Preparation method of nano calcium carbonate for anti-sagging PVC plastifying paste

A technology of nano-calcium carbonate and plastisol, applied in the direction of chemical instruments and methods, fibrous fillers, dyeing physical treatment, etc., can solve the problems of poor performance, easy sagging of PVC plastisol, storage stability, etc. The effect of impact properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

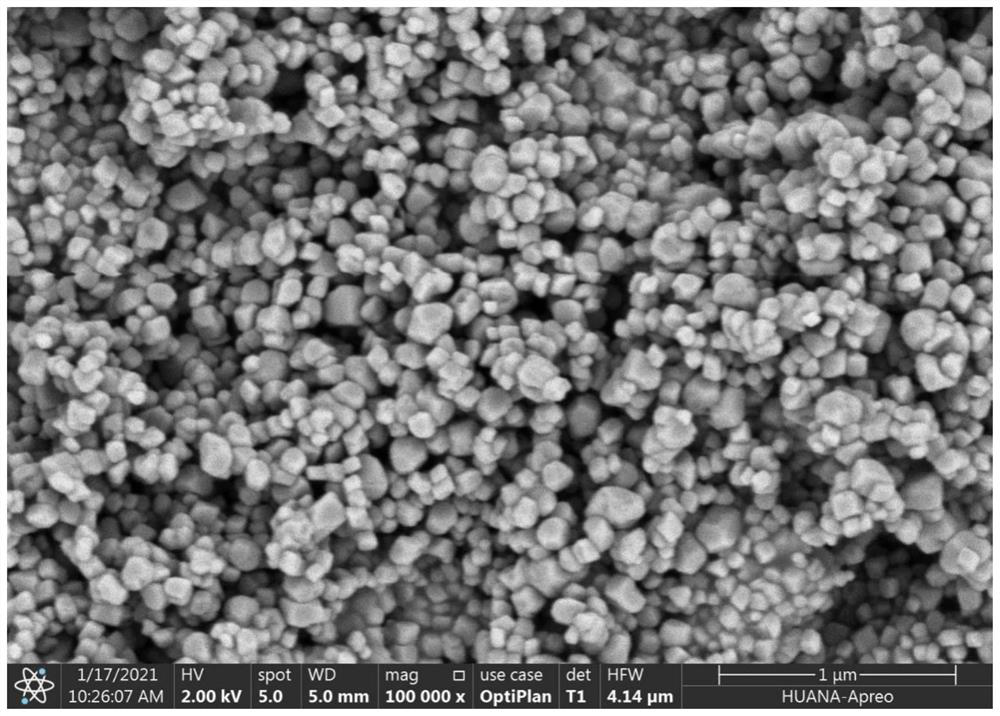

Embodiment 1

[0035] A preparation method of nano-calcium carbonate for anti-sag PVC plastisol, comprising the steps:

[0036] (1) The milk of lime with a specific gravity of 1.060 is introduced into the bubbling carbonization tower, and the temperature of the milk of lime is maintained at 25° C. After adding 1.0% crystal form control agent of calcium carbonate dry basis mass in the suspension, add 5 m 3 The gas flow rate of / h feeds the kiln gas whose volume concentration of carbon dioxide is 33%, and carries out the carbonation reaction under high-speed stirring, and when the pH of the carbonization reaction system≤7, the reaction is terminated to obtain the nano-calcium carbonate suspension; the crystal form control agent It is composed of sucrose and sodium polyacrylate with a mass ratio of 3:2;

[0037] (2) Pretreating the above suspension with phosphoric acid, the amount of phosphoric acid compound added is 0.5% of the mass of the suspension, the concentration is 8%, and the addition ...

