Synthesis method of improved efficient flame-retardant epoxy ethyl ester resin

A technology of epoxy vinyl ester and synthesis method, which is applied in the field of organic polymer compound synthesis, can solve the problems of large amount of addition, affecting the transparency and mechanical properties of products, and achieves improvement of mechanical properties, mechanical strength and heat resistance. Corrosion properties, free radical scavenging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

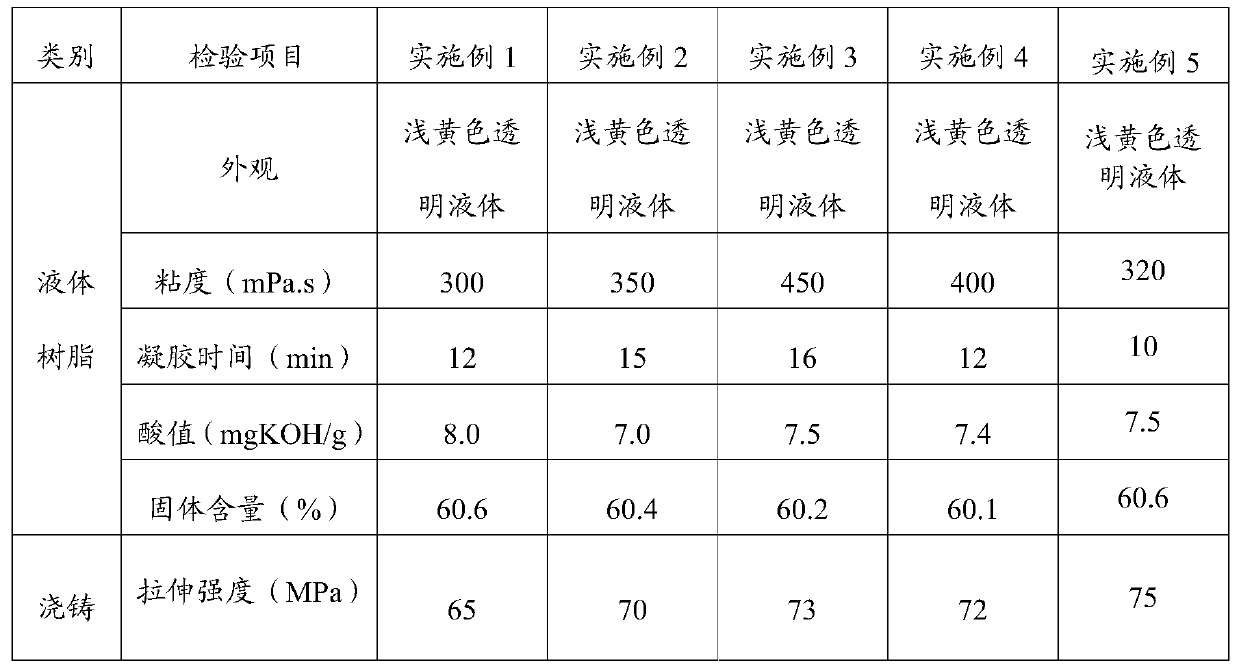

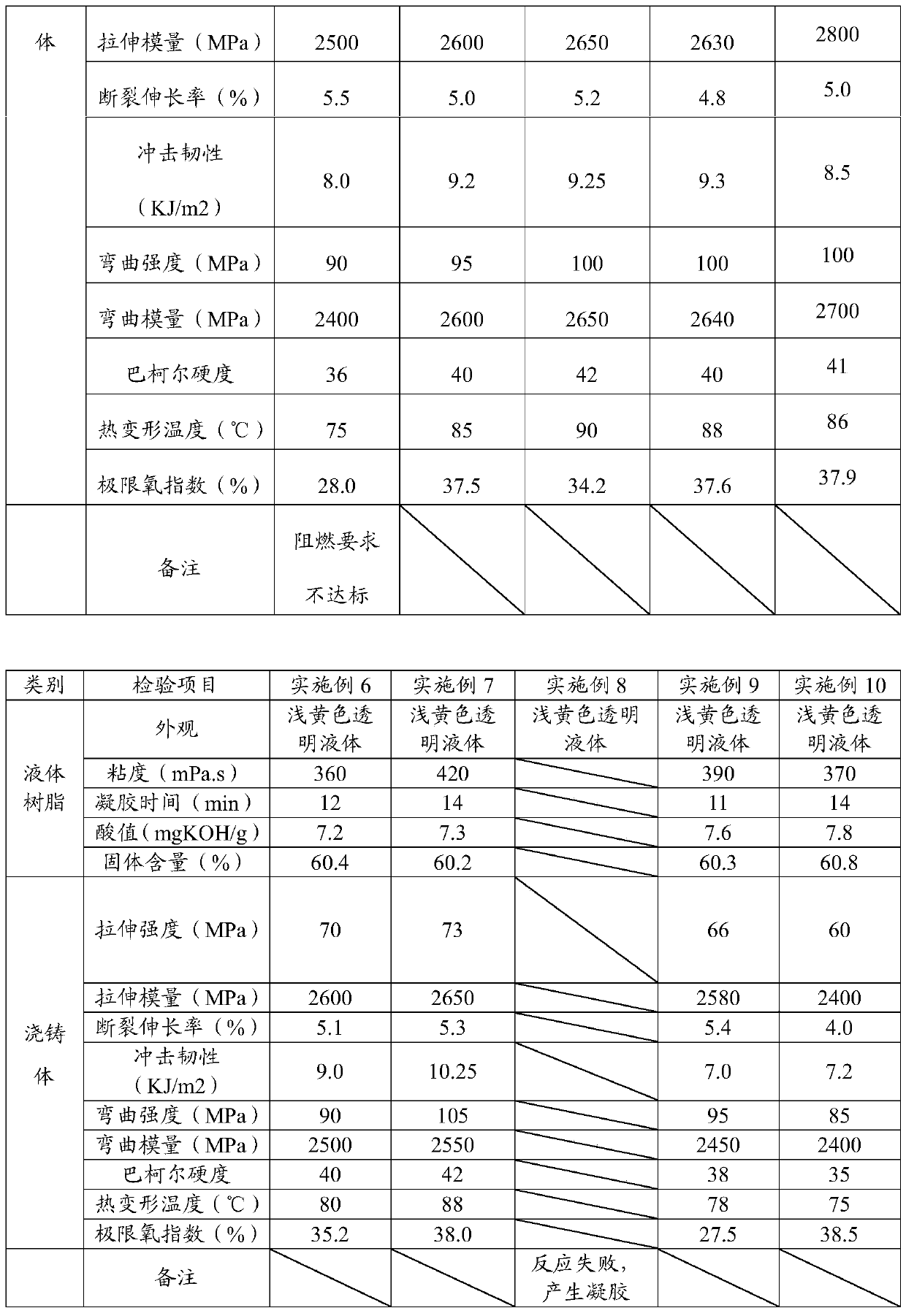

Examples

Embodiment 1

[0022] A kind of synthetic method of the present invention's improved efficient flame retardant type epoxy vinyl ester resin, its synthetic raw material comprises following components: bisphenol A type epoxy resin 370Kg, chlorobridge acid 116Kg, unsaturated monobasic acid acrylic acid 80Kg, retarding Combustion aid trichloroethyl phosphate 42.6Kg, catalyst tetraethylammonium bromide 5Kg, triphenyl phosphite 2.0Kg, polymerization inhibitor hydroquinone 500g, polymerization inhibitor copper naphthenate 600g and crosslinking agent Styrene 450Kg, wherein, the molar ratio of bisphenol A type epoxy resin and chlorobridge acid is 1:0.3, and trichloroethyl phosphate accounts for 3~5% of the total input quality of raw material, is specifically 4% in the present embodiment .

[0023] A kind of synthetic method of improved high-efficiency flame-retardant type epoxy vinyl ester resin of the present invention, its synthetic method comprises the steps:

[0024] (1) Accurately weigh each sy...

Embodiment 2

