Preparation methods of SiO2 nano particle modified expandable graphite and flame retardant polypropylene

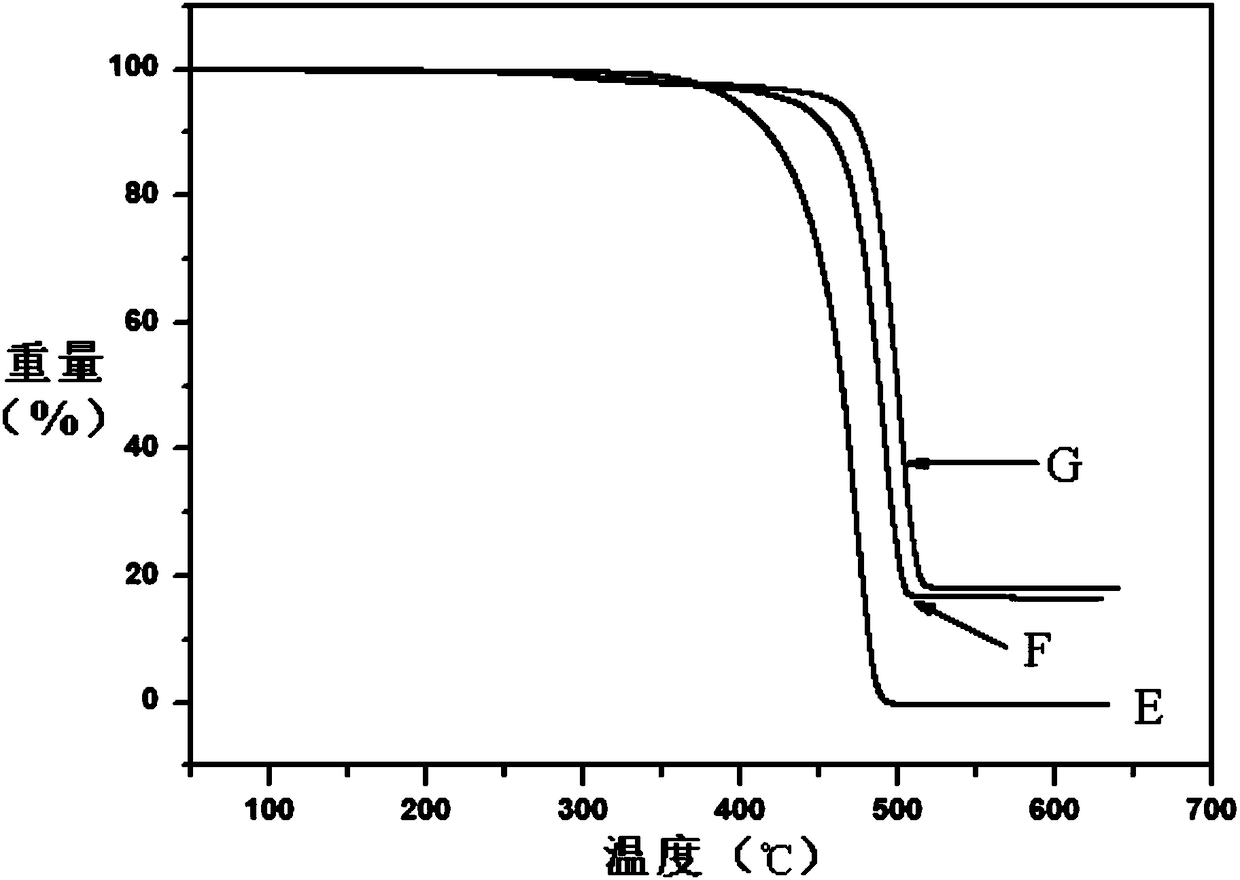

A flame-retardant polypropylene and expanded graphite technology, which is applied in the field of expandable graphite modification technology and the preparation of flame-retardant polypropylene, can solve the problem of poor compatibility between expandable graphite and a polymer matrix, and deterioration of the mechanical properties of the polymer matrix. , the carbon layer structure is easy to fall off, etc., to achieve the effect of inhibiting the popcorn effect, inhibiting thermal decomposition and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

