Halogen-free flame-retardant soft material used for automobile interior decoration, and preparation method thereof

A technology of soft materials and raw materials, which is applied in the field of halogen-free flame-retardant soft materials for automotive interiors and its preparation, can solve the problems of poor high and low temperature resistance of PU materials, and easy aging and cracking, so as to improve mechanical properties, Good surface quality and overall performance, the effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

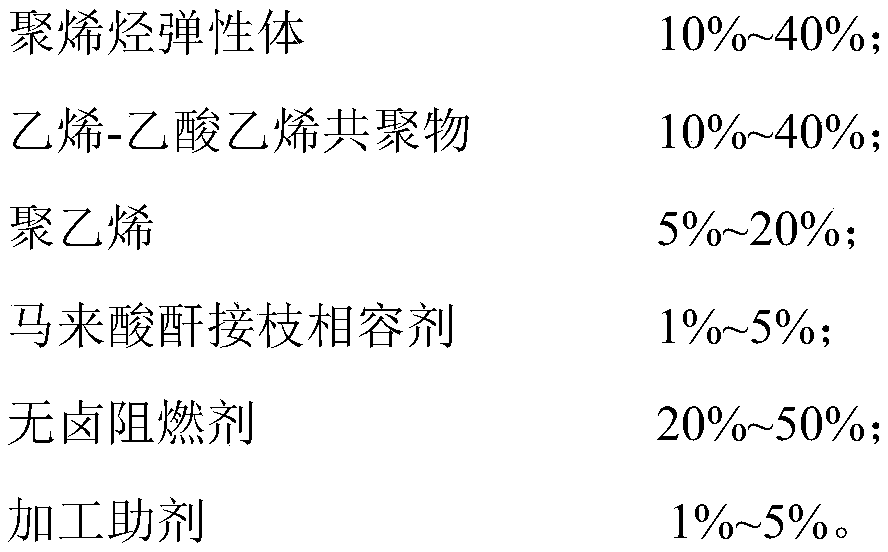

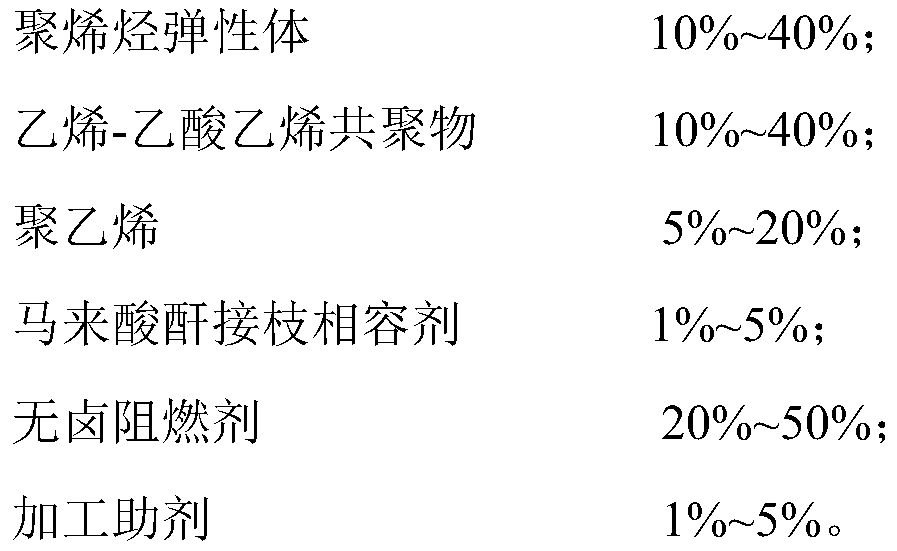

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of embodiment 1-4 in table 2 and comparative example 1 is as follows:

[0050] a) Weigh each raw material according to the formula components;

[0051] b) mixing all raw materials evenly to obtain a mixture;

[0052] c) adding the compound to the banbury mixer for banburying;

[0053] d) The mixed material after banburying is added to the twin-screw extruder through double-cone feeding;

[0054] e) Extruding and granulating with a twin-screw extruder to obtain a halogen-free flame-retardant soft material.

[0055] Wherein, the internal mixing temperature of the internal mixer is 150°C. The aspect ratio of the twin-screw extruder is 40:1. The set temperatures of each temperature zone of the twin-screw extruder are: 150°C, 180°C, 180°C, 180°C, 175°C, 175°C, 170°C, 170°C, 170°C, 165°C. The host speed is 280r / min.

