Synthetic method of efficient flame-retardant epoxy vinyl ester resin

A technology of epoxy vinyl ester and synthesis method, which is applied in the field of synthesis of high-efficiency flame-retardant epoxy vinyl resin, and can solve the problems of large amount of addition, affecting the transparency and mechanical properties of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

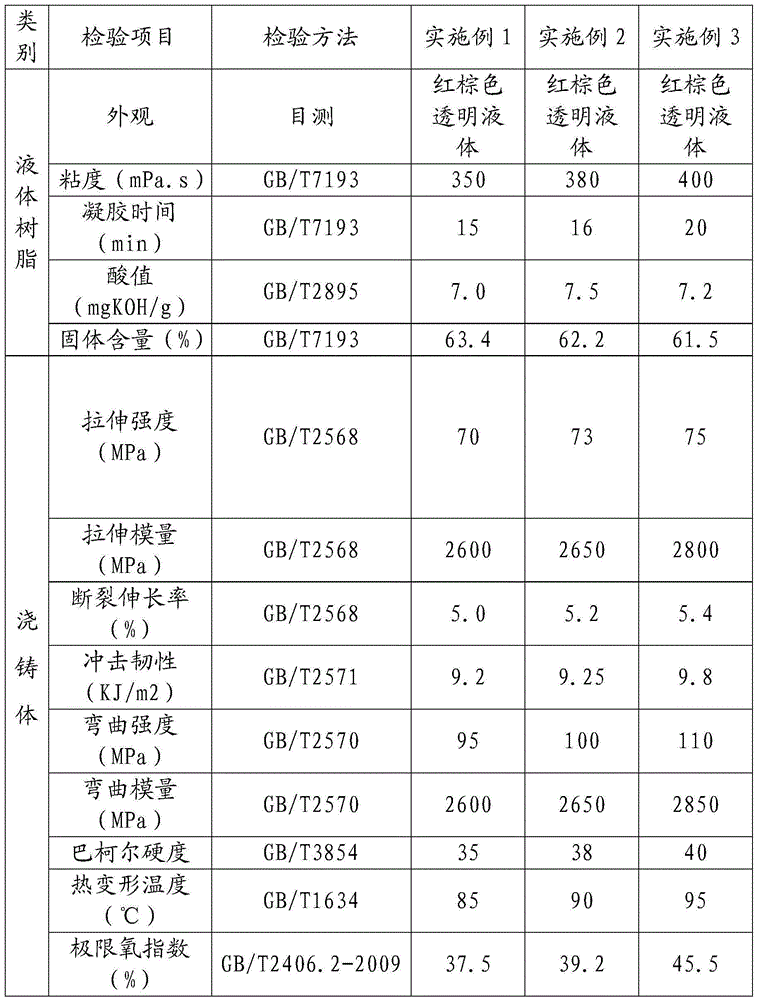

Examples

Embodiment 1

[0025] The raw material formula is as follows:

[0026] Bisphenol A diglycidyl ether 280Kg, brominated epoxy resin 525Kg, fumaric acid 62Kg, acrylic acid 144Kg, trichloroethyl phosphate 68Kg, tetraethylammonium bromide 7.0Kg, antioxidant 1Kg, p-phenylene Diphenol 300g, copper naphthenate 500g, styrene 520g.

[0027] Preparation:

[0028] ① Accurately weigh each synthetic raw material component in order according to the weight ratio, check and confirm whether the equipment, electrical appliances, instruments, valves and raw materials are normal;

[0029] ② Put the liquid material first and then the solid material into the reactor in sequence, and then put bisphenol A diglycidyl ether, brominated epoxy resin, polymerization inhibitor, catalyst and antioxidant into the reactor, and the reaction temperature rises slowly to 50°C , add a small amount of chain-extending dibasic acid in batches, raise the temperature to 75°C, keep it warm for 2 hours, and the reaction acid value wil...

Embodiment 2

[0033] The raw material formula is as follows:

[0034] Bisphenol A diglycidyl ether 200Kg, brominated epoxy resin 550Kg, fumaric acid 60Kg, acrylic acid 130Kg, trichloroethyl phosphate 75Kg, tetraethylammonium bromide 7.0Kg, antioxidant 1Kg, p-phenylene Diphenol 300g, copper naphthenate 500g, styrene 500g.

[0035] Preparation:

[0036] ① Accurately weigh each synthetic raw material component in order according to the weight ratio, check and confirm whether the equipment, electrical appliances, instruments, valves and raw materials are normal;

[0037] ② Put the liquid material first and then the solid material into the reactor in sequence, and then put bisphenol A diglycidyl ether, brominated epoxy resin, polymerization inhibitor, catalyst and antioxidant into the reactor, and the reaction temperature rises slowly to 50°C , add a small amount of chain-extending dibasic acid in batches, raise the temperature to 85°C, keep it warm for 2 hours, and the reaction acid value wil...

Embodiment 3

[0041] The raw material formula is as follows:

[0042] Bisphenol A diglycidyl ether 150Kg, brominated epoxy resin 600Kg, fumaric acid 50Kg, acrylic acid 120Kg, trichloroethyl phosphate 90Kg, tetraethylammonium bromide 7.0Kg, antioxidant 1Kg, methyl Hydroquinone 300g, copper naphthenate 500g, styrene 480g.

[0043] Preparation::

[0044] ① Accurately weigh each synthetic raw material component in order according to the weight ratio, check and confirm whether the equipment, electrical appliances, instruments, valves and raw materials are normal;

[0045] ② Put the liquid material first and then the solid material into the reactor in sequence, put bisphenol A diglycidyl ether, brominated epoxy resin, polymerization inhibitor, catalyst and antioxidant into the reactor, and the reaction temperature rises slowly to 50°C , add a small amount of chain-extending dibasic acid in batches, raise the temperature to 85°C, keep it warm for 2.5h, and the reaction acid value will drop below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com