Resin composition and copper-clad plate and PCB made of same

A technology of resin composition and copper clad laminate, which is applied in the direction of synthetic resin layered products, circuit substrate materials, chemical instruments and methods, etc., can solve the problems such as the decrease of plate processability, heat resistance and alkali resistance, and achieve electrical The effect of good performance, excellent tracking resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

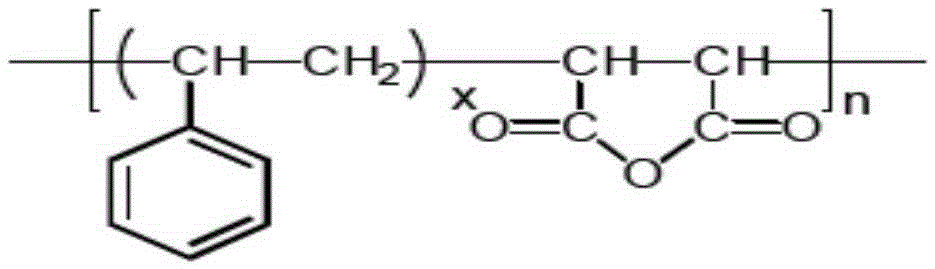

Method used

Image

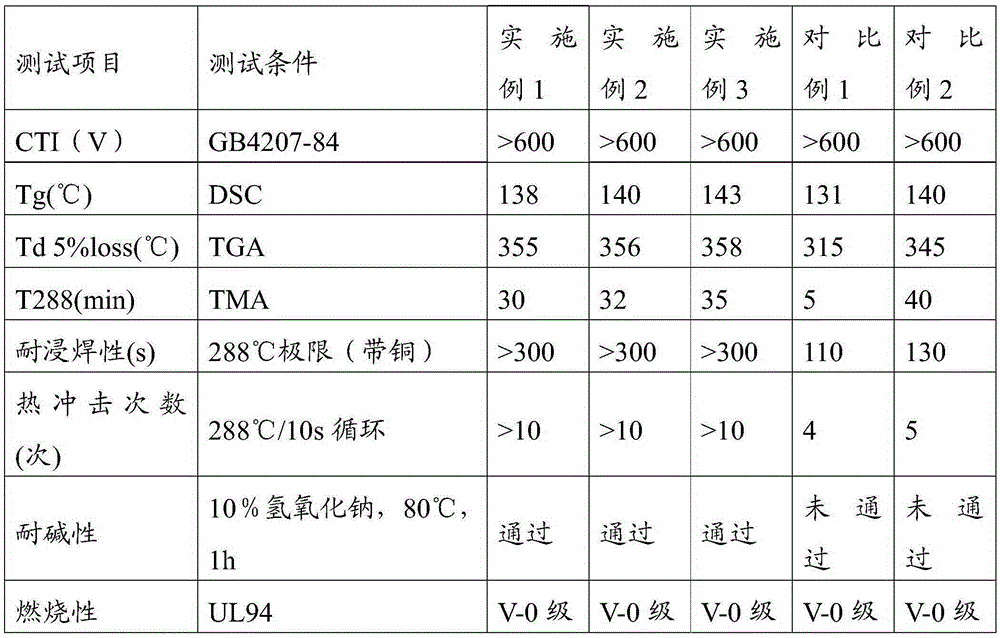

Examples

Embodiment 1

[0027] A kind of resin composition, by total weight part is 100 parts (not including curing accelerator), comprises: 20 parts of phosphorus-containing epoxy resins (Dow Chemical, XZ92530), brominated epoxy resins (Dainippon Ink Co., Ltd., Epiclon153-60M) 15 parts, cycloaliphatic epoxy resin (Dow Chemical, ERL-4221D) 20 parts, anhydride (Craig Willy, SMAEF-40) 25 parts, phosphorus-containing phenolic (SHINA Chemical, LC-950) 15 parts, 5 parts of boehmite; in addition, it also includes a curing accelerator (2-methylimidazole), calculated as a percentage by weight, which is 0.05% of the total weight of the resin composition.

[0028] The above-mentioned resin composition is applied to the production of copper clad laminates, and its production method comprises the following steps:

[0029] First, weigh the components by weight of the resin composition according to the formula, and mix them uniformly, then add 2-methylimidazole and an appropriate amount of acetone to the mixture t...

Embodiment 2

[0034] A kind of resin composition, is 100 parts by total weight (not including curing accelerator), comprising: 23 parts of phosphorus-containing epoxy resins (Dow Chemical, XZ92530), brominated epoxy resins (Dainippon Ink Co., Ltd., Epiclon153-60M) 12 parts, cycloaliphatic epoxy resin (Dow Chemical, ERL-4221D) 15 parts, anhydride (Craig Willy, SMAEF-40) 27 parts, phosphorus-containing phenolic (SHINA Chemical, LC-950) 13 parts, 10 parts of boehmite; in addition, it also includes a curing accelerator (2-phenylimidazole), calculated as a percentage by weight, accounting for 0.1% of the total weight of the resin composition.

[0035] The above-mentioned resin composition is applied to the production of copper clad laminates, and its production method comprises the following steps:

[0036] First, weigh each component of the resin composition according to the formula quantity, and after the above-mentioned components are mixed uniformly, add 2-phenylimidazole and solvent (mixtur...

Embodiment 3

[0041] A kind of resin composition, by total weight part is 100 parts (the 100 parts do not include curing accelerator), comprising: 25 parts of phosphorus-containing epoxy resin (Dow Chemical, XZ92530), brominated epoxy resin (big Nippon Ink Company, Epiclon153-60M) 10 parts, cycloaliphatic epoxy resin (Dow Chemical, ERL-4221D) 10 parts, acid anhydride (Kray Willy, SMAEF-40) 30 parts, phosphorus-containing phenolic (SHINA Chemical, 10 parts of LC-950) and 15 parts of boehmite; in addition, a curing accelerator (1-methylimidazole) is also included, in percentage by weight, which is 0.01% of the total weight of the resin composition.

[0042] The above-mentioned resin composition is applied to the production of copper clad laminates, and its production method comprises the following steps:

[0043] First, weigh each component of the resin composition according to the formula amount, and mix the above components evenly, then add 1-methylimidazole and solvent cyclohexanone to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com