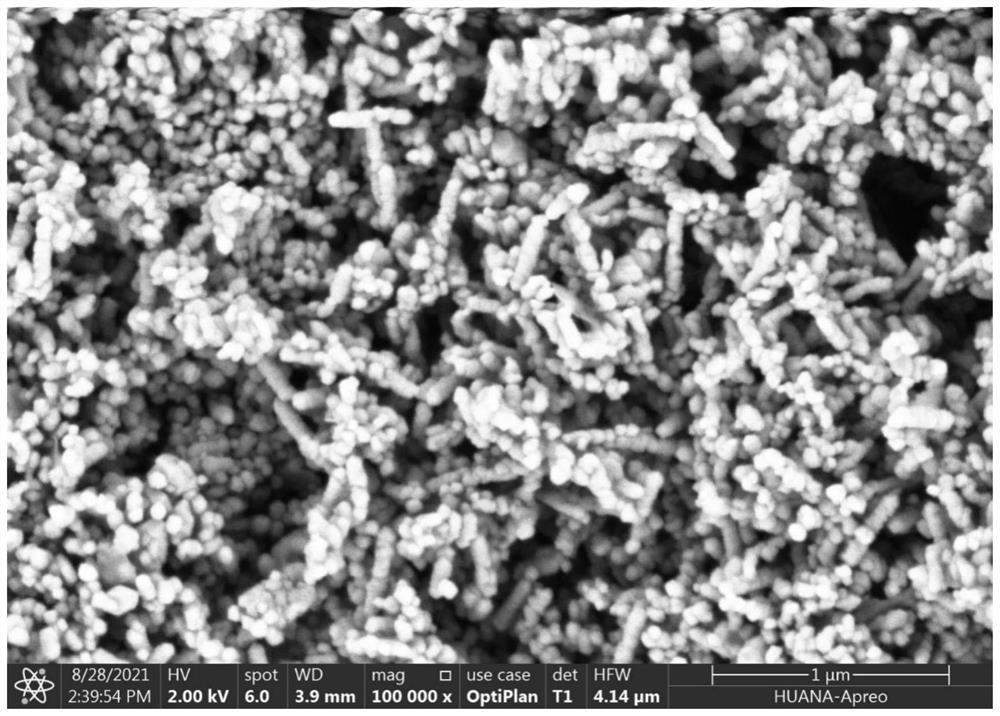

Embodiment 2

[0041] A preparation method of nano-calcium carbonate for anti-sag PVC plastisol, comprising the steps:

[0042] (1) The milk of lime with a specific gravity of 1.075 is introduced into the bubbling carbonization tower, and the temperature of the milk of lime is maintained at 28° C. After adding 1.5% of the crystal form control agent of calcium carbonate dry basis in the suspension, it is 3 The gas flow rate of / h feeds the kiln gas whose volume concentration of carbon dioxide is 33%, and carries out the carbonation reaction under high-speed stirring, and when the pH of the carbonization reaction system≤7, the reaction is terminated to obtain the nano-calcium carbonate suspension; the crystal form control agent It is composed of sucrose and sodium polyacrylate with a mass ratio of 2:1;

[0043] (2) The above-mentioned suspension is pretreated with sodium hexametaphosphate, the amount of sodium hexametaphosphate added is 0.7% of the suspension mass, the concentration is 5%, and...

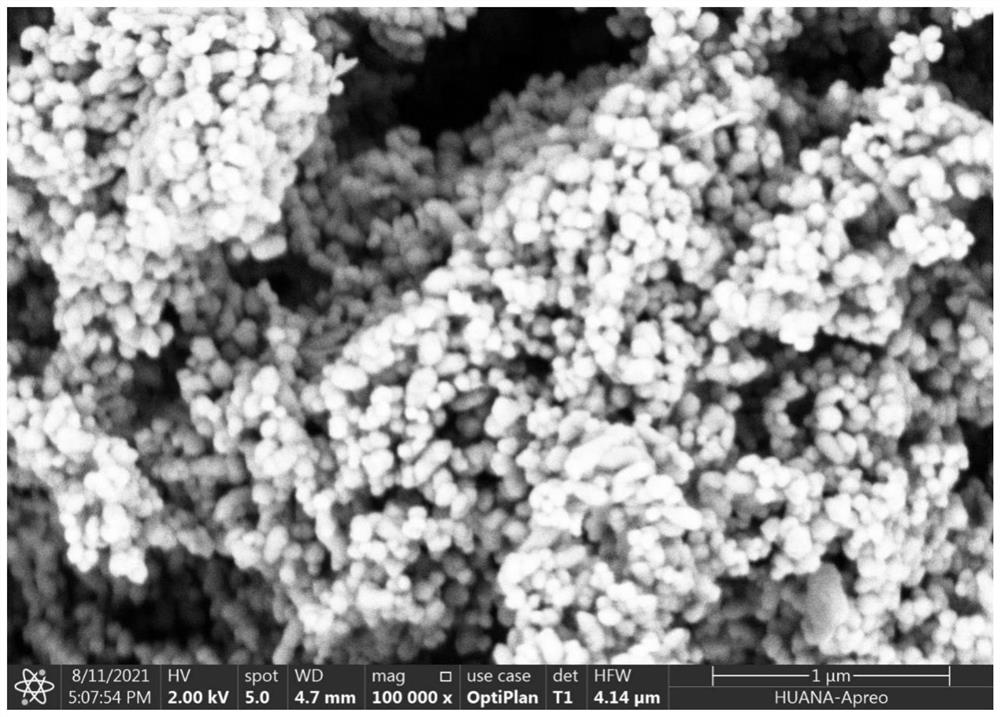

Embodiment 3

[0047] A preparation method of nano-calcium carbonate for anti-sag PVC plastisol, comprising the steps:

[0048] (1) The milk of lime with a specific gravity of 1.090 is introduced into the bubbling carbonization tower, and the temperature of the milk of lime is maintained at 35° C. After adding 2% crystal form control agent of calcium carbonate dry basis mass in the suspension, it is 3 The gas flow rate of / h feeds the kiln gas with a carbon dioxide volume concentration of 35% and carries out carbonation reaction under high-speed stirring, and when the pH of the carbonization reaction system≤7, the reaction is terminated to obtain a nano-calcium carbonate suspension; the crystal form control agent It consists of sucrose and sodium polyacrylate with a mass ratio of 1:1;

[0049] (2) The above-mentioned suspension is pretreated with stearyl phosphate, the addition amount of stearyl phosphate is 0.5% of the suspension mass, the concentration is 8%, and the addition rate is 8mL / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com