[0036] The present invention is a synthetic method of an improved high-efficiency flame-retardant epoxy vinyl ester resin, and its synthetic raw materials include the following components: 370Kg of bisphenol A epoxy resin, 151Kg of chain extender dibasic acid tetrachlorophthalic acid , unsaturated monobasic acid acrylic acid 100Kg, flame retardant additive trichloroethyl phosphate 45Kg, catalyst tetraethylammonium bromide 6.0Kg, triphenyl phosphite 2Kg, polymerization inhibitor hydroquinone 400g, polymerization inhibitor ring Copper alkanoate 500g, crosslinking agent styrene 450Kg, wherein, the molar ratio of bisphenol A type epoxy resin and chlorobridge acid is 1:0.5, and trichloroethyl phosphate accounts for 4% of the total input quality of raw materials.

[0037] A kind of synthetic method of improved high-efficiency flame-retardant type epoxy vinyl ester resin of the present invention, its synthetic method comprises the steps:

[0038] (1) Accurately weigh each synthetic r...

Embodiment 3

[0043] A kind of synthetic method of improved high-efficiency flame-retardant type epoxy vinyl ester resin of the present invention, its synthetic raw material comprises following components: bisphenol A type epoxy resin 370Kg, chlorobridge acid 157Kg, unsaturated monobasic acid acrylic acid 75Kg, retarding Combustion aid triethyl phosphate 46.5Kg, catalyst tetraethylammonium bromide 5Kg, triphenyl phosphite 2.5Kg, polymerization inhibitor hydroquinone 350g, polymerization inhibitor copper naphthenate 400g and crosslinking agent styrene 500Kg, wherein, the molar ratio of bisphenol A type epoxy resin and chlorobridge acid is 1:0.55, and triethyl phosphate accounts for 4% of the total input quality of raw materials.

[0044] A kind of synthetic method of improved high-efficiency flame-retardant type epoxy vinyl ester resin of the present invention, its synthetic method comprises the steps:

[0045] (1) Accurately weigh each synthetic raw material component in order according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com