[0056] The preparation method of comparative example 2-3 in table 2 is as follows:

[0057] a) Weigh each raw material according to ...

Embodiment 1

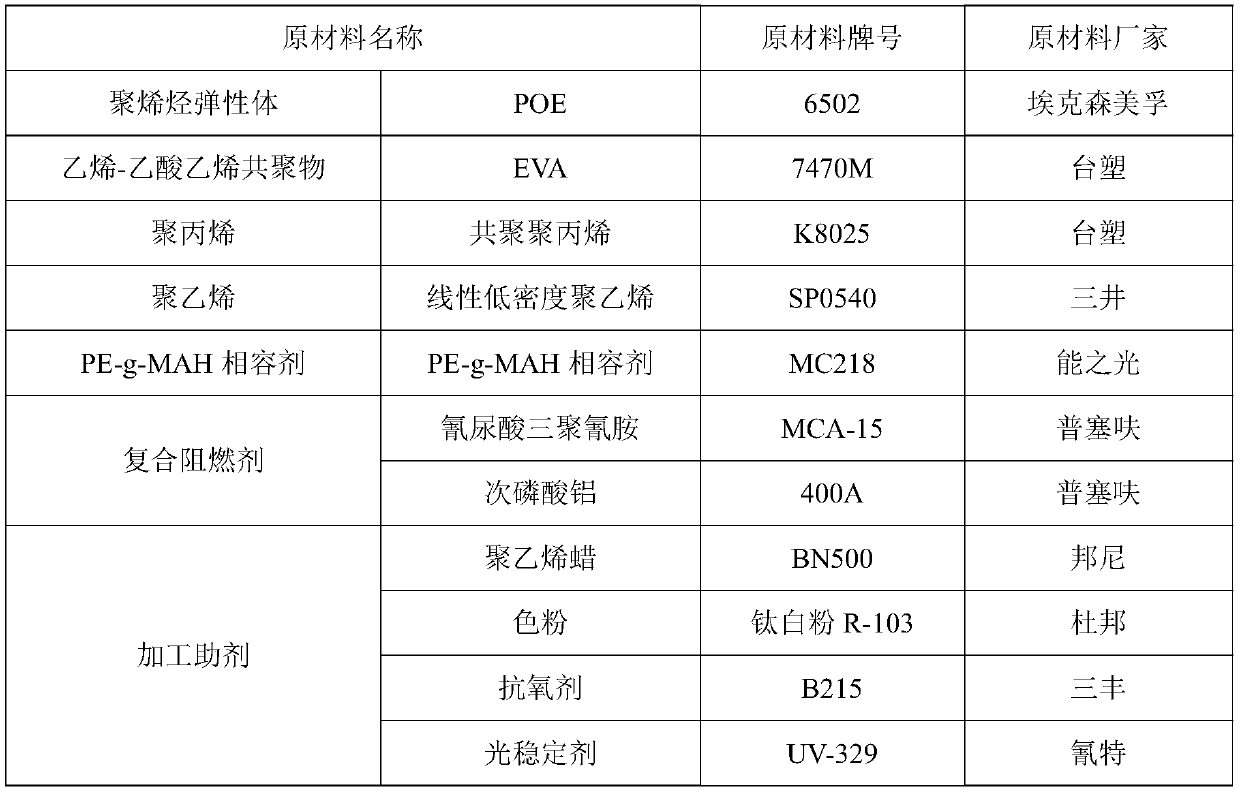

[0063] The raw material composition of the halogen-free flame-retardant soft material in Example 1 is shown in Table 2. Among them, the polyolefin elastomer is POE6502, and the melt index is 50g / 10min. The ethylene-vinyl acetate copolymer is EVA 7470M, and the VA value is 26%. The polyethylene is SP0540 with a melt index of 4g / 10min. The PE-g-MAH compatibilizer is MC218 produced by Nengzhiguang. The halogen-free flame retardant is a combination of melamine cyanurate and aluminum hypophosphite. The lubricant is polyethylene wax BN500. The colorant is titanium dioxide R-103. The antioxidant is B215, which is composed of hindered phenolic antioxidant and phosphite antioxidant. The light stabilizer is Cytec UV-329.

Embodiment 2

[0065] The difference between embodiment 2 and embodiment 1 is that the POE is 30%. EVA is 18%. Polyethylene is 12%. In this example, by adjusting these components, the hardness of the product can be increased, which is suitable for the hardness requirements of different models and components. The mass percentages of other components in this example are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com