Blended fabric of polysulfonamide and viscose fiber

A technology of viscose fiber and blended fabrics, applied in textiles, papermaking, artificial filaments made of viscose, knitting, etc., can solve the problems of small cohesion between fibers, difficulty in yarn formation, low friction coefficient and crimp stability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 30 kg of N,N'-bis(diphenoxythiophosphoryl)dithiooxalamide; 30 kg of N-hydroxymethyl-3-(dimethoxyphosphono)propionamide; three ( 2,3-dibromopropyl) 40 kilograms of isocyanurates, stir and mix uniformly and make composite flame retardant.

[0028] The above-mentioned composite flame retardant is mixed with the viscose solution, and shaped according to the conventional wet spinning and spinning process to obtain the flame-retardant viscose fiber, and the length of the flame-retardant viscose fiber is 38 mm. Wherein, the content of flame retardant in the finished product flame retardant viscose fiber is controlled to be 10wt%.

[0029] For the viscose solution in the raw materials, the weight percent content of methyl cellulose is 8.5%, the weight percent content of sodium hydroxide is 5%, the falling ball viscosity is 50 seconds, and the maturity is 12%.

[0030] Aramid sulfone fiber (provided by Shanghai Teanlun Fiber Co., Ltd. The mass ratio of aramid sulfone fi...

Embodiment 2

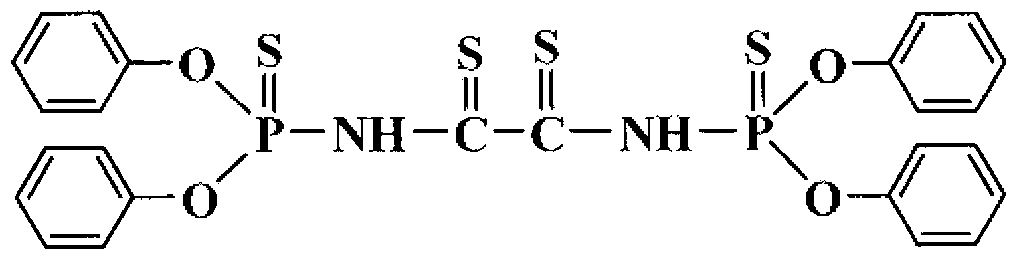

[0034] The preparation method is basically the same as in Example 1, except that the flame retardant used is N,N'-bis(diphenoxyphosphorylthio)dithiooxalamide instead of a composite flame retardant.

Embodiment 3

[0036] The preparation method is basically the same as in Example 1, except that the flame retardant used is N-methylol-3-(dimethoxyphosphono)propionamide instead of a composite flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com