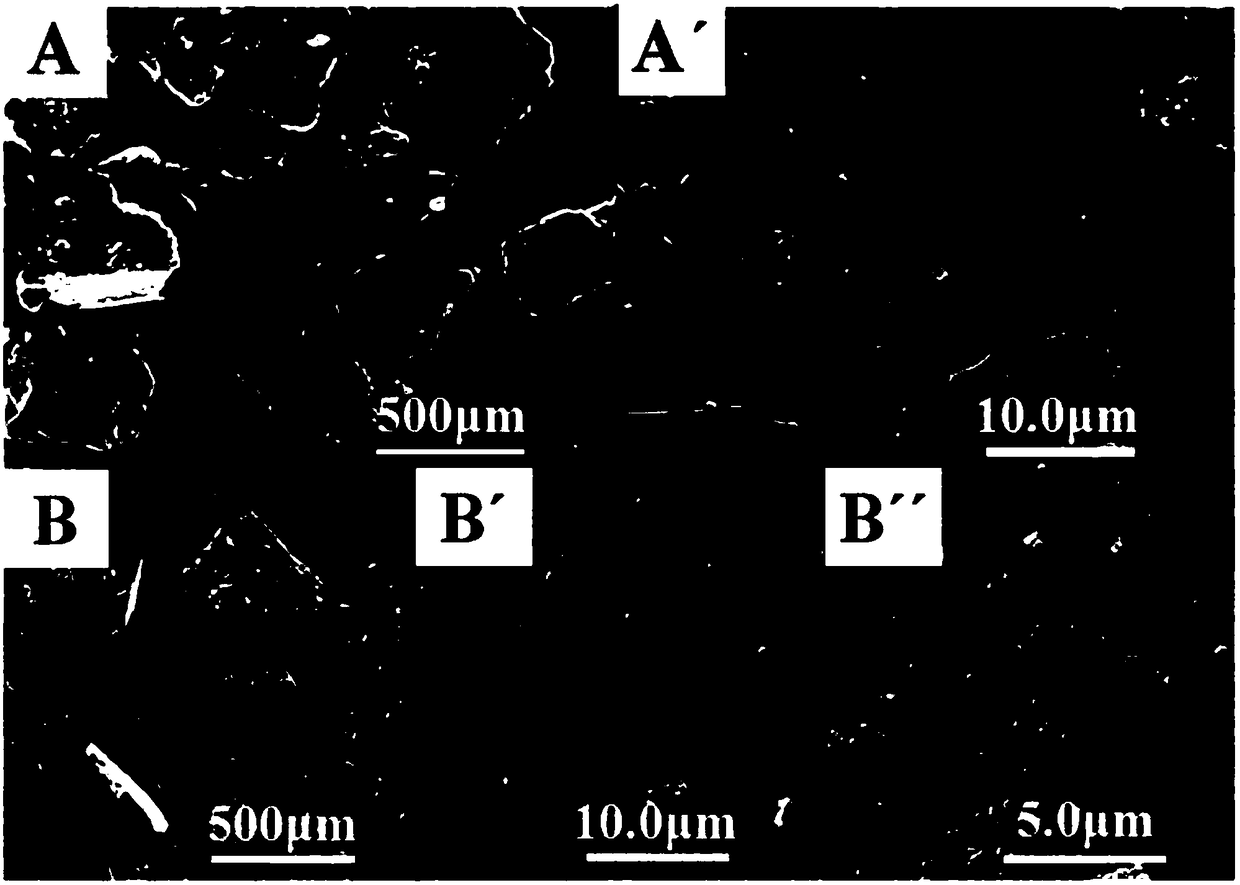

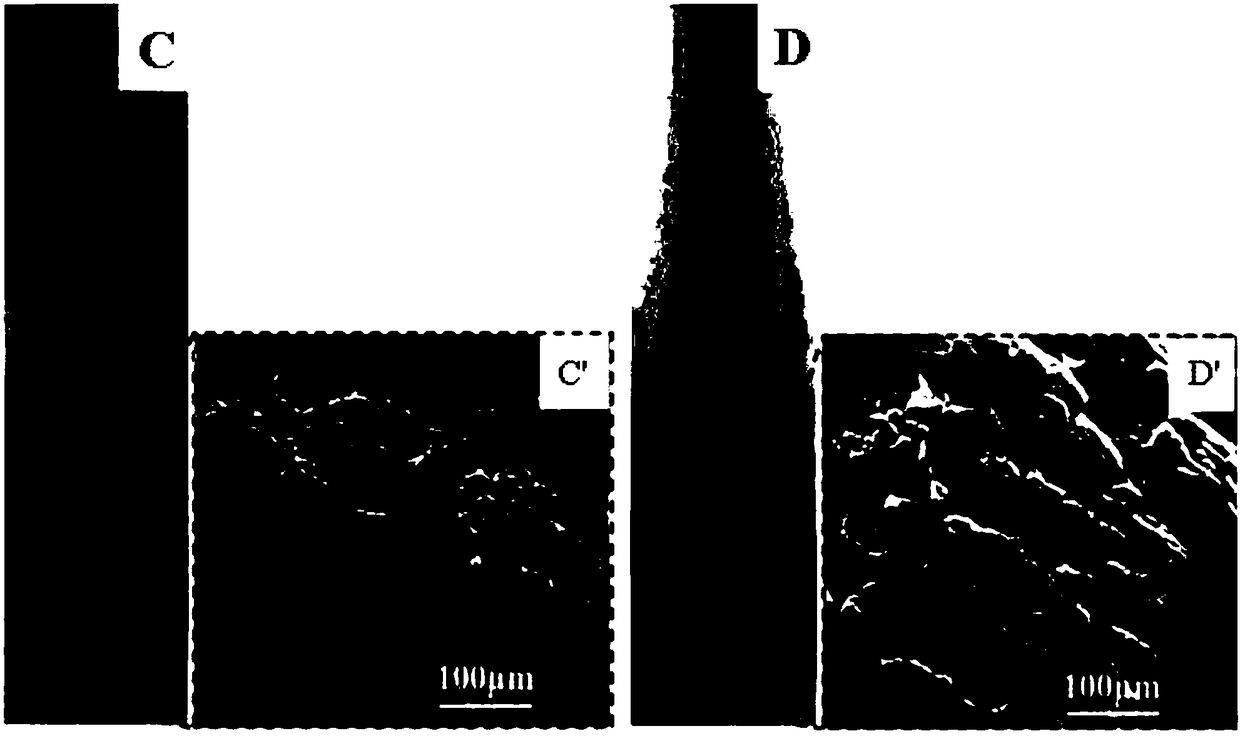

[0030] A SiO 2 A preparation method for nanoparticle modified expandable graphite, comprising the following steps:

[0031] Step 1: Add 100g of expandable graphite of 50 meshes to 240mL of ethanol aqueous solution with a water-alcohol volume ratio of 1:5; disperse through an ultrasonic instrument for about 10 minutes, and then add it to a 250mL container with a reflux condensing device, a thermometer and a stirrer In a three-necked flask; the three-necked flask is heated while stirring in a water bath, heated to 45°C, slowly dripping ammonia water with a rubber dropper to adjust the pH of the solution to 8-9, and an expandable graphite suspension is obtained.

[0032] Step 2: Slowly add 5mL of tetraethyl orthosilicate dropwise to the expandable graphite suspension obtained in step 1 with a rubber dropper, and stir evenly under the conditions of stirring temperature of 45°C and stirring speed of 350r / min Reaction 6h.

[0033] Step 3: After the reaction in step 2 is complete, ...

Embodiment 2

[0037] A SiO 2 A preparation method for nanoparticle modified expandable graphite, comprising the following steps:

[0038] Step 1: Add 150g of expandable graphite of 50 meshes to 300mL of ethanol aqueous solution formed with a water-alcohol volume ratio of 1:5; disperse through an ultrasonic instrument for about 20 minutes, and then add it to a 250mL container with a reflux condensing device, a thermometer and a stirrer In a three-necked flask; the three-necked flask is heated while stirring in a water bath, heated to 40°C, slowly dripping ammonia water with a rubber dropper to adjust the pH of the solution to 7-8, and an expandable graphite suspension is obtained.

[0039] Step 2: Slowly add 8mL of tetraethyl orthosilicate dropwise to the expandable graphite suspension obtained in step 1 with a rubber dropper, and stir evenly under the condition of stirring temperature of 40°C and stirring speed of 350r / min Reaction 8h.

[0040] Step 3: After the reaction in step 2 is comp...

Embodiment 3

[0044] A SiO 2 A preparation method for nanoparticle modified expandable graphite, comprising the following steps:

[0045] Step 1: Add 150g of expandable graphite of 50 meshes to 300mL of ethanol aqueous solution with a water-alcohol volume ratio of 1:5; disperse through an ultrasonic instrument for about 30 minutes, and then add it to a 250mL container with a reflux condensing device, a thermometer and a stirrer In a three-necked flask; the three-necked flask is heated while stirring in a water bath, heated to 45°C, slowly dripping ammonia water with a rubber dropper to adjust the pH of the solution to 8-9, and an expandable graphite suspension is obtained.

[0046] Step 2: Divide 8mL of tetraethyl orthosilicate into four parts, and slowly add one part of tetraethyl orthosilicate to the expandable graphite suspension obtained in step 1 at regular intervals; Before the second dropwise addition, adjust the pH to 8-9 until the addition is complete. Under the condition of stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com