there is no parallel filaments. In the embodiment of the present invention, the deflaking is preferably performed in ...

Embodiment 1

[0046] The melamine fiber (denier 2dtex, length 5mm) of 80 parts by weight is mixed with water to be loosened, and the melamine fiber slurry that obtains mass concentration is 3.0%;

[0047] 20 parts by weight of coniferous wood fibers are mixed with water for beating to obtain a coniferous wood fiber slurry with a beating degree of 40°SR and a mass concentration of 3.0%;

[0048] The polyamide epichlorohydrin resin (purchased in Hebei Jiheng Auxiliary Co., Ltd.) of 1 weight part is formulated as an aqueous solution of wet strength agent; Audrey Technology Co., Ltd.) to prepare an aqueous solution of defoamer;

[0049] After mixing the melamine fiber slurry, coniferous wood fiber slurry, wet strength agent aqueous solution and defoamer aqueous solution, a mixed slurry with a concentration of 0.1% on the net is obtained, and the net part is dehydrated to obtain a water-resistant and flame-retardant paper.

Embodiment 2

[0051] The melamine fiber (denier 2dtex, length 5mm) of 70 parts by weight is mixed with water and dispelled, and the melamine fiber slurry that obtains mass concentration is 2.0%;

[0052] 30 parts by weight of softwood fibers are mixed with water for beating to obtain a softwood fiber slurry with a beating degree of 36°SR and a mass concentration of 2.5%;

[0053] The polyamide epichlorohydrin resin (purchased in Hebei Jiheng Auxiliary Co., Ltd.) of 0.8 parts by weight is prepared as an aqueous solution of wet strength agent; Audrey Technology Co., Ltd.) is prepared as an aqueous solution of defoamer;

[0054] After mixing the melamine fiber slurry, coniferous wood fiber slurry, wet strength agent aqueous solution and defoamer aqueous solution, a mixed slurry with a net concentration of 0.08% is obtained, and the net part is dehydrated to obtain a water-resistant and flame-retardant paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com